You’re planning premium packaging for your products, and thick paperboard seems like the perfect foundation. But can you achieve those luxurious embossed textures and gleaming foil accents directly on heavy cardstock? This question troubles many brand owners and packaging designers who want durability without sacrificing elegance.

Yes, you can both emboss and foil stamp directly onto thick paperboard with exceptional results. Thick materials actually provide better definition, deeper impressions, and improved durability compared to standard weights. Success depends on proper material selection, equipment capabilities, and understanding how thickness enhances rather than limits these premium finishing techniques.

Let’s explore exactly how to leverage thick paperboard’s advantages for stunning embossing and foil stamping results.

Table of Contents

ToggleWhat Counts as “Thick Paperboard” for Packaging Applications?

Understanding industry thickness classifications helps you select the optimal material for your finishing requirements and target applications.

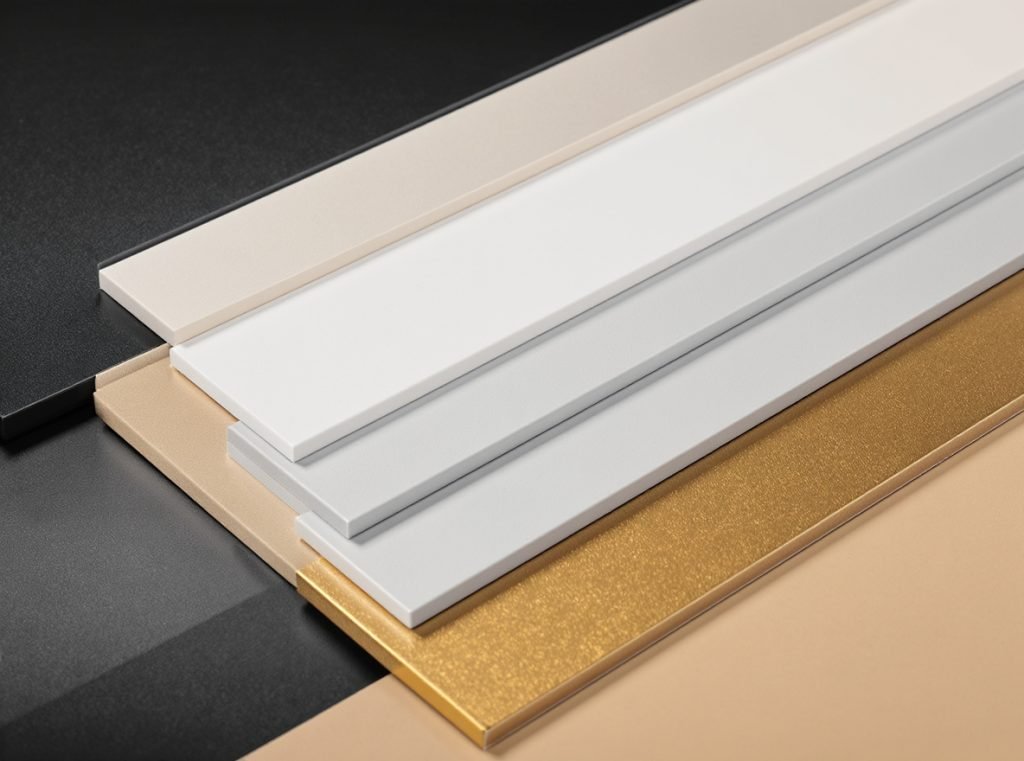

Thick paperboard is generally defined as material with thickness of 12pt (0.012 inches) or more, with heavy paperboard ranging from 24pt to 45pt, and extra thick paperboard extending beyond 45pt up to 250pt for specialized applications.

Industry Standard Classifications

Professional packaging uses specific thickness categories:

Point Measurements (Standard):

- Regular paperboard: 12pt to 24pt (0.012″ to 0.024″)

- Heavy paperboard: 24pt to 45pt (0.024″ to 0.045″)

- Extra thick paperboard: 45pt+ (0.045″+), extending to 250pt in laminated versions

Weight Classifications:

- Light: 80-150 gsm

- Medium: 150-300 gsm

- Heavy: 300+ gsm, with specialty grades reaching 1500+ gsm

| Application Type | Thickness Range | Weight Range | Embossing Performance | Foil Stamping Success |

|---|---|---|---|---|

| Folding cartons | 12pt-24pt | 150-300 gsm | Excellent | High success rate |

| Rigid boxes | 20pt-100pt+ | 300-800 gsm | Outstanding | Excellent with proper technique |

| Industrial packaging | 45pt-250pt | 800-1500+ gsm | Superior depth | Requires specialized equipment |

