Choosing the wrong GSM for your packaging can result in damaged products, dissatisfied customers, and wasted money. Many businesses make costly GSM selection errors by focusing solely on cost rather than application requirements, leading to under-spec’d packaging that damages products or over-spec’d materials that waste resources.

GSM stands for Grams per Square Meter and measures how much one square meter of paper weighs in grams. The right GSM depends on your product weight, fragility level, shipping conditions, and brand positioning. Light products need 150-250 GSM, medium-weight items require 250-350 GSM, while heavy or fragile products demand 350+ GSM for optimal protection.

Let’s explore everything you need to know to make the perfect GSM choice that balances protection, cost, and brand image for your business packaging needs.

Table of Contents

ToggleWhat Does GSM Actually Mean in Paper Packaging?

Understanding GSM fundamentals helps you make informed packaging decisions that protect your products and optimize costs.

GSM stands for Grams per Square Meter, a universal measurement indicating how much one square meter of paper weighs in grams. This metric serves as a crucial indicator of paper thickness, density, and quality, with higher GSM numbers representing heavier, thicker paper that typically offers greater durability and protection.

GSM provides a standardized comparison method for different paper types regardless of size, making it essential for quality control and material selection. Unlike other measurement systems like basis weight used in the US, GSM offers a universal metric that helps manufacturers worldwide make consistent packaging decisions.

The measurement directly correlates with packaging performance characteristics. Higher GSM typically means greater durability, better print quality, and enhanced protection capabilities, while lower GSM offers flexibility and cost savings for lighter applications.

This standardization is particularly valuable for international businesses like yours, where consistent quality across different suppliers and regions is crucial for maintaining brand standards.

| GSM Range | Paper Classification | Typical Applications |

|---|---|---|

| 35-120 GSM | Lightweight Papers | Tissue wrap, food wrapping, basic retail bags |

| 120-250 GSM | Medium-Weight Papers | Business cards, moderate packaging, inner layers |

| 250-450+ GSM | Heavy-Weight Papers | Premium boxes, e-commerce packaging, luxury items |

How Do Different GSM Levels Affect Your Packaging Performance?

Different GSM ranges deliver distinct performance characteristics that directly impact your packaging’s protective capabilities and customer experience.

GSM levels determine packaging strength, durability, and protective qualities. Lightweight papers (35-120 GSM) offer flexibility and cost savings, medium-weight papers (120-250 GSM) provide balanced performance, while heavy-weight papers (250-450+ GSM) deliver maximum protection and premium brand perception.

Lightweight Papers (35-120 GSM)

These papers excel in applications where flexibility and cost efficiency matter most. At 35-55 GSM, papers work well for tissue wrap, newspaper-style inserts, and food wrapping where the packaging doesn’t bear significant weight.

Standard printer paper weight (70-90 GSM) suits light apparel packaging and basic retail bags, while 100-120 GSM handles letterheads, brochures, and light cosmetics packaging effectively.

Medium-Weight Papers (120-250 GSM)

This range represents the sweet spot for many business applications. Papers at 120-150 GSM work well for flyers, posters, and moderate-duty packaging, while 150-200 GSM suits business cards and postcards.

The 200-250 GSM range handles premium flyers, product cards, and inner layers of rigid boxes, providing good durability without excessive cost.

Heavy-Weight Papers (250-450+ GSM)

These materials deliver superior performance for demanding applications. At 250-350 GSM, papers excel in folding cartons, consumer product packaging, and boxes requiring moderate durability.

The 350-450 GSM range provides superior strength for e-commerce packaging, industrial use, and premium box packaging, while 450+ GSM specialized paperboards handle heavy-duty applications requiring maximum compression strength.

Performance factors to consider:

- Tear resistance: Higher GSM prevents ripping during handling and shipping

- Compression strength: Heavier papers resist crushing under stacking weight

- Print quality: Thicker papers support better color reproduction and finishing options

- Moisture resistance: Higher GSM typically offers better barrier properties

What GSM Should You Choose for Different Product Categories?

