You’re designing packaging that needs to stand out on crowded shelves, but you’re torn between the sophisticated appeal of matte finishes and the eye-catching brilliance of gloss. What if you could have both?

Yes, you absolutely can combine matte and gloss finishes on the same pouch through advanced techniques like spot UV coating, matte over lacquer processes, and selective finishing methods. This dual-finish approach creates striking visual contrasts that boost brand recognition by 70% and justify premium pricing while maintaining cost-effectiveness.

Let’s explore exactly how this works and why it might be the perfect solution for your packaging needs.

Table of Contents

ToggleWhat Printing Techniques Allow Matte and Gloss Combinations?

Understanding the available technologies helps you make informed decisions about your pouch design and communicate effectively with your packaging supplier.

The primary techniques for combining matte and gloss finishes include spot UV coating, matte over lacquer processes, selective coating methods, and digital printing with specialized varnishes. Each method offers different visual effects, quality levels, and volume requirements.

Spot UV/Spot Varnish Technology

Spot UV is the primary technique for combining matte and gloss effects on the same pouch. This process applies a clear, high-gloss UV-cured coating to specific areas while leaving other sections with a matte finish. The varnish is instantly hardened using ultraviolet light, creating sharp contrast between treated and untreated areas.

The process delivers exceptional results through:

- Instant UV curing for precise application without bleeding

- Sharp contrast definition between matte and gloss areas

- Durability enhancement through hardened coating surfaces

- Complex pattern capability for intricate design elements

Matte Over Lacquer Process

Matte over lacquer offers another sophisticated approach for achieving dual finishes. This technique involves applying a matte lacquer coating over selected areas of glossy substrate, creating sophisticated contrast effects that can achieve uniform matte surfaces on specific regions while maintaining gloss in others.

Key advantages include:

- Reverse contrast effects from traditional spot UV applications

- Subtle sophistication ideal for luxury positioning

- Uniform matte coverage on complex surface geometries

- Enhanced tactile experience through varied surface textures

Selective Coating Methods by Volume

Different printing methods support mixed finishes based on your production requirements:

| Printing Method | Best For | Quality Level | Volume Requirements |

|---|---|---|---|

| Digital Printing | Small runs, variable designs | High quality | 100-5,000 units |

| Flexographic | Medium to high volumes | Good quality | 5,000+ units |

| Rotogravure | Ultra-high volumes | Premium quality | 50,000+ units |

| Offset with Spot UV | Complex designs | Maximum quality | 3,000+ units |

Why Would You Want Both Matte and Gloss on One Pouch?

The strategic use of contrasting finishes serves multiple marketing and functional purposes that significantly impact your product’s market performance.

Combining matte and gloss finishes creates a 3D visual effect that makes packages magnetic to consumers, with studies showing consumers are 70% more likely to pick up packages with tactile details, leading to increased brand recognition and purchase likelihood.

Enhanced Visual Appeal and Brand Differentiation

Mixed finishes create a three-dimensional visual effect that draws attention in crowded retail environments. The contrast between matte and glossy areas encourages product handling, which increases consumer engagement with your brand.

This enhanced appeal manifests through:

- Magnetic shelf presence that stops browsing consumers

- Tactile engagement encouraging physical product interaction

- Premium perception suggesting higher product quality

- Memorable visual signature that aids long-term brand recall

Strategic Design Highlighting

Spot UV allows brands to selectively emphasize key packaging elements for maximum marketing impact:

Brand Elements Enhancement:

- Logos and brand names stand out with glossy highlights

- Product images gain depth and enhanced vibrancy

- Text elements become more readable and impactful

- Decorative patterns create subtle luxury effects

Premium Positioning and Perceived Value

Dual finishes instantly elevate perceived product quality and justify premium pricing. The sophisticated contrast communicates luxury and attention to detail, making products appear more upscale without significantly increasing material costs.

Consumer psychology research shows:

- Premium perception increase of 25-40% with dual finishes

- Price tolerance improvement allowing 15-30% pricing premiums

- Brand trust enhancement through perceived quality signals

- Purchase intent boost in competitive retail environments

What Are the Cost Implications of Mixed Finishes?

Budget considerations play a crucial role in packaging decisions, so understanding the comprehensive financial impact helps you make informed choices about finish combinations.

The cost premium for dual finishes typically ranges from 15-40% above standard single-finish pouches, but this premium decreases significantly with higher volumes due to setup cost distribution and often pays for itself through improved sales performance.

