Why Find Custom Two Piece Rigid Box Manufacturer in China?

China leads global packaging manufacturing with advanced technology and competitive pricing. We offer superior quality materials, skilled craftsmanship, and cost-effective solutions for your luxury packaging needs. Our manufacturing expertise ensures consistent quality while maintaining affordable wholesale prices for international businesses.

Understanding Your Custom Two Piece Rigid Box Needs

Before selecting packaging, identify your specific requirements to ensure optimal results. Consider these essential factors:

Product dimensions and weight

Measure your items precisely to ensure perfect fit and protection during shipping and storage.

Brand aesthetics and color scheme

Define your visual identity to create cohesive packaging that reflects your brand values

Target market and price point

Understand your customers' expectations to balance quality with budget considerations

Quantity requirements and timeline

Plan production volumes and delivery schedules to meet your business demands effectively

Special features needed

Determine if you need inserts, windows, magnetic closures, or other custom elements

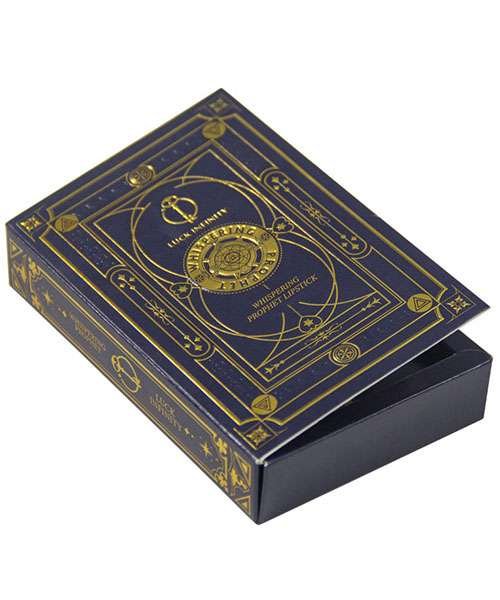

Applications of Custom Two Piece Rigid Boxes

These versatile packaging solutions serve various industries, from luxury goods to electronics, offering premium protection and presentation.

Jewelry and watches

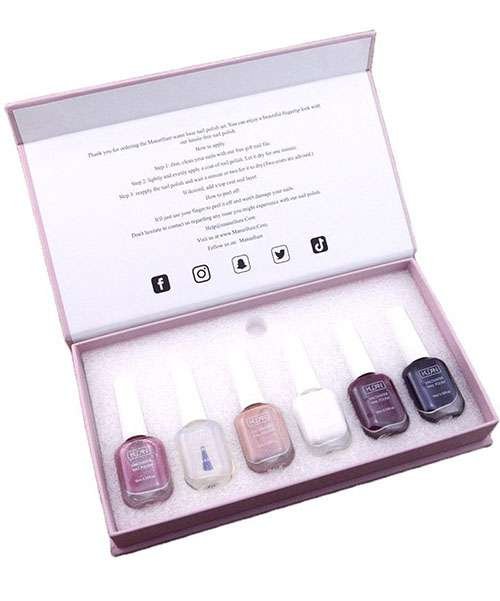

Cosmetics and skincare

Electronics and gadgets

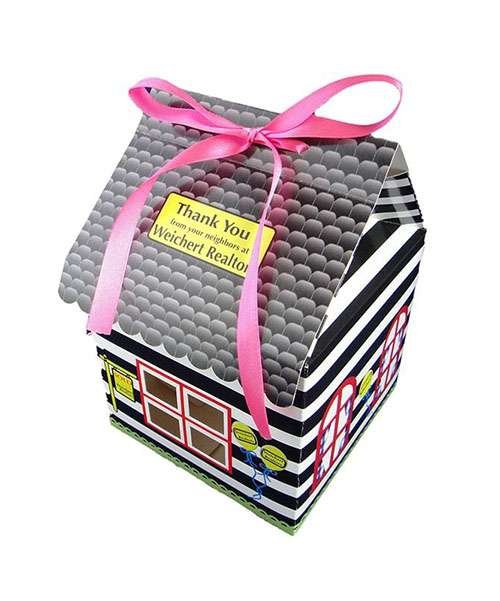

Corporate gifts and promotional items

Fashion accessories and apparel

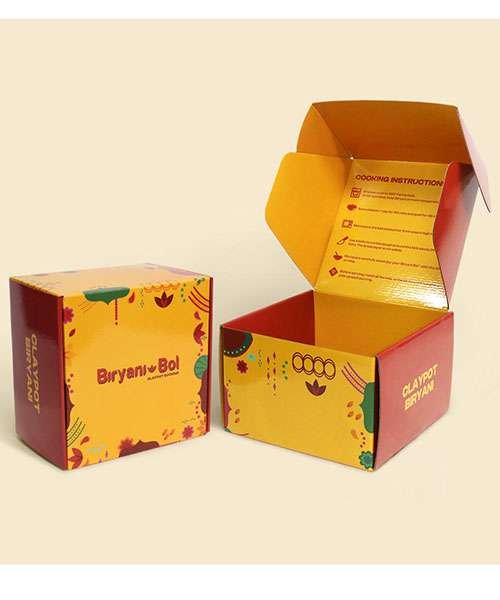

Food and beverage gifts

Benefits of Custom Two Piece Rigid Boxes

Two piece rigid boxes offer superior protection, elegant presentation, and customizable options with sturdy construction.

