Stand-up pouches dominate retail shelves, but many brand owners wonder if they can showcase their products through transparent windows. Customers want to see what they’re buying, especially with food and consumer goods. This creates a challenge: how do you maintain premium packaging while giving buyers that crucial peek inside?

Yes, you can absolutely get transparent windows on stand-up pouches. These clear viewing panels use materials like PE, PP, PVC, or PS films that are laminated into the pouch structure during manufacturing. Windows can be rectangular, oval, circular, or custom shapes, offering full product visibility while maintaining barrier protection and shelf stability.

Read on to discover everything about transparent window options, materials, costs, and how to choose the perfect solution for your brand.

Table of Contents

ToggleWhat Materials Are Used for Transparent Windows in Stand-Up Pouches?

Understanding window materials is crucial for making informed packaging decisions that balance visibility, protection, and cost-effectiveness based on your specific product requirements.

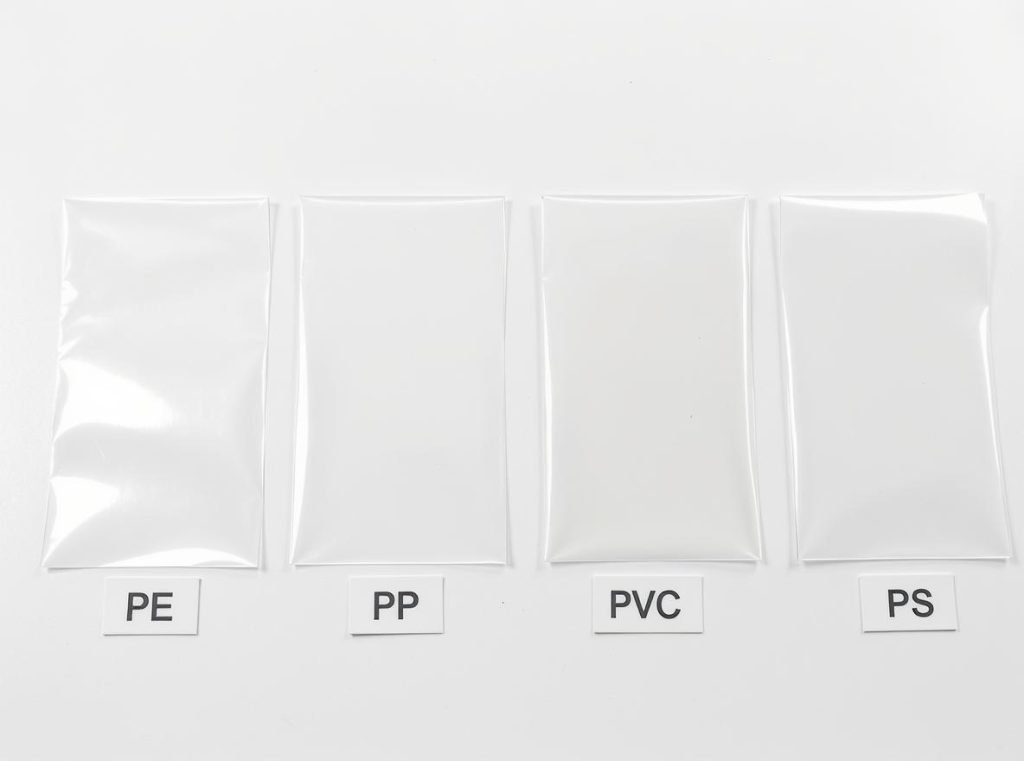

Stand-up pouch windows typically use Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), or Polystyrene (PS) films. PE offers good transparency and recyclability at lower costs, PP provides superior clarity and gloss, PVC delivers excellent clarity but presents recycling challenges, while PS offers crystal-clear viewing with exceptional transparency.

The choice of window material directly impacts your product’s protection and visual appeal. Chemical compatibility between base pouch materials and window films is essential for reliable sealing.

Polyethylene (PE) Windows

Low-density PE offers good transparency with excellent recyclability, making it an economical choice for many applications. PE pairs well with PE-based pouches, ensuring compatible sealing temperatures and maintaining recyclability where programs exist.