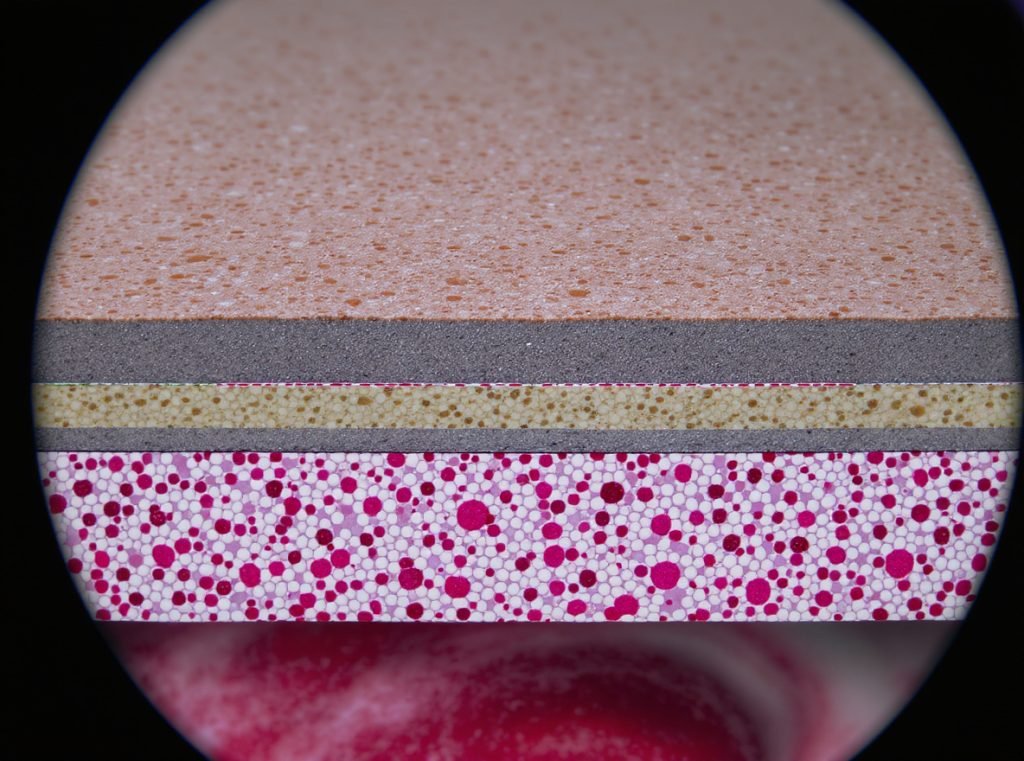

Multi-layer construction in thick paperboard actually improves finishing performance compared to single-layer materials, as laminated boards provide better dimensional stability and emboss retention.

How Does Material Thickness Actually Enhance Embossing Results?

Contrary to common assumptions, increased thickness significantly improves embossing quality and performance characteristics for premium packaging applications.

Thick paperboard delivers superior embossing results through better definition, deeper impressions that resist flattening, and reduced spring-back compared to thinner materials, making it ideal for luxury packaging requiring lasting dimensional effects.

Performance Advantages of Thick Materials

Thick paperboard provides multiple embossing benefits:

Superior Definition and Durability:

- Better shape retention: Thick materials hold embossed forms more effectively

- Deeper impressions: Allow for more pronounced 3D effects up to 15-25% compression ratios

- Reduced spring-back: Maintain embossed form permanently after pressure release

- Enhanced handling durability: Resist flattening during shipping and consumer interaction

Technical Performance Characteristics:

Fiber orientation becomes critical with thick materials. Long fibers perform significantly better than short fibers for deep embossing applications.

Moisture content control prevents cracking during the embossing process. Proper moisture levels (controlled humidity) ensure fiber flexibility without compromising structural integrity.

Chemical fiber content delivers better performance than mechanical fiber, providing cleaner impressions and reduced surface defects.

Optimal Material Specifications

The best embossing results require specific material characteristics:

- Bursting strength: Critical for deep embossing without material failure

- Flexible coatings: Prevent surface cracking during deformation

- Consistent density: Ensures uniform embossing depth across design areas

- Grain direction alignment: Embossing with fiber orientation improves quality

What Advanced Techniques Optimize Foil Stamping on Heavy Cardstock?

