Food packaging failures cost the industry billions annually through product returns, brand damage, and regulatory penalties. A single leak can contaminate entire shipments, while grease-resistant failures create negative customer experiences that spread rapidly through social media reviews.

Leak-proof and grease-resistant food packaging requires strategic material selection, advanced barrier technologies, and rigorous testing protocols. Modern solutions combine multi-layer constructions, PFAS-free coatings, and precise manufacturing processes to achieve superior protection while meeting evolving safety regulations.

Understanding these critical requirements helps you avoid costly failures, maintain product integrity, and build lasting customer trust in your food brand.

Table of Contents

ToggleWhat Makes Food Packaging Leak-Proof?

Achieving leak-proof packaging protects your products during transportation while preventing contamination that could harm customers and damage your reputation.

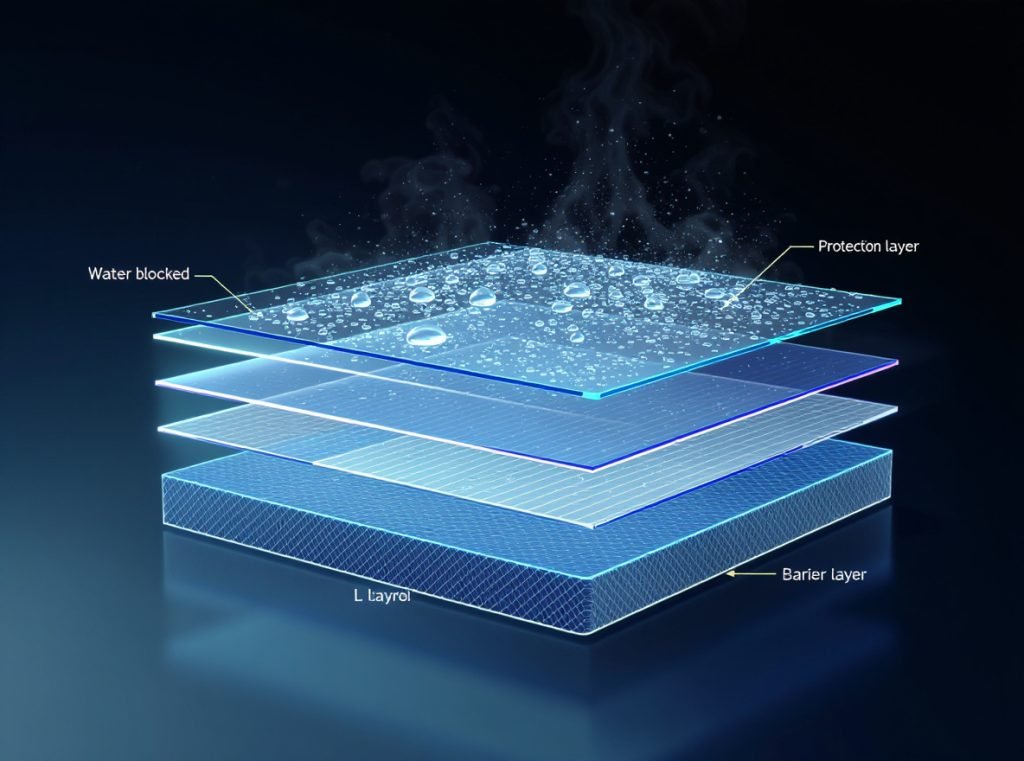

Leak-proof packaging relies on superior barrier materials, precise seal integrity, and multi-layer constructions. High-performance solutions combine 95% polyethylene with 5% EVOH (Ethylene Vinyl Alcohol) for optimal oxygen and moisture barriers, while advanced sealing techniques ensure hermetic closures.

Critical barrier materials provide the foundation for leak-proof performance:

Plastic films offer excellent protective properties. Polyethylene (PE), polypropylene (PP), and polyester create strong moisture and gas barriers when properly applied. These materials can be layered with specialized coatings to enhance protective qualities significantly.

Metal components deliver superior barrier performance. Aluminum foil and laminated forms provide exceptional protection against moisture, oxygen, and light penetration, making them ideal for sensitive food products requiring extended shelf life.

