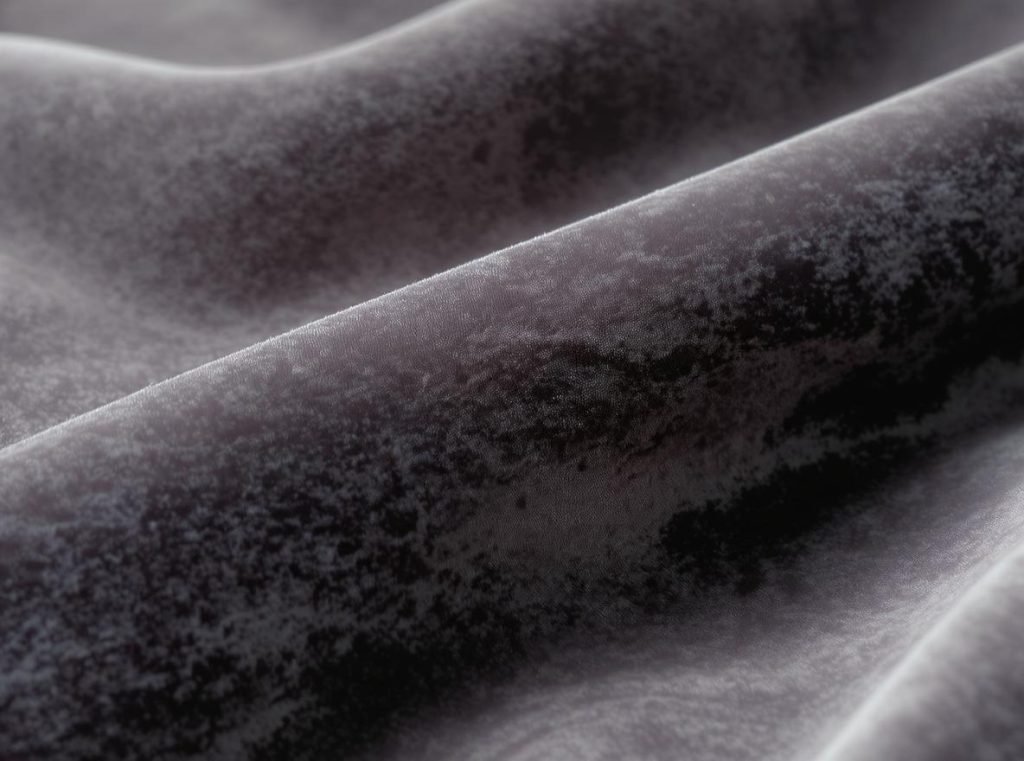

You’re launching a premium product and want packaging that screams luxury from the moment customers touch it. But you’re stuck with rigid boxes – can you really make them feel as smooth as silk? The competition is fierce, and standard packaging just won’t cut it anymore.

Yes, you can absolutely achieve a soft-touch feel on rigid boxes through specialized finishing techniques like soft-touch coating or lamination. These processes transform ordinary rigid packaging into luxurious, velvety-textured boxes that enhance customer experience and boost perceived product value by up to 70%.

Let’s explore exactly how this game-changing technique works and why it might be the competitive edge your brand desperately needs.

Table of Contents

ToggleWhat Exactly is Soft-Touch Finishing?

Many business owners hear “soft-touch” and wonder if it’s just marketing hype or a scientifically-proven finishing technique that delivers measurable results.

Soft-touch finishing is a specialized surface treatment using polyurethane compounds that create a velvety, matte texture reminiscent of suede or fine leather. This tactile coating transforms ordinary packaging into a premium sensory experience with a “buttery, velvet texture” and completely matte finish.

The science behind soft-touch effects involves carefully formulated polyurethane compounds that create elastomeric films with specific haptic properties. Research shows optimal soft-touch coatings achieve their luxurious feel through higher flexibility, lower surface roughness, and reduced friction coefficients.

This isn’t just about aesthetics. Neuroscience studies conducted by Brain House Institute found that products with soft-touch finishes are 70% more likely to be chosen by consumers, generating 275% more emotional intensity and 247% more positive emotions compared to plain packaging.

For wholesale buyers and brand manufacturers, this translates to immediate competitive advantages: premium positioning, justified higher pricing, and enhanced customer engagement that drives repeat purchases.

Three Primary Soft-Touch Methods

| Method | Process | Best For | Cost Impact |

|---|---|---|---|

| Soft-Touch Coating | Liquid application during printing, UV/heat cured | Cost-effective luxury, large runs | +$0.08-$0.15 per unit |

| Soft-Touch Lamination | BoPP film bonding with heat/pressure | Maximum durability, moisture protection | +$0.15-$0.30 per unit |

| Pre-Finished Paper | Built-in soft-touch properties | Eco-friendly applications | Variable pricing |

How Does the Science Work on Rigid Boxes?

