Struggling with rigid box designs that look premium but lack functionality? Many brands invest in beautiful packaging only to discover their customers find it difficult to open or access products inside. This common oversight can frustrate users and diminish the unboxing experience you’ve worked so hard to create.

Ribbon pulls and tabs are added to rigid boxes during the wrapping phase using specialized automated machinery or precision hand techniques. The process involves cutting ribbons to precise lengths, applying hot-melt adhesives at 193°C, and positioning pulls before final lid attachment to ensure proper functionality.

Let’s explore the complete manufacturing process, equipment, and considerations for adding these functional elements to your luxury packaging.

Table of Contents

ToggleWhat Equipment Is Used for Adding Ribbon Pulls to Rigid Boxes?

Understanding the machinery involved helps you plan production efficiently and achieve consistent quality results across large manufacturing runs.

Ribbon pull installation uses specialized automated equipment like the PERONI RUGGERO BOX RIBBON machine for high-volume production, operating at 8 cycles per minute with positioning accuracy of ±0.25mm for professional results.

Automated Ribbon Application Systems

The PERONI RUGGERO BOX RIBBON machine represents the gold standard for automated ribbon installation. This sophisticated system handles boxes ranging from 48 x 48 x 20mm minimum to 338 x 238 x 113mm maximum size, accommodating textile ribbons in 10mm, 15mm, or 20mm widths.

The automated process follows this sequence:

- Rigid boxes are automatically aligned on conveyor systems

- The first unit punches precise openings for ribbon insertion

- Ribbons feed directly from reels and are cut using hot-cutting systems

- Ribbon insertion creates round loops with consistent tension

- Hot-melt adhesive application secures the ribbon permanently

- Finished products are ejected for quality inspection

Quad Corner Pasting Machines

Before ribbon installation, automatic quad corner pasting machines secure box corners with exceptional precision. These machines feature PLC touch screen controls and achieve production speeds of 6,000 pieces per hour.

Critical specifications include:

- Positioning accuracy within ±0.25mm tolerance

- CE-approved safety systems with protective guards

- Integrated heating systems for optimal tape adhesion

- Automatic cutting mechanisms for consistent corner reinforcement

Quality Control Equipment

Professional manufacturers employ specialized testing equipment to ensure ribbon pull durability and functionality:

| Equipment Type | Function | Performance Standard |

|---|---|---|

| Pull Test Machines | Measure ribbon tensile strength | Minimum 10N force resistance |

| Hot-Melt Dispensers | Control adhesive temperature | Maintain 193°C operating temperature |

| Positioning Jigs | Verify ribbon placement | ±1mm positioning accuracy |

When During Manufacturing Are Ribbon Pulls Added?

Timing is absolutely critical in rigid box manufacturing to ensure proper adhesion, positioning, and overall functionality of the finished product.

Ribbon pulls are installed during the wrapping phase, after corner reinforcement but before final lid attachment. This sequence occurs after die-cutting, paper lamination, and box forming but before quality inspection.

Sequential Manufacturing Timeline

The complete manufacturing process follows this precise sequence:

Pre-Installation Phases

Die-cutting and board preparation create the foundation structure. Greyboard components are cut to exact specifications, followed by paper lamination where decorative covering is applied to all board surfaces.

Box forming and corner reinforcement establish structural integrity. The automatic quad corner pasting machines secure corners with heated tape application, creating a stable foundation for ribbon attachment.

Ribbon Installation Phase

During the critical wrapping phase, ribbons are cut to predetermined lengths based on box dimensions and user requirements. Hot-melt adhesives are heated to exactly 193°C for optimal flow characteristics and strong bond formation.

The ribbon application process requires precise timing – ribbons must be positioned and adhered while the adhesive maintains proper viscosity, typically within a 30-second working window.

Post-Installation Completion

Final lid attachment occurs after ribbon installation, ensuring the pulls extend properly through designated openings. Quality inspection verifies functionality, positioning accuracy, and aesthetic appearance before packaging for shipment.

Temperature Control Requirements

Hot-melt adhesive systems demand strict temperature management throughout the installation process:

- Operating temperature maintained at 193°C for high-performance applications

- Proper viscosity control ensures adequate substrate wetting

- Rapid cooling provides handling strength within seconds

- Environmental temperature and humidity affect curing characteristics

What Types of Ribbon Materials Work Best for Rigid Box Pulls?

