Rising shipping costs are crushing your profit margins. Every oversized box, every wasted inch of space, and every unnecessary pound directly impacts your bottom line. With ocean rates from Asia to North America increasing sharply, businesses need strategic solutions to control escalating logistics expenses.

Custom packaging reduces shipping costs by optimizing dimensional weight pricing, eliminating excess materials, and improving operational efficiency. Companies implementing right-sized packaging solutions can achieve an average 40% reduction in package size and 26% decrease in corrugated material usage, resulting in substantial shipping cost savings.

Let’s explore exactly how custom packaging can transform your shipping expenses into competitive advantages.

Table of Contents

ToggleWhat Is Dimensional Weight and Why Does It Matter for Shipping Costs?

Understanding dimensional weight is crucial because it directly affects how much you pay for shipping, regardless of your package’s actual weight.

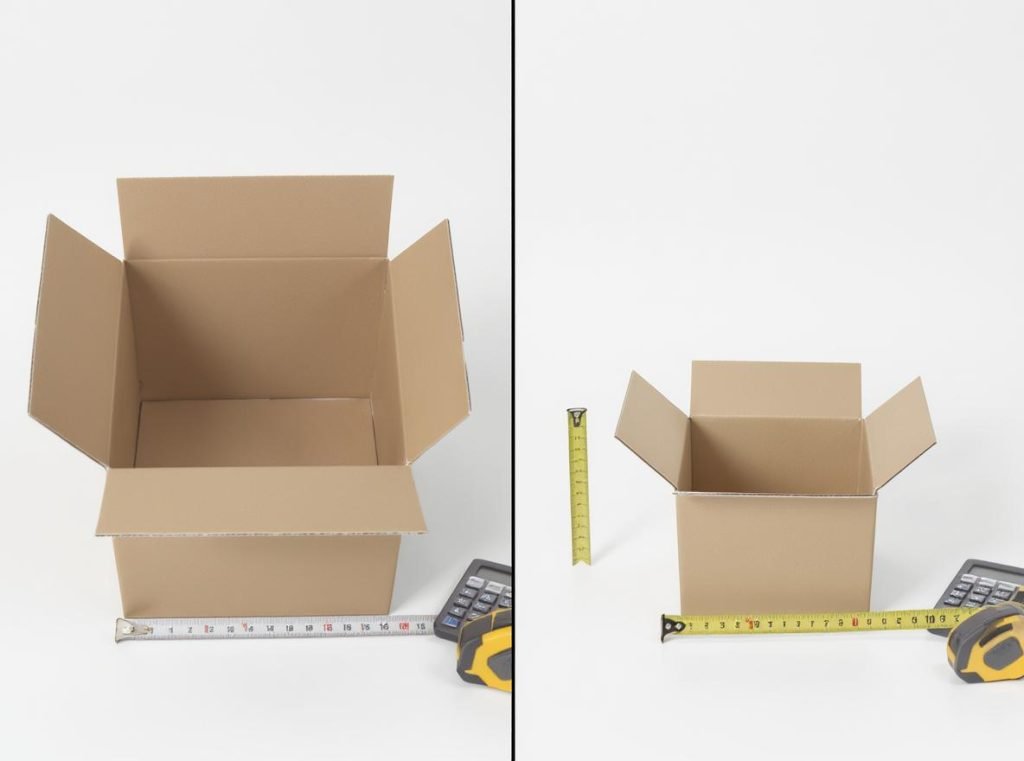

Dimensional weight (DIM weight) is a pricing method used by shipping carriers to determine costs based on the amount of space a package occupies rather than just its actual weight. The formula is: DIM Weight = Package Dimensions (Length × Width × Height) / DIM Factor. Carriers charge based on whichever is higher: actual weight or dimensional weight.

This pricing structure has profound implications for shipping costs. When packages have excessive empty space or oversized dimensions, businesses effectively pay to ship air. The impact is particularly significant for e-commerce companies shipping lightweight but bulky items.

Common DIM Factors by Carrier:

| Carrier | Domestic Shipments | International Shipments |

|---|---|---|

| UPS/FedEx | 139 | 139 |

| USPS | 166 | 166 |

| DHL | 139 | 139 |

The smaller the DIM factor, the larger the dimensional weight calculation, leading to higher shipping costs. This system encourages shippers to optimize packaging dimensions for maximum efficiency.