Technical buyers want proof that soft-touch finishing integrates seamlessly with rigid box construction without compromising structural integrity.

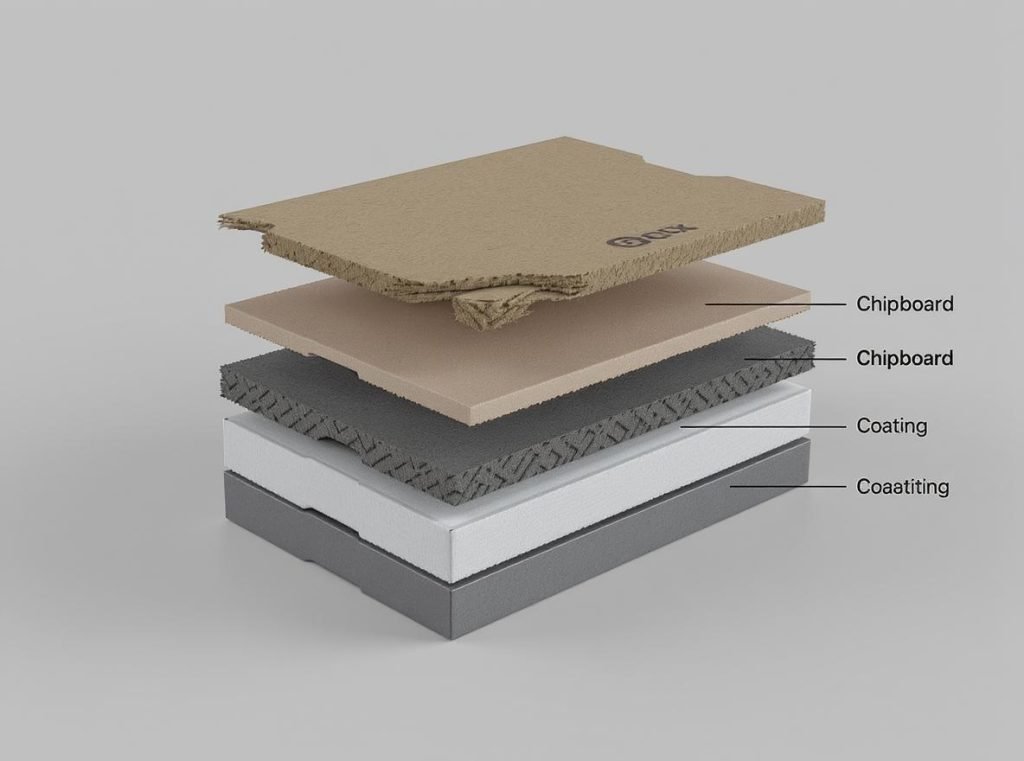

Soft-touch finishing integrates perfectly into rigid box workflows after printing, using either liquid coatings cured with UV light or specialized films laminated under precise temperature and pressure controls. The base chipboard (800-2000 GSM) provides ideal substrate properties for optimal adhesion.

Manufacturing Integration Process

The soft-touch application occurs during final coating stages after your wrapping paper undergoes printing and primary surface treatments. For liquid coatings, specialized formulations are applied via spray or roller, then cured using UV light or controlled heat, creating durable surfaces that maintain tactile properties throughout the product lifecycle.

Lamination follows a different path where pre-manufactured soft-touch films bond to printed wrappers using specialized equipment with precise controls. This method provides superior moisture protection and scratch resistance, though requiring additional production steps.

Critical Success Factors

Your rigid box success depends on three technical requirements:

- Proper substrate preparation: Minimum 105 GSM paper weight prevents curling and ensures strong adhesion

- Complete ink drying: Printed inks must fully cure before soft-touch application to prevent bubbling or adhesion failures

- Ink compatibility testing: Certain formulations don’t bond properly with soft-touch films, requiring pre-production compatibility verification

At Acreet, we’ve perfected these technical integration processes through years of experience with international wholesale customers, ensuring your rigid boxes meet exact specifications while maintaining cost-effectiveness.

What Measurable Business Benefits Can You Expect?

Smart packaging buyers demand concrete ROI data before investing in premium finishes like soft-touch.

Soft-touch finishes deliver proven business benefits including 70% higher consumer preference rates, justification for 5-20% premium pricing, enhanced brand differentiation, and measurable improvements in customer retention through superior unboxing experiences.