Material selection directly impacts durability, aesthetics, and user experience. Different ribbon types serve specific functional and design requirements.

Satin and grosgrain ribbons offer optimal performance for rigid box applications, with satin providing elegant aesthetics and grosgrain delivering superior grip and structural integrity for frequent-use applications.

Premium Textile Options

Satin Ribbons

Satin ribbons deliver exceptional visual appeal with their smooth, glossy surface finish. Made from polyester or silk fibers, these ribbons provide excellent drape characteristics and professional aesthetics suitable for luxury packaging applications.

Key performance characteristics include:

- Wide color variety matching brand requirements

- Smooth texture enhancing user experience

- Moderate durability for premium single-use applications

- Excellent printability for custom branding

Grosgrain Ribbons

Grosgrain ribbons feature distinctive ribbed texture that provides superior grip during use. The textured surface offers enhanced structural integrity and resistance to fraying, making them ideal for applications requiring frequent handling.

Advantages include:

- High durability due to reinforced weave structure

- Superior shape retention under stress

- Excellent resistance to edge fraying

- Strong color stability over extended periods

Sustainable Material Options

Cotton and natural fiber ribbons provide eco-friendly alternatives for environmentally conscious brands. These biodegradable materials offer soft texture and matte finish suitable for rustic or minimalist packaging designs.

Benefits of natural fiber ribbons:

- Sustainable and biodegradable composition

- Customizable through printing and embossing techniques

- Authentic texture appealing to eco-conscious consumers

- Compatible with recyclable packaging systems

Synthetic High-Performance Options

PVC Pull Tabs

PVC materials excel in demanding applications requiring maximum durability and environmental resistance. The tear-open packaging industry relies on PVC tabs because they maintain integrity during transportation and storage.

Polyester Pull Tabs

Polyester-based ribbons combine strength with flexibility, offering superior colorfastness and dimensional stability. Wide texture and finish ranges accommodate diverse aesthetic requirements.

| Material Type | Durability | Aesthetics | Best Application |

|---|---|---|---|

| Satin Ribbon | Medium | Premium | Luxury single-use |

| Grosgrain Ribbon | High | Professional | Frequent-access boxes |

| Natural Fiber | Medium | Rustic/Eco | Sustainable packaging |

| PVC Tabs | Very High | Industrial | Heavy-duty applications |

How Are Ribbons Positioned for Optimal User Experience?

Proper positioning determines whether ribbon pulls enhance or frustrate the customer experience. Strategic placement requires understanding ergonomics and mechanical function.