Heavy cardstock requires modified parameters and specialized approaches, but delivers superior foil stamping results when properly executed.

Successful foil stamping on heavy cardstock requires 20-30% higher temperatures, increased pressure up to 30 tons, extended dwell time for heat penetration, and specialized high-adhesion foils formulated specifically for thick substrates.

Critical Parameter Adjustments

Heavy cardstock demands specific modifications for optimal results:

Temperature and Timing Control:

- Increased heat: 20-30% higher temperatures than standard paper

- Extended dwell time: Longer contact periods allow complete heat penetration through material thickness

- Progressive heating: Gradual temperature application prevents substrate scorching

- Controlled cooling: Adequate cooling time ensures proper foil adhesion

Pressure Distribution Systems:

- Higher force requirements: Up to 30 tons for extra thick materials

- Graduated pressure application: Progressive force prevents material cracking

- Even distribution: Specialized platens ensure consistent pressure across design areas

Specialized Equipment Requirements

Professional heavy cardstock processing requires industrial-grade equipment:

Enhanced Press Specifications:

- Heavy-duty construction: Machines rated specifically for thick substrate handling

- Reinforced dies: Brass or steel construction withstands repeated high-pressure applications

- Advanced heating systems: Precise temperature control with higher heat capacity

- Servo-driven feeding: Accurate positioning systems accommodate material thickness variations

Foil Selection Optimization:

| Foil Type | Substrate Compatibility | Heat Requirements | Adhesion Strength | Best Applications |

|---|---|---|---|---|

| High-adhesion metallics | Excellent for 300+ gsm | Higher temperature | Superior bonding | Logos, premium accents |

| Heat-activated pigments | Good for coated surfaces | Extended dwell time | Strong adhesion | Solid color areas |

| Flexible carriers | Optimal for thick materials | Standard temperature | Accommodates thickness | Large coverage areas |

Surface preparation becomes more critical with thick materials, as any coating inconsistencies become magnified during the high-pressure foil application process.

How Do You Successfully Combine Embossing and Foil Stamping?

Combination work merges both techniques in a single pass, creating premium finishes that maximize the advantages of thick paperboard materials.

Combination embossing and foil stamping uses specialized dies to apply both effects simultaneously, creating enhanced light reflection, premium appearance, and cost-efficient production while eliminating registration issues between separate processes.

Single-Pass Combination Technique

This advanced process delivers superior results:

Technical Process Advantages:

- Combination dies: Feature both embossing and foil-cutting edges in single tooling

- Perfect registration: Eliminates alignment issues between separate operations

- Enhanced visual impact: Embossed surfaces create multiple light-catching angles for foil reflection

- Production efficiency: Single setup reduces processing time and handling

Application Methods and Variations

Different approaches serve various design requirements:

With Lamination Integration:

- Foil stamping over lamination plus embossing creates protective surface effects

- Foil stamping under lamination with spot UV combines multiple premium finishes

- Sequential lamination allows complex multi-layer effects

Direct Application Methods:

- Simultaneous foil stamping and embossing for maximum impact

- Foil stamping with debossing creates sophisticated contrast effects

- Selective foil application on embossed areas only

The key advantage of thick paperboard in combination work is its ability to support deep embossing while maintaining excellent foil adhesion across varying surface levels.

What Equipment Specifications Are Required for Professional Results?

Processing thick paperboard demands industrial-grade equipment with enhanced capabilities beyond standard finishing machinery.

Professional thick paperboard processing requires heavy-duty stamping presses with 1-30 ton capacity, precision heating systems up to 300°C, servo-driven feeding for accurate positioning, and pneumatic systems with minimum 0.6 MPa air supply.

Essential Machinery Specifications

Industrial processing demands specific equipment capabilities:

Heavy-Duty Press Requirements:

- Pressure capacity: 1-30 ton range depending on material thickness and design complexity

- Temperature control: 0-300°C with precise digital regulation

- Platen construction: Reinforced steel construction handles repeated high-pressure operations

- Feeding systems: Servo-driven mechanisms ensure accurate positioning of thick materials

Specialized Die Construction:

- Material grade: Brass or steel construction withstands high-pressure applications

- Multi-level capability: Handle varying emboss depths within single designs

- Heat distribution: Even temperature across entire die surface

- Durability factors: Extended life under heavy material processing conditions

Support Equipment Integration

Complete production requires additional specialized systems:

Material Handling Solutions:

- Heavy-duty feeding systems accommodate thick substrate stacks

- Precision stacking equipment handles finished thick materials

- Quality control stations inspect thick material processing results

- Safety systems protect operators during high-pressure operations

Production Monitoring:

- Temperature monitoring across die surface

- Pressure distribution measurement

- Registration accuracy verification

- Quality consistency tracking

Investment in proper equipment ensures consistent results and long-term production capability for thick paperboard finishing operations.

