When you’re building a brand that stands out in today’s competitive market, every detail matters. Your packaging isn’t just protection—it’s your first impression, your brand ambassador, and often the deciding factor in customer loyalty. But can you actually get corrugated boxes in custom colors that perfectly match your brand identity and create that unforgettable unboxing experience?

Yes, you can absolutely get corrugated boxes in custom colors through various printing methods including flexographic printing, digital printing, and litho-lamination. Modern printing technology allows manufacturers to apply virtually any color, design, or branding to corrugated packaging using Pantone color matching, CMYK printing, and specialized techniques that ensure your brand colors are reproduced accurately.

Let’s explore exactly how custom color corrugated boxes work and what options are available for your business.

Table of Contents

ToggleWhat Are the Standard Base Colors Available for Corrugated Boxes?

Understanding your base material options is crucial because the foundation color significantly impacts your final printed results. Different bases offer different advantages for your custom printing needs.

The two primary standard colors for corrugated boxes are natural brown kraft and white, with brown kraft being the natural color from the pulping process and white offering the best foundation for accurate color reproduction. Many manufacturers also stock additional colors including black, navy blue, red, green, and pink.

Natural Brown Kraft represents the most common and cost-effective option. This natural color comes from recycled wood pulp materials and creates a sustainable, professional appearance. Brown kraft boxes are completely biodegradable and have gained popularity as eco-friendly packaging solutions.

White Corrugated Board provides the optimal foundation for custom color printing. White substrates can be either plain matte white or feature a chalked surface for enhanced smoothness and superior print quality. The chalked surface offers better ink adhesion and more vibrant color reproduction.

Additional Standard Colors are readily available from many manufacturers:

- Black corrugated for premium, luxury positioning

- Navy blue (similar to PMS 2380 C) for professional applications

- Red (similar to PMS 201 C) for attention-grabbing designs

- Dark green (similar to PMS 7736 C) for natural product branding

- Grey (similar to PMS Cool Grey 7) for modern, minimalist aesthetics

- Pink (similar to PMS 1767 C) for feminine or playful branding

| Base Color | Best For | Color Reproduction | Cost Level |

|---|---|---|---|

| Brown Kraft | Eco-friendly brands, cost-conscious projects | Moderate (colors may appear muted) | Lowest |

| White | Premium printing, brand color accuracy | Excellent | Low |

| Black | Luxury positioning, high-end products | Good for light colors | Moderate |

| Colored Stock | Quick turnaround, limited customization | Limited printing options | Moderate |

How Do You Add Custom Colors to Corrugated Boxes?

There are several professional methods for adding custom colors to corrugated packaging, each offering different advantages depending on your specific requirements, budget, and timeline.

Custom colors can be added through pre-colored materials, surface printing methods including flexographic and digital printing, or litho-lamination processes. The choice depends on your volume requirements, color accuracy needs, and budget considerations.

Pre-Colored Materials involve manufacturing corrugated cardboard where all layers, including the inner fluting, are colored uniformly. This approach ensures consistent color throughout the entire box structure, including visible edges and cut areas.

Surface Printing Methods apply colors and designs directly to the corrugated surface:

- Direct Printing: Ink is applied directly to the corrugated material using specialized printing equipment

- Pre-Printing: Colors are printed on smooth liner material before lamination to the corrugated board

- Flood Printing: Covers the entire exterior surface with solid color coverage

Professional Color Matching Systems ensure brand consistency:

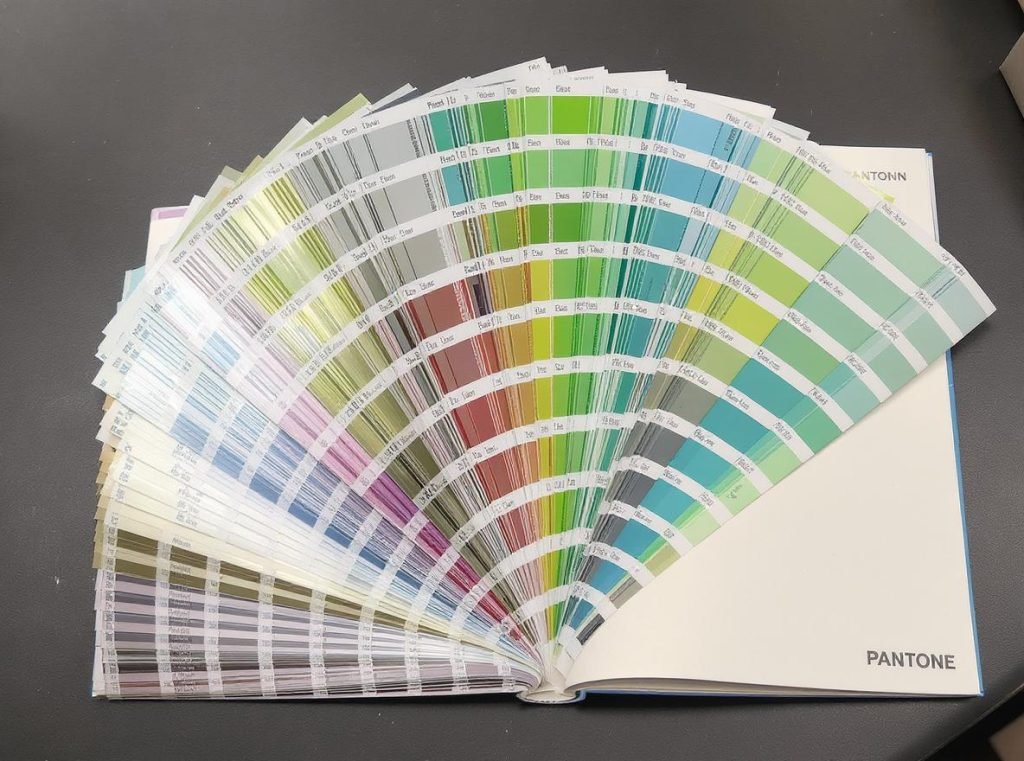

Pantone Color Matching System (PMS) provides over 2,000 standardized color formulations that ensure consistent reproduction across different manufacturers and production runs. This system is essential for maintaining brand color accuracy.

CMYK Printing uses cyan, magenta, yellow, and black inks in combination to create full-color designs. This four-color process enables reproduction of photographic images and complex graphics while remaining cost-effective for multi-color projects.

The choice between these methods depends on factors like order quantity, design complexity, color accuracy requirements, and budget constraints.

What Printing Methods Work Best for Different Custom Color Needs?

Different printing technologies excel in specific applications, making it important to choose the right method for your particular requirements. Each offers distinct advantages in terms of quality, cost, and production capabilities.

Flexographic printing works best for simple designs with up to 4 colors and large volume orders, while digital printing excels for small quantities and complex designs. Litho-lamination provides premium quality for high-end packaging applications.

Flexographic Printing is the most popular choice for corrugated box printing:

- Optimal for: Large volume orders (1,000+ boxes), simple designs, cost-conscious projects

- Color Capability: Up to 4 colors per run with excellent registration

- Advantages: Most cost-effective for high volumes, quick machine setup, durable ink adhesion

- Typical Applications: Basic logos, text, simple graphics, solid color areas

Digital Printing offers maximum flexibility for modern packaging needs:

- Optimal for: Small quantities, complex designs, quick turnarounds, prototyping

- Color Capability: Full CMYK process, unlimited color combinations

- Advantages: No minimum order quantities, photo-realistic quality, fast production (2-8 days)

- Typical Applications: Product photography, complex graphics, variable data printing

Litho-Lamination delivers premium results for high-end applications:

- Optimal for: Premium packaging, complex graphics, retail display boxes

- Color Capability: Unlimited colors with magazine-quality results

- Advantages: Superior color reproduction, enhanced durability, professional finish

- Typical Applications: Luxury packaging, retail displays, high-end product boxes

Screen Printing serves specialized applications:

- Optimal for: Vibrant colors, specialty effects, short runs

- Color Capability: Excellent opacity and vibrancy, special ink effects

- Advantages: Superior color saturation, specialty ink options

- Typical Applications: Premium packaging with special effects, limited edition products

How Does Base Color Impact Your Custom Printing Results?

The base color of your corrugated material fundamentally affects how your printed colors appear in the final product. Understanding these impacts helps you make informed decisions about material selection and design optimization.

Brown kraft base can significantly affect color vibrancy and accuracy due to ink transparency, often requiring white underprinting for true color reproduction. White base materials provide the most accurate color matching and maximum vibrancy for printed designs.

Impact on Brown Kraft Base:

Most printing inks are semi-transparent, meaning the brown substrate shows through and affects the final color appearance. This can cause several issues:

- Color Shifting: Pantone colors may appear significantly different than intended

- Reduced Vibrancy: Bright colors often appear muted or dulled

- Inconsistent Results: Colors may vary from your brand guidelines

- Limited Color Range: Some colors cannot be accurately reproduced

Benefits of White Base Materials:

- True Color Reproduction: Maintains intended color accuracy and brand consistency

- Maximum Vibrancy: Allows for bright, saturated colors that match your brand guidelines

- Better for Complex Graphics: Supports photographic images and detailed artwork

- Professional Appearance: Creates clean, modern aesthetic that appeals to customers

Solutions for Color Accuracy:

When brand color matching is critical, consider these approaches:

- Use white base corrugated materials for most accurate results

- Apply white underprinting on brown substrates when color accuracy is essential

- Work with your manufacturer to see actual color samples on your chosen substrate

- Consider how slight color variations might affect your brand perception

Can You Match Specific Brand Colors on Corrugated Boxes?