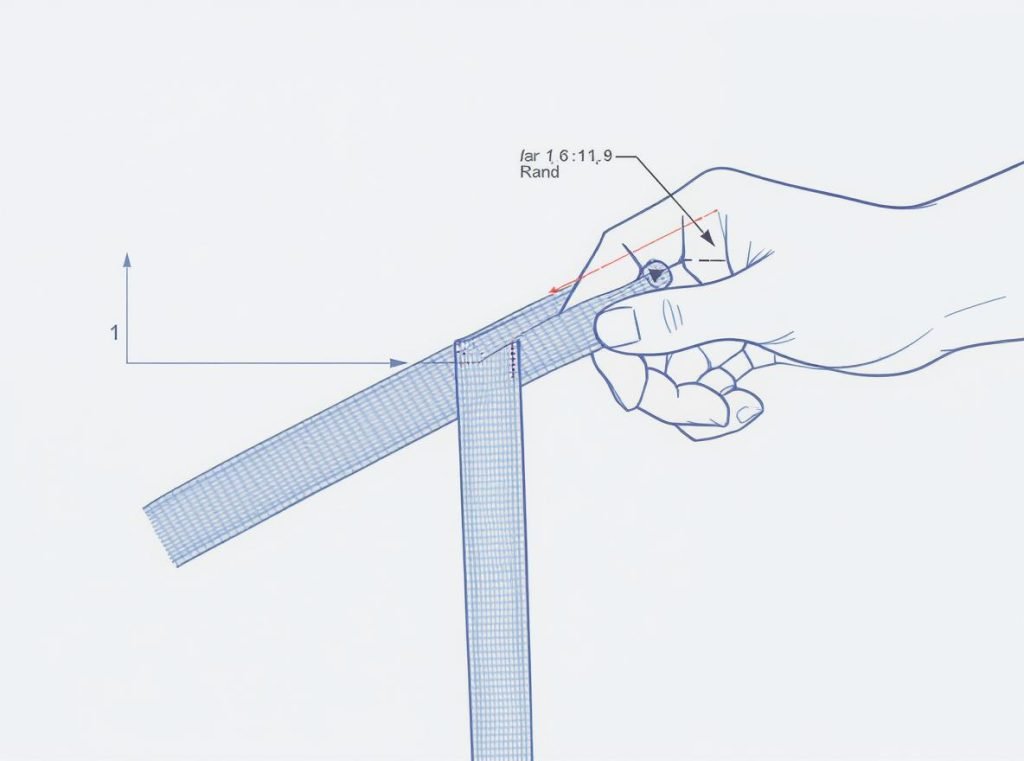

Optimal ribbon positioning places pulls 5-10mm from box edges, with loop lengths of 50-100mm for comfortable gripping, positioned to allow 15mm finger access clearance around each ribbon.

Geometric Positioning Standards

Distance and Clearance Requirements

Professional positioning follows established guidelines that ensure both functionality and durability. Ribbons positioned too close to edges risk tearing during use, while excessive distance creates awkward proportions.

Standard measurements include:

- 5-10mm minimum distance from all box edges

- 50-100mm loop length for comfortable finger access

- Equal spacing when using multiple ribbon pulls

- Symmetrical center alignment on intended opening edges

Box Type Specific Positioning

Drawer-style boxes require specific positioning strategies to ensure smooth operation. Ribbons attach to the front face of inner drawers with adequate clearance for finger access within outer sleeves.

Hinged lid boxes need different approaches – ribbons attach to lid interiors with sufficient length to bridge gaps between lid and base components during operation.

Ergonomic Optimization

User Comfort Considerations

Ribbon positioning must accommodate users with different hand sizes and pulling preferences. Natural hand motion compatibility reduces fatigue and improves overall user satisfaction.

Critical ergonomic factors:

- Minimum 15mm finger access clearance around ribbon loops

- Pull angle compatibility with natural wrist motion

- Non-slip ribbon surface materials for secure gripping

- Adequate grip surface area for various hand sizes

Load Distribution Engineering

Mechanical stress distribution prevents premature failure and ensures long-term reliability. Multiple small attachment points distribute forces more effectively than single large ones.

Engineering considerations include:

- Reinforcement behind attachment points preventing pull-through

- Multiple attachment zones spreading load across larger areas

- Gradual stress transitions avoiding concentrated failure points

- Backup attachment methods for high-stress applications

What Adhesives Provide the Strongest Ribbon Attachment?

Adhesive selection determines long-term reliability and user satisfaction. Different bonding systems suit various production requirements and performance standards.

Hot-melt adhesives operating at 193°C provide optimal ribbon attachment strength, offering rapid bonding with handling strength achieved within seconds and 100% solids content eliminating volatile organic compounds.

Hot-Melt Adhesive Systems

Hot-melt technology represents the industry standard for ribbon attachment in professional rigid box manufacturing. These thermoplastic systems provide immediate bonding with excellent performance characteristics.

Application Performance

Modern hot-melt systems deliver rapid production capabilities:

- Setting speed reaching handling strength within seconds

- 30-second working time allowing positioning adjustments

- Operating temperatures of 193°C for high-performance applications

- Proper viscosity control ensuring complete substrate wetting

Bonding Characteristics

Quality hot-melt formulations provide:

- Strong shear resistance preventing ribbon pull-out

- Controlled peel strength protecting substrate integrity

- Minimal odor during application improving working conditions

- Environmental resistance to temperature and moisture variations

Pressure-Sensitive Adhesive Options

Double-sided adhesive tapes offer alternative solutions for specific applications requiring repositioning capability or clean removal characteristics.