Product-specific GSM selection ensures optimal protection while maintaining cost efficiency across different industries and applications.

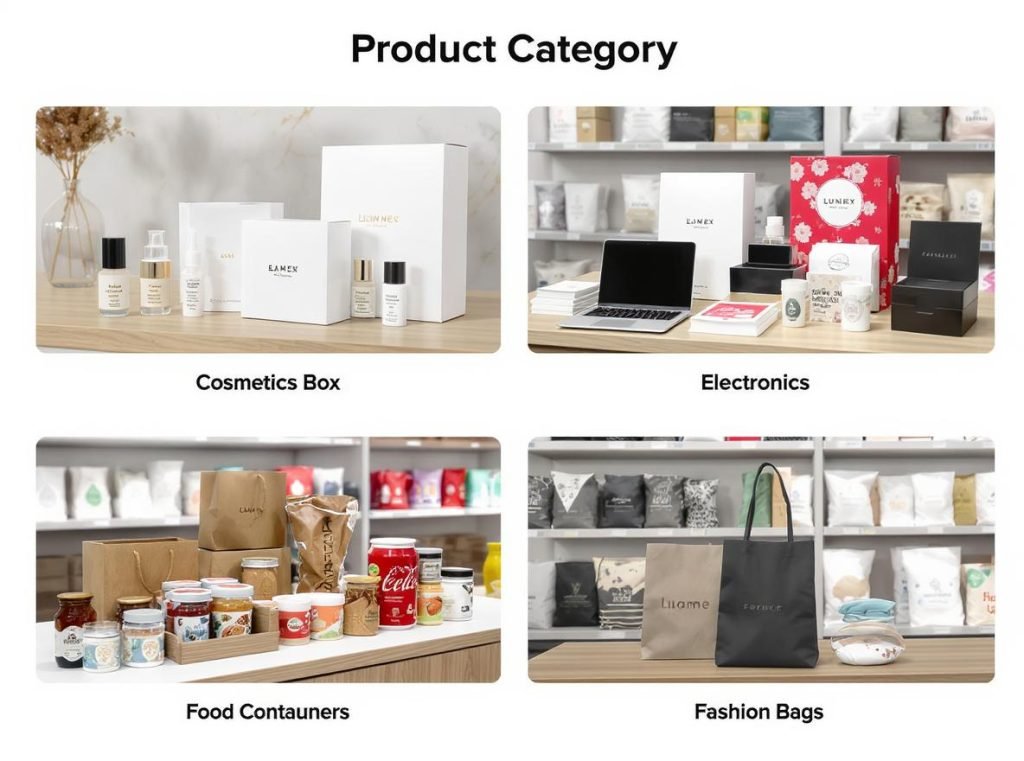

Product weight, fragility, value, and shipping conditions determine ideal GSM ranges. Food service typically uses 170-350+ GSM depending on application, cosmetics require 250-400 GSM for premium appeal, electronics demand 400+ GSM for maximum protection, while fashion packaging uses 150-350 GSM based on brand positioning.

Food Service and Restaurant Packaging

Food packaging GSM selection depends heavily on specific use cases and performance requirements. Lightweight solutions (170-210 GSM) work perfectly for dry foods, short service times, and weight-optimized applications where cost efficiency matters most.

Standard performance papers (220-300 GSM) represent the most versatile range for everyday foodservice applications, suitable for most menu items and providing reliable protection during transport and storage.

Premium heavy-duty options (310-350+ GSM) handle demanding applications like hot soups, heavy food items, and extended use scenarios. Many restaurants choose 120 GSM kraft paper for takeout bags, providing approximately 15% more durability than standard options.

Cosmetics and Beauty Products

The cosmetics industry typically requires 250-400 GSM for boxes that combine strength with stylish presentation, often featuring added texture and sheen to enhance brand appeal.

For luxury cosmetics packaging, industry experts recommend 210 GSM coated paper with glossy lamination and foil stamping to create premium feel and visual impact that justifies higher product pricing.

Electronics and Technology Products

Electronics packaging demands 400+ GSM for maximum durability and secure storage, ensuring products remain protected during shipping, handling, and potential drops during delivery processes.

