Product spoilage, customer complaints, and costly returns often stem from one critical mistake: selecting the wrong barrier film for your pouch packaging. Your products face oxygen exposure, moisture ingress, and light degradation throughout the supply chain. Without proper barrier protection, even premium products can lose quality before reaching consumers.

The right barrier film for your pouch packaging depends on three key factors: your product’s oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) requirements, environmental conditions including humidity and temperature extremes, and balancing protection performance with total cost of ownership. High-barrier options like EVOH and metallized films provide superior protection for sensitive products, while standard polyethylene works for less demanding applications.

Understanding these selection criteria will help you protect product quality while optimizing costs and meeting sustainability requirements.

Table of Contents

ToggleWhat Are the Main Types of Barrier Films Available for Pouch Packaging?

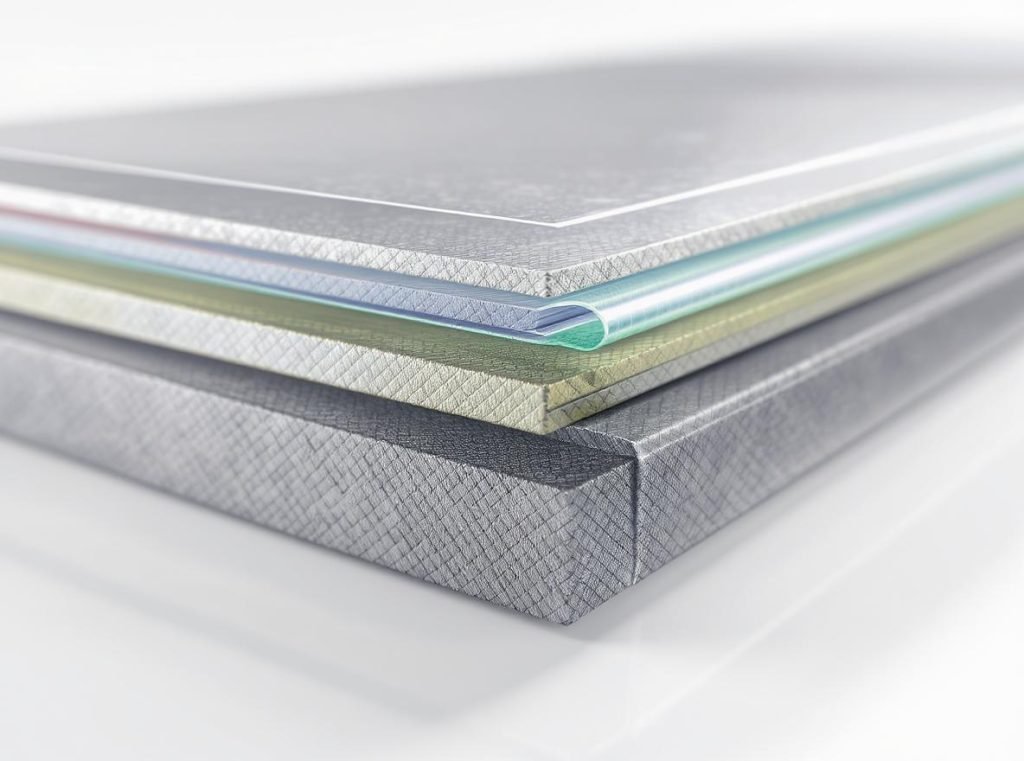

Barrier films create protective shields against oxygen, moisture, light, and mechanical damage through different mechanisms. Each film family offers distinct protective properties and performance characteristics.

Barrier films include aluminum foil (hermetic protection), metallized PET (excellent barrier with flexibility), EVOH copolymers (superior oxygen barrier), PVDC-coated films (moisture-resistant barriers), and emerging mono-material options (recyclable high-barrier solutions). Each provides different levels of oxygen and moisture protection with varying cost implications.

Barrier effectiveness works through three main mechanisms: passive barriers create tortuous diffusion paths, reflective barriers physically block permeants with metal layers, and active barriers chemically scavenge oxygen or moisture.

Traditional High-Performance Barriers

Aluminum foil delivers hermetic protection with OTR and WVTR values below 0.01, making it ideal for premium coffee, pharmaceuticals, and long shelf-life products. However, foil suffers from crease sensitivity and flex-crack issues during shipping.

