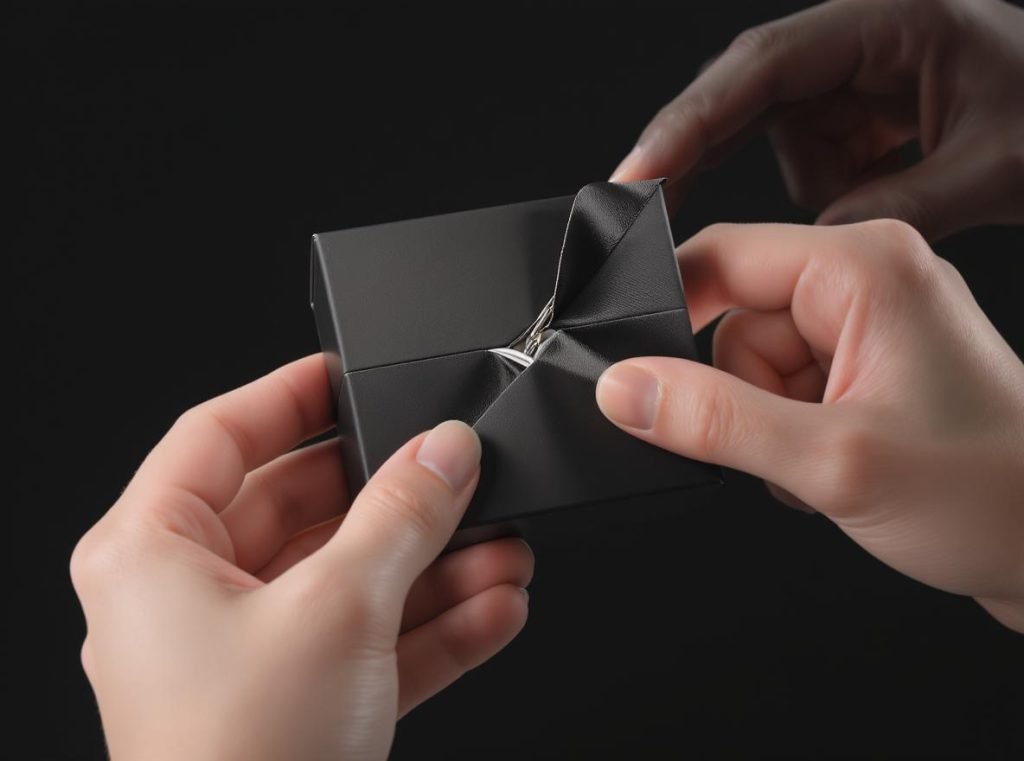

Are you looking to elevate your product packaging with a premium, effortless closing mechanism? Magnetic closures transform ordinary rigid boxes into luxury packaging experiences that customers remember. The seamless functionality frustrates many businesses who struggle to find the perfect balance between security and accessibility.

Magnetic closures are incorporated into rigid box designs by embedding neodymium magnets within precisely die-cut recesses in the box structure during manufacturing, with complementary magnets strategically placed in lid and base sections to create invisible, automatic closing mechanisms that provide 3-5 pounds of pull force for optimal security and user experience.

But there’s much more to understand about this sophisticated packaging solution that’s revolutionizing how brands present their products.

Table of Contents

ToggleWhat Are Magnetic Closures in Rigid Box Packaging?

Understanding magnetic closures is crucial for anyone considering premium packaging solutions for their brand or business.

Magnetic closures in rigid box packaging represent sophisticated closure mechanisms utilizing strategically embedded magnets to create secure, seamless seals without visible hardware, consisting of complementary magnets placed within the box structure that attract when brought together to create an elegant “snap” closure.

The magnetic closure system transforms ordinary rigid boxes into luxury packaging solutions by providing invisible closure mechanisms that maintain clean aesthetics while ensuring secure product protection. Unlike traditional packaging that relies on adhesive tapes, clasps, or mechanical fasteners, magnetic closures offer a reusable, wear-resistant solution.