The higher GSM also supports additional protective inserts, foam padding, and multiple packaging layers that electronic products require for safe transport.

Fashion and Apparel

Fashion packaging typically uses 250-350 GSM with luxurious coatings or textured papers that match seasonal collections and brand positioning.

Applications often include soft-touch lamination, linen textures, or metallic foils that enhance unboxing experience and reinforce brand premium positioning.

Here’s a practical GSM selection guide:

- Paper bags for apparel: 70-90 GSM for light items, 100-120 GSM for shoes and accessories, 130-150 GSM for heavier items

- Lightweight products (under 200g): 150-250 GSM provides adequate protection

- Medium products (200g-1kg): 250-300 GSM balances cost and performance

- Heavy products (1kg+): 300-400 GSM ensures structural integrity

- Fragile items (any weight): 300+ GSM minimum regardless of product weight

- Luxury positioning: 350+ GSM reinforces premium brand perception

How Does GSM Impact Your Packaging Costs and ROI?

GSM selection significantly affects material costs, damage prevention, and overall business profitability through multiple interconnected factors.

Higher GSM increases material costs by 20-50% but can reduce product damage claims significantly while improving brand perception. The optimal GSM balances material costs against potential losses from damaged products, customer dissatisfaction, and missed premium positioning opportunities.

Direct Material Cost Analysis

Paper costs generally increase with GSM, though the relationship varies by paper type and supplier. Recent market data shows coated virgin paperboard (200 GSM) ranging from $878-947 USD per metric ton, while PE coated papers range from $877-1099 USD per ton depending on specifications.

For specific applications, 140 GSM kraft paper costs approximately ₹35/kg ($0.42/kg) in some markets, demonstrating how regional pricing affects GSM selection economics.

ROI Impact Mechanisms

Higher GSM packaging improves return on investment through several key areas. Reduced damage rates minimize product returns and replacements, while enhanced brand perception increases perceived value and customer loyalty.

Improved customer experience through sturdy packaging creates positive unboxing experiences that drive repeat purchases and word-of-mouth marketing. Shipping optimization ensures right-sized GSM prevents over-packaging costs while maintaining adequate protection.

Cost-Effectiveness Optimization

Cost-effectiveness isn’t always about choosing the lowest GSM. Over-specifying materials adds unnecessary costs without proportional benefits, while under-specifying leads to damage claims and customer dissatisfaction that can exceed material savings.

Calculate your cost-benefit ratio by considering:

- Base material cost per unit and volume pricing tiers

- Printing and finishing costs (heavier papers may require different processes)

- Potential damage reduction savings and customer service cost reductions

- Brand positioning benefits that support premium pricing strategies

Volume Economics and Scaling

Larger orders typically reduce per-unit GSM cost differences through volume discounts and economies of scale. When ordering 10,000+ units, the percentage cost difference between GSM options decreases significantly, making higher-quality options more accessible for quality-conscious businesses.

Consider your product’s profit margins when selecting GSM. High-margin products easily absorb premium packaging costs, while budget products require more careful GSM optimization to maintain profitability.

What Common Mistakes Should You Avoid When Selecting GSM?

Understanding common GSM selection errors helps prevent costly packaging failures and optimize your material choices for better performance and cost efficiency.

The most critical mistake is assuming higher GSM is always better, leading to over-specification that increases costs without proportional benefits. Other major errors include choosing the same GSM for all paper types, ignoring environmental conditions, and relying on specifications instead of actual testing.

Critical Selection Errors to Avoid

Many businesses fall into the trap of believing that higher GSM automatically means better packaging. This misconception leads to over-specification that increases costs without delivering proportional benefits for the specific application.

Another frequent error involves choosing identical GSM across different paper types. Kraft, MG, and recycled papers perform differently even at identical GSM levels due to fiber composition and manufacturing processes, requiring individual evaluation for each paper type.

Environmental and Testing Oversights

Ignoring environmental conditions during GSM selection creates performance problems. Moisture can significantly impact paper dimensions and performance, yet many businesses measure and select GSM without considering storage and usage environments.