Superior product protection

Thick chipboard construction shields items from impacts, moisture, and handling damage during transport

Premium brand presentation

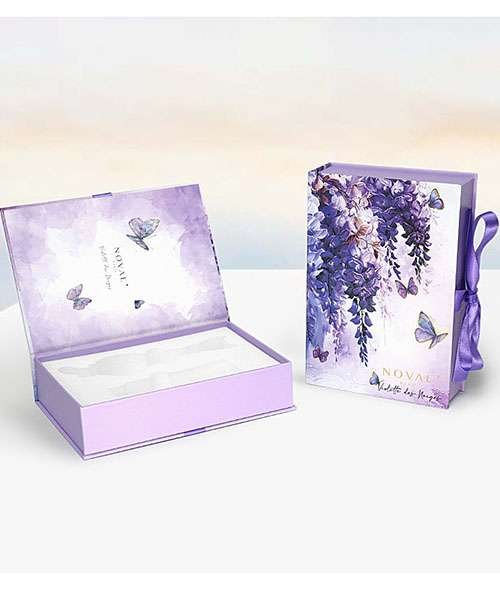

Luxury appearance elevates brand perception and creates positive first impressions with customers

Reusable and sustainable

Durable construction encourages customers to repurpose boxes, extending your brand's visibility

Easy assembly and packing

Simple two-piece design streamlines your packaging process and reduces labor costs

Versatile customization options

Unlimited design possibilities including colors, finishes, inserts, and special features

Cost-effective luxury appeal

Achieve high-end appearance without premium pricing, maximizing your packaging budget effectiveness

Custom Two Piece Rigid Box Design Process

Our streamlined design process ensures your vision becomes reality efficiently and accurately.

Initial consultation and requirements:

We discuss your needs, budget, and timeline to create comprehensive project specifications.

3D mockup and prototype development:

Digital renderings and physical samples allow you to visualize and test before production.

Material selection and testing:

Choose optimal materials considering durability, appearance, and budget while ensuring quality standards

Final approval and production setup:

Review approved designs, confirm specifications, and initialize production with quality checkpoints.

International Logistics of Custom Two Piece Rigid Boxes

We handle global shipping complexities to ensure smooth delivery worldwide with transparent processes.

Flexible shipping methods

Choose from sea freight, air cargo, or express delivery based on urgency and budget requirements

Professional packaging for transport

Secure bundling and protective wrapping prevent damage during international transit

Customs documentation support

Complete paperwork assistance ensures smooth customs clearance and compliance with regulations

Real-time tracking and updates

Monitor shipment progress with detailed tracking information and proactive communication

Insurance and quality guarantee

Comprehensive coverage protects your investment with replacement policies for damaged goods

Delivery coordination and support

Local delivery arrangement and customer service support ensure successful receipt

Production and Delivery Timeline of Custom Two Piece Rigid Boxes

Efficient production scheduling ensures timely delivery while maintaining quality standards throughout the manufacturing process.

1.Design and approval phase: 3-5 days

3.Production setup: 1-2 days

5.Quality inspection: 1-2 days

2.Material procurement: 2-3 days

4.Manufacturing phase: 7-15 days

6.Packaging and shipping: 2-5 days

Key Factors to Consider When Choosing Two Piece Rigid Box Manufacturer

Select the right manufacturing partner by evaluating these critical aspects for successful project outcomes.

Manufacturing capabilities and capacity

Assess production volume limits, technical expertise, and equipment quality for your requirements

Quality control standards and certifications

Verify ISO certifications, quality processes, and testing procedures to ensure consistent results

Material sourcing and sustainability

Evaluate supplier networks, material quality, and environmental responsibility practices

Customization flexibility and options

Review design capabilities, finishing options, and ability to accommodate special requirements

Communication and customer service

Test responsiveness, language capabilities, and support throughout the entire process

Pricing transparency and payment terms

Compare detailed quotes, hidden costs, and flexible payment options for budget planning

Why Choose Acreet as Your Wholesale Custom Two Piece Rigid Box Partner?

We deliver exceptional value through proven expertise, quality materials, and dedicated customer service.

15+ years manufacturing experience:

Extensive industry knowledge ensures superior craftsmanship and reliable production processes

Advanced production technology:

State-of-the-art equipment delivers precise cutting, folding, and finishing for consistent quality.

Competitive wholesale pricing:

Direct factory pricing eliminates middleman costs while maintaining premium quality standards.

Flexible minimum order quantities:

Accommodate both small and large orders with scalable production capabilities.

Comprehensive quality assurance:

Multi-point inspection process guarantees products meet exact specifications and standards.

Global shipping expertise:

Proven international logistics network ensures safe, timely delivery worldwide with tracking.

FAQ

A: We use premium chipboard (800-2000gsm), paperboard, and various paper finishes. Material selection depends on product weight, durability requirements, and aesthetic preferences.

A: Yes, we offer various finishing options including foil stamping, embossing, debossing, spot UV, matte/gloss lamination, and custom textures.

A: Measure your product’s length, width, and height, then add 2-5mm clearance per dimension for proper fit and easy insertion.

A: Setup boxes and rigid boxes are the same product. Both terms describe sturdy, pre-assembled boxes made from thick chipboard.

A: Yes, our design team creates custom artwork, provides 3D mockups, and offers design consultation to bring your vision to life.

A: Absolutely. We provide physical samples and prototypes so you can evaluate quality, fit, and appearance before production.

A: We use offset printing for high-quality results, digital printing for small quantities, and screen printing for special effects.

A: We use Pantone color matching system and provide color proofs for approval before bulk production to ensure accuracy.

A: Yes, we can provide food-grade materials and coatings that meet safety standards for direct food contact applications.

A: We provide comprehensive insurance coverage and replacement guarantee for any products damaged during transit to your location.