Consumer Psychology and Sales Impact

Research specifically focused on cosmetic packaging revealed customers prefer soft-touch coatings even when facing 5% price premiums, indicating the tactile experience adds perceived value that justifies higher pricing.

The “endowment effect” created by tactile interaction increases consumers’ sense of ownership and connection to products. This psychological phenomenon extends beyond initial purchase, contributing to enhanced brand loyalty and repeat purchasing behavior.

Market Performance Data

The luxury packaging sector shows robust growth supporting soft-touch investments:

- Global luxury packaging market: Growing from $17.06 billion (2025) to $21.35 billion (2030)

- Annual growth rate: 4.58% CAGR with emerging markets showing even stronger performance

- India market growth: 6.1% CAGR through 2035

- China market expansion: 5.2% CAGR, indicating expanding opportunities

Competitive Differentiation

Soft-touch packaging creates what industry experts call “premium rituals” during unboxing. Companies like Samsung and Apple leverage these experiences as product differentiation strategies, with soft-touch rigid boxes communicating quality and attention to detail while providing protective benefits during shipping.

Your products gain immediate tactile recognition among competitors, enhanced shelf appeal in retail environments, and stronger brand recall through sensory memory that standard packaging simply cannot achieve.

Which Rigid Box Applications Maximize ROI?

Distributors and manufacturers need strategic guidance on which rigid box styles deliver optimal soft-touch finishing returns.

Cosmetics packaging (48% of luxury applications), electronics unboxing experiences, premium food and beverage packaging, and gift boxes provide maximum soft-touch ROI through extended customer interaction and premium positioning alignment.

High-Impact Product Categories

Cosmetics and Personal Care: The intimate nature of these products creates natural synergy with tactile packaging that enhances sensory experiences. The 48% market share in luxury applications reflects proven consumer preference.

Electronics Packaging: Technology companies increasingly emphasize unboxing experiences as differentiation strategies. Soft-touch rigid boxes for electronics communicate quality while providing practical grip benefits and fingerprint resistance.

Premium Food and Beverage: Including spirits, artisanal chocolates, and specialty foods. Soft-touch reinforces premium positioning while providing practical benefits like improved grip during handling and fingerprint resistance maintaining appearance throughout distribution.

Optimal Box Structural Designs

- Hinged lid boxes: Extended surface contact during opening maximizes tactile engagement

- Magnetic closure boxes: Combines structural sophistication with tactile enhancement, creating “premium ritual” experiences

- Nested box sets: Extended handling during unpacking maximizes sensory benefit investment

- Presentation boxes: Multiple compartments benefit from tactile consistency across all surfaces

What Are the Real Production Costs?

Budget-conscious buyers need transparent cost analysis including hidden expenses and ROI calculations.

Soft-touch finishing adds 15-40% to base rigid box costs depending on method and volume, but consumer research shows willingness to pay 5-20% premiums for enhanced tactile experiences, often resulting in improved profit margins rather than cost increases.

Detailed Cost Breakdown

Volume Economics: Bulk orders reduce per-unit costs by 20-30% compared to smaller runs, making soft-touch more economically viable for established products with predictable demand patterns.

Equipment Investment: Companies without lamination capabilities face $50,000-$200,000 initial investments, though contract finishing services eliminate these upfront costs.

Hidden Cost Factors:

- Extended lead times (1-2 additional weeks)

- Specialized storage requirements for materials with limited shelf life

- Enhanced quality control protocols requiring additional testing

ROI Analysis Framework

Direct cost increases offset through multiple revenue streams:

- Premium pricing capability: 5-20% higher pricing supported by consumer preference research

- Reduced damage costs: Enhanced scuff and scratch resistance protects high-value products

- Marketing value: Memorable unboxing experiences generate organic social media sharing

- Customer retention: Enhanced brand differentiation reduces customer acquisition costs

What Technical Limitations Should You Know?

Experienced buyers want honest assessments of technique limitations and mitigation strategies before making investment decisions.

Key limitations include color muting effects on vibrant designs, fingerprint visibility on dark coated surfaces, extended production timelines, and environmental sensitivity during storage. However, proper planning and design adjustments minimize these challenges.

Color and Design Constraints

Soft-touch finishes inherently affect color reproduction, with both coatings and laminations potentially muting vibrant colors compared to gloss finishes. This effect particularly impacts bright, saturated colors and metallic inks.

Dark colors appear duller while potentially showing fingerprints more readily on darker surfaces. Complex graphics with fine details may lose definition, particularly with laminated applications where film thickness can obscure subtle design elements.

