Pet owners are increasingly concerned about the safety of their furry companions’ food, and rightfully so. Your pet food packaging serves as the first line of defense against contamination, moisture, and other harmful elements that could compromise your product’s quality and your customers’ trust.

Pet food packaging must adhere to FDA regulations requiring food-grade materials that are generally recognized as safe (GRAS) or pre-approved for food contact. Essential safety measures include using BPA-free materials, implementing superior barrier protection, and ensuring tamper-evident seals that maintain product integrity throughout the supply chain.

Let’s dive deeper into the essential strategies that will help you create packaging that keeps pets healthy and customers satisfied.

Table of Contents

ToggleWhat Are the FDA Safety Requirements for Pet Food Packaging?

Understanding FDA compliance is crucial because pet food packaging faces the same stringent regulations as human food packaging. The FDA treats packaging materials as “food additives” when substances can potentially transfer from containers to food, making compliance non-negotiable.

Pet food packaging must meet FDA food contact standards, requiring all materials to be generally recognized as safe (GRAS) or pre-approved for food contact, with contamination prevention measures that block bacteria, chemicals, dust, and harmful substances from entering the product.

The regulatory framework demands comprehensive safety measures. All packaging components must maintain their integrity across expected storage and transport temperature ranges while preventing any substance migration into the food product.

Key FDA compliance requirements include:

• Food-grade material certification for all packaging components

• Temperature resistance across storage and transport ranges

• Contamination prevention through proper barrier selection

• Documentation proving GRAS status or FDA pre-approval

• Traceability systems enabling rapid response to safety issues

FDA regulations also require manufacturers to maintain detailed records of all packaging materials used, including supplier certifications and testing results. This documentation becomes critical during regulatory inspections or potential recalls.

| Regulatory Requirement | Compliance Standard | Documentation Needed |

|---|---|---|

| Food Contact Approval | GRAS or FDA pre-approved | Supplier certificates |

| Material Safety | No harmful substance migration | Migration testing results |

| Temperature Stability | Function across expected ranges | Thermal stability data |

| Contamination Prevention | Effective barrier properties | Barrier testing verification |

Which Barrier Materials Provide Superior Protection for Pet Food?

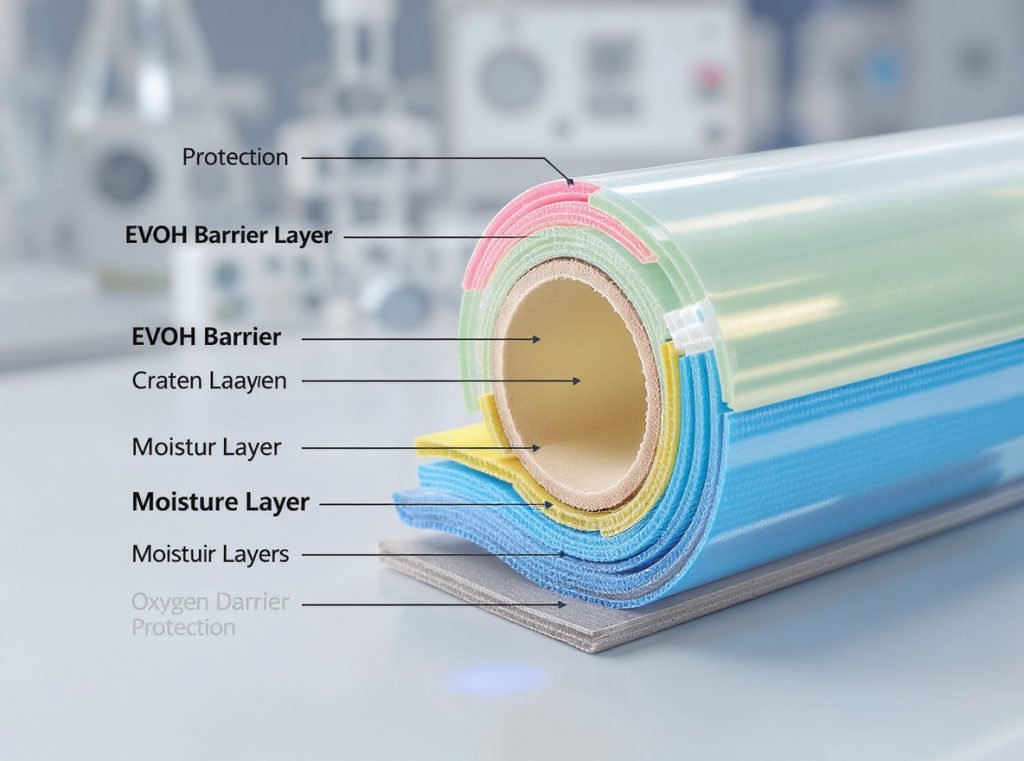

Effective barrier protection prevents the three primary causes of pet food degradation: oxygen exposure, moisture infiltration, and light penetration. Multi-layer constructions combining complementary materials deliver optimal protection while maintaining package integrity.

