Shipping fragile items can feel like playing Russian roulette with your valuable products. One wrong move during transit, and your carefully crafted items arrive as expensive jigsaw puzzles. The solution lies in combining rigid boxes with foam inserts.

Yes, foam inserts work exceptionally well with rigid boxes for fragile items. This combination provides dual benefits: superior cushioning protection that safeguards items from damage during shipping, while enhancing visual appeal and professional presentation. Rigid setup boxes with foam inserts create a secure environment where products cannot shift within the box – often the main cause of products being scuffed, chipped, or cracked during transport.

Let’s explore everything you need to know about maximizing protection for your fragile items through this powerful packaging combination.

Table of Contents

ToggleWhat Types of Foam Inserts Work Best with Rigid Boxes?

Understanding your foam options helps you make the right choice for your specific fragile items. Different foam materials offer varying levels of protection, cost-effectiveness, and presentation quality.

The four most effective foam types for rigid boxes are Polyurethane (PU) foam for lightweight fragile objects like jewelry and electronics, Polyethylene (PE) foam for mid-weight to heavy objects such as computers and industrial parts, Cross-linked Polyethylene (XLPE) foam for high-end valuable products requiring superior shock absorption, and Expanded Polystyrene (EPS) foam for excellent cost performance in blocking and bracing applications.

Polyurethane (PU) Foam: The Gentle Protector

Polyurethane foam stands as the ideal choice for lightweight and fragile objects, offering the same soft, open-cell structure found in sofa cushions and mattresses. This makes it particularly suitable for delicate items requiring gentle handling.

Key advantages include:

- Perfect for jewelry, electronics, and glass products

- Excellent cushioning without excessive pressure

- Superior conformability around irregular shapes

- Premium feel that enhances unboxing experience

Polyethylene (PE) Foam: The Versatile Workhorse

PE foam provides excellent protection for mid-weight to heavy objects through its durable, closed-cell structure. This foam type offers exceptional cost performance while delivering reliable protection.

Benefits of PE foam:

- Ideal for computers, televisions, and industrial parts

- Very durable with excellent longevity

- Good cost-to-performance ratio

- Suitable for frequent handling and reuse

Cross-linked Polyethylene (XLPE) Foam: The Premium Option

XLPE foam offers superior shock and water absorption compared to standard PE foam, making it the top choice for protecting high-end and valuable products.

Applications include:

- Military equipment and precision instruments

- Pharmaceutical products requiring sterile protection

- High-value electronics and medical devices

- Products requiring long-term storage protection

| Foam Type | Best Use Case | Protection Level | Cost | Durability |

|---|---|---|---|---|

| Polyurethane (PU) | Jewelry, electronics | High | Medium | Excellent |

| Polyethylene (PE) | Industrial parts, TVs | Very High | Low-Medium | Very High |

| XLPE Foam | Military, medical | Exceptional | High | Premium |

| EPS Foam | General blocking/bracing | Medium | Low | Good |

How Do You Design Custom Foam Inserts for Maximum Protection?

Creating effective foam inserts requires understanding your product’s vulnerabilities and designing protection accordingly. Proper design can mean the difference between safe delivery and costly damage claims.