These packaging solutions serve multiple industries effectively. Jewelry brands use them for engagement ring boxes where the secure closure prevents accidental opening during transport while the elegant appearance complements high-value pieces. Cosmetics companies rely on them for premium product lines, with the packaging enhancing perceived product value and providing secure protection for delicate items like compact powders and skincare products.

The technology behind magnetic closures involves powerful neodymium magnets embedded strategically within the box structure, typically magnetized through their thickness with opposite poles facing each other to ensure proper attraction. When positioned correctly, these magnets create sufficient holding force to keep the box securely closed during shipping and handling, yet allow easy opening by customers.

The satisfying “snap” closure creates a memorable unboxing experience that enhances customer perception and brand value, particularly important in the era of social media unboxing videos where packaging experiences become organic marketing opportunities.

How Do Manufacturers Install Magnetic Closures in Rigid Boxes?

The installation process requires precision engineering and specialized equipment to ensure optimal functionality and durability.

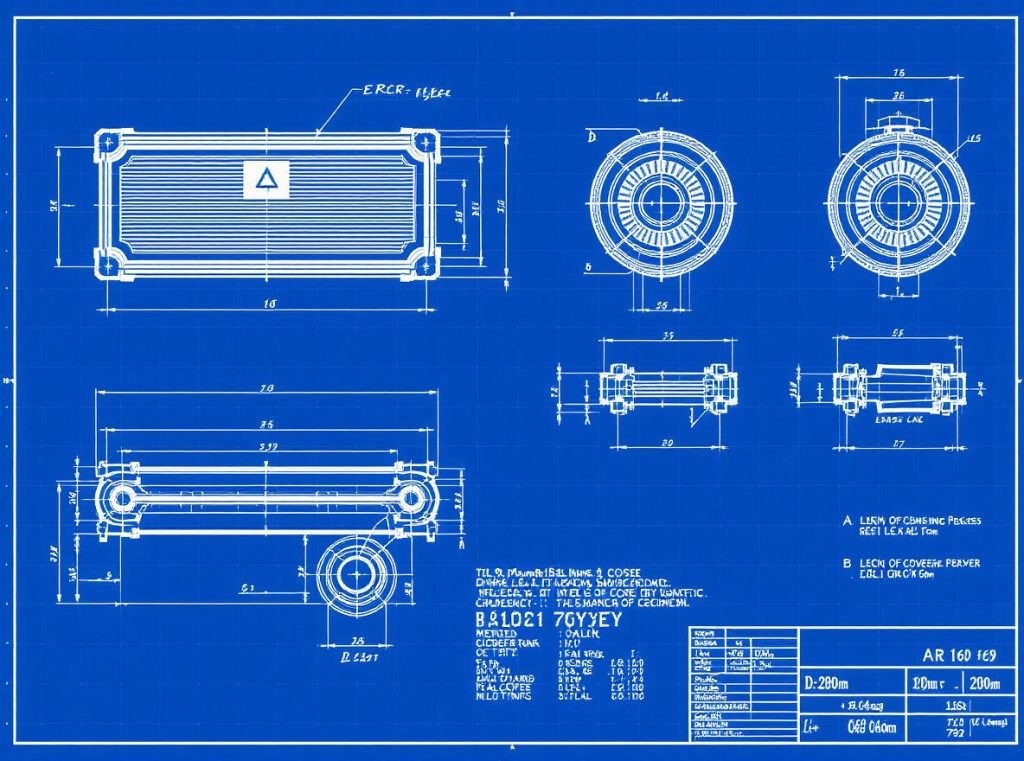

Manufacturers install magnetic closures through a precise multi-step process involving die-cutting exact recesses in rigid board material, embedding neodymium magnets using specialized adhesives with proper polarity alignment, and utilizing automated production equipment with high-precision molds to ensure consistent pull force specifications.

