Ready-to-eat meal packaging faces unique challenges balancing food safety, consumer convenience, and regulatory compliance. Poor packaging design risks contamination, shortened shelf life, and lost sales in this competitive market. Smart packaging design protects your product while driving purchase decisions.

Ready-to-eat meal packaging must comply with FDA regulations for food contact materials, provide comprehensive barrier protection against oxygen and moisture, accommodate various heating methods, and include complete labeling with ingredients, allergens, and heating instructions while maintaining visual appeal and cost efficiency.

Ready to discover the complete packaging solution that ensures safety while maximizing market appeal? Let’s explore the critical design elements.

Table of Contents

ToggleWhat Are the Essential FDA Safety Requirements for Ready-to-Eat Meal Packaging?

Food safety regulations form the foundation of RTE packaging design since these meals often bypass final cooking steps that eliminate pathogens. The FDA strictly regulates all food contact substances under Title 21 of the Code of Federal Regulations.

All food contact substances must comply with Title 21 CFR, covering plastics, cardboard, adhesives, dyes, and coatings. Materials must demonstrate no harmful substance migration under expected use conditions and operate within designated limitations. Temperature resistance requirements span from -40°F freezing to consumer reheating temperatures.

Core FDA Compliance Elements

Temperature safety requirements are critical for RTE packaging integrity. Materials must withstand hot-fill operations, freezing temperatures, and consumer reheating without structural failure or chemical migration.

Mandatory regulatory documentation includes:

- Material safety data sheets proving FDA compliance

- Migration testing results for all food contact surfaces

- Temperature resistance validation across expected use ranges

- Chemical composition disclosure for all packaging components

Comprehensive labeling requirements ensure consumer safety through product common names, net quantity, manufacturer information, complete ingredient lists, nutrition facts, allergen declarations for top nine allergens, and clear expiration dates with appropriate heating instructions.

| Safety Requirement | Compliance Standard | Testing Protocol |

|---|---|---|

| Chemical Migration | FDA 21 CFR 175-178 | Hot water extraction tests |

| Temperature Stability | -40°F to 400°F range | Thermal cycling validation |

| Barrier Integrity | Oxygen <0.1 cc/day | ASTM D3985 permeability testing |

Which Materials Deliver Superior Performance for Ready-to-Eat Meals?

Material selection directly impacts food safety, heating performance, and consumer experience. Understanding material properties helps optimize packaging for specific applications.

Polypropylene (PP) stands out for microwave applications with temperature resistance from -40°F to 260°F, excellent chemical resistance, and full recyclability. PP offers 12% lighter weight than polystyrene and 30% lighter than PET, reducing material and transportation costs.

Premium Material Performance Comparison

Crystallizable Polyethylene Terephthalate (CPET) represents the premium choice for dual-ovenable applications, withstanding temperatures from -40°F to 400°F for both microwave and conventional oven use with exceptional thermal stability and superior barrier properties.

Polypropylene advantages:

- Lowest density among packaging plastics

- Superior impact resistance at low temperatures

- Excellent oil and grease resistance for sauces

- Wide acceptance in curbside recycling programs

Standard PET provides excellent clarity for cold applications where product visibility drives purchase decisions, offering good barrier properties with high recyclability under recycling code 1, though temperature limitations restrict use below 160°F.

Paperboard and molded fiber materials address sustainability demands while maintaining functional performance. Advanced paperboard trays withstand temperatures up to 200°C when properly coated and offer complete recyclability with water-based barrier coatings.

How Do You Design for Different Heating Methods?

