Your packaging faces constant challenges during shipping and storage. Moisture, handling damage, and wear can compromise your product presentation and protection. You’re considering laminating your paperboard packaging, but you need to know if this investment will deliver the performance improvements your business requires.

Yes, you can laminate paperboard to significantly enhance its durability and water resistance. However, lamination makes paperboard water-resistant, not waterproof. The process applies thin plastic films or protective coatings to create composite materials with superior performance characteristics, but complete waterproofing requires alternative solutions.

Understanding the complete picture of lamination benefits, limitations, and costs will help you make the right packaging decision for your business.

Table of Contents

ToggleWhat Exactly Is Paperboard Lamination?

Paperboard lamination represents a sophisticated converting process that permanently bonds protective layers to your packaging substrate.

Paperboard lamination is a sophisticated converting process that permanently bonds thin films, coatings, or protective layers to paperboard substrates using heat, pressure, and specialized adhesives to create composite materials with enhanced visual, protective, and functional properties.

The lamination process combines the structural integrity of paperboard with the barrier properties of various coating materials. This transformation creates packaging materials that outperform standard paperboard in multiple performance categories.

Four primary lamination methods serve different packaging applications:

Dry Lamination

This method uses heat and pressure to bond layers using pre-applied adhesive. A thermally activated adhesive is applied to one layer, then materials pass through heated rollers to create permanent bonds. This process offers excellent clarity and bond strength.

Wet Lamination

Liquid adhesive is applied to one layer before pressing materials together under pressure. This method works well for paper-to-paper or paper-to-film applications where immediate bonding is required.

Extrusion Lamination

Molten polymer is extruded between substrates, then cooled to form strong bonds. This method is widely used in flexible packaging applications requiring maximum durability.

Solventless Lamination

This environmentally-friendly process applies adhesive without solvents, providing high bond strength while reducing environmental impact and processing costs.

Does Lamination Make Paperboard Truly Waterproof?

This critical distinction affects your material selection and performance expectations for packaging applications.