Mitigation Strategies

- Design compensation: Increase color saturation in original artwork to achieve desired final results

- Surface selection: Choose lamination for dark-colored boxes requiring frequent handling to improve fingerprint resistance

- Color testing: Conduct compatibility testing during design phase to ensure critical brand elements remain clearly visible

Environmental and Durability Factors

Soft-touch finishes provide enhanced scratch resistance compared to uncoated substrates but remain more susceptible to damage than harder coating alternatives. Extended handling can cause wear patterns, particularly in high-friction areas.

Environmental factors significantly impact performance:

| Factor | Impact | Mitigation |

|---|---|---|

| UV Exposure | Finish degradation over time | UV-resistant formulations |

| Chemical Contact | Potential surface damage | Compatibility testing, protective packaging |

| Temperature Extremes | Finish integrity issues | Controlled storage, shipping protocols |

How Do You Select the Right Manufacturing Partner?

Choosing the wrong manufacturing partner can transform your premium packaging vision into a costly disaster affecting brand reputation.

Select manufacturers with proven soft-touch experience, modern equipment with automated process controls, comprehensive quality systems, and demonstrated success with comparable applications. Request detailed samples and customer references before committing to production.

Essential Technical Capabilities

Integrated Production: Partners with both rigid box production and soft-touch finishing capabilities deliver better quality control and shorter lead times compared to operations requiring multiple subcontractors.

Equipment Sophistication: Modern application equipment with automated process controls produces more consistent results than manual systems. Partners should demonstrate capabilities through facility tours and sample production runs.

Quality Assurance Systems: Documented procedures covering incoming material inspection, process parameter monitoring, and finished product testing. ISO certifications provide additional systematic quality management assurance.

Experience Portfolio Evaluation

Industry-Specific Knowledge: Partners familiar with your industry standards navigate regulatory requirements while maintaining production efficiency. This expertise is particularly valuable for regulated sectors like cosmetics or food packaging.

Comparable Applications: Review portfolios should include soft-touch applications on similar products, demonstrating both technical capability and aesthetic understanding of your market requirements.

Customer References: Direct communication with existing customers reveals practical experience with partner capabilities and identifies potential challenges before commitment.

Service and Support Assessment

| Capability | Why Important | Questions to Ask |

|---|---|---|

| Design Assistance | Optimizes structures for soft-touch applications | Do you offer design consultation services? |

| Prototyping Services | Enables testing before full production | Can you provide samples for evaluation? |

| Supply Chain Management | Ensures reliable material sourcing | How do you manage specialized material inventory? |

| Communication Systems | Critical for complex custom applications | What project tracking systems do you use? |

At Acreet, we’ve invested heavily in modern soft-touch equipment and developed comprehensive quality systems specifically for international wholesale customers. Our experienced team provides design consultation, prototyping, and reliable project management ensuring your soft-touch rigid box vision becomes reality on schedule and within budget.

What’s the Future of Soft-Touch Packaging?

Forward-thinking buyers want to understand emerging trends that might affect their long-term packaging strategies.

The future includes UV-curable formulations with improved durability, digital printing compatibility for customization, sustainable bio-based systems, and multi-sensory experiences integrating tactile elements with personalization capabilities.

Technology Development Trends

UV-Curable Systems: Emerging formulations address traditional limitations with improved durability, faster processing, and enhanced environmental safety compared to conventional two-part urethane systems.

Digital Integration: Soft-touch formulations optimized for digital printing workflows enable shorter runs and greater customization opportunities aligned with luxury market personalization trends.

Sustainable Solutions: Bio-based polyurethane systems and recyclable film technologies provide tactile benefits while supporting environmental objectives increasingly influencing luxury purchasing decisions.

Market Evolution

Consumer expectations continue evolving toward sophisticated multi-sensory experiences engaging multiple senses simultaneously. Future applications may integrate subtle fragrance elements or textural variations enhancing tactile experiences while supporting brand differentiation.

Personalization Trends: Advanced manufacturing technologies may enable variable tactile properties within single production runs, supporting mass customization strategies that create unique consumer experiences.

Cultural Adaptation: As luxury brands expand globally, understanding regional tactile preferences helps optimize soft-touch applications for specific markets, with different cultures showing varying preferences for tactile experiences.

Summary

Soft-touch finishing absolutely transforms rigid boxes from ordinary containers into luxurious customer experiences that drive measurable business results. Whether through coating or lamination, these scientifically-proven techniques deliver 70% higher consumer preference, justify premium pricing, and create competitive differentiation that standard packaging cannot match.

Ready to explore soft-touch possibilities for your rigid box project? Contact Acreet today for samples, cost analysis, and expert consultation on achieving the perfect tactile experience that elevates your brand and drives sales growth.