Polypropylene (PP) Windows

PP provides higher clarity and gloss compared to PE, offering superior visual appeal for premium products. This material works excellently with PP-based pouches and maintains good barrier properties.

Polyvinyl Chloride (PVC) Windows

PVC delivers excellent clarity with crystal-clear views but presents recycling challenges in many regions. Consider environmental regulations and recycling infrastructure before selecting PVC options.

| Material | Clarity Level | Barrier Properties | Recyclability | Best For |

|---|---|---|---|---|

| PE | Good | Moderate barrier | Excellent | Economy products |

| PP | Very Good | Good barrier | Good | Premium foods |

| PVC | Excellent | High barrier | Limited | Specialty items |

| PS | Crystal Clear | Moderate barrier | Moderate | High-visibility needs |

What Window Shapes and Sizes Are Available for Stand-Up Pouches?

Window design flexibility allows brands to create distinctive packaging that stands out while serving functional purposes and meeting specific product display requirements.

Stand-up pouch windows come in rectangular, oval, circular, and custom cutout shapes. Standard rectangular windows offer maximum visible area, oval windows suit rounded products, circular windows create symmetrical displays, while custom shapes allow unique branding opportunities. Window widths typically range from 2-5 inches with customized dimensions.

Different window shapes serve distinct marketing and functional purposes for various product categories.

Standard Window Options:

- Rectangular: Most visible area for product display

- Oval: Ideal for rounded products and elegant presentation

- Circular: Creates symmetrical, eye-catching displays

- Custom cutouts: Unique branding opportunities matching logo shapes

Size and Placement Considerations:

Window dimensions should align with product profile and storage orientation to maximize visibility. Front panel placement generates maximum point-of-sale impact, while back panel or side panel options suit different display requirements.

Strategic positioning considers shelf angle and display arrangements. Horizontal windows work well for vertically stored pouches, while vertical windows suit horizontal display setups. Windows should typically occupy 20-40% of front panel area to achieve optimal balance between product visibility and branding space.

How Do Transparent Windows Affect Product Protection and Shelf Life?

Balancing visibility with protection requires understanding how windows impact your product’s integrity and longevity under various storage conditions.

Transparent windows can slightly reduce barrier properties compared to fully opaque pouches, but proper material selection and multi-layer constructions maintain excellent product protection. High-quality window films with barrier properties ranging from 70-200 microns provide robust moisture, oxygen, and light protection when properly integrated.

Product protection depends on careful material selection and manufacturing techniques working together effectively.

Barrier Performance Considerations:

Light exposure through windows may affect photosensitive products, but many modern window films include UV-blocking properties to mitigate this concern. Multi-layer barrier films with window integration maintain protection while enabling visibility.

Oxygen and moisture transmission rates may increase slightly in window areas, but proper lamination techniques minimize this impact significantly.

Light-Sensitive Product Solutions:

- UV-blocking window films prevent degradation

- Strategic window placement reduces direct light exposure

- Tinted window options provide partial protection

- Consider product compatibility before window implementation

Shelf Life Optimization Strategies:

- Match barrier requirements to product sensitivity

- Use appropriate film thickness for protection needs

- Ensure complete seal integrity around window edges

- Consider storage conditions in material selection

What Are the Cost Implications of Adding Windows to Stand-Up Pouches?

Understanding pricing factors helps you make informed decisions about incorporating windows into your packaging strategy while managing budget considerations effectively.

Transparent windows typically add 10-30% to standard stand-up pouch costs, depending on window size, material choice, and order quantities. The premium cost is often offset by increased sales appeal and consumer confidence, with minimum order quantities typically starting at 5,000 pieces for windowed pouches.

Several factors influence window pricing structures and long-term value propositions:

Manufacturing Cost Factors:

Additional materials and processing steps increase production costs, but windowed pouches often justify this premium through improved sales performance and consumer trust.

