Are you struggling with food packaging that’s heavy, expensive, and takes up too much storage space? Traditional metal cans require extensive warehousing, increase shipping costs dramatically, and often compromise food quality through extended heat processing. Meanwhile, standard flexible packaging can’t withstand high-temperature sterilization needed for shelf-stable products.

Retort pouches are flexible, heat-resistant food packaging made from multiple layers of plastic and metal foils that can withstand sterilization temperatures of 240-250°F (116-121°C) while providing up to 18 months shelf life without refrigeration, offering 88% weight reduction and 47% improved storage efficiency compared to traditional cans.

Let’s explore everything you need to know about retort pouches and how they can transform your packaging operations.

Table of Contents

ToggleWhat Exactly Is a Retort Pouch?

Understanding the sophisticated construction of retort pouches is essential for businesses considering this advanced packaging technology. These innovative containers represent a breakthrough in food preservation science.

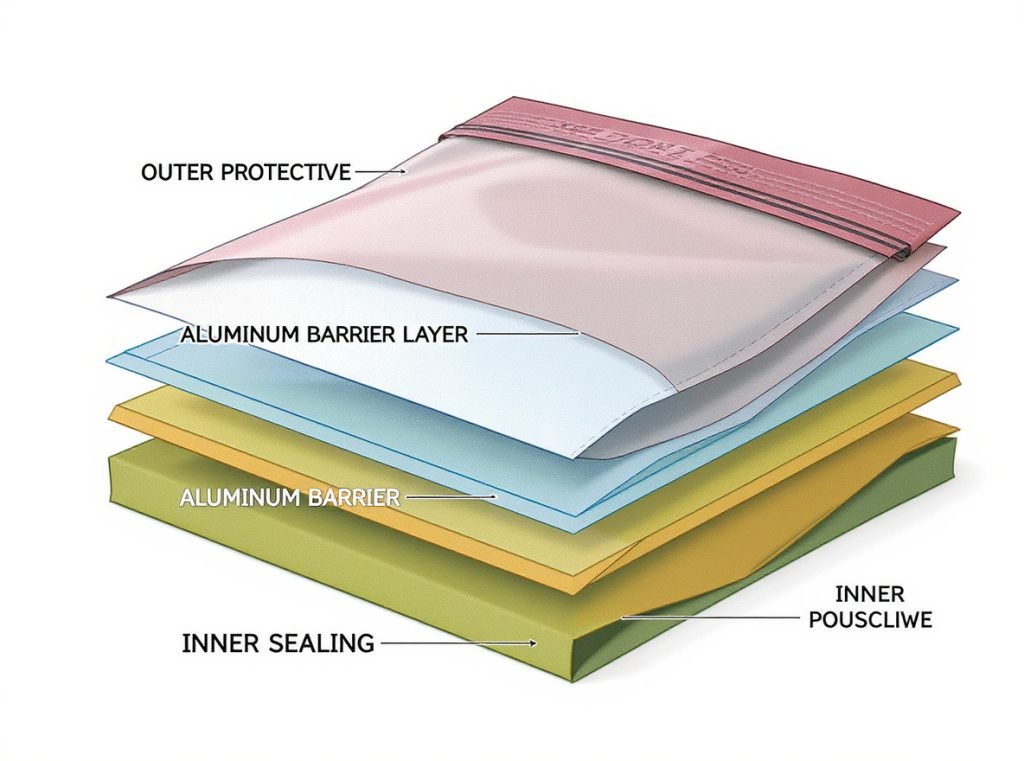

A retort pouch is a flexible, heat-resistant packaging made from sophisticated laminate structures with three to five layers, typically including polyethylene terephthalate (PET) for durability, aluminum foil for barrier protection, and cast polypropylene (CPP) for heat sealing and food contact safety. This multi-layered construction provides exceptional barrier properties against gas, light, and moisture while maintaining flexibility and puncture resistance.

The technology behind retort pouches allows for sterile packaging of a wide variety of food and drink products through aseptic processing, serving as a lightweight alternative to traditional cans and glass jars. Originally developed for military applications, this packaging solution has evolved into mainstream commercial use.

Common laminate configurations include:

- Outer layer: Polyethylene terephthalate (PET) for printability and structural integrity

- Barrier layer: Aluminum foil or specialized barrier films for oxygen and moisture protection

- Inner layer: Cast polypropylene (CPP) for heat sealing and food contact safety

| Layer Component | Material | Primary Function |

|---|---|---|

| Outer Protection | PET/Polyester | Durability, printability, handling resistance |

| Barrier Core | Aluminum foil | Gas, moisture, light protection |

| Sealing Surface | Cast Polypropylene | Heat sealing, food contact safety |

These multi-layered structures achieve commercial sterility while maintaining product quality far superior to traditional packaging methods.

How Does the Retort Process Work?

The retort sterilization process represents precision food science that ensures both safety and quality. Understanding this process helps businesses appreciate the technical sophistication behind retort packaging.