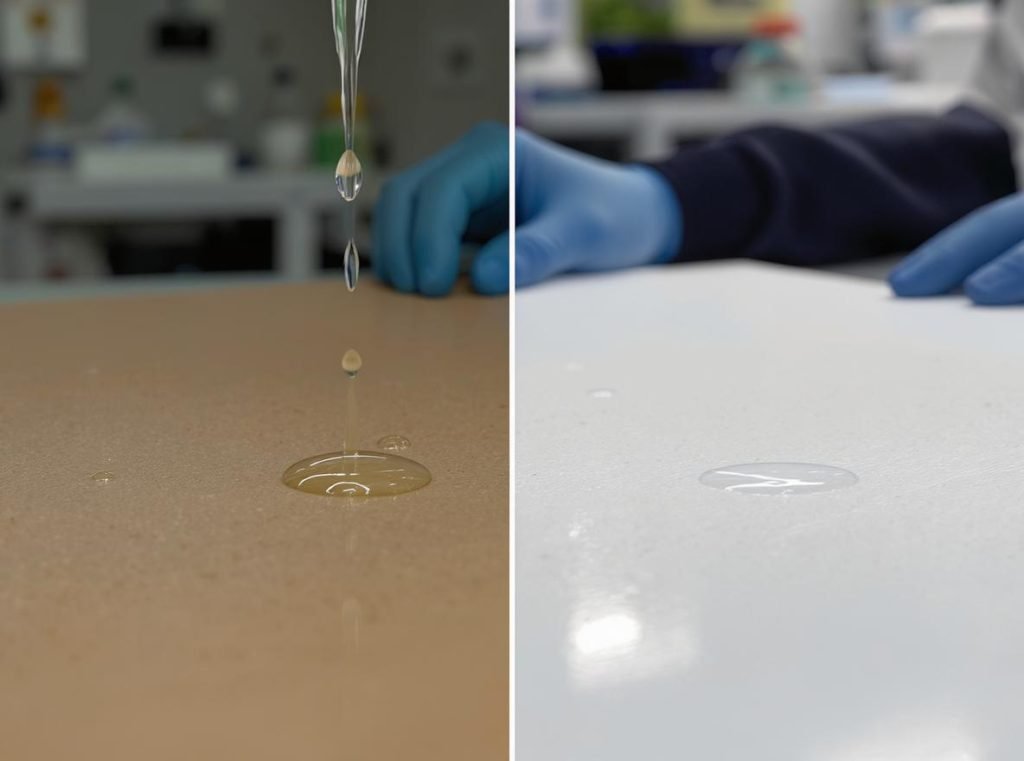

No, lamination makes paperboard water-resistant, not waterproof. The thin plastic layer creates a barrier that helps paperboard handle small amounts of moisture and brief water exposure, but laminated paperboard should not be submerged and will eventually fail under prolonged moisture conditions.

The water-resistant properties are only “skin deep.” Once the laminate film is disturbed, damaged, or removed, the underlying paperboard becomes susceptible to water damage immediately.

Performance Limitations:

- Laminated paper can be damaged by writing or scraping when wet

- The protective film can be compromised during handling

- Frequent creasing or complete submersion causes failure

- Protective coating may peel over time, reducing effectiveness

Realistic Expectations:

Your laminated paperboard packaging will handle normal shipping and storage conditions including warehouse humidity fluctuations, light rain during transport, condensation in shipping containers, and accidental spills during handling.

However, if your products require complete waterproof protection for applications like outdoor storage or marine environments, you’ll need fully synthetic materials or specialized waterproof paper alternatives.

What Types of Lamination Work Best for Packaging?

Different lamination types serve specific packaging requirements based on performance, aesthetics, and application demands.

The most effective lamination types for packaging include gloss, matte, and soft touch finishes, plus specialized barrier coatings, each offering distinct advantages for different market segments and product requirements.

| Lamination Type | Best Applications | Key Benefits | Typical Cost Impact |

|---|---|---|---|

| Gloss | Consumer products, promotional materials | High visual impact, color enhancement | +15-25% |

| Matte | Luxury goods, professional packaging | Sophisticated appearance, reduced glare | +20-30% |

| Soft Touch | Premium packaging, cosmetics | Luxurious feel, premium positioning | +25-40% |

| Barrier Coatings | Food packaging, sensitive products | Functional protection, extended shelf life | +10-20% |

Gloss Lamination

Offers a clear, lustrous finish that enhances packaging appearance and intensifies colors. This type provides good protection while creating an eye-catching, professional look ideal for consumer products competing for shelf attention.

Matte Lamination

Provides a sophisticated, minimalist appearance with reduced glare and softer feel. Often chosen for luxury products, matte lamination offers excellent readability and elegant presentation that communicates premium quality.

Soft Touch Lamination

Creates a luxurious, velvety feel while maintaining visual appeal. This premium option satisfies both sight and touch senses, making it ideal for high-end packaging applications where tactile experience matters.

Barrier Coatings

For food packaging applications, specialized barrier coatings provide critical properties including humidity control, sealing properties, airtightness, light protection, oxygen permeability, and grease-proofing capabilities.

How Much Does Lamination Actually Improve Durability?

Quantifying durability improvements helps justify the investment and processing costs for your packaging projects.

