You’re ready to source products from China, but the thought of placing a massive order without seeing the actual product keeps you up at night. What if the quality doesn’t match your expectations? What if the materials feel cheap or the colors are completely wrong?

Getting samples from Chinese manufacturers is a critical risk mitigation strategy that protects you from costly mistakes. Most suppliers offer samples for $50-$500 plus shipping costs, taking 7-15 days to produce and deliver. Simply contact manufacturers directly through B2B platforms, request specific samples with detailed requirements, and pay via secure payment methods before committing to bulk orders.

Let’s dive deeper into the complete process that will save you thousands of dollars and countless headaches.

Table of Contents

ToggleWhy Should You Always Request Samples Before Bulk Orders?

You might think samples are just an extra step that delays your business launch. However, skipping samples is like buying a car without a test drive – it’s a recipe for disaster.

Samples serve as essential quality assessment tools, verify supplier capabilities, and ensure specification accuracy before you invest in bulk inventory. They’re your insurance policy against receiving substandard products that could damage your brand reputation and cost thousands in returns.

Quality assessment is the primary benefit of sample ordering. Samples allow you to physically inspect materials, workmanship, finish, durability, and overall build quality before committing to large orders. This hands-on evaluation prevents misunderstandings and disappointments with the final product.

Supplier capability verification is equally important. Receiving a sample provides insight into the supplier’s production capabilities, adherence to deadlines, and ability to scale production while maintaining quality. If a manufacturer cannot produce samples that meet your specifications after several revisions, it’s a clear indication they may lack the capacity or ability to follow instructions.

Specification verification ensures the product meets all your detailed requirements including dimensions, material composition, color codes, and performance criteria. This is particularly crucial in industries where precise specifications are critical for product success.

What Types of Samples Can You Request from Chinese Manufacturers?

Understanding different sample types helps you make informed decisions about what to request from suppliers and avoid unnecessary costs.

Chinese manufacturers offer five main sample types: factory samples (existing products), custom/prototype samples ($50-200), production samples (batch samples), counter-samples (based on your references), and “golden samples” (highest quality examples). Choose based on your evaluation needs and budget.

Factory/Manufacturer Samples

These are existing products from the manufacturer’s production line, including previous batch samples and material samples. Factory samples demonstrate the supplier’s general capabilities and quality standards but may not represent their ability to produce customized products. They’re often free or cost minimal shipping fees.

Custom/Prototype Samples

These are made-to-order samples created specifically according to your unique specifications. Custom samples are essential for private label products or when significant modifications are needed from existing designs. They typically cost $50-200 depending on complexity.

Production Samples

Also called batch samples, these are randomly selected from actual mass production runs. Production samples provide the most accurate representation of what you’ll receive in bulk orders and are crucial for final quality verification.

Counter-Samples

These are samples created by manufacturers based on reference products you provide. This is common when you have a competitor’s product that you want to modify or improve upon.

“Golden Samples”

These represent the highest quality a supplier can deliver. Manufacturers often send their best work as samples to impress potential customers, though this may not reflect the average quality of mass production.

| Sample Type | Cost Range | Timeline | Best For |

|---|---|---|---|

| Factory Samples | Free – $50 | 3-7 days | Initial quality assessment |

| Custom/Prototype Samples | $50-200 | 7-15 days | Specific customizations |

| Production Samples | $30-100 | 5-10 days | Final quality verification |

| Counter-Samples | $50-300 | 10-20 days | Product improvements |

| Golden Samples | $100-500 | 15-30 days | Premium quality examples |

How Much Do Samples Cost and Who Pays for Shipping?

Sample costs vary dramatically based on product complexity, but understanding typical pricing helps you budget effectively and avoid surprises.

Sample costs typically range from $50 to thousands of dollars depending on product type and complexity. Samples are consistently more expensive than bulk pricing due to lack of economies of scale and setup costs. Express shipping via DHL, FedEx, or UPS costs $30-100+, and buyers typically pay both sample and shipping costs upfront.

Several factors influence sample pricing:

Mass production advantages don’t apply to single samples, making them inherently more expensive per unit. Additional tooling, molding, or materials may be required for custom samples, increasing costs significantly.

Labor costs for customization add to the base price. Complex products requiring skilled assembly or special processes command higher sample fees.

Supplier screening mechanism plays a role – serious buyers willing to pay for samples demonstrate genuine purchase intent, helping suppliers filter out casual inquiries.