Advanced coating systems enhance barrier properties:

| Material Type | Barrier Performance | Best Applications |

|---|---|---|

| EVOH coatings | Excellent oxygen barrier | Fresh meat, dairy products |

| Silicon oxide | Superior moisture protection | Dry goods, snacks |

| Multi-layer laminates | Complete barrier system | Liquid products, sauces |

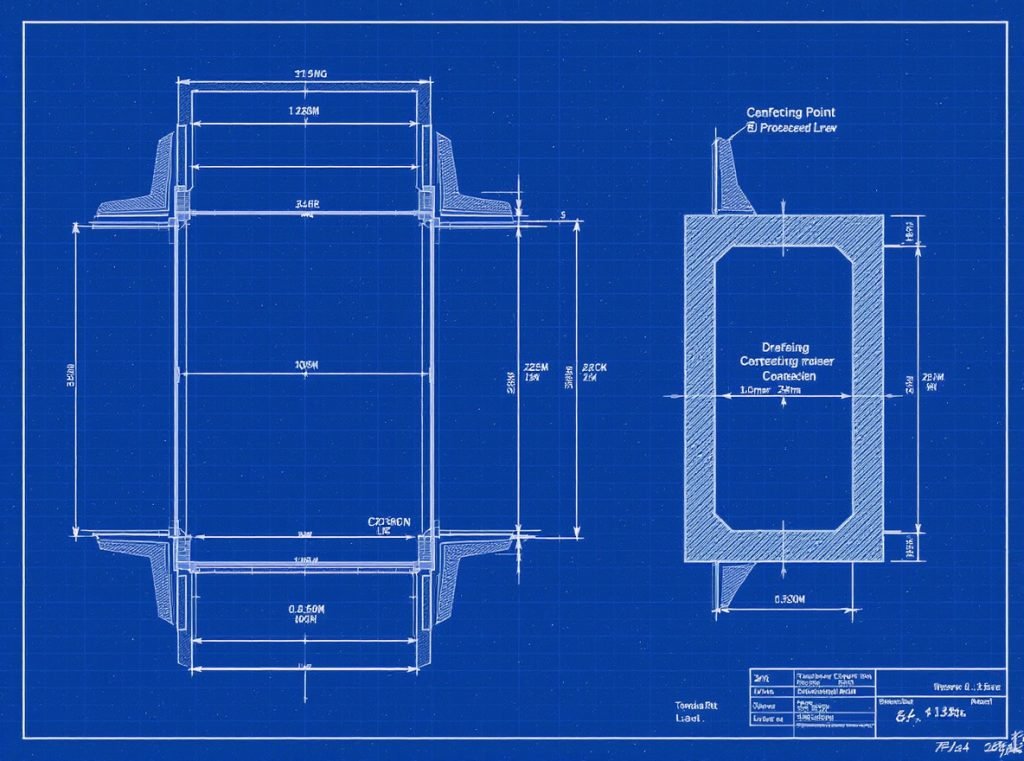

Seal geometry determines long-term performance. Heat seals, zipper locks, and hermetic seals must be designed with proper dimensions and stress distribution to prevent failures during normal use and transportation challenges.

How Do You Choose Grease-Resistant Materials?

Grease resistance prevents oil penetration that weakens packaging structure and creates messy customer experiences with your food products.

Effective grease-resistant materials include styrene-butadiene emulsion polymers, specialized barrier coatings, and multi-level classification systems. Modern solutions provide three-tier performance: standard grease resistance for basic protection, medium resistance for fast-food applications, and high resistance for oil-intensive products.

Understanding grease resistance classifications helps optimize material selection:

Three-tier classification systems guide appropriate choices. Standard grease resistance suits basic oil spill protection, while medium grease resistance enhances protection for fast-food packaging applications. High grease resistance provides strong waterproof and oil-resistant properties for high-fat food items.

Multi-level rating scales offer precise specifications. Grease resistance levels (3, 5, 7, 10, 11) indicate superior oil resistance capabilities, with higher numbers providing enhanced protection but correspondingly higher material costs.