How Do Surface Coatings Impact Finishing Success?

Surface coatings significantly affect both embossing depth and foil adhesion quality, requiring careful selection and preparation for optimal results.

Clay coatings provide smooth surfaces but may crack during embossing, PE/polymer coatings offer flexibility but challenge foil adhesion, while aqueous coatings balance environmental benefits with controlled fiber interaction for optimal finishing performance.

Coating Type Performance Analysis

Different surface treatments create specific advantages and challenges:

Clay Coating Systems:

- Smooth printing surface: Excellent ink adhesion and print quality

- Embossing limitations: May crack during deep embossing operations

- Solution approaches: Flexible coating formulations prevent surface cracking

PE/Polymer Coating Applications:

- Moisture resistance: Excellent barrier properties for packaging

- Foil adhesion challenges: Standard foils may not bond effectively

- Technical solutions: Surface treatment or specialized high-adhesion foils

Aqueous Coating Benefits:

- Environmental advantages: Water-based, reduced VOC emissions

- Fiber interaction: Controlled penetration maintains substrate integrity

- Processing compatibility: Good performance with both finishing techniques

Critical Success Factors

Achieving consistent results requires attention to specific coating characteristics:

Coating Flexibility: Essential for preventing surface cracking during embossing operations. Flexible formulations accommodate material deformation without compromising surface integrity.

Adhesion Strength: Directly affects foil bonding success. Surface energy levels must match foil adhesive requirements for permanent bonding.

Thickness Uniformity: Ensures consistent finishing results across the entire substrate surface. Variations cause uneven embossing depth or foil transfer quality.

What Design Guidelines Maximize Thick Paperboard Advantages?

Thick paperboard’s enhanced capabilities allow for more ambitious design approaches while requiring specific technical considerations for optimal results.

Design elements should feature minimum 0.5mm line widths for fine details, avoid mixing fine and large embossed areas within single designs, and take advantage of thick paperboard’s ability to support deeper impressions and more complex dimensional effects.

Embossing Design Optimization

Thick paperboard supports more aggressive embossing approaches:

Enhanced Capability Specifications:

- Minimum line width: 0.5mm for finest details (thicker materials support finer details)

- Maximum emboss depth: Inversely related to area coverage but deeper than thin materials

- Multi-level embossing: Thick materials support complex dimensional variations

- Register tolerance: Material thickness requires broader alignment allowances

Design Strategy Advantages:

- Bold dimensional effects: Thick materials support dramatic depth variations

- Complex sculptured surfaces: Multi-level embossing creates sophisticated textures

- Large embossed areas: Material thickness supports extensive coverage without distortion

Foil Stamping Design Requirements

Foil application on thick materials follows specific guidelines:

| Design Element | Minimum Specification | Optimal Specification | Technical Considerations |

|---|---|---|---|

| Text (serif fonts) | 14pt | 18pt+ | Avoid thin strokes on thick substrates |

| Text (sans-serif) | 12pt | 16pt+ | Bold weights transfer more consistently |

| Line thickness | 1.5pt | 2pt+ | Thicker lines ensure complete foil transfer |

| Element spacing | 2mm | 3mm+ | Prevents foil bleeding between elements |

Advanced Design Techniques:

- Solid coverage areas: Perform better than fine line details on thick materials

- Vector-based artwork: Required for sharp, clean edges at high pressures

- Light-catching geometry: Design specifically for optimal foil reflection angles

Reverse-out text requires extra consideration on thick materials, as large foil areas may show adhesion variations due to substrate thickness effects.

Which Paperboard Grades Deliver Superior Finishing Performance?

Material selection dramatically impacts finishing success, with specific grades consistently outperforming others for embossing and foil stamping applications.