Real-World Impact Example:

A lightweight product in a 12″ × 10″ × 8″ box creates 960 cubic inches of dimensional weight. The same product in a custom 8″ × 6″ × 4″ box uses only 192 cubic inches—an 80% reduction in billable space that translates directly to lower shipping costs.

How Much Can You Save with Right-Sized Custom Packaging?

Right-sized packaging creates measurable cost reductions by eliminating unnecessary space and materials that inflate shipping charges.

Companies implementing right-sized packaging can see an average 40% reduction in packaging size and 26% decrease in corrugated material usage. For businesses shipping 10,000 packages monthly, reducing package weight by just 1 pound can result in savings of up to $0.50 per shipment, representing potential monthly savings of $5,000.

The financial impact extends beyond basic dimensional weight savings. Custom packaging eliminates the need for standard-sized boxes that often leave 40% too much space around products. This excess space not only increases shipping costs but also requires additional void fillers, further adding to material expenses.

Quantifiable Savings Breakdown:

- Material cost reduction: 26% decrease in corrugated usage

- Shipping cost reduction: 15-40% depending on optimization level

- Labor cost savings: Up to 60% reduction in packing time

- Damage prevention: Reduced returns and replacement costs

Case Study Results:

Businesses need only a 0.4% increase in sales to break even on custom packaging costs, but potential returns can reach up to 20% increase in sales. Companies report annual sales increases ranging from $42,300 to $159,600 depending on customization investment levels.

Void Fill Elimination:

Custom-fit packaging removes the need for additional void fillers like bubble wrap, foam peanuts, or double boxing. This creates compound savings through reduced material costs and faster packing processes.

At Acreet, we’ve helped clients achieve consistent 25-35% shipping cost reductions through precision-sized packaging that eliminates dimensional weight penalties while maintaining superior product protection.

Which Lightweight Materials Can Reduce Shipping Costs?

Material selection significantly impacts both actual weight and dimensional weight calculations, directly affecting your shipping expenses.

Lightweight packaging materials significantly reduce shipping costs by lowering overall shipment weight. Reducing packaging weight by just 1 pound can save up to $0.50 per shipment. Lightweight materials also enable more units per shipment, reduce fuel consumption, and minimize dimensional weight pricing impact.

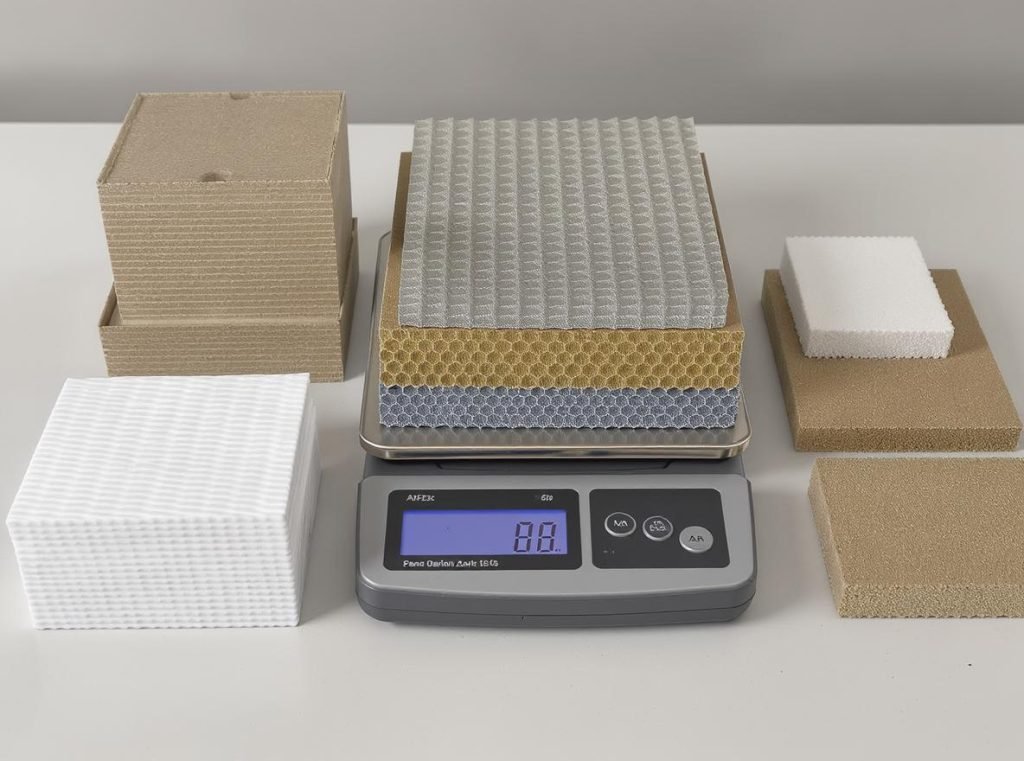

Modern packaging materials offer superior strength-to-weight ratios that traditional options cannot match. Here are the most effective materials for cost reduction:

Corrugated Cardboard Optimization:

- Single wall corrugated: 25-30% weight reduction

- Double wall corrugated: 20-25% weight reduction

- Superior crush resistance with lighter construction

- Excellent stacking strength for warehouse efficiency

Advanced Lightweight Options:

- Honeycomb board: 40-50% lighter than solid fiberboard

- Optimized paperboard: Customizable thickness based on protection needs

- Engineered corrugated: Reduces material usage without compromising strength

| Material Type | Weight Reduction | Strength Rating | Cost Efficiency |

|---|---|---|---|

| Single Wall Corrugated | 25-30% | High | Excellent |

| Double Wall Corrugated | 20-25% | Very High | Good |

| Honeycomb Board | 40-50% | High | Very Good |

| Optimized Paperboard | 15-20% | Medium | Excellent |

Additional Benefits of Lightweight Materials:

- Lower fuel consumption during transportation

- Reduced CO₂ emissions for environmental compliance

- More units per pallet or container

- Minimized handling strain on warehouse workers

- Simplified inventory management processes

The right material choice depends on your product’s protection requirements, shipping distance, and volume considerations. We help you select materials that provide optimal protection while minimizing both weight and dimensional charges.

How Does Custom Packaging Improve Shipping Efficiency?

Custom packaging transforms shipping operations by optimizing every aspect of the logistics process, creating compound cost savings throughout your supply chain.

Custom packaging reduces labor costs by up to 60% while doubling production speed. Custom-sized boxes are easier to stack, fit together more neatly, and make better use of space inside shipping containers. This allows businesses to move higher volumes with fewer shipments, reducing overall freight expenses.

Efficiency improvements compound throughout your entire supply chain:

Packaging Process Optimization:

Custom packaging eliminates the need for extra fillers, adjustments, and repacking. Employees spend significantly less time on each package because products fit perfectly without additional materials or adjustments.

Fulfillment Speed Improvements:

- Faster packing processes with fewer steps

- Reduced fulfillment complexity

- Elimination of void fill requirements

- Streamlined quality control processes

Warehouse Space Utilization:

Custom packaging optimizes storage by reducing the footprint of packaged products. This translates to:

- More efficient storage density

- Better inventory management

- Improved workflow for packing stations

- Reduced warehouse overhead costs

Container and Pallet Optimization:

When more products fit into the same shipping container or pallet space, businesses can:

- Reduce the number of required shipments

- Lower per-unit freight costs

- Minimize handling fees

- Improve logistics coordination

Damage Prevention Benefits:

Custom packaging provides superior protection during transit through:

- Precise product fit that prevents movement

- Reduced return rates and replacement costs

- Lower insurance claims

- Improved customer satisfaction scores

Automated Integration Advantages:

Custom packaging works seamlessly with automated systems, enabling:

- Consistent dimensions for conveyor systems

- Automated sorting efficiency

- Reduced manual handling requirements

- Standardized processes across facilities

When you partner with Acreet, we analyze your entire fulfillment process to identify efficiency improvements that multiply your cost savings beyond just dimensional weight reductions.

What Are the Long-Term Cost Benefits of Custom Packaging?

The true value of custom packaging extends far beyond immediate shipping savings, creating sustainable competitive advantages that impact multiple aspects of your business.

Custom packaging delivers long-term cost benefits through reduced material costs, improved operational efficiency, and enhanced customer loyalty. Studies show that 72% of consumers say packaging influences their buying decisions, and 52% of customers are more likely to make repeat purchases from retailers with appealing packaging.