Precise brand color matching is absolutely achievable with corrugated packaging when you use professional color management systems and work with experienced manufacturers who understand color science.

Yes, specific brand colors can be accurately matched on corrugated boxes using the Pantone Matching System (PMS) for spot colors or CMYK processing for full-color designs. Professional manufacturers use standardized color formulations and quality control systems to ensure consistent brand color reproduction across production runs.

Pantone Color Matching System (PMS) provides the most accurate approach:

- Universal Color Codes: Over 2,000 standardized colors ensure consistency across different manufacturers

- Precise Formulations: Each Pantone color has a specific ink formula for exact reproduction

- Brand Consistency: Maintains color accuracy across all packaging materials and marketing materials

- Industry Standard: Recognized globally by printing professionals

CMYK Color Reproduction offers cost-effective full-color options:

- Four-Color Process: Combines cyan, magenta, yellow, and black to create thousands of colors

- Cost-Effective: More economical than multiple spot colors for complex designs

- Full-Color Capability: Supports photographic images and gradient effects

- Flexible Design Options: Allows for complex artwork and detailed graphics

Professional Color Management Process:

- Color Specification: Provide exact Pantone numbers or CMYK values

- Substrate Consideration: Account for how base material affects color appearance

- Sample Approval: Review physical color samples before production

- Quality Control: Digital color control systems ensure batch-to-batch consistency

- Final Approval: Confirm colors meet your brand standards before full production

The key to successful brand color matching is working with manufacturers who understand color science and maintain professional color management systems.

What Are the Cost Factors for Custom Color Corrugated Boxes?

Understanding the various cost components helps you budget effectively while maximizing the value of your custom packaging investment. Several factors influence pricing, and knowing these helps you make informed decisions.

The main cost factors include printing method selection, number of colors, order quantity, design complexity, and material choices. Digital printing offers cost-effective solutions for small quantities, while flexographic printing provides better value for large volume orders.

Printing Method Economics:

Each printing method has different cost structures:

- Digital Printing: Higher per-unit costs but no setup fees, ideal for orders under 1,000 boxes

- Flexographic Printing: Lower per-unit costs for large volumes but requires plate creation costs ($600-$1,000)

- Litho-Lamination: Premium pricing for highest quality, typically 20-40% higher than flexographic

Volume-Based Pricing:

Quantity significantly impacts per-unit costs:

- Small Quantities (100-500 boxes): Digital printing most economical

- Medium Quantities (500-2,000 boxes): Flexographic becomes cost-effective

- Large Quantities (2,000+ boxes): Flexographic offers best value

Design Complexity Impact:

- Single-Color Printing: Most economical option, starting around $0.41 per box

- Two-Color Printing: Moderate increase, good balance of cost and impact

- Full-Color CMYK: Higher costs but maximum design flexibility

- Special Effects: UV coating, embossing, or foil stamping add premium pricing

Additional Cost Considerations:

- Setup and Tooling: One-time charges for plates and cutting dies

- Rush Orders: Expedited production typically adds 20-50% to standard pricing

- Custom Sizes: Non-standard dimensions may increase costs

- Material Upgrades: Premium substrates or thicker materials affect pricing

To optimize costs, plan ahead to avoid rush charges, consider standardizing on fewer colors, and order larger quantities when storage allows.

How Long Does It Take to Produce Custom Color Corrugated Boxes?

Production timelines vary significantly based on your chosen printing method, order complexity, and current manufacturer capacity. Understanding these timelines helps you plan effectively for product launches and inventory management.

Standard production times range from 2-8 days for digital printing to 15-20 days for flexographic printing, with litho-lamination requiring 20-25 days. Rush production options can reduce these timelines significantly for urgent projects.

Standard Lead Times by Method:

Digital Printing: 2-8 business days

- Fastest option due to no plate creation requirements

- Ideal for urgent projects and small quantities

- Quick setup and immediate production capability

Flexographic Printing: 15-20 business days

- Requires time for plate creation and press setup

- Standard for most commercial packaging orders

- Balances quality and production efficiency

Litho-Lamination: 20-25 business days

- Multi-step process requiring printing, laminating, and converting

- Premium quality requires additional processing time

- Worth the wait for high-end packaging applications

Factors Affecting Production Time:

- Design Approval Process: Delays in approving artwork extend timelines

- Order Complexity: Complex designs or special requirements need extra time

- Manufacturer Capacity: Peak seasons may extend standard lead times

- Material Availability: Custom colors or special substrates may require additional time

- Quality Control: Larger orders need more time for inspection and testing

Expedited Production Options:

Many manufacturers offer rush services:

- 3-5 days: Single samples and prototypes

- 6-8 days: Small production runs with expedited processing

- Same-day options: Available for urgent situations with premium pricing

Planning Recommendations:

For optimal results, plan 2-6 weeks ahead for custom packaging projects. This allows adequate time for design consultation, color matching, production, and delivery while avoiding rush charges.

