Whether you’re shipping delicate electronics, storing frozen foods, or transporting products in humid conditions, moisture can be your cardboard packaging’s worst enemy. Water damage leads to weakened boxes, compromised products, and frustrated customers.

Yes, multiple water-resistant coatings are readily available for cardboard boxes. These include traditional wax-based coatings, PE lamination, acrylic treatments, and advanced nanotechnology solutions that can reduce water absorption by up to 30 times while maintaining recyclability and structural integrity.

But choosing the right coating depends on your specific needs, budget, and environmental requirements. Let’s explore your options.

Table of Contents

ToggleWhat Types of Water-Resistant Coatings Are Available?

Understanding your coating options helps you make the best choice for your specific packaging needs. Each type offers different levels of protection and environmental impact.

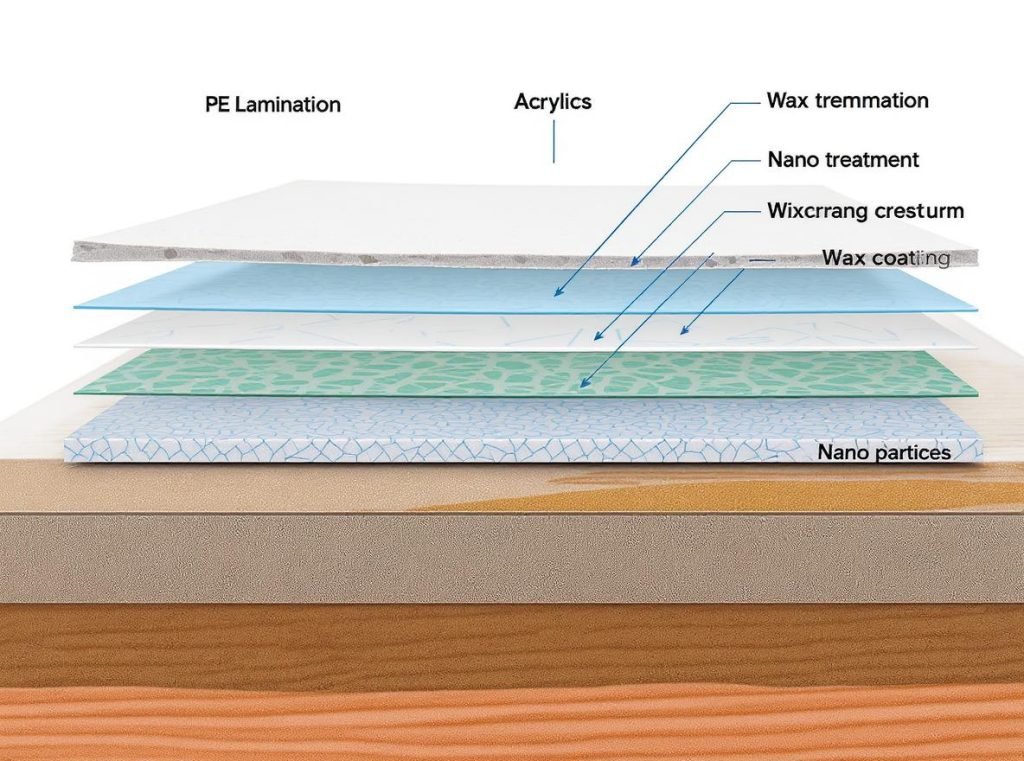

The main water-resistant coatings include traditional wax-based treatments, PE lamination, acrylic coatings, hydrophobic nano coatings, and advanced barrier varnishes. Modern solutions can increase durability three times longer than traditional alternatives while maintaining full recyclability.

The packaging industry offers several proven solutions for water-resistant cardboard:

Traditional Coating Options

Wax-based coatings using paraffin wax or wax blends provide excellent water resistance and are commonly used in food packaging and shipping applications. However, these petroleum-based coatings cannot be recycled through standard channels.