Cost-Saving Strategies

Ask suppliers to quote shipping through their accounts, which is sometimes cheaper than standard rates. Bundle samples from multiple suppliers through consolidation services to reduce individual shipping costs.

Work with sourcing agents who can consolidate samples from different manufacturers. Request samples marked as “no commercial value” to avoid import duties in some countries.

Most reputable suppliers offer sample fee refunds when you place bulk orders. This refund is typically deducted from your purchase order amount, making samples effectively free if you proceed with the supplier.

Which Platforms Are Best for Finding Reliable Sample Suppliers?

Choosing the right platform dramatically affects your sample sourcing success and overall supplier reliability.

Alibaba remains the dominant platform for international buyers, offering comprehensive supplier verification, Trade Assurance protection, and multilingual support. 1688 offers lower prices but requires Mandarin language skills, while Global Sources focuses on specialized industries and higher-quality suppliers.

Alibaba

The most popular platform for international buyers, Alibaba offers verified suppliers, trade assurance, and built-in communication tools. Look for Gold Suppliers and Trade Assurance badges when selecting manufacturers. The platform provides verified suppliers with strong track records and established quality standards.

1688

This is Alibaba’s domestic Chinese platform offering lower prices but requiring Mandarin language skills. It’s ideal for buyers with Chinese language capabilities or local agents. Prices are often 20-30% lower than Alibaba, but communication barriers can be significant.

Global Sources

This platform focuses on specialized industries and higher-quality suppliers, making it suitable for buyers seeking premium products. They offer more detailed supplier information and stronger verification processes, particularly good for electronics and industrial products.

Made-in-China

Another reliable platform with good supplier selection and verification processes. They offer sample services and have established quality control measures.

When evaluating suppliers on these platforms, check for:

- Verified supplier status and certifications

- Positive customer reviews and ratings

- Response time to inquiries

- Years in business and transaction history

- Product certifications and compliance documents

How Do You Request Samples Professionally?

Your sample request sets the tone for your entire supplier relationship, so professionalism and clarity are crucial for success.

Contact suppliers directly through platform messaging with specific product details, quantity requirements, customization needs, and shipping address. Include your business information, target market, and expected order volumes to establish credibility and serious buyer status.

Professional Email Structure

Start with a clear subject line like “Sample Request for [Product Name] – Bulk Order Inquiry.” This immediately communicates your intent and helps suppliers prioritize your message.

Your message should include:

Company Introduction: Brief overview of your business and role to establish credibility.

Product Specifications: Exact dimensions, materials, colors (including Pantone codes when applicable), and any special requirements. The more detailed you are, the more accurate your sample will be.

Business Context: Your intended order volumes and timeline to demonstrate serious purchase intent.

Sample Requirements: Specific sample types needed, quantity, and timeline expectations.

Here’s an optimized sample request template:

“Subject: Sample Request for [Product Name] – Bulk Order Inquiry

Dear [Supplier Name],

I am [Your Name] from [Company Name], and we specialize in [business type] for the [target market] market.

We are interested in sourcing [product type] and would like to request samples with the following specifications:

- [Detailed dimensions and materials]

- [Color requirements with Pantone codes]

- [Finish and customization requirements]

- [Quantity needed for evaluation]

We are planning to place bulk orders of [quantity] units monthly if the samples meet our quality standards. Could you please provide:

- Sample cost and shipping fees

- Production timeline for samples

- MOQ requirements for bulk orders

- Bulk pricing structure

- Sample refund policy

Please confirm sample availability and expected delivery time to [Your Address].

We look forward to establishing a long-term partnership.

Best regards,

[Your Name]

[Title]

[Company Name]

[Contact Information]”

Communication Best Practices

Be specific and detailed in your requirements to avoid misunderstandings. Request photos and videos before ordering samples to ensure alignment.

Ask for detailed cost breakdowns including shipping to avoid surprise charges. Establish clear timelines for sample delivery and maintain professional tone throughout communications.

What Should You Do When Samples Arrive?

Receiving samples is exciting, but systematic evaluation ensures you make informed decisions about bulk orders and supplier capabilities.

Conduct comprehensive inspection across multiple dimensions: physical inspection against specifications, documentation review, and performance testing. Document everything with photos and notes for future reference and supplier communication.

