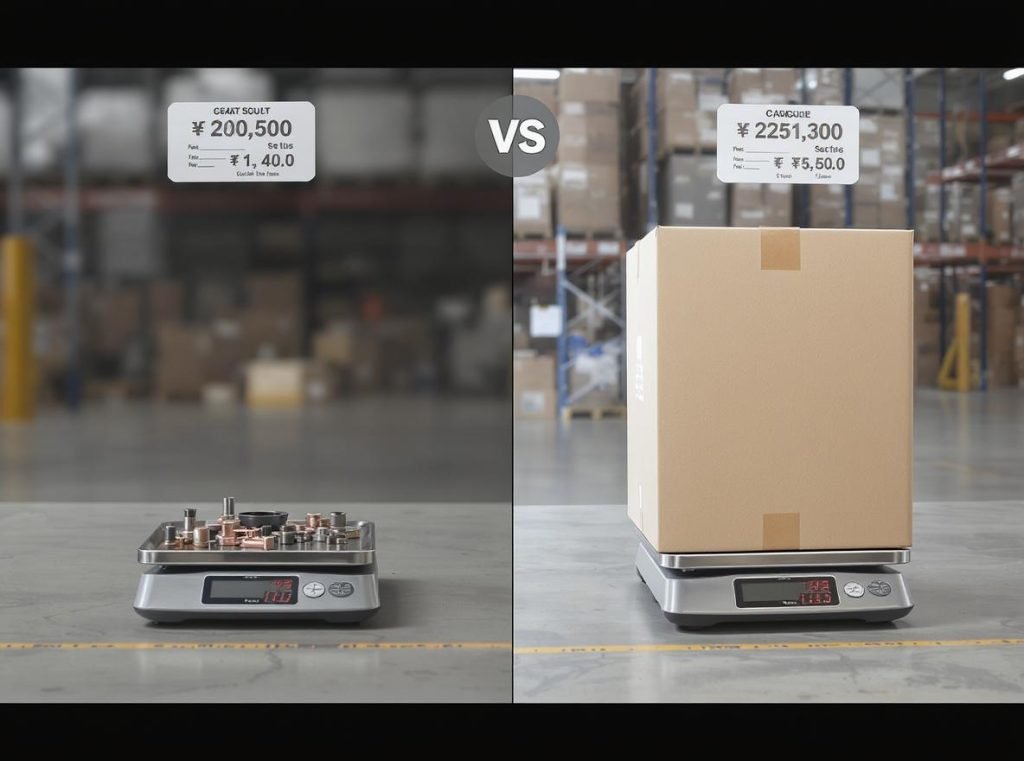

Shipping costs are eating into your profits, but you’re not sure why your lightweight packages cost so much to ship. The culprit is often dimensional weight pricing, which can increase your shipping expenses by 20-40% if not properly managed.

Dimensional weight (DIM weight) is calculated by multiplying a cardboard box’s length, width, and height in inches, then dividing by a carrier-specific divisor. UPS uses 139 for daily rates and 166 for retail rates, FedEx uses 139, and USPS uses 166 for packages exceeding one cubic foot. Carriers charge whichever is higher: dimensional weight or actual weight.

Understanding this calculation can save your business thousands in shipping expenses and help you choose optimal packaging solutions for your products.

Table of Contents

ToggleWhat Is Dimensional Weight and Why Does It Matter for Your Business?

Dimensional weight, also known as volumetric weight or cubed weight, reflects a package’s density by considering the space it occupies relative to its actual weight. This pricing method was introduced because lightweight, bulky packages became unprofitable for carriers when charges were based solely on weight.

Since 2015, major carriers like UPS, FedEx, and USPS use dimensional weight pricing for most shipments, affecting approximately 70% of packages shipped. This fundamental shift makes understanding and optimizing packaging strategies essential for modern businesses.