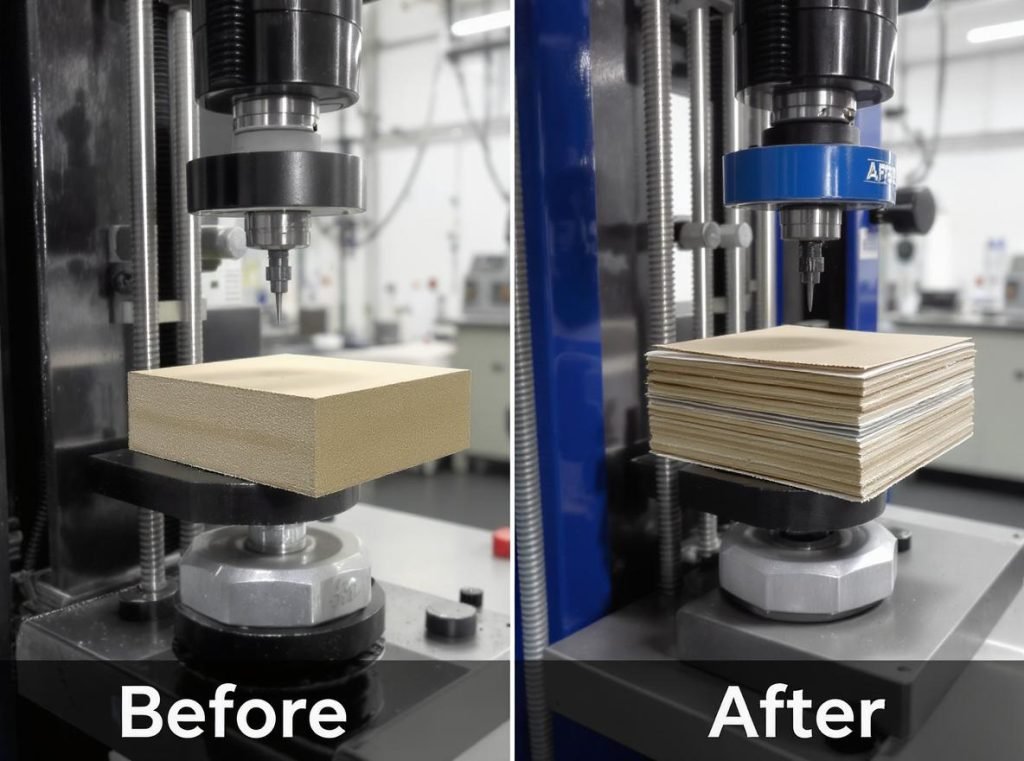

Laminated paperboard demonstrates increased thickness, rigidity, and resistance to bending and creasing. Heat and water-resistant laminates can last 10-20 years depending on location, material quality, and maintenance practices, representing significant improvement over uncoated paperboard.

Structural Improvements:

The additional layers distribute physical stresses more effectively, making each section more resistant to tearing, warping, and general wear and tear. Your packaging maintains structural integrity under normal handling conditions.

Environmental Protection:

Lamination provides enhanced resistance to moisture, grease, chemicals, and general handling damage. The protective layer acts as a barrier against dirt, fingerprints, and various contaminants that could otherwise damage or stain paperboard.

Measurable Performance Gains:

- Enhanced tear resistance during shipping and handling

- Improved moisture protection in humid storage conditions

- Extended graphic quality retention with reduced fading

- Better surface protection against scratches and scuffs

However, it’s important to understand that while laminated paperboard offers improved durability over uncoated materials, waterproof paper alternatives often provide superior long-term durability without the environmental and recycling challenges associated with plastic lamination.

When Should You Choose Laminated Paperboard Over Alternatives?

Strategic material selection depends on balancing performance requirements, environmental considerations, and cost-benefit analysis.

Choose laminated paperboard for high-end packaging where visual appeal is crucial, food packaging requiring moderate moisture protection, short to medium-term applications where recyclability isn’t the primary concern, and premium retail packaging where enhanced appearance justifies additional cost.

Ideal Applications:

- Consumer electronics packaging requiring attractive presentation

- Cosmetics and personal care products emphasizing premium feel

- Food packaging with moderate moisture exposure

- Promotional materials needing durability and visual impact

- Retail packaging competing for shelf attention

Consider Alternatives When:

- Complete waterproofing is required for outdoor applications

- Environmental sustainability is a primary concern

- Long-term outdoor exposure is expected

- Cost sensitivity is high and basic protection suffices

Environmental Reality Check:

Laminated paperboard cannot be effectively recycled because the plastic film must be separated from paper before recycling, which is not feasible in standard recycling processes. Paper mills can handle a maximum of 1.5% non-paper components in recycling streams.

For environmentally conscious brands, water-based coatings and biopolymer solutions offer more sustainable lamination options using renewable materials and generating only steam as byproducts.

What Are the Cost Implications of Laminating Paperboard?

Understanding the complete cost structure helps you make informed purchasing and budgeting decisions.

Paper typically accounts for 60-70% of final lamination costs, ranging from $40 to $150 per 100 pounds depending on grade and quality. Adhesives and laminating machine time account for the remaining 30-40% of project costs.

