Choosing the wrong box size or style can lead to damaged products, increased shipping costs, and unhappy customers. Poor packaging decisions cost businesses thousands in dimensional weight charges, product returns, and lost customer trust.

The key to selecting the perfect custom box lies in precise product measurement, understanding FEFCO box styles, matching ECT ratings to weight requirements, and optimizing for dimensional weight pricing. Start by measuring your product on its natural base, add minimal clearance, and choose the smallest style that ensures safe transit.

Let’s explore the essential factors that will help you make the best packaging decisions for your business while avoiding costly mistakes.

Table of Contents

ToggleWhat Are the Critical Steps for Accurate Product Measurement?

Precise measurement forms the foundation of successful custom packaging design. Many businesses make costly errors by measuring incorrectly, leading to oversized boxes and excessive shipping charges.

Place your product on its natural base (the side it sits on unaided), face the default front panel, and measure length × width × height to the farthest points. Add only 0.5-1 inch (12-25mm) clearance for cushioning to avoid paying to ship empty space.

Getting measurements right requires following industry-standard GS1 guidelines:

First, position your product on its natural base – the side it naturally sits on without support. Face the main graphics panel or default front toward you. This establishes consistent orientation for measurement.

Measure length (L) × width (W) × height (H) to the absolute farthest points, including caps, seams, handles, or any protruding elements. Don’t forget irregular projections like pumps or hang tabs, which can trigger carrier surcharge disputes later.

For flexible items, follow GS1 rules: flatten pouches completely, fold excess film, and record maximum diameter for cylindrical products. This ensures accurate dimensional weight calculations.

Add minimal clearance – typically 0.5-1 inch per dimension for inner cushioning. Excessive clearance leads to paying for empty space and higher dimensional weight charges.

Critical Measuring Mistakes to Avoid

- Measuring before full assembly: Dimensions often grow during final packaging and sealing

- Rounding down: Carriers round every fraction up to the next whole inch, so always round up

- Ignoring projections: Overlooking handles, spouts, or protruding parts leads to sizing errors

- Measuring without orientation: Inconsistent positioning creates measurement variations

How Do Different FEFCO Box Styles Impact Protection and Shipping Efficiency?

Box style selection directly affects product protection, shipping costs, and packing efficiency. Understanding FEFCO (European Federation of Corrugated Board Manufacturers) codes helps you choose the optimal style for your specific needs.

Regular Slotted Containers (FEFCO 0201) offer the lowest cost for general goods, while Roll-End Mailers (FEFCO 0427) excel for e-commerce with self-locking design and superior brand presentation. Match the style to your product geometry and fulfillment requirements.

Understanding different FEFCO box styles helps optimize your packaging choice:

| FEFCO Code | Description | Best Applications | Key Advantages | Shipping Impact |

|---|---|---|---|---|

| 0201 | Regular Slotted Carton (RSC) | General goods, industrial items | Lowest cost, no die-cutting needed | Good cube efficiency, center void from overlapping flaps |

| 0203 | Full-Overlap Carton (FOL) | Heavy or long items | Double-layer top/bottom, superior crush resistance | Adds weight but provides excellent edge strength |

| 0427 | Roll-End Mailer Box | E-commerce, D2C shipping | Self-locking, no tape required, premium unboxing | Higher die-cut cost, excellent branding canvas |

| 0410 | Five-Panel Folder (FPF) | Flat items, books, artwork | Wrap-around strength, minimal depth | Ships at letter rates if under 1″ thick |

Specialized Options for Specific Needs

Rigid Mailers use 400 gsm chipboard to prevent bending, perfect for documents, photos, and small apparel. They’re extremely lightweight and avoid dimensional weight penalties.

Poly Mailers offer the lowest weight option for soft goods and textiles. They’re moisture-resistant but provide no stacking strength or crush protection.

Choose the smallest style that allows quick packing while ensuring safe transit. Over-engineering protection increases costs without proportional benefits.