The manufacturing process follows these critical steps: offset printing of exterior materials, die-cutting of all components, hot stamping for branding elements, pasting outer printed materials onto rigid cardboard, precise magnet insertion with proper polarity alignment, interior material application, double-sided tape application for structural integrity, and final box assembly with quality inspection.

Professional installation involves several sophisticated stages:

- Material Preparation: High-quality rigid materials using chipboard or greyboard ranging from 1200-2000gsm thickness

- Precision Die-Cutting: Creating several small die-cut holes precisely positioned to accommodate magnet placement

- Magnet Selection: Choosing neodymium magnets with appropriate strength specifications

- Adhesive Application: Using specialized adhesives designed for permanent magnet attachment

| Manufacturing Stage | Equipment Required | Quality Control |

|---|---|---|

| Die-Cutting | High-precision cutting tools | Dimensional accuracy verification |

| Magnet Installation | Automated feeding systems | Pull force testing (3-5 lbs) |

| Assembly | Specialized molds | Closure alignment inspection |

| Final Inspection | Quality control systems | Repeated open/close testing |

Modern magnetic box manufacturing utilizes automated production equipment with high-precision molds, automated feeding systems, and quality inspection systems to ensure consistency and efficiency. The magnetic closure installation requires precise engineering to achieve the optimal pull force—typically 3-5 pounds—that provides security while remaining easy for customers to open.

The curing and bonding process is particularly critical. Magnets must be held in position under controlled pressure and temperature conditions to ensure permanent bonding that prevents magnet displacement during shipping or repeated use cycles.

Quality control testing verifies that each closure system meets pull force specifications to ensure consistent performance across production batches, with each box undergoing opening and closing tests to confirm smooth operation and appropriate holding strength.

What Materials Work Best with Magnetic Closure Systems?

Material selection directly impacts both the effectiveness and cost-efficiency of magnetic closure systems in rigid boxes.

The most effective materials for magnetic closure systems include neodymium magnets for superior strength-to-size ratio, rigid chipboard or greyboard (1200-2000gsm) for structural integrity, and premium exterior wrapping materials like coated art paper or specialty finishes that accommodate magnet installation without compromising aesthetics.

Neodymium magnets (NdFeB) are the preferred choice for packaging applications due to their exceptional properties: superior strength-to-size ratio providing maximum holding power in compact dimensions, corrosion resistance with nickel-coated surfaces protecting against moisture, temperature stability operating effectively at temperatures up to 176°F (80°C), and durability maintaining magnetic strength through repeated use cycles.

Substrate material selection requires careful consideration of multiple factors:

Rigid Board Options:

- Chipboard (1200-1500gsm): Standard for mid-range packaging applications

- Greyboard (1500-2000gsm): Premium applications requiring enhanced durability

- Multiple thickness options (1.5mm-3mm): Based on product weight and protection requirements

Exterior Wrapping Materials:

- Coated art paper (157gsm): High-quality printing surface for premium graphics

- Kraft paper (120gsm): Sustainable, durable option for eco-conscious brands

- Specialty papers: Soft-touch, textured, or metallic finishes for luxury appeal

- Laminated options: Matte, gloss, or soft-touch coatings for enhanced aesthetics

The chosen substrate must accommodate magnet placement without compromising structural integrity or visual appeal. Adequate material thickness (minimum 1.5mm) around magnet recesses prevents structural weakness while maintaining closure strength.

Material considerations extend beyond basic strength requirements. The substrate must accept high-resolution graphics, maintain dimensional stability under varying environmental conditions, and provide compatibility with various finishing techniques like foil stamping, embossing, or spot UV applications.

Environmental considerations increasingly influence material selection. Recycled chipboard options and sustainable exterior papers allow brands to maintain premium packaging while meeting corporate sustainability objectives.

Which Industries Benefit Most from Magnetic Closure Rigid Boxes?

Understanding industry applications helps businesses evaluate whether magnetic closures align with their market positioning and customer expectations.