Setup and Tooling Costs

Mixed finish packaging requires additional setup costs compared to single-finish options due to specialized equipment and process requirements:

Primary cost factors include:

- Spot UV plates: $200-800 depending on design complexity

- Registration alignment systems: Requiring precise printing equipment

- Quality control measures: Additional inspection steps increasing production time

- Color matching protocols: Ensuring consistent appearance across runs

Volume-Based Pricing Structure

Cost efficiency improves dramatically with larger order quantities:

| Order Quantity | Additional Cost per Unit | Setup Cost Distribution |

|---|---|---|

| 1,000-5,000 units | $0.15-0.30 | High per-unit impact |

| 5,000-25,000 units | $0.08-0.20 | Moderate per-unit impact |

| 25,000+ units | $0.05-0.12 | Low per-unit impact |

Material and Process Considerations

Matte finishes generally cost 10-20% more than glossy finishes due to specialized materials and coating processes. However, the marketing benefits often justify the additional investment, particularly for premium brands targeting discerning consumer segments.

ROI considerations include:

- Sales velocity improvements from enhanced shelf appeal

- Premium pricing opportunities from elevated perceived value

- Brand differentiation advantages in competitive markets

- Customer retention gains from memorable packaging experiences

Which Product Categories Benefit Most from Dual Finish Pouches?

Certain product categories and market positions gain more significant advantages from matte/gloss combinations than others.

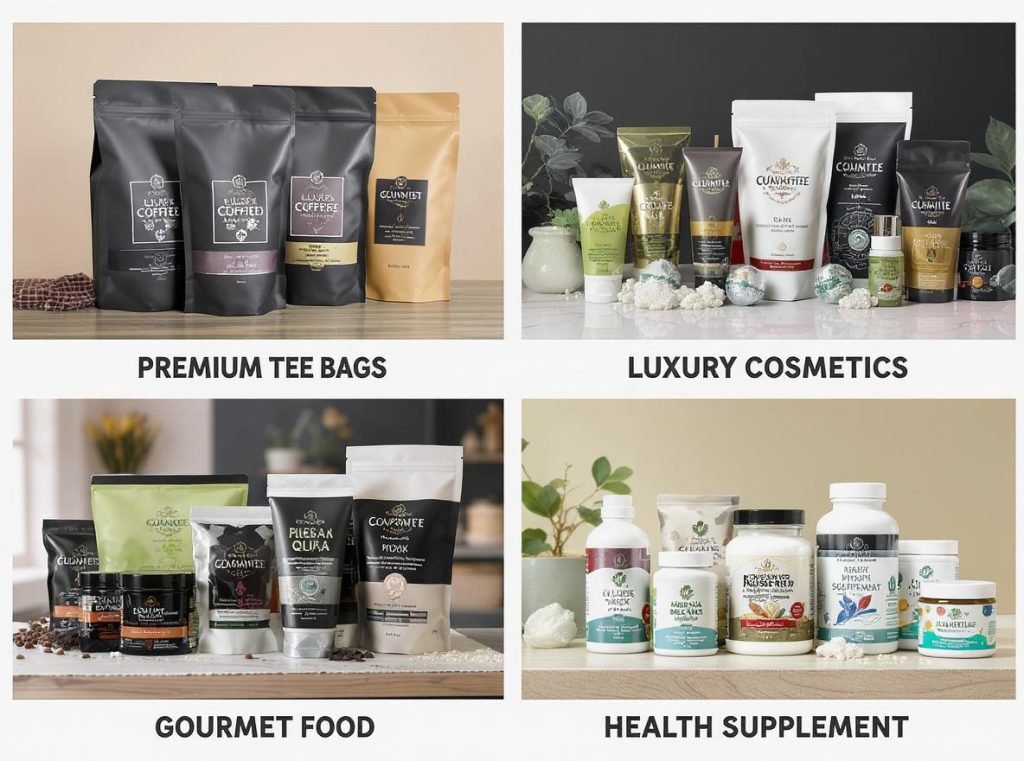

Mixed finishes are especially effective in oversaturated markets where shelf differentiation is crucial, particularly for premium consumer goods, luxury food items, beauty products, and highly competitive categories.

High-Competition Categories

Categories with intense shelf competition benefit most from dual finish differentiation:

Food and Beverage Applications:

- Specialty coffee where premium positioning is essential

- Gourmet snacks requiring sophisticated brand communication

- Organic products aligning with natural yet refined positioning

- International foods needing to convey authenticity and quality

Beauty and Personal Care:

- Skincare products where packaging suggests efficacy

- Makeup items requiring eye-catching shelf presence

- Luxury personal care justifying premium price points

- Men’s grooming differentiating in growing market segments

Premium Product Lines

Products positioned as luxury or premium benefit most from dual finish effects:

- Limited edition items requiring special visual treatment

- Gift products where packaging adds perceived value

- Health and wellness supplements targeting quality-conscious consumers

- Cannabis products where premium positioning is legally required

International Market Considerations

Global brands use sophisticated packaging to maintain consistent premium positioning across diverse markets where local competition varies significantly:

| Market Type | Dual Finish Benefits | Key Considerations |

|---|---|---|

| Developed Markets | Differentiation in saturated categories | Higher quality expectations |

| Emerging Markets | Premium positioning establishment | Cost sensitivity balance |

| Luxury Segments | Brand credibility reinforcement | Maximum quality standards |

| E-commerce | Unboxing experience enhancement | Shipping durability needs |

How Do You Design for Maximum Impact with Mixed Finishes?