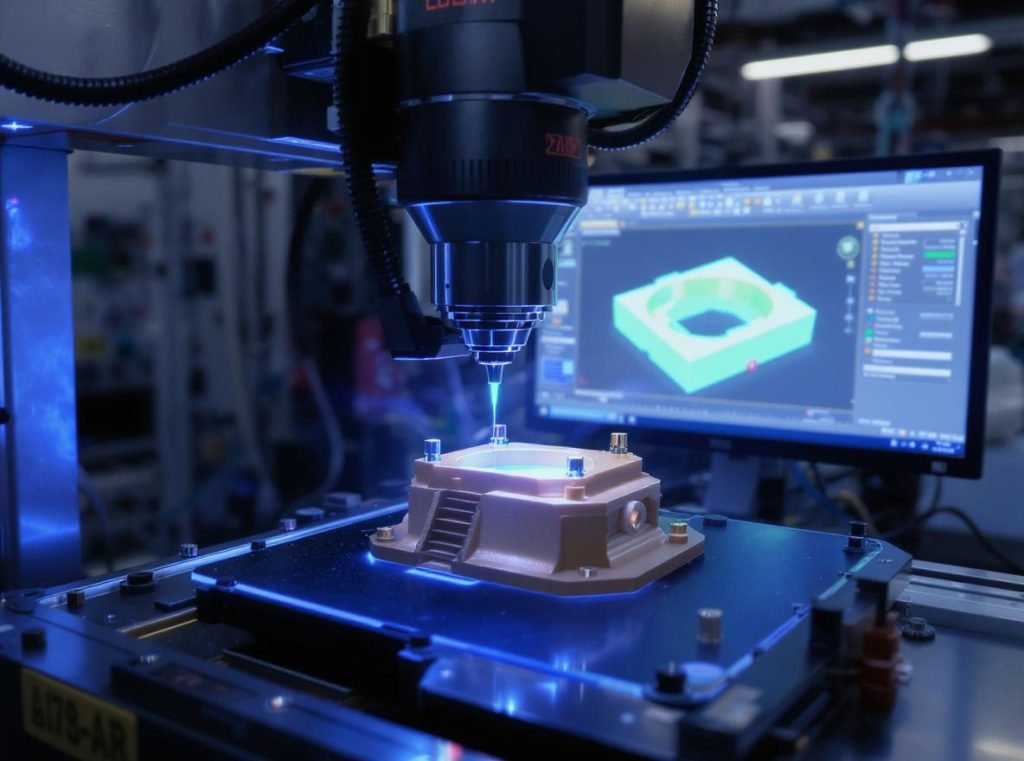

Custom foam insert design utilizes advanced 3D scanning technology and industry-leading CAD software like SolidWorks and AutoCAD, achieving accuracy up to 0.05mm. The process begins with analyzing product weight, fragility, and vulnerability points, then creates precision-cut cavities that eliminate movement while providing optimal cushioning. CNC routers produce the final inserts with exact specifications for perfect fit.

Advanced Design and Manufacturing Process

Modern foam insert creation employs sophisticated technology for maximum precision and protection effectiveness.

3D Scanning and CAD Integration: Advanced 3D scanning technology captures exact product dimensions with accuracy up to 0.05mm. Industry-leading CAD software such as SolidWorks and AutoCAD creates detailed 3D models for customer approval before production.

CNC Precision Manufacturing: Once designs are confirmed, CNC routers accurately produce foam inserts following exact specifications. The precision cutting process utilizes advanced cutting, molding, and adhesive technologies for consistent quality.

Quality Control Standards: Comprehensive testing includes fit testing with actual products, drop and impact testing to verify protection levels, and surface inspection to ensure products meet approved design standards.

Critical Design Considerations

When designing your foam inserts, consider these essential factors:

- Compression Ratio: Foam should compress 15-20% when the product is inserted

- Corner Radius: Round all foam corners to prevent stress concentration

- Ventilation Channels: Include small air gaps for products sensitive to moisture

- Access Points: Design easy removal without damaging the product

Which Industries Benefit Most from Foam Insert Rigid Box Combinations?

Different industries have varying fragile item protection needs, making foam insert rigid box combinations particularly valuable for specific sectors. Understanding industry requirements helps you choose the right protection level.