Application Requirements

Pressure-sensitive systems require careful surface preparation:

- Clean, dry surfaces free from dust and processing residues

- Adequate pressure application ensuring full contact

- Temperature considerations optimizing bond development

- Primer application for difficult substrate materials

Performance Benefits

Quality pressure-sensitive tapes provide:

- Immediate tack for quick positioning and adjustment

- Conformability to irregular or textured surfaces

- Clean removal capabilities when repositioning is required

- Superior environmental resistance across temperature ranges

Specialized High-Performance Systems

Structural Adhesives

Heavy-duty applications may require structural bonding systems offering maximum strength and environmental resistance:

| Adhesive Type | Setting Time | Temperature Range | Shear Strength |

|---|---|---|---|

| Hot-Melt | 30 seconds | -20°C to 80°C | 15+ lbs/sq inch |

| Pressure-Sensitive | Immediate | -40°C to 120°C | 12+ lbs/sq inch |

| Structural Acrylic | 24-48 hours | -40°C to 150°C | 25+ lbs/sq inch |

What Are Common Installation Problems and Solutions?

Understanding potential issues helps prevent costly mistakes and ensures consistent quality across production runs. Most problems stem from inadequate preparation or process control.

Common ribbon installation problems include misalignment causing uneven pull forces, inadequate surface preparation preventing proper adhesion, and incorrect temperature control resulting in weak bonds or premature adhesive setting.

Positioning and Alignment Issues

Misalignment Problems

Incorrect ribbon positioning creates multiple operational issues that affect both functionality and aesthetics. Uneven spacing between multiple ribbons creates visual inconsistency, while off-center placement causes binding during operation.

Common alignment problems include:

- Asymmetrical positioning affecting visual balance

- Inadequate clearance causing interference with box components

- Inconsistent loop sizes creating uneven pull forces

- Poor angle orientation resulting in difficult operation

Prevention Strategies

Automated positioning systems eliminate human error and ensure consistent placement accuracy. Quality fixtures and jigs maintain proper alignment throughout production runs.

Effective prevention includes:

- Standardized positioning templates for different box sizes

- Automated alignment systems with positioning feedback

- Regular calibration of positioning equipment

- Operator training on proper manual positioning techniques

Adhesive Application Failures

Surface Preparation Issues

Inadequate surface preparation represents the primary cause of adhesive failure in ribbon pull applications. Contaminated surfaces prevent proper bonding regardless of adhesive quality or application technique.

Critical preparation requirements:

- Complete removal of dust, oils, and processing residues

- Appropriate surface energy levels for chosen adhesive systems

- Proper texture compatibility ensuring adequate contact

- Controlled moisture content affecting adhesive performance

Temperature Control Problems

Hot-melt adhesive systems require precise temperature management throughout the application process. Incorrect temperatures cause poor flow characteristics, inadequate wetting, or premature setting.

Temperature control solutions include:

- Calibrated heating systems maintaining 193°C operating temperature

- Environmental monitoring preventing contamination during application

- Proper equipment maintenance ensuring consistent performance

- Real-time temperature feedback with automatic adjustment capabilities

Quality Assurance and Testing

Performance Validation

Comprehensive testing protocols ensure ribbon pulls meet durability and functionality requirements before products leave the manufacturing facility.

Standard testing includes:

- Pull strength verification using calibrated test equipment

- Functional operation testing under normal use conditions

- Visual inspection confirming proper positioning and appearance

- Sample retention for ongoing quality monitoring and improvement

Continuous Improvement

Data collection and analysis identify trends and opportunities for process optimization. Regular review of installation problems leads to improved procedures and reduced defect rates.

Summary

Adding ribbon pulls and tabs to rigid boxes requires precise coordination of specialized equipment, proper timing, and quality materials. The process occurs during the wrapping phase using automated machinery like the PERONI RUGGERO system operating at 8 cycles per minute. Success depends on hot-melt adhesives at 193°C, optimal positioning with 5-10mm edge clearance, and comprehensive quality control testing. Understanding these manufacturing fundamentals ensures your ribbon pulls enhance user experience while maintaining long-term durability and professional appearance.

Ready to integrate functional elegance into your rigid box packaging? Contact Acreet today for expert consultation on ribbon pull systems and custom packaging solutions. Our advanced manufacturing capabilities and experienced engineering team can help you select optimal materials, positioning, and production methods for your specific requirements and volume needs.