Luxury and premium product industries including cosmetics, jewelry, electronics, fashion accessories, and corporate gifting benefit most from magnetic closure rigid boxes because these sectors prioritize customer experience, brand differentiation, and product protection, with the global magnetic closure boxes market projected to grow from USD 5.6 billion in 2025 to USD 9.2 billion by 2035.

The global magnetic closure boxes market is projected to grow from USD 5.6 billion in 2025 to USD 9.2 billion by 2035, reflecting expanding adoption across industries including food and beverage, pharmaceuticals, and e-commerce fulfillment.

Primary Market Segments:

The beauty industry extensively uses magnetic closure boxes for premium product lines, with the packaging enhancing perceived product value and providing secure protection for delicate items like compact powders, lipsticks, and skincare products. The reusable nature of magnetic closures provides extended brand exposure as customers repurpose the packaging.

Corporate and marketing applications have expanded significantly. Businesses use magnetic closure boxes for sales kits, marketing materials, and promotional items where first impressions are crucial for business relationship building.

Industry-specific benefits include:

- Jewelry & Watches: Secure protection for high-value items, elegant presentation enhancing emotional impact

- Electronics: Premium device packaging, protection during shipping, enhanced unboxing experience

- Fashion Accessories: Brand differentiation, durable presentation for luxury scarves, ties, belts

- Food & Beverage: Artisanal chocolates, premium teas, specialty wines requiring gift-worthy presentation

| Industry Sector | Market Growth Rate | Primary Applications |

|---|---|---|

| Cosmetics & Beauty | 8.2% annually | Premium product lines, gift sets |

| Jewelry & Accessories | 6.7% annually | Engagement rings, watches, luxury items |

| Electronics | 9.1% annually | Smartphones, tablets, premium accessories |

| Corporate Gifting | 5.4% annually | Executive gifts, marketing materials |

The e-commerce sector particularly benefits from magnetic closures because they enhance the unboxing experience that customers often share on social media platforms. This organic marketing value often justifies the premium packaging investment through increased brand visibility and customer engagement.

Emerging applications include pharmaceutical packaging for premium health supplements and specialty food products where the reusable packaging adds perceived value and environmental benefits.

What Are the Cost Implications of Adding Magnetic Closures?

Understanding the comprehensive cost structure helps businesses make informed investment decisions about magnetic closure integration.

Magnetic rigid boxes typically cost approximately $6.50 per unit compared to standard cardboard boxes at $3.50 per unit, with bulk pricing ranging from $2.04 for 500 units to $1.26 for 20,000+ units, though the premium pricing is often justified by enhanced brand perception and customer loyalty that allows for higher retail price points.

Magnetic rigid boxes typically cost approximately $6.50 per unit compared to standard cardboard boxes at $3.50 per unit. However, this premium pricing reflects significant value additions in materials, manufacturing complexity, and customer experience enhancement.

Detailed Cost Breakdown:

Bulk pricing examples for 9.5″ x 5.7″ x 2.9″ boxes: 500pcs at $2.04 per unit, 1,000pcs at $1.66, 5,000pcs at $1.32, and 20,000pcs at $1.26 per unit.

Cost factors include multiple components beyond basic materials:

- Raw Materials: Neodymium magnets, specialized adhesives, premium substrates

- Manufacturing Equipment: High-precision molds, automated production systems

- Labor Costs: Additional assembly steps, quality control requirements

- Customization Features: Embossing, foil stamping, spot UV adding $0.20-$1.00 per box

Volume significantly impacts per-unit economics. Economies of scale become significant at quantities above 5,000 units, with per-unit costs decreasing substantially in bulk orders. Small quantities (under 1,000 units) may experience cost premiums of 80-90% over standard packaging, while large orders (10,000+ units) typically see 30-40% increases.

Return on Investment Considerations:

Many businesses find the premium pricing justified through multiple value drivers:

- Enhanced customer experience leading to improved reviews and repeat purchases

- Social media sharing of unboxing experiences providing organic marketing value

- Premium brand positioning allowing for higher retail price points

- Reduced packaging waste through reusable design appealing to environmentally conscious consumers

Consider long-term cost benefits beyond initial investment. The reusable nature of magnetic closures provides extended brand exposure as customers repurpose the packaging, unlike single-use adhesive closures that create disposal waste.