PE (polyethylene) lamination creates a moisture barrier by applying plastic films to the cardboard surface. This method provides strong water resistance but reduces recyclability, making it less suitable for environmentally conscious applications.

Acrylic coatings offer good water resistance while maintaining better environmental credentials than petroleum-based alternatives. These water-based coatings can be applied via spraying or rolling and are more eco-friendly.

Advanced Coating Technologies

Hydrophobic nano coatings represent cutting-edge technology that can reduce water absorption by up to 30 times compared to untreated cardboard. These coatings achieve contact angles of up to 150°, providing superhydrophobic properties.

Modern water-soluble barrier varnishes provide excellent water and grease resistance while maintaining full recyclability. These coatings are applied during the printing process and integrate seamlessly with recycling systems.

| Coating Type | Protection Level | Environmental Impact | Recyclability | Best Applications |

|---|---|---|---|---|

| Wax-Based | High | High Impact | No | Food packaging, shipping |

| PE Lamination | Very High | High Impact | No | Heavy-duty shipping |

| Acrylic Coatings | Medium | Low Impact | Yes | General packaging |

| Nano Coatings | Very High | Low Impact | Yes | Premium applications |

| Barrier Varnishes | High | Very Low Impact | Yes | Sustainable packaging |

How Do These Coatings Protect Against Water Damage?

The science behind water-resistant coatings involves creating sophisticated barriers that prevent moisture penetration while maintaining the cardboard’s structural integrity and performance.

Water-resistant coatings protect cardboard through physical barrier formation, hydrophobic properties, and mechanical property preservation. Advanced coatings create reticulated polymeric structures that prevent water penetration while maintaining air permeability and structural strength.

The protection mechanism varies by coating technology:

Physical Barrier Formation

Coatings create a continuous film on the cardboard surface that prevents water molecules from penetrating the cellulose fibers. This barrier maintains the cardboard’s structural integrity even in humid conditions.