Traditional coating solutions include proven technologies:

- Styrene-butadiene polymers: Applied as thin, lightweight coatings on paper substrates

- Styrene-acrylic emulsions: Provide excellent oil and grease resistance for paperboard

- Polyethylene barriers: Offer good moisture protection with limited grease resistance

Temperature considerations affect material performance. Hot food applications require coatings that maintain integrity under elevated temperatures, while cold storage applications may utilize different barrier technologies for optimal cost-effectiveness.

What Are the Latest PFAS-Free Solutions?

Health concerns and regulatory restrictions have accelerated innovation toward safer grease-resistant alternatives that maintain performance standards while protecting consumer safety.

The global PFAS-free food packaging market is projected to grow from $48 billion in 2025 to $84.96 billion by 2034. Revolutionary bio-based coatings derived from tomato peels, graphene oxide technologies, and modified starch solutions provide comparable performance to traditional synthetic polymers.

Emerging bio-based alternatives offer sustainable performance:

Plant-based coatings utilize renewable resources effectively. Solutions derived from starch, cellulose, alginate, chitosan, and proteins provide sustainable alternatives to synthetic polymers while maintaining necessary barrier properties.

Tomato peel-based innovations represent breakthrough technology. 100% bio-based coatings derived from tomato peels (cutin dispersion) provide water, oil, and grease resistance comparable to synthetic polymers while maintaining essential heat sealability properties.

Advanced technology solutions include cutting-edge developments:

- GO-Eco graphene oxide: Food-safe, biodegradable barriers that are cost-effective and commercially scalable

- Ceramic coatings: Paper treatments providing plastic-equivalent properties without fluorine or harmful chemicals

- HyperBarrier technology: Patented nanocomposite coatings delivering 20x oxygen barrier improvement and 15x moisture barrier enhancement

Modified starch coatings gain market traction. Sources including wheat, tapioca, potato, and corn provide oil and grease resistance comparable to traditional synthetic options while enabling lightweighting and improved recyclability.

How Do You Test Packaging Integrity?

Comprehensive testing protocols verify that your packaging meets leak-proof and grease-resistant specifications before products reach customers.

Modern integrity testing employs non-destructive methods including Vacuum Decay Method (VDM), pressure decay testing, and helium leak detection. These sophisticated techniques detect microscopic leaks without damaging products, allowing tested packages to return to production lines.

Essential non-destructive testing methods include:

Vacuum Decay Method provides reliable leak detection. This technique uses vacuum pressure to identify leaks in sealed containers without product destruction, enabling tested packages to rejoin production workflows while maintaining quality assurance.

Pressure decay testing measures precise leak rates. Packages undergo pressurization followed by pressure monitoring over time, with leak detection occurring when decay rates exceed predetermined thresholds for specific applications.

Specialized food packaging protocols address safety requirements:

- Seal integrity testing: Prevents contamination by bacteria (1 μm cocci or 0.5 μm x 10 μm rod-shaped)

- Helium leak testing: Mass spectrometry detection for extremely high sensitivity applications

- Ultrasonic seal evaluation: Real-time, non-destructive seal quality assessment

- Dye penetration testing: Visual indicators reveal microscopic seal defects

| Test Method | Sensitivity Level | Testing Duration | Cost Effectiveness |

|---|---|---|---|

| Visual inspection | Basic | Minutes | High |

| Vacuum decay | Excellent | Hours | Moderate |

| Helium detection | Superior | Hours | Low |

Quality control integration ensures consistent results. Automated testing equipment evaluates hundreds of packages hourly, providing statistical data supporting continuous improvement initiatives throughout manufacturing operations.

What Design Features Enhance Protection?

Strategic design elements maximize leak-proof and grease-resistant performance while maintaining functionality and customer appeal.

Effective protective design incorporates multi-layer architecture, optimized material thickness, reinforced stress points, and heat-sealable properties. Bagasse packaging utilizes cellulose (50%) for strength, hemicellulose (25-35%) for water resistance, and lignin (18-24%) for structural rigidity.