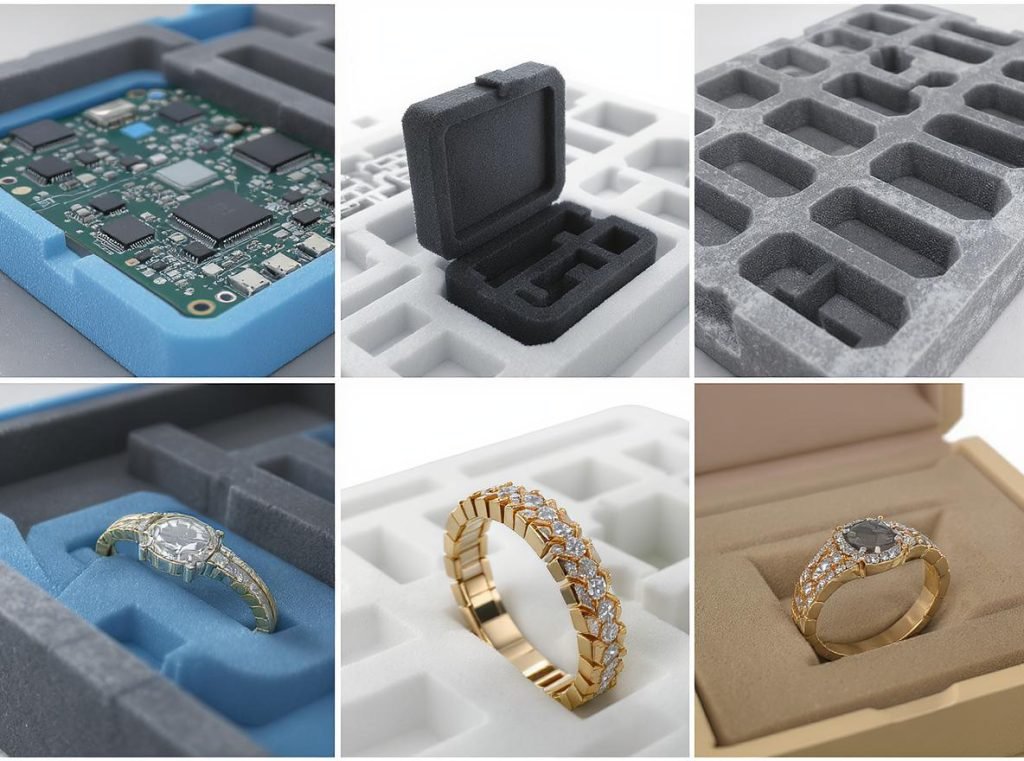

Electronics, automotive, medical device, and luxury goods industries benefit most from foam insert rigid box combinations. The electronics industry uses specialized anti-static foam inserts (typically dyed pink) for ESD protection, while the automotive sector relies on foam for vibration dampening and impact protection. Medical packaging requires foam inserts meeting stringent safety standards, and luxury goods utilize this combination for both protection and enhanced unboxing experiences.

Electronics and Anti-Static Protection

The electronics industry heavily relies on specialized foam inserts for protecting sensitive components from both physical damage and electrostatic discharge.

Anti-static protection requirements:

- ESD (Electrostatic Discharge) foams typically dyed pink to signify anti-static properties

- Protection for computer chips, circuit boards, and sensitive electronics

- Static damage prevention during transportation and storage

- Custom compartments for cables, batteries, and electronic accessories

Automotive Industry Applications

The automotive sector uses foam inserts extensively across multiple applications, from component protection to noise reduction systems.

Automotive foam applications include:

| Application | Foam Benefit | Industry Impact |

|---|---|---|

| Vibration Dampening | Reduces mechanical stress | Improved component longevity |

| Noise Reduction | Sound absorption | Enhanced user experience |

| Impact Protection | Shock absorption | Safety compliance |

| Parts Packaging | Secure transport | Reduced damage claims |

Jewelry and Luxury Goods

Foam inserts enhance gift packaging, making them ideal for jewelry and gifts with customizable, protective, and premium quality features.

Luxury item considerations include:

| Requirement | Foam Solution | Brand Benefit |

|---|---|---|

| Presentation | Velvet-topped foam | Premium unboxing experience |

| Security | Tight-fitting cavities | Prevents theft during shipping |

| Reusability | Durable foam materials | Customer retention value |

| Customization | Logo embossing capability | Brand reinforcement |

Medical Device Protection

Medical equipment requires FDA-compliant materials and sterile packaging environments. Foam inserts provide necessary protection while meeting regulatory requirements.

What Are the Cost Considerations for Foam Insert Packaging?

Budget planning for foam insert packaging involves multiple factors beyond initial material costs. Understanding the total cost picture helps you make informed decisions for your fragile item protection strategy.

Foam insert costs are calculated using a board foot pricing model: thickness × width × length (in inches) ÷ 144 = board feet. Custom design typically costs $45-$95 setup fee plus design work around $95. While initial costs are higher than standard packaging, the foam packaging inserts market is projected to reach $551.8 Million in 2025, growing at 3.6% CAGR to $785.9 Million by 2035.

Professional Pricing Structure

Foam insert pricing follows industry-standard calculation methods that ensure transparent and predictable costs.

Board Foot Calculation Method: The standard pricing model uses thickness × width × length (in inches) divided by 144 to convert to board feet. Total cost equals board feet multiplied by price per board foot, which varies by foam type and density.

Setup and Design Investment: Custom foam packaging design requires approximately $45-$95 setup fee plus design costs around $95. This one-time investment ensures optimal protection and eliminates costly revisions during production.

Volume Scaling Benefits: Higher quantities significantly reduce per-unit costs through economies of scale and reduced setup cost distribution across larger orders.

Return on Investment Calculations

Consider these financial benefits when evaluating foam insert investments:

Damage reduction typically saves 5-15% of product value per shipment. For a $100 fragile item, proper foam protection costing $8 prevents potential $100 losses.

Market Growth and Industry Outlook

The foam packaging industry shows strong growth potential driven by e-commerce expansion and increased demand for protective packaging.