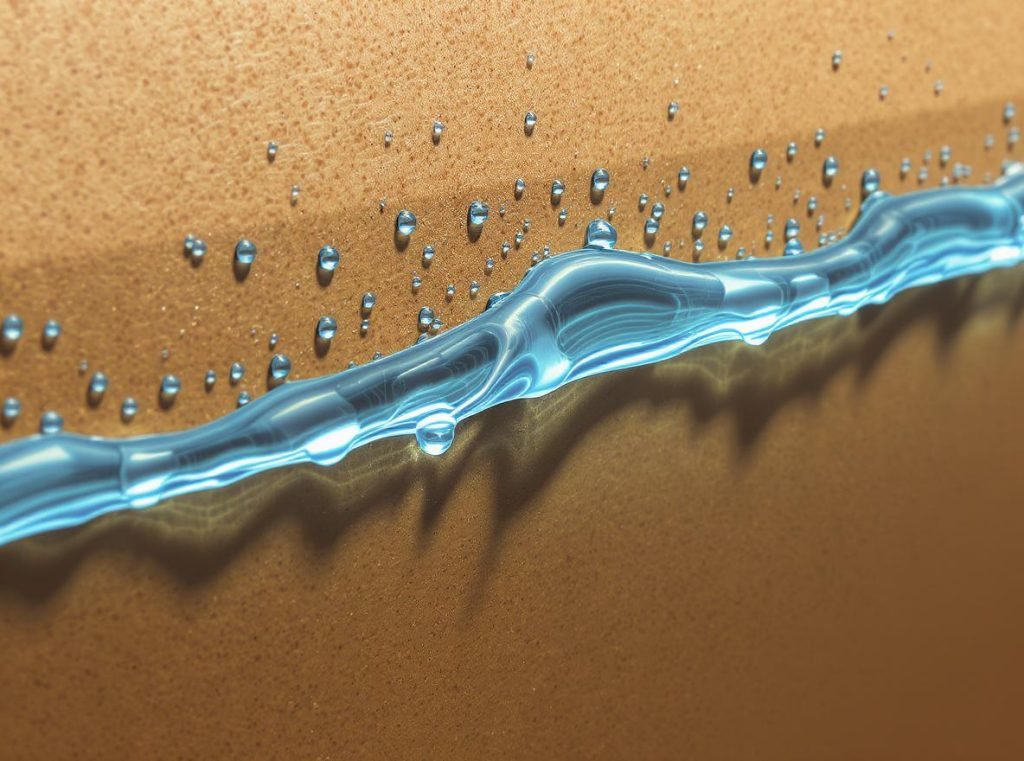

Hydrophobic Properties

Advanced coatings make the cardboard surface hydrophobic, causing water to bead up and roll off rather than being absorbed. The most advanced nano coatings achieve superhydrophobic properties that repel water completely.

Mechanical Property Preservation

Research shows that properly treated cardboard maintains its mechanical properties even when exposed to water. TPU-treated cardboard demonstrates enhanced Young’s modulus, tensile stress, and elongation at break by 226%, 727%, and 116% respectively when wet.

Vapor Barrier Protection

Modern coatings also provide protection against water vapor transmission, with some achieving Water Vapor Transmission Rate (WVTR) levels as low as 400.30 g/(m²·24h), providing comprehensive moisture protection.

Are Water-Resistant Coatings Environmentally Friendly?

Sustainability concerns drive many businesses to seek eco-friendly coating options that don’t compromise on protection or recyclability while addressing environmental challenges.

Many modern water-resistant coatings are environmentally friendly and 100% recyclable. Bio-based coatings using lignin and biomass materials can completely decompose in soil within 2 months while providing comparable waterproofing to traditional petroleum-based options.

Sustainable Coating Innovations

Lignin-based coatings developed by Queensland University of Technology use lignin (a natural wood by-product) and are 100% recyclable. They provide comparable waterproofing to wax while being cost-competitive and environmentally sustainable.

Bio-based coatings using materials like beeswax-in-water Pickering emulsions stabilized with hemicellulose are non-toxic, biodegradable, and can completely decompose in soil within 2 months.

Companies like Cortec Corporation have developed EcoShield® Barrier Coating, which is recyclable and 100% repulpable, eliminating the need for traditional wax and polyethylene coatings.

Environmental Impact Statistics

In Australia alone, approximately 400,000 tonnes of wax-coated cardboard enter landfills annually because they cannot be recycled. PE-coated materials are similarly problematic, as plastic components interfere with recycling processes.

The EU experiences product losses worth up to €9 million annually due to water damage in cardboard packaging, making sustainable water-resistant solutions economically and environmentally essential.

Which Industries Benefit Most from Water-Resistant Cardboard?

Different industries face unique moisture challenges, making water-resistant coatings essential for specific applications where product integrity and customer satisfaction are paramount.

Food and beverage, fresh produce, electronics, pharmaceuticals, and shipping industries benefit most from water-resistant cardboard coatings. These sectors require protection against condensation, humidity, and direct water contact during storage and transportation.

Food and Beverage Industry

Water-resistant cardboard is essential for packaging fresh produce, dairy products, and frozen foods. Companies like McCormack Family Farms have successfully replaced wax-lined packaging with water-resistant coated cardboard trays for produce.

The food industry particularly benefits from FDA-approved coatings for direct food contact, ensuring both protection and safety compliance.

Fresh Produce and Agriculture

The fresh produce industry extensively uses water-resistant packaging for fruits and vegetables. In Spain, which exports 11 million tons of produce annually, moisture-related losses can reach €1.8 billion, making water-resistant packaging crucial for economic viability.

Electronics and Pharmaceuticals

Industries dealing with moisture-sensitive products like electronics and pharmaceuticals rely on water-resistant packaging to prevent damage during storage and transport. These applications require precise moisture control to maintain product quality.