Multi-layer architecture provides comprehensive protection:

Advanced barrier combinations deliver superior performance. Multi-layer structures combine different materials with complementary properties, creating packaging systems that exceed single-material capabilities while optimizing cost-effectiveness.

Material thickness optimization balances protection and flexibility. Thicker materials enhance durability and grease resistance but may sacrifice necessary flexibility for efficient packaging design and consumer handling.

Critical structural considerations include:

- Reinforced stress points: Areas subject to handling stress require additional material support

- Heat sealability: Modern barrier coatings maintain heat-sealing properties for secure closures

- Temperature resistance: Materials must withstand up to 450°F (230°C) without degradation

- Flexibility maintenance: Substantial barrier properties must preserve packaging flexibility

Functional design elements enhance user experience. Proper seal geometry ensures tight closures preventing leaks, while ergonomic considerations enable easy opening and resealing without compromising seal integrity during consumer use.

How Do Manufacturing Processes Affect Quality?

Production methods significantly impact the leak-proof and grease-resistant properties of finished packaging products.

Manufacturing quality control requires precise temperature management, consistent coating application, and automated inspection systems. HyperBarrier coatings apply in layer thicknesses from 15 to 75 microns, while Overall Equipment Effectiveness (OEE) optimization reduces machine failures and lengthy changeovers.

Temperature control affects coating performance fundamentally:

Heat sealing processes require exact temperature management. Different materials demand specific temperature ranges for proper bonding, while coating applications need precise cure temperatures to achieve proper barrier formation.

Process monitoring prevents quality deviations. Routine inspections during material preparation, printing, assembly, and sealing stages identify errors early, reducing waste and ensuring consistent product performance.

Critical manufacturing variables include:

- Coating thickness uniformity: Barrier coatings require precise application for consistent performance

- Material handling protocols: Proper storage prevents contamination and degradation

- Environmental condition control: Humidity and temperature stability maintain processing consistency

- Process validation procedures: Manufacturing processes require validation for specification compliance

Automated systems improve consistency significantly. Implementation of automated inspection systems reduces human error while improving quality control consistency, enabling high-speed production without compromising product integrity.

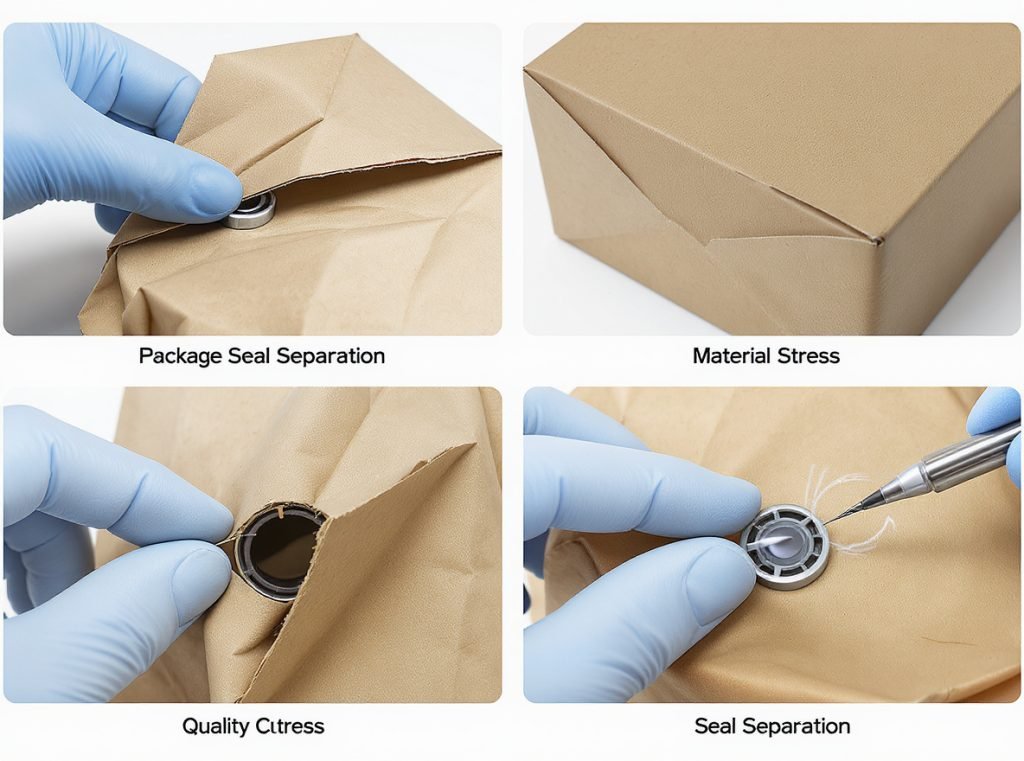

What Are Common Packaging Failure Points?