Comprehensive Inspection Checklist

Physical Inspection:

Compare against your specifications exactly, checking dimensions, materials, and finish quality. Test functionality and performance under intended use conditions. Assess workmanship and consistency across all sample elements.

Documentation Review:

Verify packaging and labeling accuracy against your requirements. Check certifications and compliance documents for completeness. Confirm product markings and branding meet your standards.

Testing Protocol:

Conduct stress tests for durability and longevity. Test performance under intended use conditions and environmental factors. Verify safety standards compliance and regulatory requirements.

Create a detailed evaluation scorecard:

- Visual appearance and finish quality (25%)

- Dimensional accuracy and specifications (25%)

- Material quality and durability (20%)

- Functionality and performance (20%)

- Documentation and compliance (10%)

Red Flags to Watch For

Samples that don’t match specifications exactly indicate potential quality control issues. Poor communication from suppliers during the process suggests future problems.

Inability to provide requested modifications shows limited manufacturing capabilities. Inconsistent quality between multiple samples raises concerns about production consistency.

Missing certifications or compliance documents indicate potential regulatory issues. Address these concerns immediately or consider alternative suppliers.

How Do You Negotiate Sample Refunds and Bulk Order Terms?

Smart negotiation during the sample phase sets you up for better bulk order terms and stronger supplier relationships.

Establish sample refund terms upfront by confirming sample fees will be deducted from bulk orders. Most experienced suppliers agree to this arrangement as standard practice. Use successful sample evaluation as leverage for better pricing, improved payment terms, and quality guarantees.

Sample Refund Negotiation Strategies

Request sample fee waivers for serious bulk inquiries with specific volume commitments. Negotiate reduced sample costs for multiple product evaluations from the same supplier.

Propose volume commitments in exchange for free samples, demonstrating your serious purchase intent. Get refund agreements in writing before paying for samples.

Bulk Order Term Negotiations

Use successful sample evaluation as leverage for:

Better pricing on bulk orders by demonstrating sample satisfaction. Improved payment terms and conditions based on proven supplier performance.

Quality guarantees based on approved sample standards as your quality benchmark. Delivery timeline commitments with penalties for delays.

Establish clear quality standards based on approved samples. State explicitly that bulk orders must match approved sample quality exactly, with remedies for non-compliance.

What Are the Common Mistakes to Avoid When Ordering Samples?

Learning from others’ mistakes saves you time, money, and frustration in your sample ordering journey.

Avoid requesting free samples too casually, ordering samples with full customization initially, assuming sample quality equals production quality, and failing to communicate specific requirements clearly. Start with basic samples from 3-5 suppliers maximum and be extremely specific about your needs.

Critical Errors in Sample Ordering

Requesting free samples too casually can damage supplier relationships and indicate you’re not a serious buyer. Suppliers may perceive this as unprofessional or assume you’re collecting samples without purchase intent.

Ordering samples with full customization initially is expensive and unnecessary. Start with basic samples to assess quality, then move to customized versions for serious candidates.

Assuming sample quality equals production quality is a dangerous misconception. Samples often represent the supplier’s best work, not average production quality. Always request production samples for final verification.

Failing to communicate specific requirements clearly leads to unsuitable samples and wasted time. Provide detailed specifications, drawings, and reference materials upfront.

Not ordering from multiple suppliers limits your options and comparison ability. Order samples from 3-5 suppliers to ensure adequate evaluation and backup options.

Shipping and Logistics Mistakes

Not consolidating samples from multiple suppliers increases shipping costs significantly. Work with agents or consolidation services to reduce expenses.

Ignoring customs regulations can result in unexpected fees and delays. Research import requirements for your country beforehand.

Not confirming shipping costs upfront can lead to budget overruns. Always get complete cost breakdowns before ordering.