How Do Magnetic Closures Compare to Traditional Closure Methods?

Comparing closure technologies helps businesses select the optimal solution for their specific product requirements and market positioning.

Magnetic closures offer superior user experience through consistent 3-5 pound pull force, exceptional durability with no moving parts to deteriorate, and premium aesthetic appeal, while traditional methods like ribbons, clasps, or adhesive closures may weaken over time, require tools for opening, or lack professional appearance.

Magnetic closures provide consistent holding strength that doesn’t weaken over time, unlike adhesive tapes or mechanical clasps that may deteriorate with repeated use, while the satisfying “snap” closure creates a memorable unboxing experience that enhances customer perception and brand value.

Performance Comparison Analysis:

Traditional closure methods each present distinct limitations:

- Ribbon Ties: Economical but lack security, may fray or discolor, require manual tying

- Adhesive Closures: Single-use applications, lose strength over time, create waste

- Mechanical Clasps: Moving parts subject to breakage, may require tools to operate

- Friction Fits: May loosen with handling, lack premium feel, inconsistent performance

Magnetic closure advantages extend across multiple performance criteria:

| Performance Factor | Magnetic | Traditional Clasps | Ribbon Ties | Adhesive |

|---|---|---|---|---|

| Security Level | Consistent High | Variable | Low | Decreasing |

| User Experience | Excellent | Good | Fair | Poor |

| Durability | Very High | Medium | Low | Single Use |

| Aesthetics | Premium | Industrial | Decorative | Utilitarian |

| Environmental Impact | Reusable | Moderate | Biodegradable | High Waste |

Functional Advantages:

Unlike single-use adhesive closures, magnetic systems remain functional through multiple open/close cycles, adding environmental benefits and extended brand exposure. This reusability factor becomes increasingly important as consumers prioritize sustainable packaging options.

The maintenance requirements strongly favor magnetic closures. Traditional clasps require replacement when damaged, ribbons deteriorate and require periodic replacement, but magnetic systems maintain functionality throughout the packaging lifecycle without maintenance needs.

Operational benefits include consistent performance across temperature variations, resistance to humidity and environmental factors, and independence from consumable components that require replacement or replenishment.

What Design Considerations Apply to Magnetic Closure Integration?

Successful magnetic closure integration demands careful attention to both functional engineering and aesthetic design elements.

Key design considerations include precise magnet placement with complementary polarities, structural integrity maintenance around magnet recesses, achieving optimal 3-5 pound pull force balance, hidden hardware philosophy for premium aesthetics, and accommodation of custom inserts without interference with magnetic mechanisms.

Magnet placement requires exact alignment to ensure proper attraction force and smooth operation, with magnets embedded at complementary locations with opposite polarities, while box dimension tolerances typically include 3-5mm on all sides to accommodate inserts and ensure easy product fitting.

Structural Engineering Requirements:

Adequate material thickness (minimum 1.5mm) around magnet recesses prevents structural weakness while maintaining closure strength. The die-cut recesses must be precisely positioned to maximize magnetic attraction while preserving the box’s overall structural integrity.

Critical design parameters include:

- Magnetic Positioning: Complementary locations ensuring optimal attraction force

- Pull Force Engineering: Balancing security (preventing accidental opening) with usability

- Dimensional Tolerances: Accounting for manufacturing variations and insert requirements

- Material Stress Distribution: Preventing weakness around magnet installation points

Aesthetic Integration Principles:

The magnetic closure’s primary advantage lies in its invisible operation, requiring careful design to conceal all mechanical elements while maintaining premium appearance, with different box panels requiring specific design orientations.