Metallized PET films provide excellent barrier properties with OTR ranges of 0.05-0.14 and superior flex-crack resistance compared to foil. These films offer attractive aesthetics while maintaining protection during distribution stress.

Advanced Barrier Technologies

EVOH copolymers excel in dry conditions with OTR values of 0.1-1.7, making them perfect for meat, dairy, and oxygen-sensitive products. However, EVOH performance degrades significantly above 60% relative humidity.

PVDC-coated films maintain stable barrier properties at high humidity with OTR around 0.5 and WVTR of 0.4. These films work well for retort applications but face sustainability concerns in European markets.

| Film Type | OTR (cc/100 in²/24h) | WVTR (g/100 in²/24h) | Key Applications | Limitations |

|---|---|---|---|---|

| Aluminum Foil | <0.01 | <0.01 | Premium coffee, pharmaceuticals | Crease sensitivity, not microwavable |

| Metallized PET | 0.05-0.14 | 0.05-0.08 | Snacks, pet food | Metal layer can fracture |

| EVOH | 0.1-1.7 | 1.4-8.0 | Fresh foods, meat products | Humidity sensitivity |

| PVDC-Coated | 0.5 | 0.4 | Retort applications | Environmental concerns |

| High-Barrier MDO-PE | ≤0.15 | ≤0.20 | Recyclable applications | Limited suppliers |

How Do You Determine Your Product’s Barrier Requirements?

Product characteristics determine which barrier properties are most critical for maintaining quality and achieving target shelf life. Different products face unique degradation mechanisms requiring specific protection levels.

Product barrier requirements depend on sensitivity to oxidative rancidity, moisture absorption, aroma loss, and vitamin degradation. Calculate allowable permeant ingress using shelf-life models, consider residual oxygen after packaging, and factor in regulatory requirements for food contact or pharmaceutical applications.

Technical requirements are based on quantifying how much oxygen and moisture your product can safely absorb while maintaining acceptable quality throughout the distribution cycle.

Mapping Chemical Sensitivities

Oxidative rancidity affects nuts, chips, and oil-containing products. Monitor peroxide value increases and target OTR below 0.1 cc/100 in²/24h for sensitive snack foods.

Moisture gain causes texture changes in crispy products, clumping in powders, and microbial growth in susceptible items. Products requiring dry conditions need WVTR below 0.05 g/100 in²/24h.

Aroma loss particularly impacts coffee, spices, and fragrant products. Combine low OTR (below 0.06) with specialized aroma barrier layers to prevent volatile compound migration.

Quantifying Shelf-Life Goals

Use Fickian diffusion models or barrier calculators to determine precise OTR and WVTR requirements. Include residual oxygen levels after modified atmosphere packaging or vacuum sealing in your calculations.

Consider accelerated aging studies at elevated temperatures to predict real-world performance. These tests reveal how barrier requirements change under stress conditions.

Process and Regulatory Constraints

Filling methods impact barrier selection significantly. Hot-fill applications require films that maintain barrier properties at elevated temperatures, while retort processing demands materials that withstand 121°C sterilization cycles.

Regulatory compliance adds another layer of requirements. FDA food contact regulations and EU 10/2011 standards specify approved materials, while pharmaceutical applications may require USP Class VI certification.

What Environmental Factors Should You Consider?

Environmental conditions throughout the supply chain significantly impact barrier film performance. Understanding these variables helps select films that maintain protection under real-world stress.

Environmental factors include relative humidity above 75% (which degrades EVOH performance by 10 times), freezing temperatures causing brittle fracture, high-temperature abuse up to 60°C in truck transport, flexing during e-commerce shipping, and sustainability directives affecting material selection.

Storage and distribution environments vary dramatically across global markets, seasonal changes, and different handling practices throughout the supply chain.

Humidity Impact on Barrier Performance

High relative humidity severely affects certain barrier materials. EVOH loses significant barrier effectiveness when humidity exceeds 75%, requiring external moisture barriers or alternative materials like PVDC or metallized films.

Consider worst-case humidity scenarios in your distribution network. Tropical climates, warehouse condensation, and seasonal variations can exceed design assumptions.

Temperature Extremes

Freezing conditions at -20°C can cause brittle fracture in certain film combinations. Incorporate nylon or higher-density polyethylene to maintain flexibility at low temperatures.

High-temperature abuse during transportation can reach 60°C on truck decks or in non-climate-controlled warehouses. Oxide coatings may develop micro-cracks under these conditions, requiring more robust barrier solutions.