The retort process involves heating sealed pouches to precisely controlled temperatures of 240-250°F (116-121°C) for predetermined time periods under high pressure inside specialized retort machines, specifically designed to eliminate Clostridium botulinum, the most heat-resistant pathogenic bacterium capable of producing deadly botulinum toxin. This temperature range ensures commercial sterility while preserving nutritional value.

The process begins with filling prepared food into pouches, then sealing them using specialized heat-sealing equipment that creates airtight barriers. The sealed pouches are placed into retort machines (autoclaves) where they undergo precise thermal treatment.

Heat penetration characteristics provide significant advantages over traditional canning. Due to their thin profile, retort pouches achieve heat penetration to the cold spot up to 40% faster than conventional methods. Research demonstrates:

- Come-up time: 24 minutes for retort pouches versus 28 minutes for glass jars

- Processing time reduction: Up to 30-40% faster sterilization while maintaining food safety

- Temperature uniformity: More consistent heat distribution throughout the product

Industrial retorts employ various sterilization methods:

- Water immersion retorts: Products submerged in hot water for even heat distribution

- Steam retorts: Direct steam injection for efficient heating

- Water spray retorts: Mist-like spray for uniform temperature without dead spots

- Steam-air retorts: Combined circulation for specialized product requirements

This faster, more efficient processing translates directly into better food quality and reduced energy consumption.

What Products Use Retort Pouch Packaging?

Retort pouches serve diverse applications across multiple industries, offering shelf-stable solutions that revolutionize product distribution and storage. Understanding these applications helps identify opportunities for your product lines.

Retort pouches are widely used for ready-to-eat meals, military MREs, pet food, baby food, soups, sauces, and beverages, with applications expanding rapidly into emergency food, institutional foodservice, and specialty products due to their convenience and extended shelf life capabilities. The versatility continues expanding into new market segments.

Primary food industry applications include:

Ready-to-eat meals such as curry, pasta dishes, and rice meals benefit from extended shelf life and convenient heating options. These products maintain texture and flavor far better than traditionally canned alternatives.

Military rations (MREs) represent one of the most successful applications, utilizing retort technology for field-ready meals that are lightweight and durable for harsh conditions.

Pet food manufacturers increasingly adopt retort pouches for wet cat and dog food, providing hygienic packaging with excellent portion control capabilities.

| Product Category | Common Applications | Key Advantages |

|---|---|---|

| Ready-to-eat meals | Curry, pasta, rice dishes | Convenience heating, texture retention |

| Military/Emergency | MREs, field rations | Lightweight, durability, long shelf life |

| Pet food | Wet food, treats | Hygiene, portion control, easy opening |

| Baby food | Purees, snacks, beverages | Safety assurance, convenient feeding |

| Institutional | Hospital meals, school food | Minimal preparation, hygienic service |

Specialized applications continue expanding into emergency preparedness markets due to lightweight nature and refrigeration-free storage. Hospitals, schools, and large-scale food operations rely on retort pouches for convenient, hygienic meal solutions requiring minimal preparation.

What Are the Main Benefits of Using Retort Pouches?

The comprehensive advantages of retort pouches extend far beyond simple food preservation, offering measurable improvements in quality, economics, and operational efficiency. These benefits translate directly into competitive advantages.

Retort pouches offer superior food quality preservation with up to 30% faster processing times, 88% weight reduction compared to cans, 47% improved storage efficiency, and enhanced consumer convenience features while maintaining equivalent food safety standards. These measurable benefits create substantial operational improvements.

Superior food quality preservation results from faster processing capabilities:

Nutrient retention improves significantly due to reduced thermal exposure. The faster heat penetration means shorter sterilization cycles, preserving vitamins, minerals, and original flavors that longer processing destroys.

Texture quality remains firmer and less overcooked compared to traditional canning methods. Products maintain their original appearance and mouthfeel rather than developing the soft, overprocessed characteristics common in canned foods.

Economic and operational benefits provide measurable cost savings:

- Weight reduction: 88% lighter per equivalent capacity reduces shipping expenses dramatically

- Storage efficiency: 47% improved space utilization minimizes warehousing costs

- Processing speed: 40% faster heat penetration lowers energy consumption

- Material costs: More economical production than metal containers

Consumer convenience features enhance market appeal:

- Easy opening with built-in tear notches eliminates can opener requirements

- Microwave compatibility allows direct heating in transparent varieties

- Portion control options from single-serve to family sizes

- Reduced disposal waste compared to rigid containers

Environmental sustainability considerations increasingly influence packaging decisions. Modern retort pouches demonstrate up to 60% lower carbon footprint when recycled, require less packaging material than cans or jars, and new mono-material structures enable improved recycling capabilities.

How Do Retort Pouches Compare to Traditional Canning?

Understanding the fundamental differences between retort pouches and traditional canning reveals significant advantages in processing efficiency, food quality, and economic performance. Both methods achieve commercial sterility but through very different approaches.