Visual design must seamlessly accommodate magnetic closure requirements:

- Hidden Hardware Philosophy: Concealing all mechanical elements for clean aesthetics

- Brand Element Placement: Coordinating logos, graphics, and text with magnetic positioning

- Finishing Techniques: Integrating embossing, foil stamping, or UV coatings around closures

- Color Coordination: Ensuring closure mechanism doesn’t interfere with brand color schemes

Functional Usability Factors:

Achieving the ideal balance between security and usability typically requires 3-5 pounds of pull force. Natural hand positions for opening must align with magnet placement to ensure intuitive operation without customer confusion.

Custom foam inserts, thermoformed trays, or die-cut partitions must account for magnetic mechanism placement to avoid interference. The insert design becomes particularly important for products requiring specific positioning or protection during shipping.

Consider finishing options that complement magnetic functionality. Soft-touch coatings enhance the premium feel, but some finishes may interfere with magnetic operation and require compatibility testing during design development.

How Can Businesses Optimize Magnetic Closure Box Production?

Production optimization ensures consistent quality while managing costs and delivery timelines for magnetic closure applications.

Businesses optimize production through strategic supplier partnerships specializing in magnetic closure systems, automated manufacturing equipment with precision quality control, bulk material procurement for cost efficiency, and regional production advantages that balance quality standards with economic benefits.

Modern magnetic box manufacturing utilizes automated production equipment with high-precision molds, automated feeding systems, and quality inspection systems to ensure consistency and efficiency. Investment in proper equipment significantly improves both quality consistency and production throughput.

Manufacturing Optimization Strategies:

Production efficiency starts with supplier selection and relationship management. Partnering with manufacturers who specialize in magnetic closure systems ensures access to proper equipment, technical expertise, and established quality control processes.

Key optimization areas include:

- Template Standardization: Creating reusable design frameworks for quick customization across product lines

- Material Consolidation: Standardizing substrate weights and magnet specifications when possible

- Volume Planning: Coordinating multiple product launches for combined orders and improved pricing

- Quality Automation: Implementing automated testing for magnetic strength and closure alignment

Material waste reduction through press-to-shape manufacturing minimizes scrap material compared to machining from block stock, particularly beneficial for high-volume production.

Supply Chain Management:

Establishing relationships with magnet and substrate suppliers enables better pricing and consistent material quality. Long-term partnerships often provide priority access to materials during supply constraints and opportunities for custom specifications.

Consolidating packaging and product assembly in manufacturing locations can reduce shipping costs by up to 30% compared to separate operations. This integration also improves quality control by reducing handling between processes.

Quality Control Systems:

Each closure system requires verification of pull force specifications to ensure consistent performance across production batches. Automated testing equipment can verify magnetic strength, closure alignment, and dimensional accuracy more consistently than manual inspection.

Seasonal planning becomes crucial for optimal production scheduling. Many businesses experience peak demand during holiday seasons, requiring advance planning to secure production capacity and avoid rush charges that can increase costs by 20-40%.

Strategic Production Partnership:

Working with experienced packaging partners like Acreet, who understand both international manufacturing capabilities and foreign trade wholesale requirements, helps businesses navigate the complexity of magnetic closure production while optimizing costs and quality. Our expertise in custom packaging design ensures your magnetic closure boxes meet international quality standards while supporting your business growth objectives through reliable supply chain management and competitive pricing structures.

Summary

Magnetic closures represent a premium packaging solution that enhances customer experience through sophisticated engineering and luxury appeal. The integration involves precise manufacturing with neodymium magnets, appropriate material selection, and careful design consideration to create packaging that balances security, aesthetics, and user satisfaction. While requiring higher initial investment than traditional closures, the enhanced brand perception, customer loyalty, and extended marketing value through reusable design often justify the premium positioning for quality-conscious markets.

Ready to elevate your packaging with magnetic closure rigid boxes? Contact Acreet today for a free consultation on custom magnetic closure solutions tailored to your specific products and international market requirements. Our experienced team specializes in foreign trade wholesale operations and can help you design and manufacture premium packaging that sets your brand apart in competitive global markets.