Market Projections: The foam packaging inserts market is estimated to reach $551.8 Million in 2025, growing at 3.6% CAGR to reach $785.9 Million by 2035.

Long-term economic benefits justify initial investment through:

- Reduced product damage during shipping and handling

- Lower replacement costs for damaged goods

- Increased operational efficiency through faster packing times

- Extended product lifecycle through superior protection

How Do You Choose the Right Foam Density for Different Fragile Items?

Foam density selection directly impacts protection effectiveness and cost efficiency. Choosing inappropriate density can result in either inadequate protection or unnecessary expenses.

Foam density selection follows industry-standard measurements in pounds per cubic foot (PCF). Fair Quality (0.8-1.5 PCF) suits light applications, Medium Quality (1.5-2.5 PCF) provides balanced durability for everyday use, and High Quality (2.5+ PCF) offers premium protection. Product fragility is measured in G-limits: extremely fragile items (15-25 G’s) need specialized high-density foams, while delicate products (40-60 G’s) require standard protective foam densities.

Industry-Standard Density Classifications

Understanding foam density classifications helps ensure optimal protection for different product categories.

Fair Quality (0.8-1.5 PCF): Suitable for light applications and specialty uses, though less durable under frequent handling. Best for decorative items and lightweight products requiring minimal protection.

Medium Quality (1.5-2.5 PCF): Provides balanced durability and cost-effectiveness for everyday applications. Ideal for standard consumer electronics, household items, and moderate-weight products.

High Quality (2.5+ PCF): Premium materials offering exceptional durability and resilience for demanding applications. Required for heavy equipment, precision instruments, and high-value items.

G-Limit Based Protection Standards

Product fragility is scientifically measured using G-limits, which determine the acceleration point at which damage occurs:

Extremely Fragile (15-25 G’s): Special military applications and precision instruments requiring specialized high-density foams with superior shock absorption capabilities.

Very Delicate (25-40 G’s): Mechanically shock-mounted instruments and sensitive electronic equipment needing medium to high-density foam protection.

Delicate (40-60 G’s): Aircraft accessories, computer equipment, and standard electronics requiring protective foam densities within normal ranges.

Testing and Validation Methods

Professional packaging validation ensures your foam selection meets real-world shipping challenges:

- Drop tests from 3-6 feet simulate typical handling scenarios

- Compression tests verify foam maintains protection under stacking loads

- Vibration testing replicates transportation stress

- Temperature cycling confirms foam performance across climate variations

What Customization Options Are Available for Foam Inserts?

Modern foam insert manufacturing offers extensive customization possibilities to meet specific product protection and branding needs. These options allow you to create packaging that protects products while reinforcing your brand identity.

Modern foam insert customization includes multi-layer designs, conductive and antistatic properties, flame-retardant materials, temperature resistance, and color-coding systems. Manufacturing methods include die-cutting for high-volume replication, CNC routing for complex designs, waterjet cutting for precise geometries, and pick-and-pluck foam for user-customizable layouts. Advanced options include integrated overlays with printed labels, QR codes, and branding elements.

Advanced Material Customization Options

Modern foam technology offers extensive customization possibilities for specialized applications and enhanced functionality.

Material enhancement options include:

- Multi-layer foam inserts combining different densities for complex protection needs

- Conductive and antistatic properties for electronic component safety

- Flame-retardant and UV-resistant materials for specialized environments

- Temperature and chemical resistance for harsh operating conditions

- Color, haptic, and optical customization for branding and identification systems

Precision Manufacturing Methods

Various manufacturing techniques provide different customization capabilities and production volumes:

Die-Cutting: High-volume, precise replication using specialized templates for consistent results across large production runs.

CNC Routing: Complex, one-off designs with intricate details and precise dimensional control for custom applications.

Waterjet Cutting: Extremely precise cuts and complex geometries capable of handling the most demanding design requirements.

Pick-and-Pluck Foam: User-customizable layouts allowing end-users to create their own configurations by removing foam sections.

| Customization Type | Applications | Manufacturing Method | Lead Time |

|---|---|---|---|

| Basic cutting | Standard shapes | Die-cutting | 1-2 weeks |

| Multi-layer inserts | Complex protection | CNC routing | 2-3 weeks |

| Antistatic treatment | Electronics | Chemical processing | 2-4 weeks |

| Integrated overlays | Branding/QR codes | Multi-process | 3-5 weeks |

How Do You Integrate Foam Inserts with Different Rigid Box Styles?