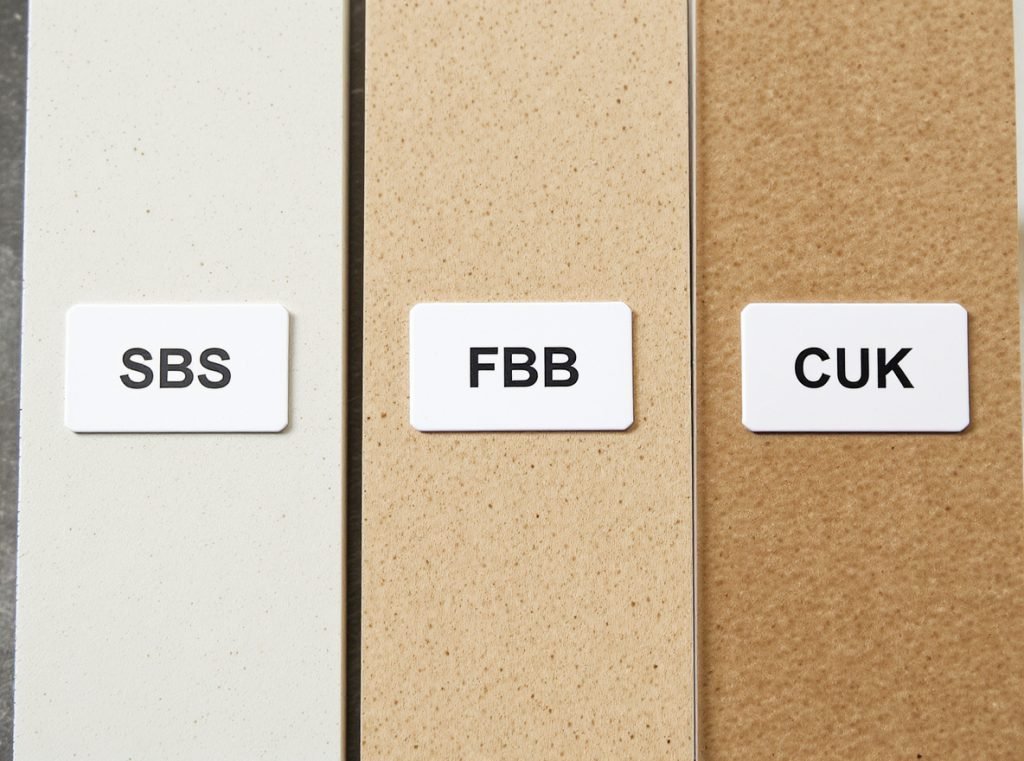

Solid Bleached Sulfate (SBS) provides optimal finishing performance, followed by Folding Box Board (FBB) for excellent embossing characteristics, while Coated Unbleached Kraft (CUK) offers high strength but limits light-colored foil options.

Premium Grade Performance Rankings

Professional finishing requires careful grade selection:

Solid Bleached Sulfate (SBS) – Superior Performance:

- Consistent thickness: Uniform density throughout material thickness

- Superior print surface: Smooth, even coating accepts foil excellently

- Excellent embossing: Clean impressions with minimal fiber separation

- Application versatility: Ideal for cosmetics, pharmaceuticals, luxury packaging

Folding Box Board (FBB) – Excellent Embossing:

- Multi-layer construction: Provides dimensional stability during processing

- Smooth surface finish: Good foil adhesion characteristics

- High durability: Maintains embossed shapes under handling stress

- Strength characteristics: Supports deep embossing without material failure

Coated Unbleached Kraft (CUK) – Specialized Applications:

- High strength properties: Excellent tear resistance and durability

- Embossing capability: Good dimensional retention and depth

- Foil limitations: Dark substrate color limits light foil visibility

- Cost advantages: Lower material cost for appropriate applications

Performance Optimization Strategies

Achieving best results requires matching grade characteristics to specific requirements:

Surface Finish Considerations:

- Smooth, calendered surfaces: Provide optimal foundation for both techniques

- Linen or laid finishes: Add texture but reduce fine detail reproduction capability

- Clay-coated surfaces: Offer excellent foil adhesion but may resist deep embossing

Virgin fiber content consistently outperforms recycled content for finishing applications due to consistent density and clean fiber characteristics.

What Production Issues Should You Anticipate and Prevent?

Understanding common failure modes and prevention strategies ensures consistent quality and reduces costly production problems.

The most frequent issues include material cracking from excessive force, poor foil adhesion from inadequate temperature or pressure, inconsistent embossing from uneven material thickness, and die wear from heavy material processing requirements.