Strategic design planning ensures your investment in dual finishes delivers optimal visual and marketing results.

Effective mixed finish design follows the 70/30 contrast rule: use one finish as the dominant background (70%) and the contrasting finish for key elements (30%), ensuring clear visual hierarchy and professional appearance that maximizes consumer engagement.

Strategic Contrast Placement

Create visual flow that guides consumer attention through your packaging information in the desired sequence:

Primary design principles:

- Use matte backgrounds to make glossy elements pop dramatically

- Apply gloss to logos for instant brand recognition

- Highlight product images with selective UV coating for enhanced appeal

- Create subtle patterns with matte-on-gloss effects for sophistication

Color and Finish Coordination

Strategic color and finish combinations maximize visual impact:

| Background Finish | Accent Finish | Best Applications |

|---|---|---|

| Matte Black | Spot Gloss | Luxury products, electronics |

| Glossy White | Matte Elements | Clean, modern aesthetics |

| Matte Kraft | Glossy Graphics | Natural, organic products |

| Mixed Metallic | Selective Matte | Premium confectionery |

Typography and Readability Enhancement

Mixed finishes can significantly enhance text readability when applied strategically. Glossy text on matte backgrounds improves contrast, while matte text on glossy surfaces reduces glare and enhances legibility under various lighting conditions.

Typography best practices:

- Headlines benefit from gloss treatment for attention-grabbing impact

- Body text reads better with matte finish to reduce eye strain

- Call-to-action elements should use contrasting finish for emphasis

- Regulatory text requires matte treatment for legal compliance readability

What Should You Know About Production Timelines?

Mixed finish pouches require additional production planning due to the complexity of multiple coating applications and quality control requirements.

Dual finish pouch production typically requires 5-8 weeks for complete manufacturing, with the timeline dependent on design complexity, order volume, and supplier capacity, though rush options are available for 25-50% premium pricing.

Standard Production Schedule

The manufacturing sequence typically follows this comprehensive timeline:

Week-by-week breakdown:

- Week 1: Artwork approval, plate preparation, and material sourcing

- Week 2: Film proof production and color matching verification

- Week 3: Lamination application and coating process setup

- Weeks 4-5: Pouch formation, dual finish application, and curing

- Weeks 6-8: Quality control inspection, finishing, and packaging

Factors Affecting Timeline

Several variables can extend production schedules beyond standard timelines:

Timeline extension factors:

- Complex registration requirements for precise spot UV placement

- Custom material specifications requiring special sourcing and testing

- Multiple revision rounds during proof approval processes

- Peak season demand affecting supplier capacity and resource allocation

- Weather conditions impacting curing times and quality control

Rush Order Capabilities

Most experienced suppliers can accommodate expedited timelines when business needs require faster delivery:

- Express processing: 2-3 week expedited timelines available

- Premium pricing: 25-50% additional cost for rush orders

- Limited customization: Reduced options for complex design elements

- Priority scheduling: Dedicated production slots for urgent projects

How Do You Choose the Right Packaging Partner?

Not all packaging manufacturers possess the equipment, expertise, and quality control systems necessary for consistent dual finish production.

Select packaging partners with demonstrated experience in mixed finish techniques, advanced equipment capabilities, comprehensive quality control systems, and clear communication processes for managing complex projects successfully.

Technical Capabilities Assessment

Evaluate potential partners based on specific dual-finish expertise and infrastructure:

| Capability | Questions to Ask | Red Flags |

|---|---|---|

| Equipment | Do you have in-house spot UV capabilities? | Outsourcing critical processes |

| Experience | Can you show samples of similar projects? | Limited dual-finish portfolio |

| Quality Control | What QC measures ensure registration accuracy? | Vague quality procedures |

| Capacity | Can you handle our volume requirements? | Overcommitted production schedules |

Partnership Evaluation Criteria

Key factors for selecting packaging partners who can deliver consistent results:

Essential qualifications:

- End-to-end service capability from design consultation to delivery

- Industry-specific experience in your product category

- Sustainability credentials and eco-friendly material options

- Geographic proximity to reduce shipping costs and lead times

- Financial stability ensuring long-term partnership reliability

Communication and Support Standards

Look for partners offering comprehensive support throughout the production process:

- Dedicated project management for complex orders and timeline coordination

- Technical consultation on material selection and process optimization

- Prototype development capabilities for testing and approval processes

- Regular progress updates with transparent communication protocols

When evaluating packaging partners, consider Acreet’s extensive experience in advanced finishing techniques. Our state-of-the-art equipment and skilled technicians consistently deliver the precise registration and quality control required for successful dual finish pouches. We offer comprehensive technical consultation, prototype development, and dedicated project management to ensure your mixed finish packaging meets the highest standards.