Successful integration of foam inserts with rigid boxes requires understanding box construction and insert placement strategies. Proper integration ensures seamless functionality and professional appearance.

Foam insert integration varies by rigid box style: magnetic closure boxes require foam designs that avoid magnetic zones while providing complete protection, shoulder-and-tray boxes accommodate layered protection systems, sleeve boxes enable simple elegant presentation, and die-cut rigid packaging allows specialized shapes. Success requires careful planning of box dimensions, lid clearance, weight distribution, and access methods like finger pulls for easy product removal.

Rigid Box Style Compatibility

Modern rigid boxes offer various closure and presentation styles, each requiring specific foam insert integration approaches.

Magnetic Closure Boxes: The most popular luxury presentation option requires careful consideration of magnetic placement zones. Foam inserts must avoid magnetic areas while providing complete product protection and maintaining smooth closure operation.

Shoulder-and-Tray Boxes: These configurations offer excellent opportunities for layered protection systems with organized product presentation and easy access for both packing and unpacking.

Sleeve Boxes: Simple, elegant presentation style enables straightforward foam integration focused on product protection without complex mechanical considerations.

Die-Cut Rigid Packaging Solutions: Specialized shapes and sizes accommodate unique products requiring custom protection solutions with foam inserts designed to exact specifications.

Professional Installation Techniques

Foam inserts are shipped inside rigid boxes to reduce freight costs, as that’s where they belong, but proper installation ensures optimal performance.

Installation best practices:

- Pre-fit testing before final placement

- Adhesive selection for permanent or removable mounting

- Corner stress relief to prevent foam tearing

- Quality control checks for fit and function

What Environmental Considerations Apply to Foam Insert Packaging?

Environmental responsibility increasingly influences packaging decisions as businesses and consumers prioritize sustainability. Understanding eco-friendly foam options and disposal considerations helps you make responsible choices.

Environmental considerations include material recyclability (polyethylene foam contains minimum 65% recycled content), biodegradable alternatives from plant-based sources, and manufacturers’ waste reduction programs recycling over 1.5 million pounds of scrap foam annually. Modern sustainable foam options offer low VOC emissions, energy-efficient manufacturing, non-toxic composition, and lightweight properties that reduce shipping fuel consumption. However, traditional polystyrene foam should be avoided due to its 500+ year decomposition time.

Advanced Sustainability Solutions

Modern foam manufacturing has made significant environmental improvements while maintaining superior protection capabilities.

Recycled Content Integration: Many polyethylene foam materials now contain a minimum of 65% recycled content, reducing reliance on virgin materials while maintaining durability and protection performance.

Waste Reduction Programs: Leading manufacturers implement comprehensive recycling systems, processing over 1.5 million pounds of scrap foam annually through closed-loop recycling programs where used foam inserts are collected and reprocessed.

100% Recyclable Options: Contemporary foam materials are designed with end-of-life considerations, offering completely recyclable solutions that can be reprocessed into new products without quality degradation.

Environmental Performance Benefits

Sustainable foam packaging provides multiple environmental advantages over traditional alternatives:

- Low VOC Emissions: Improved air quality during production and use through reduced volatile organic compound releases

- Energy-Efficient Manufacturing: Reduced greenhouse gas emissions through optimized production processes

- Non-Toxic Composition: Safe decomposition without harmful chemical releases into the environment

- Lightweight Properties: Reduced shipping fuel consumption and emissions due to lower package weights

Material Selection Guidelines

Recommended Sustainable Options: Choose polyethylene foams with high recycled content, participate in manufacturer take-back programs, and consider biodegradable alternatives for large-volume applications.

Materials to Avoid: Traditional polystyrene foam should be avoided due to its resistance to recycling processes and 500+ year decomposition timeline in landfill environments.

Summary

Foam inserts with rigid boxes provide unparalleled protection for fragile items through the combination of structural stability and cushioned support. Success depends on choosing appropriate foam density, designing custom-fit inserts, and selecting materials that balance protection needs with cost considerations and environmental responsibility. Whether you’re shipping electronics, jewelry, or collectibles, this packaging combination ensures safe delivery while enhancing your brand’s professional image.

Ready to protect your fragile products with custom foam insert solutions? Contact Acreet today for expert packaging design consultation and competitive quotes for your custom rigid box and foam insert combinations. Our experienced team will help you create the perfect protection strategy for your valuable products.

Looking for custom packaging solutions for your fragile items? Acreet specializes in designing and manufacturing custom rigid boxes with precision foam inserts. Contact us today to discuss your specific protection needs and receive a personalized quote for your project.