Embossing Problem Prevention

Thick paperboard presents specific embossing challenges requiring proactive management:

Material Cracking Prevention:

- Sharp corner modification: Use minimum 0.5mm radius on design corners

- Moisture content control: Maintain proper humidity levels during processing

- Grain direction awareness: Align embossing direction with fiber orientation

- Progressive pressure application: Avoid sudden force application

Definition and Consistency Issues:

- Die maintenance: Regular cleaning and inspection prevents quality degradation

- Pressure uniformity: Ensure even force distribution across embossing area

- Material thickness variation: Sort materials by thickness for consistent results

- Temperature stability: Maintain consistent heating throughout production runs

Foil Stamping Quality Control

Heavy cardstock foil stamping requires attention to specific failure modes:

Adhesion Failure Prevention:

- Foil compatibility testing: Verify adhesion on actual substrate before production

- Temperature optimization: Find optimal heat settings for specific material/foil combinations

- Surface contamination control: Maintain clean dies and substrate surfaces

- Pressure distribution: Ensure complete contact across foil application area

Production Consistency Strategies:

| Issue Type | Prevention Method | Monitoring Approach | Corrective Action |

|---|---|---|---|

| Poor adhesion | Pre-production testing | Visual inspection every 100 pieces | Adjust temperature/pressure |

| Incomplete coverage | Die maintenance | Check foil transfer quality | Clean dies, replace foil |

| Registration drift | Equipment calibration | Measure alignment frequently | Recalibrate positioning |

| Material handling | Proper storage | Monitor substrate condition | Control humidity/temperature |

Documentation of successful parameters ensures repeatability and quick problem resolution when issues occur.

How Do Investment Costs Compare Across Different Finishing Options?

Equipment and operational costs vary significantly based on finishing complexity and production volume requirements for thick paperboard applications.

Processing thick paperboard typically increases costs 25-40% over standard weights, with manual foil stamping starting at $69-$300, small automatic systems at $6,000-$7,000, and industrial systems requiring $14,000+ investment for high-volume production.

Equipment Investment Analysis

Cost considerations span initial equipment through ongoing operational expenses:

Entry-Level Equipment Costs:

- Manual foil stamping: $69-$300 for basic hand-operated systems

- Small automatic systems: $6,000-$7,000 for moderate volume production

- Industrial systems: $14,000+ for high-volume, thick material capabilities

Specialized Die Investment:

- Basic foil stamping dies: $200-$1,000+ depending on complexity and size

- Embossing dies: $300-$1,500+ for sculptured dimensional effects

- Combination dies: $500-$2,000+ (most expensive but single-pass efficiency)

Operational Cost Structure

Production costs include both fixed and variable elements:

Per-Piece Cost Analysis:

- Foil stamping: $0.10-$0.50 per piece including materials and labor

- Embossing: $0.05-$0.30 per piece (no consumable foil costs)

- Combination work: $0.15-$0.75 per piece (highest complexity but premium results)

Material Cost Factors:

- Foil materials: $0.50-$2.00 per square foot depending on type and quality

- Thick paperboard premium: 15-25% higher substrate costs

- Waste rates: Higher setup waste with thick materials requires cost consideration

Cost Optimization Strategies

Smart planning reduces overall finishing costs:

Volume Considerations: Higher production volumes justify investment in automated equipment and combination dies that reduce per-piece costs.

Design Simplification: Reducing design complexity lowers die costs and improves production efficiency while maintaining visual impact.

Material Standardization: Bulk purchasing and consistent material specifications reduce both substrate and setup costs.

Quality planning through proper testing prevents costly rework and ensures first-pass success rates that optimize overall production economics.

Summary

Embossing and foil stamping directly onto thick paperboard not only works exceptionally well but actually provides superior results compared to thinner materials. Thick paperboard delivers better definition, deeper impressions, enhanced durability, and premium visual impact that justifies the additional investment. Success requires understanding material advantages, proper equipment selection, and optimized processing parameters.

Ready to create stunning thick paperboard packaging with professional embossing and foil stamping? Contact Acreet today for expert guidance on your custom packaging project. Our experienced team specializes in premium finishing techniques on thick materials and can help you select optimal paperboard grades, design for maximum impact, and execute flawless production runs. Send us your inquiry and let’s transform your packaging vision into reality with the luxury appeal that only thick paperboard finishing can deliver!