Mechanical Stress Factors

E-commerce shipping subjects packages to significant flexing, compression, and vibration. Traditional foil laminates may develop pinholes under these conditions, making flexible alternatives like top-coated metallized films preferable.

International shipping involves multiple handling points, extended transit times, and varying transportation methods. Your barrier film must withstand these demanding conditions while maintaining protection integrity.

Sustainability Requirements

Environmental regulations increasingly influence barrier film selection. CEFLEX guidelines and APR (Association of Plastic Recyclers) standards discourage PVDC use and promote mono-material solutions.

Keep EVOH content below 5% by weight in mono-PE laminates to maintain recyclability certifications. Consider emerging high-barrier MDO-PE films that achieve 98% recyclability ratings.

How Do Cost Considerations Affect Barrier Film Selection?

Balancing protection requirements with cost constraints requires understanding total cost of ownership beyond raw material prices. Smart selection optimizes protection while maintaining profitability and meeting budget targets.

Barrier film costs increase with performance levels, but total packaging costs include productivity impacts, inventory management, waste reduction, and brand protection benefits. Calculate comprehensive costs including material pricing, processing efficiency, product loss prevention, and sustainability compliance fees.

Raw material costs represent only part of the total packaging expense equation when evaluating barrier film options.

Material Cost Analysis

High-performance barrier films command premium prices, but cost differences often justify themselves through improved protection. Metallized PET costs approximately 40% less than aluminum foil while providing adequate barrier properties for many applications.

Volume purchasing, supplier relationships, and long-term contracts significantly impact material costs. Larger quantities typically provide better pricing for specialized barrier films.

Hidden Cost Drivers

Processing efficiency affects total costs substantially. Metallized PET laminates seal 12% faster than foil alternatives, improving productivity and reducing manufacturing costs.

Gauge optimization offers cost savings but requires careful testing. Reducing film thickness from 4 mil to 3 mil saves approximately 20% in resin costs but may reduce puncture resistance by 15%.

Product loss prevention justifies premium barrier films for high-value items. Foil pinholes can increase spoilage returns by over 1% of shipped units, making flexible alternatives cost-effective.

Sustainability Cost Impact

Extended Producer Responsibility (EPR) fees add €80-€120 per ton for non-recyclable multilayer pouches in EU markets. These fees make recyclable alternatives more attractive from a total cost perspective.

| Cost Factor | Impact Level | Mitigation Strategy |

|---|---|---|

| Raw Material Premium | Direct | Balance with protection requirements |

| Processing Efficiency | 12% productivity gain | Choose faster-sealing materials |

| Product Loss Prevention | >1% return reduction | Invest in flex-crack resistant films |

| EPR Fees | €80-€120/ton | Select recyclable mono-materials |

What Are the Key Performance Specifications to Evaluate?

Technical specifications provide objective measures for comparing barrier film performance. Understanding these metrics enables data-driven decisions based on measurable criteria rather than subjective assessments.