The financial implications are substantial for your operations:

Studies reveal that the average package contains about 40% wasted space, leading to unnecessary dimensional weight charges. When dimensional weight exceeds actual weight, shipping costs can increase by 20-40% compared to weight-based pricing alone.

For businesses shipping 500+ packages daily, even small dimensional weight increases compound into significant additional expenses. A simple 0.1-inch measurement error that gets rounded up can add $1.43 per package due to dimensional weight increases, creating substantial cost impacts over time.

Understanding dimensional weight helps you make informed decisions about packaging selection, product arrangement, and shipping carrier choices that directly affect your bottom line.

How Do Different Shipping Carriers Calculate Dimensional Weight?

Each major shipping carrier uses different dimensional weight factors, creating varying cost structures that significantly impact your shipping expenses.

UPS operates with two distinct pricing tiers: 139 for daily rates (frequent shippers with accounts) and 166 for retail rates (occasional shippers). FedEx consistently uses 139 for most services, while USPS applies 166 and only charges dimensional weight for packages exceeding one cubic foot.

Comprehensive Carrier Comparison

| Carrier | Service Type | DIM Factor (Imperial) | DIM Factor (Metric) | Volume Threshold |

|---|---|---|---|---|

| UPS | Daily/Commercial Rates | 139 | 5000 | All packages |

| UPS | Retail Rates | 166 | 6000 | All packages |

| FedEx | All Services | 139 | 5000 | All packages |

| USPS | Priority Mail/Ground | 166 | 6000 | >1,728 cubic inches |

| DHL | Express Services | 139 | 5000 | Varies by region |

The calculation formula remains consistent: DIM Weight = (Length × Width × Height) ÷ DIM Factor. However, these varying divisors create significant cost differences for identical packages.

For international shipments, most carriers standardize on 139 as the DIM factor for air freight, while domestic ground shipments may use 166. Express couriers like DHL typically use 5000 for metric calculations, making international shipping calculations more predictable.

Understanding these carrier-specific differences allows you to choose the most cost-effective shipping option for your specific package dimensions and shipping frequency.

What’s the Step-by-Step Process to Calculate Dimensional Weight?

Accurate dimensional weight calculation requires precise measurements and understanding carrier-specific requirements to avoid unexpected charges.

The calculation process involves five critical steps: measure accurately, calculate volume, apply the correct DIM factor, round up to whole pounds, and compare with actual weight to determine billable weight.

Detailed Calculation Steps

Step 1: Measure Package Accurately

Use the longest point on each side of your cardboard box, including any protrusions, bulges, or irregular shapes. Carriers measure outermost dimensions, so handles, protective corners, or tape buildup must be included. Round each measurement to the nearest whole inch.

Step 2: Calculate Total Volume

Multiply all three dimensions: Volume = Length × Width × Height. For example, a box measuring 20″ × 15″ × 10″ equals 3,000 cubic inches.

Step 3: Apply Carrier-Specific DIM Factor

Divide volume by your carrier’s dimensional factor:

- FedEx/UPS daily rates: 3,000 ÷ 139 = 21.6 pounds

- USPS/UPS retail rates: 3,000 ÷ 166 = 18.1 pounds

Step 4: Round Up to Whole Pounds

Always round up to the nearest whole pound. In our example, 21.6 becomes 22 pounds, and 18.1 becomes 19 pounds.

Step 5: Determine Billable Weight

The billable weight is whichever is higher: dimensional weight or actual package weight. If your 3,000 cubic inch box weighs 15 pounds, you’d pay for 22 pounds (139 factor) or 19 pounds (166 factor).

Metric Calculation Example

For international shipments using metric measurements, a box measuring 51cm × 38cm × 25cm:

- Volume: 51 × 38 × 25 = 48,450 cubic centimeters

- DIM weight: 48,450 ÷ 5,000 = 9.69 kg → 10 kg dimensional weight

When Does Dimensional Weight Apply to Your Shipments?

Understanding when dimensional weight pricing kicks in helps you optimize packaging strategies and avoid unexpected charges across different carrier services.

