Why Choose Custom Collapsible Rigid Box Manufacturers in China?

China leads the global packaging industry with advanced manufacturing capabilities and competitive pricing. Our collapsible rigid boxes maintain premium look and feel while significantly reducing shipping and storage costs. Chinese manufacturers offer extensive customization options, quality materials, and efficient production processes that meet international standards for wholesale buyers worldwide.

Understanding Your Custom Collapsible Rigid Box Requirements

We help you identify the perfect packaging solution by understanding your specific business needs and product requirements.

Product Protection Needs:

Determine cushioning requirements, fragility levels, and environmental protection needed for your products during shipping and storage.

Brand Positioning:

Define your target market segment, luxury level expectations, and how packaging reflects your brand values to customers.

Size and Dimensions:

Calculate optimal box dimensions based on product specifications, shipping constraints, and retail display requirements.

Budget Considerations:

Establish cost parameters including unit price targets, minimum order quantities, and total packaging budget allocation.

Timeline Requirements:

Plan production schedules, seasonal demands, inventory cycles, and launch dates for effective project management.

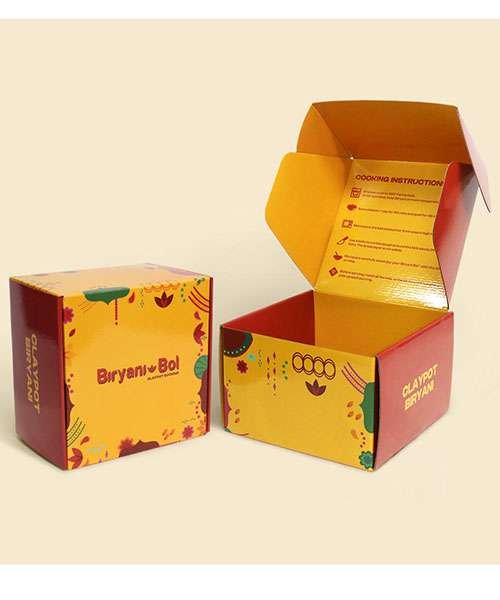

Custom Collapsible Rigid Box Applications Across Industries

These boxes find application in retail, cosmetics, electronics, and other industries due to their flexibility in handling several product types.