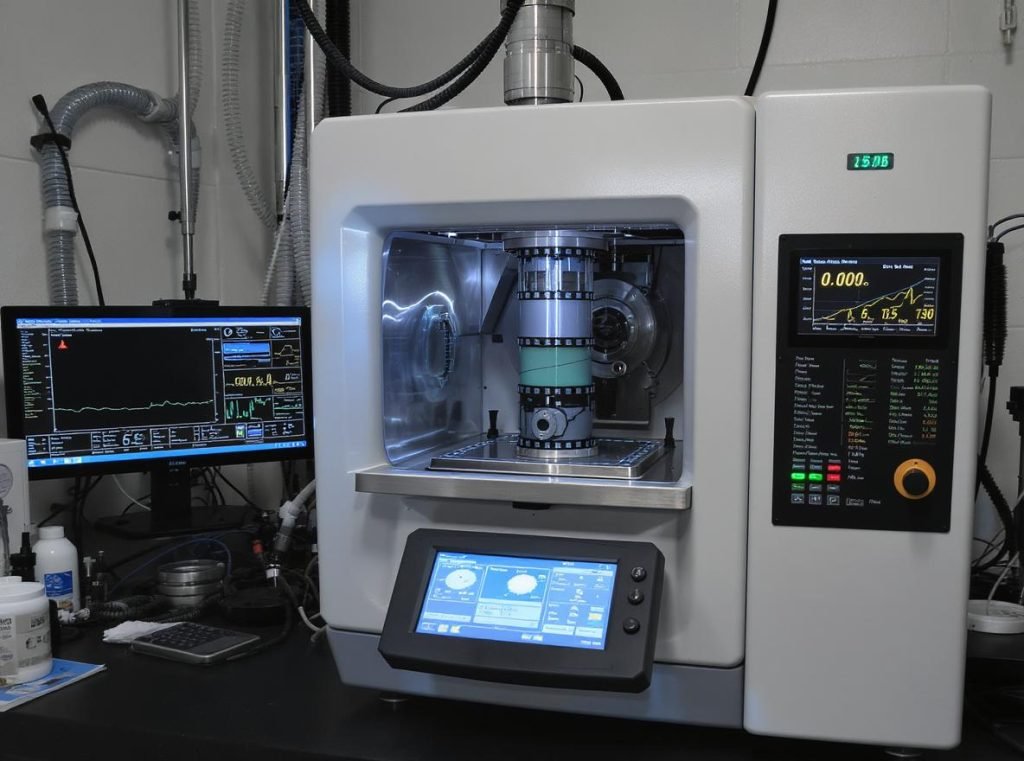

Key performance specifications include oxygen transmission rate (OTR) measured by ASTM D3985, water vapor transmission rate (WVTR) using ASTM F1249, flex-crack resistance via ASTM F392 Gelbo testing, puncture resistance, heat-seal strength, and coefficient of friction for machinability.

These standardized test methods allow direct comparison between different barrier film options under controlled conditions.

Barrier Property Measurements

Oxygen transmission rate quantifies oxygen permeability through the film structure. Use coulometric methods per ASTM D3985 at both 23°C/0% RH and worst-case 38°C/90% RH conditions.

Water vapor transmission rate measures moisture permeability using infrared sensor methods per ASTM F1249. Test at standard conditions and elevated temperature/humidity to simulate distribution stress.

Light transmission becomes critical for UV-sensitive products. Measure both total light transmission and specific wavelength ranges that affect your product quality.

Mechanical Performance Testing

Flex-crack resistance testing using ASTM F392 Gelbo flex simulates shipping abuse. Acceptable performance typically requires fewer than 10 pinholes after 20 flex cycles for e-commerce snack applications.

Puncture resistance measured by ASTM F1306 ensures package integrity during handling. Liquid products typically require minimum 1.5 lb puncture resistance for safe distribution.

Heat-seal strength testing per ASTM F88 verifies seal integrity under stress. Retort applications demand minimum 3 lb/in seal strength to prevent failures during thermal processing.

Machinability Characteristics

Coefficient of friction (COF) measured by ASTM D1894 affects form-fill-seal line performance. Optimal COF ranges from 0.1-0.3 for high-speed vertical form-fill-seal operations.

Metal adhesion testing prevents metal layer pick-off during converting. Maintain adhesion above 600 g/in using MA-1 tape test methods for metallized films.

| Specification | Test Method | Critical Value | Application |

|---|---|---|---|

| OTR | ASTM D3985 | Product-specific | Oxygen-sensitive items |

| WVTR | ASTM F1249 | Product-specific | Moisture-sensitive products |

| Flex-Crack | ASTM F392 | <10 pinholes/20 cycles | E-commerce shipping |

| Puncture | ASTM F1306 | ≥1.5 lb | Liquid products |

| Heat-Seal | ASTM F88 | ≥3 lb/in | Retort applications |

How Do You Test and Validate Your Barrier Film Choice?

Comprehensive testing confirms barrier film selection meets performance requirements before full production implementation. Proper validation prevents costly field failures and customer complaints.

Barrier film validation involves laboratory permeation testing using ASTM standards, mechanical abuse simulation through Gelbo flex and puncture tests, accelerated aging studies, pilot-scale machinability trials, and field distribution testing with real products under actual conditions.

Testing programs should progress from controlled laboratory conditions to real-world validation trials that simulate actual distribution environments.

Laboratory Testing Protocols

Permeation testing forms the foundation of barrier validation. Conduct OTR testing via ASTM D3985 coulometric methods at both standard conditions (23°C/0% RH) and stress conditions (38°C/90% RH).

WVTR testing using ASTM F1249 infrared sensor methods or gravimetric ASTM E96 dessicant methods provides moisture barrier verification. Test at multiple temperature and humidity combinations.