EVOH (Ethylene Vinyl Alcohol) provides exceptional oxygen barrier properties with superior flex crack resistance, while aluminum foil offers comprehensive protection against light, moisture, and temperature fluctuations. Multi-layer laminates like PET/EVOH/PE create synergistic barrier effects for maximum product protection.

EVOH significantly outperforms traditional barrier materials in preventing oxidation that leads to rancidity and nutrient loss. Unlike metallized films that can develop micro-cracks, EVOH maintains barrier integrity even under repeated flexing during handling and transport.

The PET/AL/PE structure (polyethylene terephthalate/aluminum/polyethylene) represents the gold standard for premium pet food protection. This combination delivers comprehensive barrier properties while maintaining structural integrity throughout the product lifecycle.

Top-performing barrier solutions include:

Superior Oxygen Barriers:

- EVOH films with exceptional oxygen transmission rates

- Multi-layer EVOH constructions for extended shelf life

- Controlled atmosphere packaging with nitrogen flushing

Comprehensive Protection Systems:

- PET/AL/PE laminates for premium products

- Metallized PET films with enhanced tear resistance

- Multi-layer combinations like PET/EVOH/PE or PET/Nylon/PE

| Barrier Material | Oxygen Protection | Moisture Resistance | Light Protection | Flex Crack Resistance |

|---|---|---|---|---|

| EVOH | Excellent | Good | Poor | Excellent |

| Aluminum Foil | Excellent | Excellent | Excellent | Poor |

| Metallized PET | Very Good | Good | Very Good | Good |

| Multi-layer Laminates | Excellent | Excellent | Excellent | Very Good |

How Do You Select Safe BPA-Free Materials for Pet Food?

Consumer awareness of BPA health risks has driven demand for safer alternatives, with studies showing 81% of tested dog food cans contained BPA traces. Several proven alternatives deliver equivalent performance without chemical exposure risks for pets or their owners.

Polypropylene (PP) offers excellent chemical resistance and food safety certification while remaining fully recyclable. Mylar (Metallized PET) contains no BPA or BPS chemicals while providing superior barrier protection, and EVOH-based structures eliminate petroleum-based chemical concerns entirely.

The shift toward BPA-free materials reflects growing health consciousness among pet owners who want the same safety standards for their pets as for their families. Manufacturers must balance safety requirements with performance needs and cost considerations.

Polypropylene provides durability without BPA-related health concerns, offering excellent chemical resistance and moisture barriers. This material maintains its properties across temperature ranges while meeting all FDA food contact requirements.

Proven BPA-free alternatives include:

Synthetic Options:

- Polypropylene (PP) with excellent chemical resistance

- Mylar (Metallized PET) with no BPA or BPS content

- EVOH-based structures for barrier excellence

- PET materials with verified BPA-free certification

Natural Alternatives:

- Bio-based materials from corn or sugarcane sources

- Plant-derived packaging with reduced environmental impact

- Sustainable alternatives maintaining performance standards

When selecting BPA-free materials, verify certifications from suppliers and conduct migration testing to ensure no harmful substances transfer to food products. Third-party testing provides additional assurance of material safety.

What Testing Standards Validate Pet Food Package Performance?

Rigorous testing protocols ensure your packaging maintains seal integrity, barrier performance, and overall durability throughout the product lifecycle. Industry-standard test methods provide quantitative data for quality assurance and regulatory compliance.

ASTM D3078 (Bubble Emission Test) detects package leaks through vacuum bubble testing, while ASTM F88 measures seal strength and ASTM D6653 evaluates performance under altitude variations. Barrier testing methods like ASTM D3985 verify oxygen transmission rates for shelf life validation.

The ASTM D3078 bubble emission test identifies micro-holes that could compromise product safety through non-destructive testing methods. This approach maintains product salability while verifying hermetic seal integrity.

ASTM F88 seal strength testing determines the force required to separate sealed materials, ensuring packages withstand handling and transportation stresses. Regular testing during production prevents field failures from weak seals.