Using specification data instead of actual testing often results in inaccurate performance assessments. Specification data may not reflect real-world performance under your specific conditions, shipping stresses, and handling requirements.

Quality Control and Measurement Mistakes

Calculating packaging requirements by extrapolation frequently leads to undervaluing dimensions and weight. Measuring one unit and calculating total case weight/dimensions by multiplication provides unreliable results that don’t account for production variations.

Inadequate sampling compounds these problems. Testing insufficient quantities or non-representative samples provides unreliable results that don’t reflect sustained production run quality and consistency.

Equipment calibration issues introduce systematic errors that affect all subsequent decisions. Failing to regularly calibrate scales and measuring equipment, while ignoring temperature and moisture effects on measurement accuracy, leads to poor GSM selection.

Common testing and validation errors include:

- Not testing with actual products under real shipping conditions

- Failing to account for stacking strength requirements for retail display

- Ignoring humidity effects on paper performance during seasonal variations

- Not considering complete customer journey from unboxing to disposal

- Mixing product families and assuming identical weights across variants

Prevention Strategies

Avoid these pitfalls by implementing systematic testing procedures. Test multiple GSM options with real products under actual shipping and storage conditions before committing to large production runs.

Consider your complete customer experience, balancing cost, performance, and environmental impact while consulting with packaging professionals for complex applications that require specialized knowledge and testing.

How Can You Test and Validate Your GSM Choice?

Proper GSM testing and validation ensures your packaging performs optimally under real-world conditions while meeting cost and quality requirements.

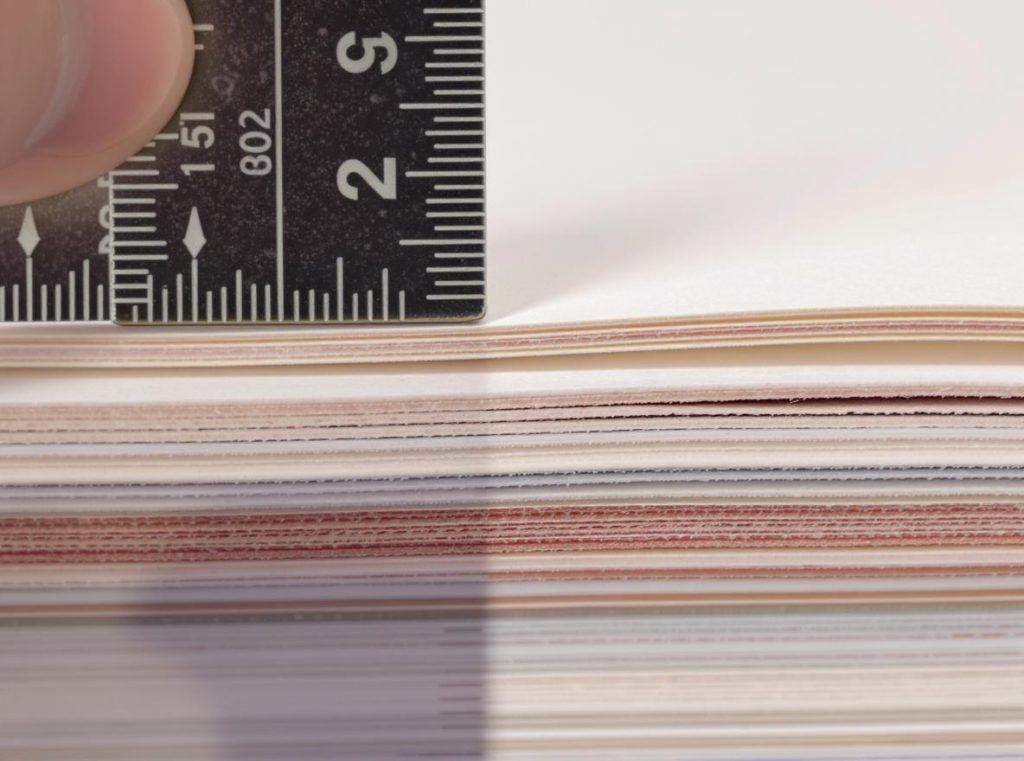

Effective GSM validation requires professional testing methods, multiple sample measurements, and performance verification under actual use conditions. Use GSM checking kits with precision weighing balances, test at least 5 samples from different positions, and validate performance through drop tests, stacking tests, and environmental conditioning.