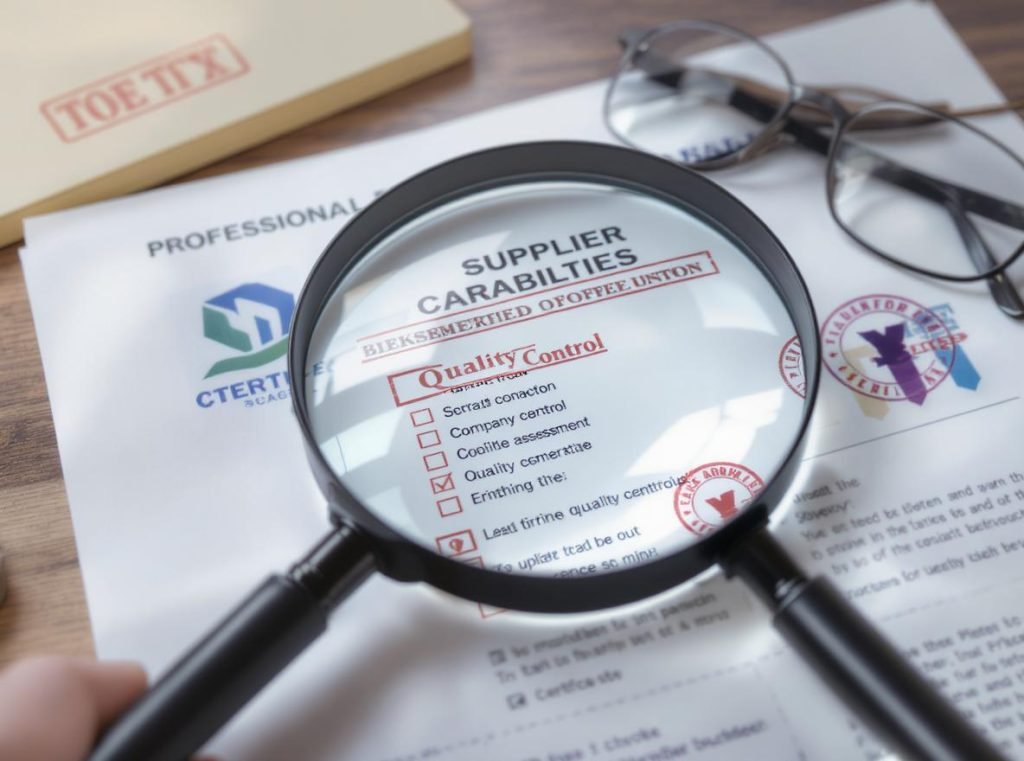

How Do You Use Samples to Verify Supplier Capabilities?

Samples reveal much more than product quality – they’re comprehensive windows into supplier capabilities and reliability.

Evaluate technical capabilities (engineering expertise, production sophistication, quality control systems), operational capabilities (communication responsiveness, timeline adherence, flexibility), and use systematic assessment with standardized criteria to compare suppliers objectively.

Capability Assessment Framework

Technical Capabilities:

Engineering expertise and problem-solving abilities become evident through sample quality and customization accuracy. Production process sophistication shows in finish quality and attention to detail.

Quality control systems effectiveness is demonstrated through consistency and specification adherence. Scalability for volume production can be assessed through sample complexity and turnaround time.

Operational Capabilities:

Communication responsiveness and clarity during the sample process predict future interactions. Timeline adherence and project management skills are revealed through delivery performance.

Flexibility for modifications and customizations shows supplier adaptability. Documentation and compliance procedures indicate professionalism and regulatory awareness.

Evaluation Methodology

Systematic assessment using standardized criteria helps compare suppliers objectively. Create scoring systems that weight factors according to your priorities and business needs.

Multiple sample rounds may be necessary to fully evaluate capabilities. Don’t hesitate to request revisions or additional samples if initial results are unsatisfactory.

Reference checks with other customers provide additional validation of supplier capabilities. Request customer testimonials or references from suppliers for comprehensive evaluation.

Use this comprehensive supplier evaluation scorecard:

- Technical capabilities and quality (40%)

- Communication and responsiveness (20%)

- Timeline adherence and reliability (20%)

- Problem-solving and flexibility (15%)

- Documentation and compliance (5%)

Suppliers scoring above 80% deserve serious consideration for bulk orders.

Summary

Getting samples from Chinese manufacturers is your critical risk mitigation strategy before committing to bulk orders. Request specific samples based on your needs, evaluate them systematically across multiple dimensions, and use the process to verify supplier capabilities comprehensively. This strategic investment prevents costly mistakes and builds stronger supplier relationships.

Ready to start your sample ordering journey with confidence? Contact Acreet today for professional packaging samples that showcase our quality and capabilities. Our experienced team will guide you through the entire process, from sample evaluation to bulk order success. Send us your detailed requirements, and let’s create custom packaging solutions that elevate your brand and exceed your expectations!