Critical testing protocols include:

Seal Integrity Testing:

- ASTM D3078 for leak detection through bubble emission

- ASTM F1140 for internal pressure burst validation

- Quantitative leak detection providing precise measurements

- Non-destructive testing maintaining product salability

Barrier Performance Verification:

- ASTM D3985 for oxygen transmission rate measurement

- ASTM F1249 for water vapor transmission testing

- Environmental simulation through accelerated aging

- Temperature cycling to validate thermal stability

| Test Standard | Purpose | Test Duration | Critical Parameters |

|---|---|---|---|

| ASTM D3078 | Leak detection | 15-30 minutes | Bubble emission presence |

| ASTM F88 | Seal strength | 5-10 minutes | Force required for separation |

| ASTM D3985 | Oxygen transmission | 24-48 hours | Transmission rate measurement |

| ASTM D6653 | Altitude performance | Variable | Package integrity under pressure |

How Can You Achieve Optimal Seal Integrity and Tamper Evidence?

Proper sealing protects pet food from contamination while tamper-evident features provide consumer confidence and regulatory compliance. Heat seal validation combined with advanced detection systems ensures consistent quality throughout production.

Heat seal validation ensures thermoplastic surfaces bond properly without compromising barrier properties, while tamper-evident solutions like glued tabs with perforations, color-change indicators, and tear strips provide visible evidence of package integrity.

Quantitative leak detection systems provide precise measurements rather than simple pass/fail results, enabling process optimization and quality improvement. Advanced systems can detect extremely small leaks that might compromise product safety over time.

Heat sealing requires precise control of temperature, pressure, and dwell time for each material combination. Regular calibration of sealing equipment ensures consistent results across production runs.

Seal integrity validation methods:

Heat Seal Optimization:

- Temperature and pressure calibration for each material

- Dwell time optimization preventing barrier damage

- Regular equipment maintenance ensuring consistent performance

- Statistical process control monitoring seal strength variations

Advanced Detection Systems:

- Quantitative leak detection with precise measurements

- Non-destructive testing methods preserving product value

- Automated inspection systems reducing human error

- Real-time monitoring enabling immediate process adjustments

Proven tamper-evident features include glued tabs with perforations that create visible evidence of opening attempts, color-change indicators using materials that alter when packaging is breached, and structural tear strips that cannot be resealed invisibly.

What Design Elements Maximize Package Durability?

Durability encompasses both physical strength and barrier maintenance throughout the product’s shelf life. Strategic material selection and structural engineering distribute stress effectively while maintaining protective properties under real-world conditions.

Multi-layer construction distributes stress across materials preventing single-point failures, while nylon and polyamide layers provide puncture resistance against sharp objects. Box-bottom pouches and gusseted designs distribute weight effectively, reducing stress concentration points.

EVOH films demonstrate superior flex crack resistance compared to alternatives, maintaining barrier integrity even under repeated bending during handling and transport. This flexibility becomes critical in flexible packaging applications where materials must withstand consumer use.

Structural reinforcement through strategic design prevents common failure modes. Gusseted bottoms provide stability while distributing weight across the package base, while reinforced seams handle stress concentrations at critical points.

Durability-enhancing design features:

Structural Engineering:

- Multi-layer construction for stress distribution

- Box-bottom pouches reducing stress concentration

- Gusseted designs improving weight distribution

- Reinforced seams at critical stress points

Material Selection:

- Nylon layers providing puncture resistance

- EVOH films with superior flex crack resistance

- Polyamide materials handling rough transportation

- Strategic thickness variations optimizing protection

| Design Element | Durability Benefit | Material Options | Cost Impact |

|---|---|---|---|

| Multi-layer Construction | Stress distribution | PET/EVOH/PE, PET/Nylon/PE | Moderate increase |

| Puncture Resistance | Sharp object protection | Nylon, Polyamide layers | Low to moderate |

| Flex Resistance | Handling durability | EVOH, specialized films | Moderate increase |

| Structural Reinforcement | Weight distribution | Gussets, box bottoms | Low increase |

How Do Environmental Factors Impact Package Performance?

Pet food packaging must maintain integrity across diverse environmental conditions, from warehouse storage to consumer homes. Temperature fluctuations, humidity variations, and UV exposure all contribute to package degradation requiring careful material selection and design considerations.

Effective environmental protection requires temperature-resistant materials functioning between freezing and elevated storage temperatures, moisture barriers preventing mold growth, and UV-blocking materials preventing vitamin degradation and nutritional value loss.

Temperature cycling causes expansion and contraction of packaging materials, creating repeated stress that can weaken seals and develop micro-cracks compromising barrier properties. Materials must resist thermal cycling without losing protective capabilities.

Humidity control becomes increasingly important in high-humidity environments where moisture infiltration can promote bacterial growth and compromise product safety. Effective moisture barriers maintain product quality while preventing package degradation.