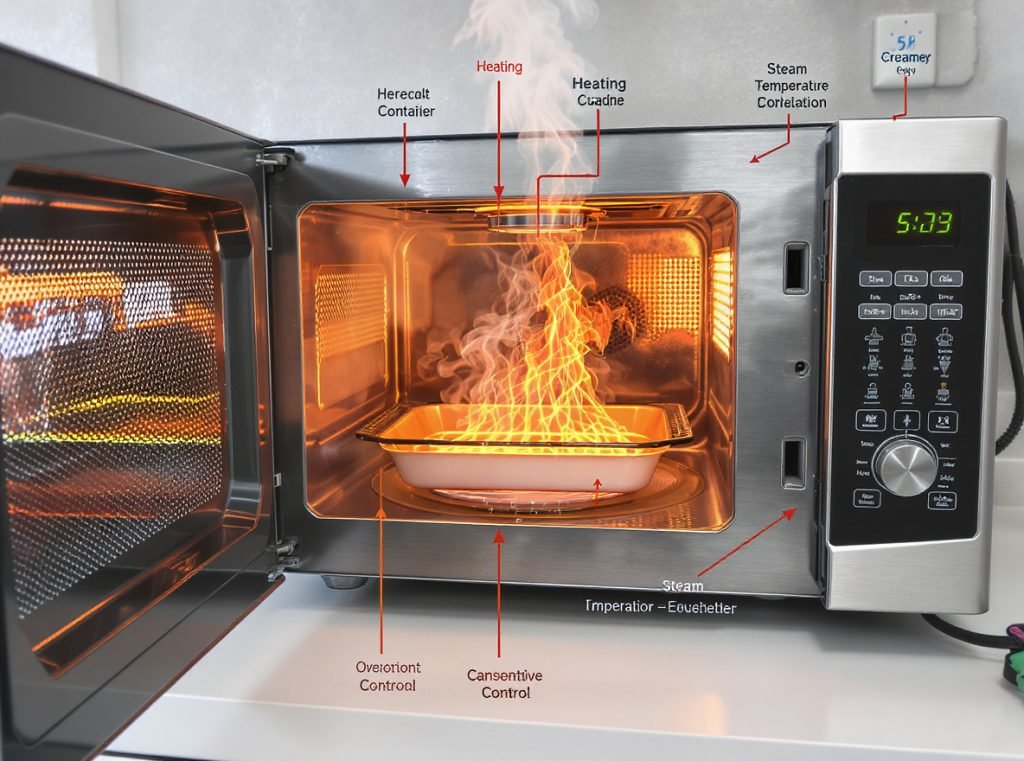

Heating method compatibility determines material selection and structural design requirements. Each heating method creates unique challenges requiring specific solutions.

Microwave-specific design requires materials allowing efficient heat transfer while managing steam buildup. Advanced microwave packaging incorporates steam release valves and metalized elements for heating uniformity, with VSteam technology enabling steam release without package perforation.

Advanced Heating Technologies

Dual-ovenable solutions demand materials like CPET withstanding both microwave and conventional oven temperatures up to 400°F, enabling consumer choice while maintaining food safety and quality through specialized lidding films.

Microwave optimization features:

- Controlled steam venting prevents container deformation

- Strategic perforation placement allows safe steam release

- Rounded corners prevent overheating at edges

- Susceptor films improve browning and crisping

Conventional oven applications utilize CPET or specialized paperboard with susceptor technology. MicroRite susceptor trays manage microwave energy distribution for even heating while reducing cooking time by up to 50% compared to standard materials.

Steam-in-package technologies incorporate specialized valves automatically releasing steam during microwave heating, enabling cooking without package puncturing while offering exceptional customization with various printing options and easy-open features.

What Packaging Formats Maximize Product Appeal?

Format selection impacts consumer experience, product protection, and operational efficiency across different RTE product categories.

Tray configurations dominate the RTE meal market due to versatility and consumer familiarity. Multi-compartment designs prevent flavor migration in complex meals, while three and four-compartment bistro-style trays gained popularity for protein bowls and customizable meals.

Strategic Format Applications

Bowl formats excel for products requiring mixing during consumption, such as grain bowls and Asian-inspired dishes. The curved shape facilitates stirring while deeper profiles accommodate higher liquid content. Pressed paperboard bowls offer sustainable alternatives while maintaining functional performance.

Tray configuration benefits:

- Single-compartment designs for homogeneous products like pasta

- Multi-compartment separation prevents sauce migration

- Stackable designs optimize retail space efficiency

- Premium appearance suggests higher quality

Flexible pouch systems provide excellent space efficiency and barrier properties for higher liquid content products. Stand-up pouches with gussets maximize shelf presence while minimizing material usage, with steam-in-bag technologies transforming flexible packaging into cooking vessels.

Hybrid packaging solutions combine rigid and flexible elements optimizing performance through rigid trays with flexible lidding films providing easy opening, optimal barrier properties, and clear product visibility while allowing independent optimization of container and lid.

How Can Advanced Barrier Technologies Extend Shelf Life?