Accelerated aging studies simulate extended storage periods using elevated temperature and humidity. Analyze product quality parameters like peroxide values and sensory scores throughout the study period.

Mechanical Abuse Testing

Flex-crack testing using ASTM F392 Gelbo flex simulates e-commerce shipping stress. Follow flex testing with pinhole detection using 10-second bubble tests to identify barrier compromises.

Drop testing per ASTM D5276 validates package integrity for liquid products. Combine with burst testing (ASTM F1140) to ensure seal integrity under impact conditions.

Pilot Scale Validation

Form-fill-seal trials using over 10,000 units validate machinability characteristics. Monitor coefficient of friction, hot-tack sealing windows, and scrap rates during production runs.

Process temperature mapping ensures barrier films maintain properties throughout converting operations. Document any processing issues that could affect barrier performance.

Field Distribution Trials

Ship testing using ISTA 6A protocols simulates e-commerce distribution stress. Include time-temperature data loggers to verify environmental conditions during transit.

Market testing with real products provides final validation under actual storage and handling conditions. Compare oxygen ingress measurements with theoretical predictions to validate barrier models.

What Common Mistakes Should You Avoid When Choosing Barrier Films?

Learning from typical selection errors helps avoid costly mistakes that compromise product protection or increase unnecessary expenses. Understanding these pitfalls improves decision-making processes.

Common barrier film mistakes include relying on dry OTR values for humidity-sensitive EVOH materials, over-specifying expensive solutions like foil when metallized alternatives suffice, ignoring recycling guidelines leading to EPR fees, skipping flex-crack testing on oxide coatings, and assuming laboratory WVTR matches real-world performance.

These errors can result in barrier failures, excessive costs, regulatory non-compliance, or processing difficulties during production.

Technical Specification Errors

Relying solely on dry OTR measurements for EVOH materials ignores humidity effects that can reduce barrier effectiveness by 10 times. Always test EVOH-based films at high humidity conditions and add moisture barriers when necessary.

Over-specifying foil barriers when metallized PET provides adequate protection wastes over 40% in material costs. Match barrier requirements to actual product needs rather than selecting maximum protection options.

Ignoring coefficient of friction requirements can cause form-fill-seal line problems. Films with inappropriate COF values may slip, stick, or cause web tension issues during converting.

Processing and Compatibility Issues

Forgetting sealant layer compatibility leads to seal failures and potential recalls. Match seal layers (LLDPE, ionomer) to filling temperatures and processing requirements.

Skipping flex-crack testing on oxide-coated films can result in barrier loss during distribution. Always perform Gelbo flex testing followed by OTR retesting to verify maintained protection.

Assuming laboratory moisture barrier performance matches field conditions often leads to unexpected moisture ingress. Include seal integrity screening and field trials in validation programs.

Sustainability and Regulatory Oversights

Ignoring recyclability guidelines results in future EPR fees and potential retailer rejection. Keep EVOH content below 5% by weight in mono-PE laminates to maintain recyclability certification.

Missing food contact compliance requirements can delay product launches or require expensive reformulation. Verify FDA and EU regulatory approval for all barrier film components.

| Common Mistake | Consequence | Prevention Strategy |

|---|---|---|

| Ignoring EVOH humidity sensitivity | Unexpected barrier failure | Test at high RH, add moisture barrier |

| Over-specifying foil barriers | 40%+ cost premium | Match requirements to metallized alternatives |

| Skipping flex-crack testing | Distribution barrier loss | Include Gelbo flex plus OTR retest |

| Missing recyclability targets | EPR fees, retailer rejection | Follow CEFLEX/APR guidelines |

| Inadequate field validation | Real-world performance gaps | Include distribution trials |

How Do You Implement a Systematic Selection Process?

A structured approach to barrier film selection ensures thorough evaluation of all relevant factors while maintaining project timelines. Following proven methodologies reduces risks and improves outcomes.