Volume-Based Pricing:

| Order Quantity | Cost Premium | Production Method | Economic Benefit |

|---|---|---|---|

| 500-1,000 | 25-30% | Digital printing | Small batch flexibility |

| 2,500-5,000 | 20-25% | Traditional printing | Better unit economics |

| 5,000+ | 10-20% | Volume production | Optimal cost efficiency |

Long-term ROI Analysis:

Enhanced shelf appeal and consumer confidence through product visibility frequently offset additional packaging costs through improved sales conversion rates and customer satisfaction.

Production Considerations:

Digital printing enables smaller runs at higher per-unit costs, while traditional printing offers better economics for larger volumes, allowing brands to match production methods to market testing or full-scale launch requirements.

Which Industries Benefit Most from Windowed Stand-Up Pouches?

Different sectors leverage transparent windows for specific advantages that drive purchasing decisions, build consumer trust, and enhance brand recognition across retail environments.

Food and beverage, personal care and cosmetics, pharmaceutical and healthcare, and pet food industries benefit most from windowed pouches. These sectors rely on visual product assessment for quality perception, freshness evaluation, and purchase confidence, making transparency a crucial sales driver and trust-building element.

Let’s examine how various industries utilize window technology strategically:

Food and Beverage Applications:

- Coffee and tea products showcase bean quality and freshness

- Snacks and dried fruits display color and texture

- Nuts and confectionery reveal premium appearance

- Powdered beverages demonstrate consistency and quality

Personal Care and Cosmetics:

- Skincare products and facial masks show texture and color

- Beauty treatments highlight premium ingredients

- Bath and body products display appealing visual characteristics

- Scrubs and treatments demonstrate quality and consistency

Pharmaceutical and Healthcare Uses:

- Vitamins and supplements build trust through visibility

- Powdered medications ensure accuracy and quality

- Medical devices provide verification of contents

- Health products demonstrate professional packaging standards

Pet Food Industry Benefits:

Pet owners particularly value seeing treats and specialty foods before purchase, building confidence in product quality and freshness for their pets’ health and satisfaction.

How Do You Design Effective Window Placement for Maximum Impact?

Strategic window positioning maximizes both product visibility and brand messaging effectiveness across different retail environments and consumer shopping patterns.

Effective window placement considers product characteristics, branding requirements, and retail display conditions. Front panel positioning generates maximum point-of-sale impact, while window size should balance product visibility with adequate print space for branding, typically occupying 20-40% of the panel area for optimal consumer psychology impact.

Design considerations extend beyond simple placement decisions to encompass comprehensive consumer experience optimization:

Visibility Optimization Strategies:

Position windows to align with product storage orientation and retail display arrangements. Consider shelf positioning when determining window height and placement for maximum consumer engagement.

Product-Specific Design Guidelines:

- Round products: Oval or circular windows enhance visual appeal

- Granular items: Rectangular windows maximize visible area

- Layered products: Strategic placement highlights key features

- Premium items: Smaller, elegant windows suggest exclusivity

Retail Environment Factors:

Eye-level shelf products can use smaller windows effectively, while lower shelf items benefit from larger visibility areas to attract attention. Consider typical shopping patterns and store lighting conditions.

Brand Integration Balance:

Maintain adequate print space for essential branding elements while maximizing product visibility impact. Strategic window framing with brand colors creates cohesive visual presentation that reinforces brand identity.

What Quality Control Measures Ensure Window Integrity?

Maintaining consistent window performance requires comprehensive quality systems throughout manufacturing and distribution to prevent defects that compromise product protection.

Quality control for windowed pouches includes seal integrity testing through bubble emission and vacuum decay methods, visual inspection under fluorescent lighting, mechanical burst testing, and peel testing. Critical leak detection focuses on defects larger than 15 micrometers, which cause sterility breaches in flexible pouches.

Comprehensive quality control encompasses multiple testing protocols and inspection standards:

Seal Integrity Testing Methods:

- Bubble emission testing submerges pouches in water under vacuum conditions

- Vacuum decay testing monitors pressure changes in sealed chambers

- Dye penetration testing uses colored solutions for visual defect identification

- Critical leak threshold maintains 15-micrometer detection standards

Visual Inspection Standards:

Regular examination under fluorescent lamp conditions detects scratches, pinholes, contamination at sealing areas, and proper window alignment according to industry quality standards.