Processing Costs Breakdown:

Professional lamination services charge $1.00-$3.00 per sheet depending on size and thickness. For example, A4 sheets cost approximately $0.40-$2.00, while A3 sheets range from $0.70-$2.50.

Volume Economics:

Bulk processing offers cost advantages, but minimum quantities and setup costs must be considered. Commercial lamination often requires 24-hour turnaround times and may cost $115-$150 for substantial quantities.

Hidden Cost Factors:

- Cutting and finishing services

- Waste from setup and quality control testing

- Storage and handling requirements for laminated materials

- Potential replacement costs due to peeling or damage over time

- Environmental disposal costs for non-recyclable materials

Long-term Value Analysis:

While lamination adds 15-30% to paperboard costs initially, waterproof paper alternatives often prove more cost-effective long-term, eliminating lamination processing costs while providing superior durability and environmental benefits.

How Does Lamination Affect Environmental Considerations?

Environmental impact significantly influences packaging decisions in today’s sustainability-focused market.

Laminated paperboard creates substantial sustainability challenges because it cannot be recycled through standard processes. Paper recycling uses water-based systems while plastic recycling requires heat-based processes, making material separation impossible in conventional facilities.

Critical Environmental Issues:

Non-recyclable laminated paperboard contributes to landfill pollution, with plastic components being non-biodegradable. When burned, laminated materials release toxic fumes, and rainfall can cause toxic erosion into the environment.

Industry Guidelines:

Industry guidelines recommend restricting plastic content to 5% of pack weight for single-sided laminates to maintain recyclability. However, most laminated paperboard exceeds this threshold.

Sustainable Alternative Rankings:

| Solution | Environmental Impact | Recyclability | Long-term Sustainability |

|---|---|---|---|

| Uncoated Paperboard | Excellent | Excellent | Highest |

| Water-based Coatings | Good | Good | High |

| Biopolymer Lamination | Good | Good | High |

| Plastic Lamination | Poor | Poor | Lowest |

Sustainable Solutions:

Water-based coatings and biopolymer solutions offer environmentally friendly lamination options. These alternatives use renewable materials and water-based coatings that generate only steam as byproducts, maintaining reasonable performance while supporting sustainability goals.

What Quality Standards Should You Expect?

Quality standards vary by application, with food contact materials requiring the most stringent compliance requirements.

High-quality laminated paperboard should demonstrate uniform formation, thickness consistency, freedom from visible defects, consistent adhesive application within ±5% variation, and compliance with relevant food safety regulations where applicable.

Food Contact Requirements:

Objects intended for food contact are governed by EC Regulation 1935/2004. Materials must be free from harmful transfers and comply with composition and purity requirements including PCB limits and absence of contaminants.

Manufacturing Standards:

Good Manufacturing Practices (GMP) are mandatory to ensure constituents are not transferred to food and do not endanger human health. This includes controlling permissible raw materials, process control, and chemical testing requirements.

Critical Quality Parameters:

- Uniform formation, thickness, and substance consistency

- Freedom from visible specks, grease marks, cuts, and pinholes

- Temperature control within ±2°C during processing

- Pressure variations maintained within ±3%

- Thickness ranges from 1.5 mil to 10 mil (0.0015″ to 0.010″)

Industry Certifications:

NABL accredited laboratory certification is required for packaging materials in direct food contact. BRC standards ensure food safety compliance for laminated cardboard products used in food applications.

Comprehensive testing includes chemical contamination assessment, heavy metals analysis, microbiological contamination checks, and physical/mechanical property verification to ensure consumer safety.

Summary

Laminating paperboard significantly improves durability and water resistance, making it valuable for many packaging applications. While not waterproof, laminated paperboard offers cost-effective protection that extends product lifespan and maintains attractive appearance. However, environmental challenges and recycling limitations require careful consideration when selecting materials for sustainability-conscious brands.

Ready to explore the best packaging solution for your specific requirements? Contact Acreet today for expert guidance on laminated paperboard options, sustainable alternatives, and custom packaging solutions. Our experienced team can help you balance performance, cost, and environmental goals to create packaging that protects your products while supporting your brand values and business objectives.