Professional Testing Methods

The most accurate GSM measurement uses a GSM checking kit with a round cutter and precision weighing balance. This standardized approach ensures consistent, reliable results across different materials and suppliers.

The testing process involves cutting circular samples using standardized templates (typically 10cm x 10cm for heavy papers above 100 GSM), conditioning samples in a desiccator for 5-10 minutes to stabilize moisture content, and weighing samples on calibrated electronic balances.

Calculate GSM using the formula: GSM = (Weight in grams × 10,000) ÷ Area in cm². This calculation converts your sample measurements to the standard grams per square meter metric.

Gravimetric Method for Comprehensive Analysis

The gravimetric method provides accurate testing by measuring total mass of paper or cardboard, including fiber materials, additives, coating, fillers, and water content. This comprehensive approach reveals material characteristics beyond basic weight measurement.

Validation Procedures and Quality Control

Multi-sample testing is essential for accuracy. Take at least 5 readings from different positions on each sample to ensure results account for material variations across the sheet. Calculate average GSM to establish reliable baseline measurements.

Environmental control during testing minimizes variables that affect measurements. Conduct testing in controlled conditions, minimizing moisture exposure that can affect results, and use proper conditioning procedures before testing.

Equipment verification maintains measurement accuracy over time. Regularly calibrate testing equipment and validate measurement procedures to ensure repeatability within laboratory conditions and reproducibility across different testing environments.

Standards Compliance and Documentation

Follow established testing standards such as TAPPI (Technical Association of the Pulp & Paper Industry) guidelines for consistent, reliable results that meet industry standards and supplier requirements.

Practical Performance Validation

Beyond basic GSM measurement, validate actual performance under use conditions. Conduct drop tests from various heights (3-6 feet onto concrete surfaces) using different GSM options with actual products to simulate shipping handling.

Perform stacking tests to determine shelf stability by stacking packaged products five boxes high for 24 hours, checking for bottom box deformation or collapse that could affect retail display performance.

Environmental Condition Testing

Test GSM performance under various environmental conditions that your packaging will encounter. Evaluate behavior in high humidity conditions, cold conditions for food packaging applications, and heat exposure that simulates summer shipping conditions.

Systematic Validation Workflow

- Baseline Testing: Establish GSM requirements based on intended use and performance criteria

- Sample Preparation: Cut samples using appropriate templates for accurate area measurement

- Conditioning: Allow samples to reach equilibrium under standard testing conditions

- Multiple Measurements: Take several readings to account for material variability

- Data Analysis: Calculate averages and verify results fall within acceptable tolerances

- Performance Testing: Validate selected GSM performs adequately under actual use conditions

Quality assurance protocols should include regular GSM verification throughout production to ensure consistency and maintain packaging performance standards. This systematic approach helps avoid costly packaging failures and ensures optimal material selection for your specific applications.

For high-volume applications, consider professional packaging testing services. ISTA (International Safe Transit Association) testing provides standardized evaluation of packaging performance under controlled conditions that simulate real-world shipping and handling stresses.

Summary

Selecting the right GSM for your paper packaging requires balancing protection, cost, and brand image based on your specific product requirements. Understanding that GSM measures grams per square meter helps you choose appropriate weights: light products typically need 150-250 GSM, medium items require 250-350 GSM, while heavy or fragile products demand 350+ GSM for optimal protection and professional presentation.

Ready to optimize your packaging with the perfect GSM for your products? Contact Acreet today for expert consultation and testing samples. Our packaging specialists will help you find the ideal paper weight that protects your products while optimizing costs and enhancing your brand image. Send us your product details and requirements – let’s design custom packaging solutions that deliver measurable results for your international business.