Retort pouches offer superior heat transfer efficiency due to large surface area and thin profiles, achieving target sterilization temperatures 30-40% faster than traditional canning while providing better nutrient retention, texture quality, and flavor preservation. This fundamental difference creates numerous practical advantages.

Processing advantages demonstrate clear technical superiority:

Heat transfer efficiency represents the most significant advantage. While canned foods require longer processing times due to heat transfer limitations through thick container walls, retort pouches achieve faster, more uniform heating throughout the product.

Temperature distribution research shows retort pouches achieve target sterilization temperatures faster than glass jars, with processing times reduced from 67 minutes to 62 minutes for equivalent sterilization values.

Quality and nutrition comparisons show measurable differences:

| Performance Factor | Retort Pouches | Traditional Canning |

|---|---|---|

| Processing time | Reduced 30-40% | Extended exposure required |

| Nutrient retention | Higher vitamin/mineral preservation | Greater loss from prolonged heat |

| Texture quality | Firmer, less overcooked | Often softer from extended heating |

| Flavor preservation | Better original taste retention | May develop “canned” flavors |

Economic considerations favor retort pouches in most applications. While initial equipment investment may be substantial, operational costs typically run lower than canning systems. The compact footprint of vertical form-fill-seal equipment (10×12 feet) contrasts sharply with extensive canning line requirements.

Transportation and storage advantages provide ongoing cost benefits. The 88% weight reduction per equivalent capacity translates to significant logistics savings, while the 47% improved storage efficiency reduces warehousing expenses.

However, traditional canning maintains advantages in specific applications, particularly for products requiring longer shelf lives or more robust physical protection during handling and distribution.

What Should You Consider When Choosing Retort Pouch Suppliers?

Selecting the right retort pouch supplier impacts product safety, quality, cost-effectiveness, and market success. Multiple critical factors determine supplier suitability for your specific requirements and business objectives.

When evaluating retort pouch suppliers, prioritize those with proper certifications (ISO 22000, HACCP, FDA compliance), proven technical capabilities including third-party testing, measurable performance metrics (≥97% on-time delivery), and production capacity that matches your volume needs and growth projections. The right supplier partnership directly affects product safety and business sustainability.

Essential supplier qualifications include comprehensive certifications and compliance standards:

Food safety certifications demonstrate commitment to quality and regulatory compliance. Verify suppliers maintain ISO 22000 or HACCP certification for food safety management, FDA approval for food-grade materials compliance, and BRC (British Retail Consortium) certification for quality assurance.

Technical capabilities require rigorous assessment of quality testing and validation processes. Leading suppliers provide third-party lab testing for seal integrity under retort conditions, ASTM F2094 compliance for pinhole testing, ASTM F2029 certification for burst strength testing, and comprehensive heat distribution and penetration validation studies.

Operational performance metrics separate exceptional suppliers from average ones:

| Performance Indicator | Target Standard | Industry Leading |

|---|---|---|

| On-time delivery rate | ≥97% | 100% (top-tier suppliers) |

| Response time | ≤4 hours | ≤1-2 hours (premium service) |

| Customer reorder rate | >25% | 45-47% (high retention) |

| Production capacity | 2,000-35,000 m² facilities | Scalable manufacturing |

Geographic manufacturing considerations affect logistics and service quality. China manufacturing clusters in Guangdong Province offer the largest concentration with integrated supply chains, Shandong Province provides competitive pricing with export infrastructure, while Fujian Province specializes in export-oriented facilities.

North American suppliers focus on regulatory compliance and rapid response with higher costs but reduced logistics complexity and strong customer service capabilities.

Key selection criteria for production capability evaluation include minimum order quantities (typically 50,000-100,000+ units), custom design capabilities with multiple material options, scalability for growing business needs, and comprehensive batch traceability with quality control processes.

When working with international suppliers like Acreet, consider factors such as comprehensive quality control processes, multilingual communication capabilities, reasonable lead times that match production schedules, and cultural understanding of your target market requirements.

Summary

Retort pouches represent revolutionary packaging technology that combines commercial sterility with superior food quality, operational efficiency, and economic advantages. With 88% weight reduction, 47% storage efficiency improvement, and 30-40% faster processing times, these flexible packages outperform traditional canning while maintaining equivalent food safety standards. From military MREs to consumer ready meals and pet food applications, retort pouches offer extended shelf life without refrigeration while preserving nutrition and flavor. Ready to explore how retort pouch technology can transform your product packaging and reduce operational costs?

Transform Your Product Packaging with Acreet’s Retort Pouch Solutions

At Acreet, we specialize in manufacturing high-quality retort pouches for international wholesalers, distributors, retailers, and brand manufacturers. Our ISO-certified facility produces custom retort packaging that meets global food safety standards while delivering the performance advantages your products deserve. From initial design consultation to full-scale production, our experienced team ensures your retort pouch packaging meets your exact specifications and regulatory requirements. Contact us today for technical consultation and competitive quotes on your next packaging project – let’s discuss how our retort pouch solutions can enhance your product line while reducing costs and improving market performance.