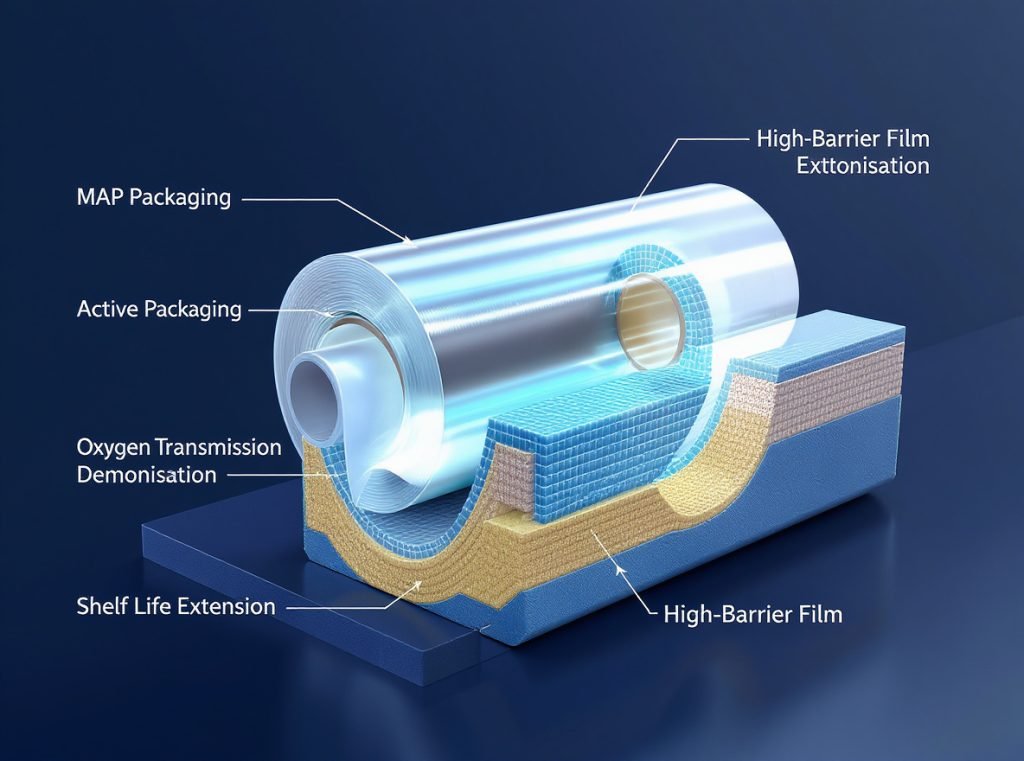

Shelf life extension requires systematic approaches combining appropriate materials, barrier technologies, and environmental protection strategies.

High-barrier film technologies incorporating EVOH (ethylene vinyl alcohol) or nylon barriers provide exceptional oxygen transmission resistance while maintaining flexibility. These multilayer films include specialized layers for UV protection, moisture control, and aroma retention.

Comprehensive Preservation Systems

Modified Atmosphere Packaging (MAP) extends shelf life by replacing package atmosphere with protective gas mixtures, working synergistically with high-barrier films to maintain optimal conditions. Gas mixture selection depends on product characteristics, with higher oxygen barriers critical for preventing oxidative deterioration.

Active packaging technologies:

- Oxygen scavengers actively remove residual oxygen from packages

- Moisture regulators prevent condensation damage

- Ethylene absorbers preserve fresh components

- Temperature indicators monitor cold chain integrity

Oxygen scavenging systems prove particularly effective for products sensitive to oxidation, including those containing fats, vitamins, and natural colors. Active packaging technologies can extend shelf life significantly compared to conventional barrier-only approaches.

| Barrier Technology | Oxygen Transmission Rate | Shelf Life Extension |

|---|---|---|

| Standard PP | 500-800 cc/m²/day | Baseline |

| EVOH Barriers | <1 cc/m²/day | 200-300% improvement |

| Metallized Films | <0.1 cc/m²/day | 400-500% improvement |

What Visual Design Elements Drive Purchase Decisions?

Consumer psychology research reveals specific visual elements significantly influencing purchase intentions for RTE meal packaging.

Color psychology research demonstrates warm colors (reds, oranges, yellows) enhance purchase intent for indulgent comfort meals, while cool colors (blues, greens) better suit healthy foods like salads and lean proteins through perceptual fluency creating positive emotional responses.

Strategic Visual Impact Elements

Material transparency and product visibility directly impact consumer confidence, particularly for fresh and premium products. Clear PET packaging allows quality assessment at purchase, while strategic window placement provides product visibility while maintaining structural integrity.