Long-term benefits create compound value over time:

Material Cost Optimization:

- Elimination of excess packaging materials

- Reduced void fill requirements

- Lower inventory carrying costs for packaging supplies

- Decreased waste disposal expenses

Operational Efficiency Gains:

Custom packaging reduces labor costs through more efficient packing solutions. The streamlined process enables:

- Faster order fulfillment cycles

- Reduced training requirements for new employees

- Improved quality control consistency

- Better resource allocation across operations

Customer Loyalty and Retention:

Professional packaging creates memorable unboxing experiences that encourage repeat purchases. The business impact includes:

- Increased customer lifetime value

- Higher average order values through premium perception

- Reduced customer acquisition costs

- Enhanced brand recognition and recall

Damage Prevention Savings:

Custom packaging provides superior protection, resulting in:

- Fewer product returns due to transit damage

- Reduced replacement and reshipping costs

- Lower insurance premiums

- Improved supplier relationships

Peak Season Cost Mitigation:

Custom-sized packaging helps minimize seasonal surcharges that carriers impose based on package size and weight. These savings become particularly valuable during high-volume periods when surcharges can significantly impact margins.

| Benefit Category | Year 1 Impact | Year 3 Impact | Year 5 Impact |

|---|---|---|---|

| Shipping Cost Reduction | 15-25% | 25-35% | 30-40% |

| Material Efficiency | 20-30% | 30-40% | 35-45% |

| Labor Productivity | 30-40% | 45-55% | 50-60% |

| Customer Retention | 10-15% | 20-25% | 25-35% |

Return on Investment Timeline:

Most businesses see positive ROI within 6-12 months of implementing custom packaging solutions. The initial investment in design and tooling pays for itself through reduced shipping costs, improved efficiency, and enhanced customer satisfaction.

Environmental Compliance Benefits:

As environmental regulations tighten, custom packaging positions your business ahead of sustainability trends while maintaining cost control through reduced material usage and lower transportation emissions.

How to Choose the Right Custom Packaging Partner?

Selecting the appropriate custom packaging partner determines whether you achieve maximum cost savings or encounter costly delays and quality issues.

Choose a partner with proven expertise in dimensional weight optimization, material engineering, and scalable manufacturing capabilities. The ideal partner should offer end-to-end service capability, industry-specific expertise, and comprehensive support from design to delivery.

Critical Evaluation Factors:

Technical Expertise Requirements:

- Dimensional weight calculation experience

- Material science knowledge and testing capabilities

- Structural engineering expertise

- Shipping regulation compliance understanding

- Quality control systems and certifications

Manufacturing Capabilities:

Your partner should demonstrate scalable production capacity that grows with your business:

- Modern equipment and technology

- Flexible minimum order quantities

- Consistent quality standards

- Contingency plans for supply chain disruptions

End-to-End Service Capability:

Look for partners who can support the entire process:

- Material selection and testing

- Artwork proofing and design optimization

- Production timeline management

- Integration with filling lines

- Logistics coordination support

Industry-Specific Expertise:

Partners with experience in your sector provide valuable guidance on:

- Technical requirements and compliance

- Regulatory standards

- Market expectations and trends

- Barrier properties and performance needs

Innovation and Customization Capabilities:

Superior partners actively invest in:

- New materials and technologies

- Smart packaging features

- Sustainable packaging solutions

- Market trend analysis and adaptation

Sustainability Credentials:

With increasing environmental focus, your partner should offer:

- Guidance on recyclable materials

- Reduced-material packaging options

- Sustainable manufacturing practices

- Environmental compliance support

Production Capacity and Scalability:

Evaluate partners based on:

- Lead times and production capabilities

- Ability to handle urgent orders

- Scalability for business growth

- Geographic reach and distribution

At Acreet, we combine advanced design capabilities with deep shipping cost expertise to deliver custom packaging solutions that consistently reduce your shipping expenses while protecting your products and enhancing your brand image. Our comprehensive approach ensures optimal results from initial consultation through ongoing optimization support.

Summary

Custom packaging significantly reduces shipping costs through dimensional weight optimization, lightweight materials, and improved operational efficiency. Companies implementing right-sized packaging achieve average cost reductions of 15-40%, with additional benefits including reduced material usage, faster fulfillment, and enhanced customer satisfaction. The long-term ROI typically exceeds 20% through compound savings across multiple operational areas.

Ready to reduce your shipping costs with custom packaging solutions? Contact Acreet today for a free consultation and discover how our expert team can design cost-effective packaging that maximizes your shipping budget efficiency while protecting your products and strengthening your brand presence.