USPS only applies dimensional weight to packages exceeding one cubic foot (1,728 cubic inches) for Priority Mail, Priority Mail Express, and Parcel Select Ground services. UPS and FedEx apply dimensional weight to all domestic and international package services, regardless of size.

Carrier-Specific Thresholds

Prior to 2015, dimensional weight only applied to packages over 3 cubic feet, but major carriers eliminated this threshold to maximize space utilization. Today’s reality means even small packages face potential dimensional weight charges.

USPS Flat-Rate Exception: USPS flat-rate boxes and envelopes remain exempt from dimensional weight pricing, making them cost-effective for heavy items that fit within standard flat-rate dimensions.

Oversize Surcharges and Additional Fees

Beyond dimensional weight, carriers impose additional penalties for oversized packages:

• UPS and FedEx add a $45 oversize surcharge for packages with combined length and girth over 130 inches

• USPS charges a $15 surcharge for packages over 30 inches in any dimension or exceeding 2 cubic feet

• Some carriers apply different rules based on package volume, with certain services only calculating dimensional weight for packages exceeding 799 cubic inches

These surcharges compound dimensional weight charges, making package optimization even more critical for cost control.

How Can You Reduce Dimensional Weight Charges?

Strategic packaging optimization can reduce dimensional weight charges by 20-40%, significantly impacting your shipping budget and overall profitability.

The most effective strategy is right-sizing your packaging by choosing the smallest box that safely accommodates your products. Custom packaging solutions and efficient material selection can eliminate wasted space while maintaining product protection.

Proven Cost-Reduction Strategies

Optimize Package Selection

Maintain a variety of box sizes to ensure optimal fits for different products. Right-sizing eliminates excess space that directly contributes to dimensional weight calculations.

Improve Packaging Materials

Replace bulky materials like foam or excessive bubble wrap with lightweight alternatives such as air cushions, paper fill, or padded mailers. Flexible packaging materials conform to product shapes, eliminating wasted space.

Advanced Optimization Techniques

| Strategy | Potential Savings | Implementation Method |

|---|---|---|

| Right-size packaging | 20-30% | Measure products, select optimal box sizes |

| Custom box design | 30-50% | Partner with packaging manufacturer |

| Efficient material selection | 10-25% | Use lightweight, space-efficient protection |

| Strategic product arrangement | 15-35% | Optimize nesting and consolidation |

Strategic Product Arrangement

Efficient nesting of products within packages reduces overall volume. Consider how items fit together and group similar products to occupy less space. Sometimes splitting shipments into multiple smaller packages proves more economical than one large package.

Custom Packaging Investment

On-demand packaging systems can create right-sized boxes for each shipment, potentially reducing dimensional weight charges by 20-40%. While requiring upfront investment, the long-term savings justify costs for high-volume shippers.

At Acreet, we specialize in designing custom cardboard boxes that minimize dimensional weight while providing optimal product protection. Our engineering team analyzes your current packaging and recommends solutions that reduce shipping costs without compromising product safety.

What Are Common Mistakes When Calculating Dimensional Weight?

Dimensional weight calculation errors can lead to unexpected charges, delivery delays, and compliance issues that impact your business operations and customer satisfaction.

The most costly mistake is failing to account for complete package dimensions, including protruding parts, handles, or irregular shapes. Measurement errors and using incorrect DIM factors for specific carriers can result in significant cost discrepancies.

Critical Measurement Errors

Incomplete Dimension Accounting

Not measuring outermost dimensions creates the most expensive errors. Protruding handles, protective corners, or tape buildup must be included in calculations. Failing to account for these elements can underestimate charges by 15-20%.

Rounding Inconsistencies

Carriers round measurements differently – some round up at 0.5 inches, others round to the nearest whole inch. Small measurement discrepancies compound into substantial cost differences over multiple shipments.