Appetite-stimulating design strategies:

- High-quality food photography positioned prominently drives emotional engagement

- Clear typography hierarchy prioritizes product identification and heating instructions

- Premium finishes like soft-touch coatings suggest higher quality

- Brand consistency builds recognition and trust

Graphic design must balance appetite appeal with informational clarity, ensuring important information remains accessible while high-quality food photography creates emotional engagement and clear typography maintains information hierarchy.

Packaging shape and form factor influence perceived value and convenience. Rounded corners and ergonomic design suggest premium quality, while stackable rectangular formats optimize retail space. Consumer research shows packaging shape affects taste expectations, with angular designs associated with intense flavors.

How Do You Balance Cost and Performance Effectively?

Effective cost management requires understanding total applied costs rather than focusing solely on material prices.

Material cost analysis reveals polypropylene offers lowest costs at $0.15-0.30 per unit for standard trays, while CPET commands premium pricing at $0.25-0.50 per unit. However, material costs represent only 20-30% of total packaging expenses including processing, logistics, and disposal.

Total Cost Optimization Strategies

Operational efficiency factors significantly impact total packaging costs. Thermoformed trays process faster than alternatives, increasing throughput while reducing labor costs. Nestable designs reduce storage space by up to 25%, while lighter materials decrease transportation costs.

Value engineering approaches:

- Lightweighting strategies reduce material usage without compromising function

- Mono-material designs improve recyclability and reduce sorting complexity

- Strategic material selection based on actual requirements prevents over-engineering

- Volume purchasing agreements achieve significant per-unit savings

Hidden cost components include disposal fees varying significantly by material type. Foam packaging disposal costs average 15-20% higher per ton than recyclable alternatives, with regulatory compliance costs for sustainable packaging potentially qualifying for government incentives.

Processing efficiency gains can offset higher material costs through increased production capacity, while strategic material selection optimizes performance while controlling costs through proper value engineering approaches.

What Environmental Solutions Balance Sustainability and Performance?

Environmental sustainability increasingly drives packaging decisions, requiring balance between performance requirements and ecological impact.

Lifecycle environmental impact assessment reveals packaging represents only 10% of a food product’s total environmental footprint, while preventing food waste accounts for 90%. This emphasizes optimizing packaging for product protection rather than minimizing materials alone.

Comprehensive Sustainability Strategies

Material selection for sustainability involves considerations beyond recyclability. Renewable materials like paperboard and molded fiber offer biodegradability and lower carbon footprints, though barrier coatings affect recyclability, necessitating water-based or repulpable coatings versus plastic laminations.

Circular economy integration focuses on:

- Mono-material designs facilitating recycling by eliminating separation complexity

- Reusable packaging systems for premium product lines reducing per-use impact

- Local material sourcing reducing transportation emissions

- Supply chain optimization maximizing load efficiency

Circular economy integration focuses on designing packaging for multiple lifecycle stages through mono-material designs facilitating recycling, while reusable packaging systems require higher initial investment but significantly reduce per-use environmental impact.

Consumer education and disposal programs enhance sustainability outcomes through clear recycling instructions, material identification symbols, and waste management partnerships. Some companies provide prepaid return programs ensuring proper specialized material processing.

| Sustainability Metric | Traditional Packaging | Optimized Solution | Impact Reduction |

|---|---|---|---|

| Material Weight | 45g average | 32g lightweighted | 29% reduction |

| Carbon Footprint | 0.8 kg CO2e | 0.5 kg CO2e | 38% improvement |

| Recycling Rate | 15% actual | 65% mono-material | 333% increase |

Summary

Effective ready-to-eat meal packaging design balances FDA safety requirements, material performance, heating compatibility, and visual appeal while optimizing costs and sustainability. Focus on comprehensive barrier protection, consumer convenience, and regulatory compliance to create packaging that protects products and drives sales success.

Ready to develop packaging that sets your ready-to-eat meals apart in the competitive marketplace? Contact Acreet today for custom packaging solutions that combine FDA compliance, advanced barrier technologies, and compelling visual design. Our experienced team specializes in RTE meal packaging that maximizes shelf life, ensures heating performance, and creates powerful shelf appeal. Send us your inquiry to discuss your specific requirements and discover how our expertise can optimize your packaging for safety, sustainability, and market success.