What Quality Control Measures Ensure Consistent Results?

Maintaining consistent quality across production runs requires systematic monitoring of multiple variables affecting both matte and gloss finish applications.

Effective quality control for dual finish pouches involves automated inspection systems using cameras and sensors, in-process monitoring of registration accuracy, coating consistency testing, and comprehensive final inspection protocols that verify both visual appearance and tactile properties.

Pre-Production Standards and Setup

Before full production begins, establish clear quality benchmarks through comprehensive sampling and testing:

Critical preparation steps:

- Color accuracy verification under different lighting conditions and retail environments

- Finish contrast evaluation for optimal visual impact and brand alignment

- Registration precision measurement within ±0.5mm tolerance standards

- Durability testing for both finish types under normal handling conditions

In-Process Monitoring Systems

Continuous quality oversight during production prevents costly errors and ensures consistency:

Real-time monitoring includes:

- Registration alignment checked every 1,000 units with automated systems

- Coating thickness measured for consistency using precision instruments

- Gloss level testing to ensure consistent sheen across production runs

- Color matching confirmed against approved samples throughout production

Comprehensive Final Inspection Protocols

Multi-stage final quality checks ensure your pouches meet specifications before shipping:

| Inspection Point | Standard | Acceptance Criteria |

|---|---|---|

| Registration Accuracy | ±0.5mm tolerance | 99%+ within specification |

| Finish Consistency | Visual comparison | No visible variation |

| Color Matching | Spectrophotometer | ΔE ≤ 2.0 |

| Durability | Rub resistance test | No finish degradation |

Statistical Process Control

Leading packaging partners implement systematic quality improvement through data-driven approaches:

- Statistical process control tracking quality metrics and trend analysis

- Customer feedback integration driving continuous process refinements

- Regular equipment calibration maintaining accuracy standards

- Staff training programs ensuring consistent execution and quality awareness

What Are Current Market Trends and Future Outlook?

Understanding market dynamics helps you make strategic decisions about packaging investments and positioning.

The dual finish packaging market continues expanding as brands seek differentiation in competitive retail environments, with sustainability considerations driving innovation in eco-friendly coating materials, while digital printing advances make mixed finishes more accessible for smaller production runs.

Growing Market Demand

Consumer preference for tactile, premium packaging experiences supports continued growth in dual finish applications, particularly as e-commerce brands seek to create memorable unboxing experiences that justify premium pricing and build long-term brand loyalty.

Key growth drivers include:

- Increased competition requiring enhanced shelf differentiation

- Premium positioning trends across multiple product categories

- E-commerce growth demanding memorable unboxing experiences

- Consumer sophistication expecting higher packaging quality standards

Sustainability Innovation

Environmental considerations are driving significant innovation in coating materials and processes:

- Eco-friendly UV coatings reducing environmental impact

- Water-based matte finishes replacing solvent-based alternatives

- Recyclable dual finish materials supporting circular economy goals

- Reduced waste processes improving production efficiency

Technology Advancement

Digital printing and coating technologies continue advancing, making sophisticated finishes more accessible:

- Digital spot UV capabilities for shorter runs and variable designs

- Improved registration accuracy through automated systems

- Faster curing processes reducing production timelines

- Cost reduction trends making premium finishes more accessible

Summary

Combining matte and gloss finishes on the same pouch is not only possible but increasingly popular among brands seeking sophisticated packaging differentiation. Through techniques like spot UV coating, matte over lacquer processes, and selective finishing methods, you can create eye-catching packages that boost consumer engagement by 70% and enhance shelf appeal. While mixed finishes add 15-40% to production costs, the marketing benefits often justify the investment through improved brand recognition, premium pricing opportunities, and enhanced sales performance. Success depends on thoughtful design planning, proper volume considerations, and partnering with experienced manufacturers who possess the advanced equipment and quality control systems necessary for consistent, high-quality results.

Ready to explore how dual finish pouches can transform your brand’s market presence and drive sales growth? Contact Acreet today for a comprehensive consultation on your packaging design needs and receive samples showcasing our advanced dual finish capabilities and precision manufacturing expertise.