Calculation and Process Mistakes

Wrong DIM Factor Application

Using incorrect dimensional factors for specific carriers or service types leads to inaccurate cost projections. Always verify current DIM factors, as carriers periodically adjust these numbers.

Packaging Weight Omission

Forgetting to factor in the weight of pallets, crates, wraps, and other packaging elements is common but costly. Wood pallets alone can vary significantly in weight depending on materials used.

• Always measure complete package dimensions including all protrusions

• Round each dimension up to the nearest whole inch before calculating

• Double-check arithmetic when multiplying three dimensions

• Verify you’re using the correct carrier-specific DIM factor

• Include all packaging materials in weight calculations

• Account for irregular shapes using longest measurement points

Automated System Issues

Dimensional scanner mistakes can misread dimensions, especially when packages travel together on conveyors or have irregular shapes. Regular auditing of scanner accuracy prevents billing discrepancies and ensures cost control.

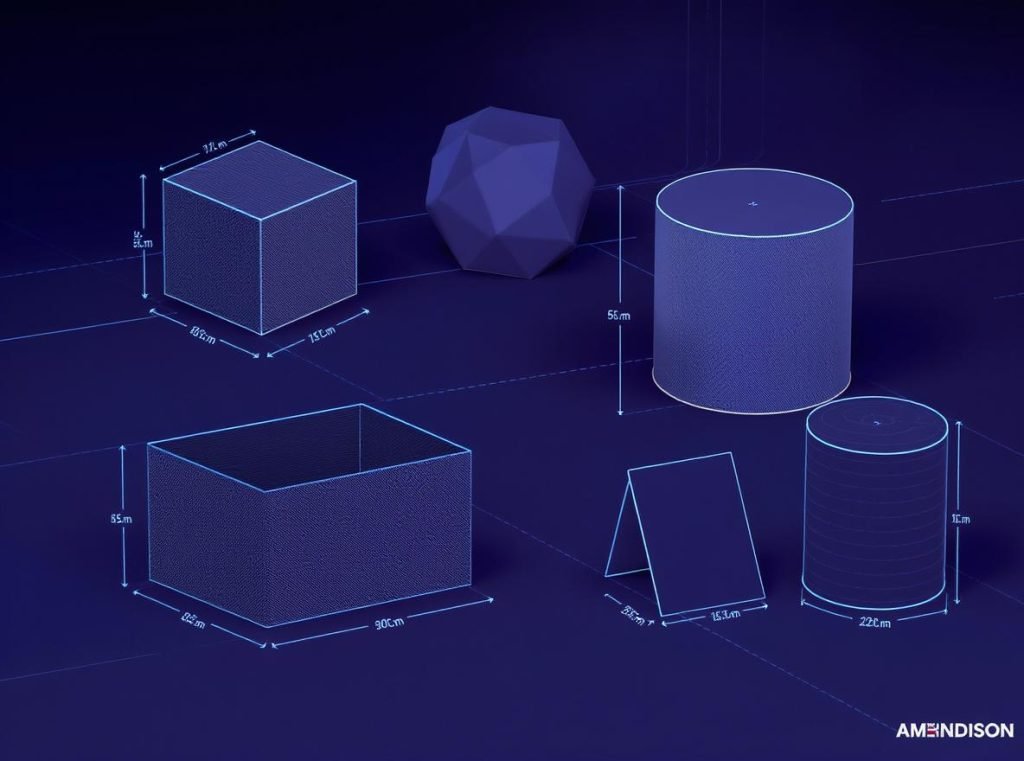

How Does Package Shape Affect Dimensional Weight?

Package shape significantly influences dimensional weight calculations and shipping costs, even when containing identical products with the same actual weight.

Rectangular boxes typically offer the most efficient dimensional weight ratios, while irregular shapes and cylindrical packages often result in higher charges due to measurement methods that assume maximum dimensions.

Shape Impact on Calculations

Regular vs. Irregular Shapes

Rectangular boxes are measured at their longest points on each axis, making calculations straightforward. However, irregular shapes are measured at their widest points, potentially inflating dimensional weight beyond the package’s actual volume.