Are There Environmental Considerations for Custom Color Corrugated Boxes?

Sustainability is increasingly important for businesses and consumers alike. Custom colored corrugated boxes can maintain environmental benefits when you choose the right materials and printing methods.

Custom colored corrugated boxes can be environmentally friendly when using water-based or soy-based inks, maintaining recyclability through proper ink formulations, and choosing sustainable base materials. Brown kraft bases offer the most eco-friendly option, while minimal ink coverage preserves recycling efficiency.

Sustainable Color Options:

Water-Based Inks provide the most environmentally friendly printing solution:

- Lower environmental impact than solvent-based alternatives

- Reduced air pollution during production

- Better compatibility with recycling processes

- Safer for workers and end-users

Soy-Based and Algae-Based Inks offer renewable alternatives:

- Made from renewable resources rather than petroleum

- Biodegradable formulations

- Lower VOC emissions

- Sustainable supply chains

Recyclability Considerations:

Impact on Recycling: Printing inks can affect the recyclability of corrugated boxes:

- Brown kraft boxes remain highly recyclable with minimal printing

- Heavy ink coverage may affect recycling classification

- De-inkable formulations help maintain recyclability

- Proper ink selection preserves environmental benefits

Environmental Benefits Maintained:

Custom colored corrugated boxes retain many environmental advantages:

- 100% recyclable and compostable base materials

- Made from up to 100% recycled content

- Biodegradable in appropriate conditions

- Energy-efficient production compared to plastic alternatives

Best Practices for Sustainability:

- Choose water-based inks over solvent-based options

- Minimize ink coverage where possible

- Select brown kraft base for maximum environmental benefit

- Use FSC-certified materials when available

- Consider natural/unprinted options for maximum sustainability

One company saved 50 tonnes of CO2 yearly by switching from white to brown corrugated boxes, demonstrating the real environmental impact of material choices.

What Custom Color Options Work Best for E-commerce and Retail Applications?

E-commerce and retail applications have specific requirements that make certain color choices more effective for customer engagement, brand recognition, and practical shipping considerations.

E-commerce packaging benefits from brand-matched colors using Pantone systems, with black packaging for premium positioning, white for professional appearance, and vibrant colors for memorable unboxing experiences. Interior printing enhances the customer experience while full-color graphics support marketing objectives.

Popular E-commerce Color Strategies:

Brand-Matched Colors: Using Pantone or CMYK systems to maintain consistency across all customer touchpoints creates professional brand recognition and customer trust.

Premium Positioning Colors:

- Black packaging suggests luxury and exclusivity

- White boxes provide clean, professional appearance

- Metallic accents add perceived value

Engagement-Focused Colors:

- Vibrant colors including pink, blue, orange, and red create excitement

- Seasonal colors for holiday or special occasion packaging

- Trending colors that align with current design aesthetics

E-commerce-Specific Features:

Interior Printing transforms the unboxing experience:

- Thank-you messages and care instructions

- Social media handles and review requests

- Brand story and company values

- Complementary or contrasting interior colors

Marketing Integration:

- QR codes linking to digital content

- Promotional messages and offers

- Product information and usage instructions

- Cross-selling opportunities for related products

Practical Considerations:

- Shipping Visibility: Colors that photograph well for social media sharing

- Durability: Ink formulations that resist shipping damage

- Cost Management: Balancing visual impact with budget constraints

- Scalability: Colors that work across different product lines

The goal is creating packaging that customers want to share on social media while reinforcing your brand identity and encouraging repeat purchases.

Summary

Custom color corrugated boxes are readily available through modern printing technologies including flexographic, digital, and litho-lamination methods. You can achieve precise brand color matching using Pantone systems, create stunning full-color designs, and even print on interior surfaces for enhanced customer experiences. The key is selecting the right printing method, base material, and color approach for your specific needs and budget.

Ready to elevate your packaging with custom colors that perfectly represent your brand? Contact Acreet today for expert guidance on your custom corrugated box project. Our experienced team understands the technical aspects of color matching, printing methods, and sustainable options to help you create packaging that drives sales and builds customer loyalty. Send us your inquiry with your design requirements, and let’s bring your brand vision to life with precision-crafted custom colored corrugated boxes.