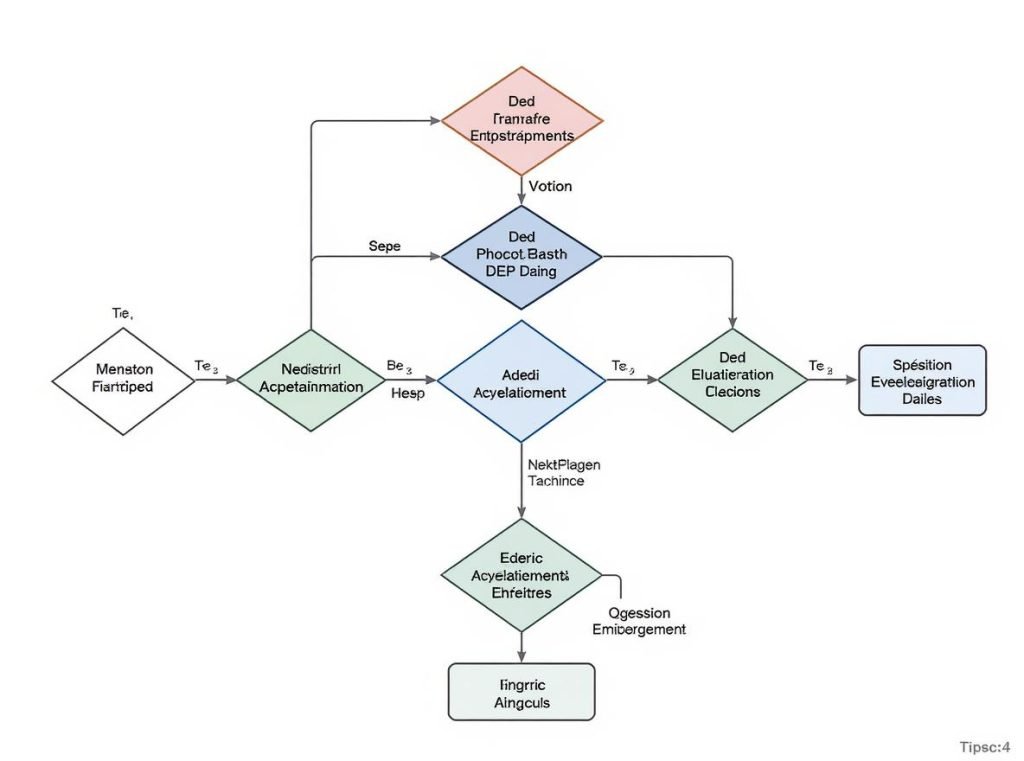

Implement barrier film selection through a nine-step process: define shelf-life and regulatory targets, screen film families using performance data, model oxygen/moisture ingress, build prototype laminates, conduct laboratory testing to ASTM standards, validate machinability at pilot scale, perform distribution trials, audit costs and sustainability impact, and freeze final specifications.

This systematic approach ensures comprehensive evaluation while maintaining focus on critical success factors.

Define Requirements Phase

Start by establishing clear shelf-life targets, regulatory compliance requirements, and sustainability goals. Document OTR and WVTR limits based on product sensitivity analysis.

Include processing constraints like hot-fill temperatures, retort requirements, or modified atmosphere packaging considerations in your requirement definition.

Screening and Modeling Phase

Use barrier film performance data to eliminate options that cannot meet basic requirements. Apply barrier calculators or Fickian diffusion models to predict performance under various conditions.

Build prototype laminate structures combining barrier cores with appropriate print and seal layers. Consider converting compatibility and processing requirements during structure design.

Testing and Validation Phase

Conduct comprehensive laboratory testing following ASTM standards for permeation, mechanical properties, and seal integrity. Include accelerated aging studies to predict long-term performance.

Progress to pilot-scale trials evaluating machinability characteristics including COF, seal windows, and scrap rates. Document any processing issues that could affect production efficiency.

Implementation Phase

Complete field distribution trials using ISTA protocols and real-time environmental monitoring. Validate barrier model predictions against actual performance data.

Perform final cost and sustainability audits including total cost of ownership calculations and EPR impact assessments. Document all specifications, tolerances, and approved test methods.

This systematic approach ensures comprehensive evaluation while maintaining project momentum and avoiding common selection pitfalls.

Summary

Choosing the right barrier film requires systematic evaluation of product sensitivity, environmental conditions, and cost considerations. Start with clear OTR and WVTR requirements based on shelf-life goals, then screen film families for technical compatibility. Validate selections through comprehensive ASTM testing and field trials before full implementation.

Ready to optimize your pouch packaging with the perfect barrier film solution? Contact Acreet today for expert consultation on barrier film selection and custom packaging design. Our technical team can help you balance protection requirements with cost targets while meeting sustainability goals. Send us your product specifications for a personalized barrier analysis and custom pouch development proposal.