Mechanical Performance Testing:

| Test Type | Purpose | Acceptance Criteria | Frequency |

|---|---|---|---|

| Burst Testing | Seal strength verification | Meets force specifications | Per production batch |

| Peel Testing | Window adhesion measurement | Adequate handling strength | Random sampling |

| Visual Inspection | Surface defect detection | Zero visible defects | Continuous monitoring |

In-Line Quality Monitoring:

Modern production systems incorporate automated inspection technology that detects window defects in real-time, reducing waste and ensuring consistent delivery quality throughout production runs.

How Do Environmental Factors Affect Windowed Pouch Performance?

Understanding environmental impacts helps brands make informed decisions about window materials and design specifications for different market conditions and storage requirements.

Environmental factors including temperature fluctuations, humidity levels around 70%, UV exposure, and transportation stress significantly impact window performance. Proper storage conditions and material selection ensure windows maintain clarity, adhesion, and barrier properties throughout the product lifecycle and distribution chain.

Multiple environmental variables influence window durability, appearance, and functional performance:

Temperature and Humidity Management:

Environmental temperature and humidity create thermal gradients that affect seal integrity and material performance. Extreme conditions require careful material selection for target market environments.

Light Exposure Considerations:

Extended UV exposure degrades window materials and products over time. UV-blocking films maintain clarity and prevent yellowing during extended retail display periods while protecting light-sensitive contents.

Storage and Transportation Factors:

Controlled humidity around 70% and appropriate temperature conditions extend pouch life and maintain window clarity. This becomes particularly important for products requiring extended shelf life or international distribution.

Mechanical Stress Management:

Pouches must withstand handling, stacking, and transportation pressures throughout the supply chain. Window placement and seal design should account for these mechanical stresses to prevent failure during distribution.

What Customization Options Are Available for Window Features?

Advanced customization capabilities allow brands to create distinctive packaging that reinforces brand identity while maintaining functional excellence and meeting specific market requirements.

Window customization includes side gussets with windowed panels, multiple window configurations, combination clear and tinted areas, custom die-cut shapes, resealable zippers, tear notches, hang holes, and various printing options including flexographic, rotogravure, and digital methods with sustainable material alternatives.

Customization possibilities extend across functional, aesthetic, and environmental considerations:

Advanced Window Features:

- Side gusset panels with integrated windows for 360-degree visibility

- Multiple window configurations for complex product displays

- Combination clear and tinted window areas for selective visibility

- Custom die-cut shapes matching brand logos or product contours

Functional Enhancement Options:

- Resealable zippers maintaining product freshness after opening

- Easy-open tear notches improving consumer convenience

- Hang holes enabling versatile retail display options

- Spouts and fitments for liquid product applications

Printing and Finishing Capabilities:

| Method | Color Range | Volume Suitability | Quality Level |

|---|---|---|---|

| Flexographic | Up to 8 colors | High volume | Good |

| Rotogravure | Complex designs | Large runs | Exceptional |

| Digital | Full spectrum | Small batches | Excellent |

Sustainable Customization Options:

Mono-material constructions for improved recyclability, biodegradable window films for environmental responsibility, post-consumer recycled content materials, and compostable alternatives support environmentally conscious brand positioning while maintaining performance standards.

Summary

Transparent windows on stand-up pouches offer excellent opportunities to showcase products while maintaining protection and shelf appeal. PE, PP, PVC, and PS materials provide various clarity and barrier options suited to different products and budgets. While adding 10-30% to packaging costs, windows often boost sales through improved consumer confidence and product visibility. Food and beverage, personal care, pharmaceutical, and pet food industries benefit most from windowed packaging solutions that build trust and drive purchase decisions.

Ready to enhance your packaging with transparent windows? Contact Acreet today for custom windowed stand-up pouch solutions that showcase your products while maintaining premium protection, optimal barrier properties, and outstanding shelf appeal for your global market success.