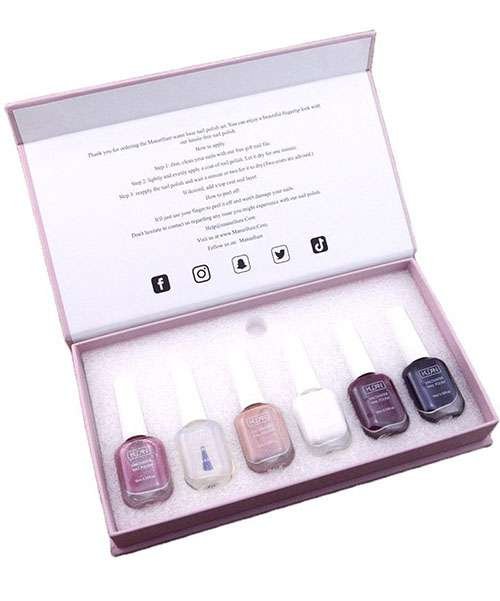

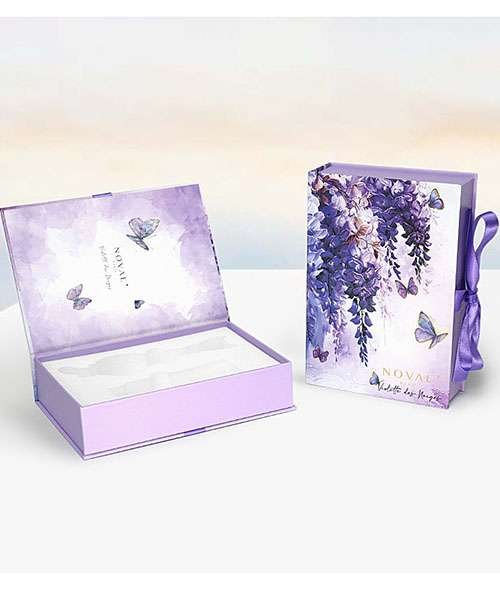

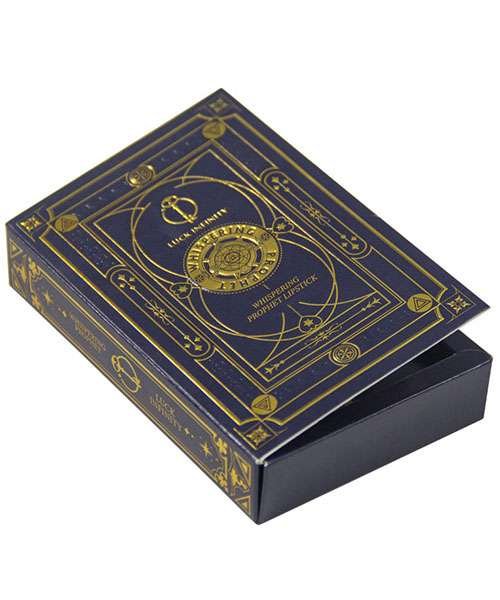

Luxury Cosmetics

Electronics Accessories

Jewelry and Watches

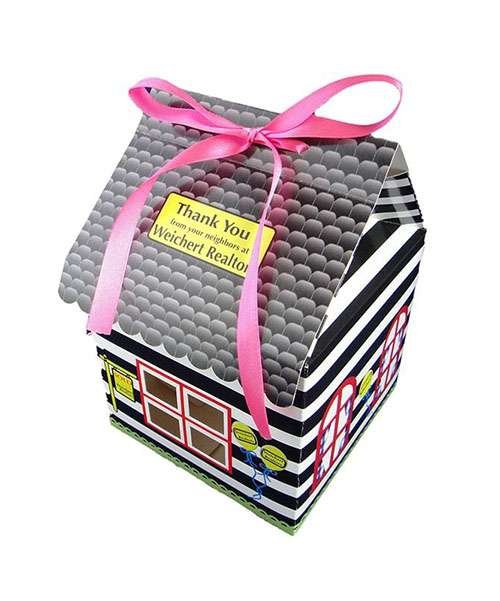

Gift Sets and Hampers

Fashion Accessories

Home Decor Items

Key Benefits of Custom Collapsible Rigid Box Solutions

These boxes fold flat when not in use, allowing companies to save significant storage space and reduce warehouse costs.

Cost-Effective Shipping

Reduced shipping volumes lower logistics costs significantly compared to pre-assembled rigid boxes, improving profit margins.

Space-Saving Storage

Flat-packed design minimizes warehouse requirements, reducing storage costs and improving inventory management efficiency.

Premium Brand Image

Maintains luxury appearance and feel while offering practical benefits, enhancing customer perception and brand value.

Environmental Sustainability

Uses recyclable materials and reduces packaging waste through efficient design and reusable construction.

Easy Assembly

Quick setup process requires no special tools or training, simplifying operations for retailers and end users.

Versatile Applications

Suitable for multiple industries and product types, offering flexible packaging solutions for diverse business needs.

Custom Collapsible Rigid Box Design and Development Process

We follow a systematic approach to create packaging that perfectly matches your brand requirements and functional needs.

Initial Consultation:

Discuss your product specifications, branding requirements, target audience, and budget parameters to establish project scope and objectives.

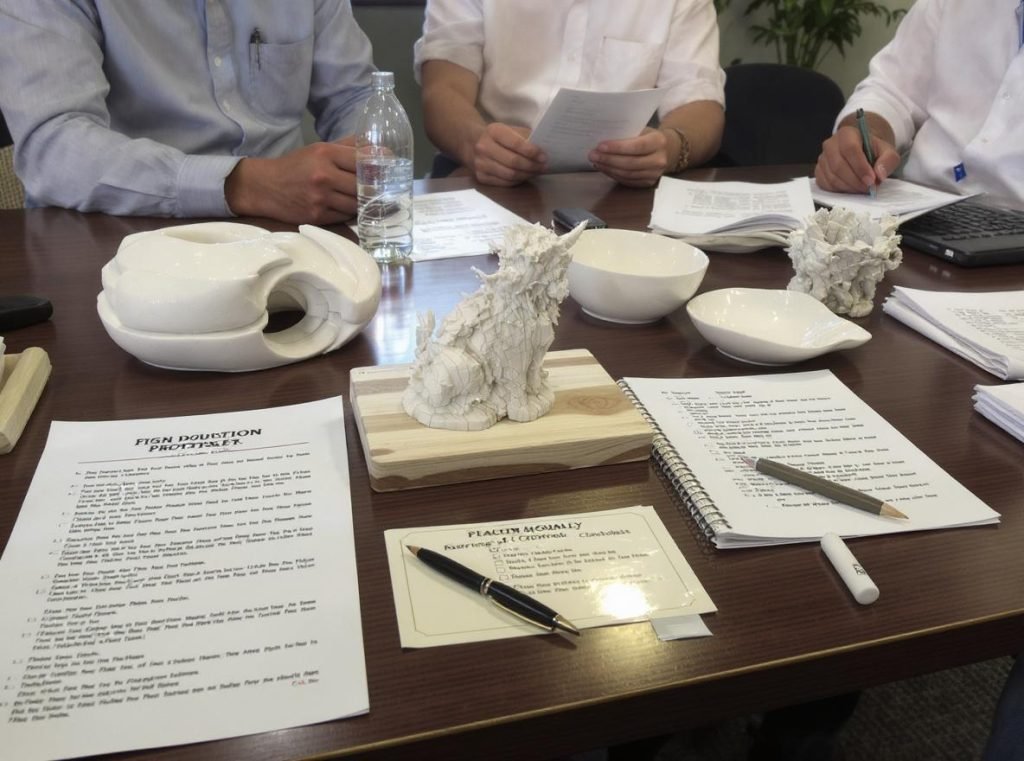

Prototype Development:

Create physical samples with your specifications, allowing hands-on evaluation of materials, construction, and functionality before production.

Design Refinement:

Incorporate your feedback, adjust dimensions, colors, and features to perfect the design and ensure brand consistency.

Production Approval:

Finalize all specifications, approve final samples, and confirm production timeline before manufacturing begins to ensure quality standards.

International Logistics for Custom Collapsible Rigid Box Shipments

Collapsible design significantly reduces shipping volume, directly lowering logistical costs for international buyers.

Shipping Methods

Air freight for urgent orders, sea freight for large volumes, express courier for samples, each optimized for cost and delivery speed.

Packaging Standards

International shipping regulations compliance, protective wrapping methods, and documentation requirements for smooth customs clearance.

Volume Optimization

Flat-packed design maximizes container utilization, reducing per-unit shipping costs and environmental impact significantly.

Insurance Coverage

Comprehensive protection options for high-value shipments, damage claims procedures, and quality guarantee policies.

Customs Documentation

Proper classification codes, value declarations, and certificate requirements for different destination countries and regions.

Tracking Systems

Real-time shipment monitoring, delivery confirmation, and proactive communication throughout the shipping process.

Custom Collapsible Rigid Box Production and Delivery Timeline

We maintain transparent timelines to help you plan inventory and launch schedules effectively.

1.Sample Production

3.Production Setup

5.Quality Inspection

2.Design Approval

4.Manufacturing Process

6.International Shipping

Key Factors When Choosing Custom Collapsible Rigid Box Manufacturers

Select a manufacturing partner that understands your quality standards and business requirements.

Manufacturing Capabilities

Advanced equipment, production capacity, quality control systems, and ability to handle complex customization requirements.

Material Quality

Premium substrate options, eco-friendly choices, durability testing, and compliance with international safety standards.

Customization Options

Design flexibility, printing capabilities, finishing techniques, and ability to accommodate unique specifications.

Industry Experience

Track record with similar products, understanding of market requirements, and proven success with international clients.

Communication Standards

English proficiency, responsive customer service, clear documentation, and regular project updates throughout production.

Certifications and Compliance

ISO certifications, environmental standards, safety regulations, and quality management system implementations.

Why Choose Acreet for Your Wholesale Custom Collapsible Rigid Box Needs?

We combine industry expertise with personalized service to deliver exceptional packaging solutions for your business.

Proven Experience:

Over a decade serving international wholesale clients with consistent quality, on-time delivery, and comprehensive support services.

Advanced Technology:

State-of-the-art manufacturing equipment, automated quality control, and innovative design capabilities for superior results.

Flexible MOQ:

Competitive minimum order quantities accommodating both small businesses and large enterprises with scalable solutions.

Quality Guarantee:

Comprehensive quality assurance program, defect replacement policy, and customer satisfaction commitment for peace of mind.

Competitive Pricing:

Factory-direct pricing, transparent cost structure, and volume discounts maximizing your investment return.

Global Support:

Worldwide shipping network, multilingual customer service, and local market expertise for seamless international business.

FAQ

A: We use premium cardboard, greyboard, and specialty papers with various finishing options including lamination, UV coating, and foil stamping.

A: Our boxes typically support 2-10 kg depending on size and construction, suitable for most consumer products.

A: Yes, boxes are designed for easy assembly and integration with most automated packaging systems and equipment.

A: We offer offset printing, digital printing, spot UV, embossing, debossing, and metallic foil applications.

A: When assembled, they provide equivalent protection and structural integrity while offering storage and shipping advantages.

A: Our MOQ starts from 500 pieces, with volume discounts available for larger orders and repeat customers.

A: Absolutely, we offer various closure options including magnetic flaps, ribbon ties, and custom hardware attachments.

A: Properly stored boxes maintain structural integrity for 2-3 years under normal warehouse conditions.

A: Yes, we offer recycled materials, biodegradable coatings, and sustainable printing inks for green packaging solutions.

A: We implement multi-stage inspection, automated quality checks, and random sampling throughout the manufacturing process.