Understanding typical failure locations helps implement preventive measures that protect product integrity and customer satisfaction.

Most packaging failures occur at seal areas (inadequate sealing), material defects (poor selection or storage), and contamination issues (substance migration). Physical damage including crushed boxes and torn packaging results from insufficient material strength or improper handling procedures.

Primary failure modes require targeted solutions:

Seal failures represent the most critical vulnerability. Inadequate sealing leads to moisture exposure, dust contamination, and product compromise, particularly affecting food and pharmaceutical applications where sterility is essential.

Material defects stem from multiple sources. Poor material selection, incompatible raw materials, or improper storage conditions lead to packaging failure, while quality control deficiencies create uneven seal strength and contamination risks.

Environmental factors contribute to failure:

| Failure Type | Primary Cause | Prevention Strategy |

|---|---|---|

| Seal separation | Inadequate heat/pressure | Process optimization |

| Material cracking | Temperature stress | Material selection |

| Contamination | Migration issues | Barrier enhancement |

Physical damage occurs during transportation and storage. Packages must withstand handling vibration, temperature variations, and unexpected logistics stresses that exceed original design parameters.

Quality control deficiencies create systematic problems. Uneven seal strength, incorrect labeling, foreign object presence, and inadequate inspection systems failing at high production rates compromise product safety and brand reputation.

How Do You Work with Packaging Manufacturers?

Successful collaboration with packaging suppliers ensures you receive products meeting your specific leak-proof and grease-resistant requirements.

Effective manufacturer partnerships require certification verification (SQF Food Safety Code, ISO 9001:2015, HACCP compliance), clear material specifications, and comprehensive documentation systems. Technical collaboration enables understanding of specific requirements while establishing continuous improvement processes.

Establishing quality standards guides supplier selection:

Certification requirements demonstrate manufacturer capabilities. Look for suppliers certified under recognized standards including SQF Food Safety Code, ISO 9001:2015, and HACCP compliance, ensuring systematic quality management approaches.

Material specifications require detailed documentation. Establish clear quality requirements for strength, durability, dimensions, barrier properties, and visual appearance to guide manufacturer recommendations and ensure accurate project quotations.

Collaboration best practices include:

- Technical partnership development: Work closely with manufacturer technical teams for requirement understanding

- Comprehensive material testing: Conduct thorough strength, durability, and suitability testing before production

- Supply chain management: Partner with trusted suppliers maintaining consistent quality and sustainable sourcing

- Regular review processes: Address recurring issues and implement continuous improvements

Regulatory compliance support ensures market acceptance. Manufacturing partners should demonstrate FDA compliance expertise (21 CFR Parts 170-199), Food Contact Notification requirements, international standards familiarity, and comprehensive documentation capabilities.

At Acreet, we specialize in developing custom PFAS-free packaging solutions that meet your exact leak-proof and grease-resistant specifications. Our certified manufacturing facility combines advanced barrier technologies with rigorous quality control systems to deliver packaging that protects your products while supporting your brand reputation. Contact us today to discuss your specific packaging challenges and discover how our technical expertise can ensure your products reach customers in perfect condition.

Summary

Ensuring leak-proof and grease-resistant food packaging requires advanced barrier materials, PFAS-free alternatives, rigorous testing protocols, and strategic manufacturer partnerships. Modern solutions balance performance, sustainability, and regulatory compliance while protecting product integrity throughout the supply chain.

Ready to upgrade your food packaging with cutting-edge solutions? Contact Acreet for custom designs that exceed industry standards and satisfy demanding customers worldwide.