Environmental protection strategies:

Temperature Management:

- Material selection based on expected temperature ranges

- Thermal cycling resistance preventing seal failure

- Storage condition optimization reducing stress

- Climate-controlled facilities where feasible

Moisture and Light Protection:

- Humidity-resistant barriers preventing infiltration

- UV-blocking materials protecting nutrients

- Aluminum foil and metallized films for comprehensive protection

- Controlled atmosphere packaging extending shelf life

Oxygen exclusion through nitrogen flushing or vacuum sealing extends shelf life significantly while protecting against rancidity and nutrient degradation. These techniques become particularly important for premium products with extended distribution cycles.

What Quality Control Measures Prevent Packaging Failures?

Comprehensive quality control programs prevent costly package failures through systematic monitoring and testing protocols. Early detection of quality issues protects brand reputation while ensuring regulatory compliance and customer satisfaction.

Essential quality control includes incoming material inspection with barrier property verification, in-process monitoring through regular seal strength testing, finished product integrity verification, and environmental simulation through accelerated aging tests predicting long-term performance.

Statistical sampling ensures consistent quality without disrupting production flow, while automated inspection systems reduce human error and provide real-time feedback for process adjustments.

Documentation systems enable complete traceability from raw materials through finished products, facilitating rapid response to quality issues and supporting regulatory compliance requirements.

Quality control implementation:

Pre-Production Controls:

- Incoming material testing including barrier verification

- Supplier certification review and approval

- Contamination screening for all components

- Equipment calibration and maintenance verification

Production Monitoring:

- Regular seal strength testing during production

- Visual inspections for defects and inconsistencies

- Statistical process control identifying trends

- Automated systems providing real-time feedback

Post-Production Validation:

- Finished product integrity testing before distribution

- Accelerated aging studies validating shelf life claims

- Environmental simulation identifying failure modes

- Mock recall exercises testing response procedures

| Quality Stage | Testing Frequency | Key Parameters | Documentation Required |

|---|---|---|---|

| Incoming Materials | Every lot | Specifications, certificates | Material compliance records |

| Production | Continuous sampling | Seal strength, dimensions | Process control charts |

| Finished Product | Statistical sampling | Integrity, appearance | Quality release certificates |

| Long-term Performance | Periodic studies | Shelf life validation | Accelerated aging reports |

How Can Custom Packaging Solutions Meet Specific Requirements?

Modern pet food brands require flexible packaging solutions accommodating diverse product types, market segments, and distribution channels. Custom solutions optimize performance while meeting specific regulatory requirements and consumer expectations.

Custom packaging solutions include size flexibility from single-serve pouches to bulk family packages, barrier optimization tailored to specific product requirements, convenience features like resealable closures, and sustainable alternatives meeting environmental expectations without compromising performance.

AAFCO labeling requirements and FDA safety standards vary by product type and market, requiring custom solutions ensuring compliance while maintaining brand consistency. Regulatory expertise becomes essential when developing packaging for multiple markets.

Premium positioning through high-definition printing, textured surfaces, and specialty finishes communicates quality while justifying higher price points. These aesthetic enhancements must be balanced against functional requirements and cost considerations.

At Acreet, we specialize in developing custom packaging solutions meeting the unique requirements of international pet food brands. Our expertise in global regulatory requirements ensures your packaging performs reliably across diverse markets and distribution channels.

Custom solution categories:

Product-Specific Optimization:

- Barrier selection optimized for product characteristics

- Size ranges serving different market segments

- Material compatibility with existing production equipment

- Shelf life optimization through advanced barrier technology

Market Differentiation:

- Unique structural designs creating shelf impact

- Custom printing and graphics reinforcing brand identity

- Premium materials justifying price positioning

- Sustainable options appealing to environmentally conscious consumers

Regulatory Compliance:

- FDA safety standard compliance for US markets

- International regulatory requirement navigation

- AAFCO labeling requirement adherence

- Documentation supporting global distribution

Whether you need moisture-resistant bags for dry kibble, high-barrier pouches for wet food, or sustainable packaging appealing to environmentally conscious consumers, our custom solutions ensure optimal performance while meeting budget and timeline requirements.

Our packaging engineers work closely with pet food manufacturers developing solutions exceeding safety requirements while meeting cost constraints. Contact Acreet today to discuss your specific packaging requirements and learn how our custom solutions can enhance your product’s market success.

Summary

Safe and durable pet food packaging requires FDA-compliant materials, superior barrier protection, rigorous testing protocols, and comprehensive quality control measures. Success depends on choosing appropriate materials like EVOH and BPA-free alternatives, implementing proven testing standards, and working with experienced packaging manufacturers who understand regulatory requirements and market demands.

Ready to enhance your pet food packaging performance? Contact Acreet today for a consultation on custom packaging solutions prioritizing safety, durability, and market appeal. Our experienced team navigates complex regulatory requirements while creating packaging that protects your products and strengthens your competitive position in the global pet food market.