Cylindrical Package Challenges

For cylinder-shaped items, carriers often use a “square assumption” calculation. A cylinder with a 10-inch diameter would be calculated as 10″ × 10″ × length, rather than using actual circular volume. This method typically results in higher dimensional weights than true volume would suggest.

Optimization by Product Category

Different product types benefit from specific packaging approaches:

Electronics and Small Items: Compact rectangular boxes that closely follow product contours minimize dimensional weight while providing adequate protection against shipping impacts.

Clothing and Soft Goods: Poly mailers or flexible packaging often reduce dimensional weight compared to rigid boxes, though protection requirements may require compromise based on product value.

Fragile Items: While protection requirements may necessitate larger boxes with cushioning, strategic packaging design minimizes dimensional weight impact through efficient void fill placement and custom inserts.

Packages with Protrusions: Items with integrated handles or grips can eliminate the need for additional outer packaging, potentially reducing overall dimensional weight compared to separately packaged components.

Choosing rectangular, cube-shaped packaging minimizes wasted space and reduces dimensional weight compared to complex shapes with numerous edges and vertices.

What Tools and Calculators Can Help With Dimensional Weight?

Professional dimensional weight calculation tools eliminate human error and streamline shipping processes, especially crucial for businesses handling multiple package sizes daily.

Most major carriers provide free dimensional weight calculators on their websites, with FedEx, UPS, and USPS offering web-based tools that automatically apply current DIM factors. Third-party calculators and mobile applications provide additional calculation options for field measurements.

Essential Calculation Resources

Carrier-Provided Tools

Official carrier calculators offer the most accurate results because they connect directly to carrier systems for real-time pricing. These tools automatically update when carriers adjust DIM factors or pricing structures.

Mobile Applications for Field Use

- Dev Box Size to Weight Calculator: Calculates weight based on dimensions and material density

- Engineering Weight Calculator: Handles various structural components and materials

- Multi-Metal Weight Estimator: Specialized for metal products with different densities

Professional Dimensioning Systems

For high-volume operations, automated dimensioning equipment provides accurate measurements:

| Tool Type | Best Applications | Key Features |

|---|---|---|

| Carrier websites | Single-carrier shipping | Official rates, service integration |

| Multi-carrier calculators | Cost comparison shopping | Multiple carriers, rate analysis |

| Mobile apps | Field measurements | Portability, quick calculations |

| Automated scanners | High-volume operations | Speed, accuracy, integration |

Advanced Integration Options

vMeasure Dimensional Scanner measures parcels in under one second with 1.5cm accuracy, while Size-IT Mobile wirelessly captures dimensions and auto-calculates DIM weights for immediate cost analysis.

Software Integration Benefits

Cartonization software works with warehouse management systems to optimize packaging selection and reduce dimensional weight charges. These systems consider dimensions, weight, fragility, and positioning requirements to determine optimal packaging strategies.

For businesses without dedicated shipping software, several free online calculators like Newtum’s Dimensional Weight Calculator provide secure, local calculations without data transmission, ensuring privacy while maintaining accuracy.

Summary

Calculating dimensional weight for cardboard boxes involves measuring length, width, and height in inches, multiplying these dimensions, and dividing by your carrier’s specific divisor (139 for FedEx and UPS daily rates, 166 for USPS and UPS retail rates). This calculation determines whether you pay based on actual weight or package size, potentially increasing shipping costs by 20-40%. Strategic packaging optimization, accurate measurements, and understanding carrier-specific requirements help minimize dimensional weight charges while ensuring product protection and customer satisfaction.

Ready to reduce your shipping costs through optimized packaging? Contact Acreet today for custom cardboard box solutions engineered to minimize dimensional weight while protecting your products. Our packaging experts can analyze your current shipping expenses and recommend strategies that improve your bottom line through smarter packaging design.