Shipping and Logistics

E-commerce businesses and shipping companies use water-resistant boxes to protect goods during transit. Weather-resistant boxes with water-resistant adhesives (WRA) are specifically designed for challenging shipping conditions.

| Industry | Annual Market Impact | Primary Protection Need | Recommended Solution |

|---|---|---|---|

| Food & Beverage | €1.8B losses (Spain) | Condensation, freezing | FDA-approved coatings |

| Electronics | Growing demand | Humidity, static | Nano coatings |

| Pharmaceuticals | Critical compliance | Moisture contamination | Barrier varnishes |

| Shipping/Logistics | €9M losses (EU) | Weather exposure | Multi-layer treatments |

What Are the Cost Considerations?

Budget planning for water-resistant coatings requires understanding both upfront costs and long-term savings from reduced product damage and improved customer satisfaction.

Water-resistant coatings cost between $0.15-$0.30 per square foot for basic treatments, while advanced nano coatings cost approximately $11 per liter covering 250-350 square feet. The global waterproof coating market is valued at $3.7 billion and growing at 4.8% annually.

Coating Application Costs

The cost of waterproofing cardboard varies significantly based on the method chosen:

- Waterproof spray: $0.15-$0.30 per square foot

- Hydrophobic nano coating: $11 per liter (covers 250-350 square feet)

- Water-resistant coatings: Industrial applications vary by volume and specifications

Market Economics

The global waterproof coating market for paper and paperboard packaging is valued at $3.7 billion in 2024 and is expected to grow at a 4.8% CAGR to reach $5.9 billion by 2034. This growth reflects increasing demand and improving cost-effectiveness.

Long-Term Value Analysis

While initial coating costs may add expense, the protection against product losses makes water-resistant packaging economically advantageous. The EU experiences product losses worth up to €9 million annually due to water damage in cardboard packaging.

Cost-benefit factors include:

- Reduced product damage claims

- Lower replacement and return costs

- Improved customer satisfaction and retention

- Enhanced brand reputation for quality

- Reduced waste disposal costs

How to Choose the Right Coating for Your Needs?

Selecting the appropriate water-resistant coating depends on your specific protection requirements, environmental conditions, sustainability goals, and regulatory compliance needs.

Choose coatings based on your water resistance level needs, recyclability requirements, food safety compliance, and temperature conditions. Nano coatings offer maximum protection, while barrier varnishes provide excellent sustainability, and acrylic treatments offer balanced performance.

Application Requirements Assessment

Level of water resistance needed varies from basic moisture protection to complete waterproofing. Light spray coatings work for minimal exposure, while heavy-duty applications require multi-layer treatments or advanced nano coatings.

Food safety applications require FDA-approved coatings that comply with direct food contact regulations, ensuring both protection and safety compliance.

Temperature considerations are crucial as some coatings perform better in specific temperature ranges. Acrylic elastomeric coatings work well in extreme temperatures and provide UV protection.

Environmental and Regulatory Considerations

Recyclability requirements should guide coating selection. Water-soluble barrier coatings and lignin-based options are preferable to petroleum-based alternatives for environmentally conscious applications.

Biodegradability needs vary by application. Bio-based coatings that can decompose naturally are ideal for single-use applications and environmentally sensitive markets.

Application Method Selection

Spray applications suit DIY projects and small-scale operations but require good ventilation and proper protective equipment.

Industrial coating operations benefit from roll-to-roll application methods that can be integrated into manufacturing processes, providing consistent quality and cost efficiency.

Can You Apply Water-Resistant Coatings to Existing Boxes?

Many businesses wonder if they can retrofit existing cardboard inventory with water-resistant treatments rather than ordering new coated boxes from manufacturers.

You can apply water-resistant coatings to existing cardboard boxes through spray applications, brush-on treatments, or lamination methods. However, proper surface preparation and curing time (24-48 hours) are essential for optimal protection and durability.

Surface Preparation Requirements

Clean the surface thoroughly by removing dust, dirt, and any existing coatings to ensure proper adhesion. Proper preparation is crucial for coating effectiveness and longevity.

Seal exposed edges with duct tape or waterproof sealant, as these are the most vulnerable to water penetration. Edge sealing significantly improves overall protection.

Application Methods

Spray application requires applying waterproof spray evenly, holding the applicator 6-8 inches from the surface. Multiple thin coats are more effective than single thick applications.

Brush-on coatings like polyurethane use a brush or roller for even application. Allow proper drying time between coats for optimal performance.

Lamination provides maximum protection through plastic lamination or self-adhesive laminating sheets for heavy-duty applications.

Curing and Performance

Most coatings require 24-48 hours for complete curing. Ensure adequate ventilation during application and drying. Some coatings may require elevated temperatures for optimal curing.

| Application Method | Protection Level | Cost Range | Curing Time | Best Use Case |

|---|---|---|---|---|

| DIY Spray | Light-Medium | $0.15-0.30/sq ft | 24 hours | Small batches |

| Brush-on Coating | Medium-High | Variable | 24-48 hours | Custom applications |

| Professional Lamination | High | Higher | 24-48 hours | High-value products |

| Factory Application | Maximum | Most economical | Integrated | Large volumes |

What Are the Latest Innovations in Water-Resistant Cardboard?

The packaging industry continuously develops new technologies to improve water resistance while addressing environmental concerns and performance requirements through cutting-edge research and development.

Recent innovations include hydrophobic nano coatings that are imperceptible to touch, peptide-enhanced biodegradable materials, and chromatogeny processes that create 100% recyclable super cellulose. The waterproof cardboard market is projected to reach $4.2 billion by 2031.

Nanotechnology Advances

Recent developments in nanotechnology have produced coatings that are imperceptible to the eye and touch while providing superior water resistance. These nanocoatings form reticulated polymeric structures just nanometers thick without preventing air penetration.

Smart and Functional Coatings

Researchers have developed coatings that can change color at specific temperatures, providing visual indicators of temperature exposure. This multifunctional approach adds value beyond basic water resistance.

Biodegradable Material Innovations

A groundbreaking 2025 study showcased hydrophobic paper enhanced with cellulose nanofibers and peptides, offering a biodegradable alternative to petroleum-based materials. This innovation represents a significant advancement in sustainable packaging technology.

Revolutionary Processing Methods

The chromatogeny process applies bio-sourced oils to paper and cardboard, creating water-resistant materials that remain 100% recyclable. This treatment involves precise temperature and timing controls to create “super cellulose” that repels water completely.

Market Growth Projections

The waterproof cardboard market is projected to reach $4.2 billion by 2031, with a 7.3% CAGR from 2025 to 2031. This growth is driven by industrial adoption and continuous innovation in packaging applications.

The future of water-resistant cardboard coatings lies in sustainable, recyclable technologies that provide superior protection while minimizing environmental impact. As regulations tighten around plastic use and recycling, bio-based and water-soluble coatings are becoming the preferred solutions.

Summary

Water-resistant coatings for cardboard boxes are readily available and offer excellent protection against moisture damage. From traditional wax and PE treatments to advanced nano coatings and bio-based solutions, there’s a coating for every application and budget. Modern innovations can reduce water absorption by up to 30 times while maintaining full recyclability, with the market projected to reach $4.2 billion by 2031.

Ready to protect your products with cutting-edge water-resistant packaging? Contact Acreet today for expert consultation on custom water-resistant cardboard solutions. Our team can help you select the perfect coating system for your specific needs, provide samples for testing, and ensure your packaging meets both protection and sustainability requirements. Send us your inquiry to discover how our advanced coating technologies can safeguard your shipments and enhance customer satisfaction.