What ECT and Mullen Ratings Do You Need for Your Product Weight?

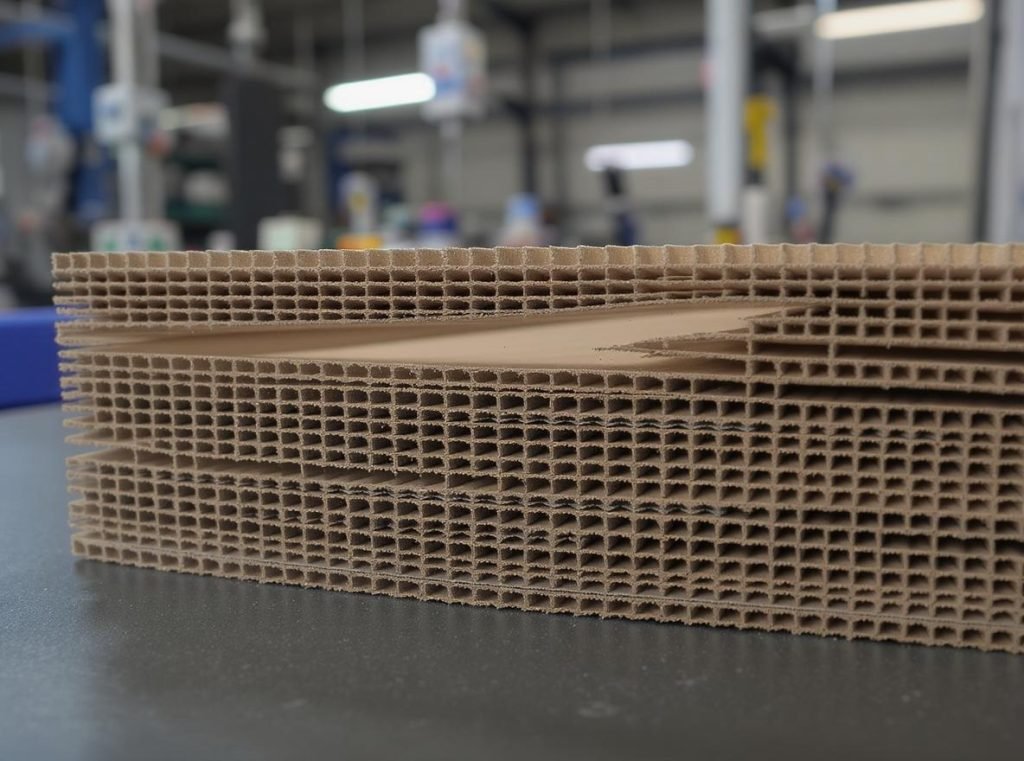

Corrugated board strength determines whether your packaging will survive shipping stress and warehouse stacking. Understanding ECT (Edge Crush Test) and Mullen ratings ensures you select adequate protection without over-engineering.

Use 32 ECT single-wall for products up to 30 pounds, 44 ECT single-wall for 31-65 pound items, and 48 ECT double-wall for 66-80 pound products. Fragile goods benefit from higher Mullen ratings for better puncture resistance, regardless of weight.

Corrugated strength is measured two ways:

Edge Crush Test (ECT) – Stacking Strength

ECT measures how much vertical pressure the corrugated edge can withstand before crushing. Higher ECT ratings mean better performance in stacked warehouse environments.

Mullen/Burst Test – Puncture Resistance

Mullen ratings indicate resistance to puncture impacts during handling. Fragile items benefit from higher Mullen ratings even if stacking loads are moderate.

| Product Weight | Recommended Grade | Applications | Comments |

|---|---|---|---|

| ≤ 30 lb (14 kg) | 32 ECT single-wall / 200# Mullen | Retail items, cosmetics, textiles | Standard grade for most lightweight products |

| 31-65 lb | 44 ECT single-wall / 275# Mullen | Electronics, moderate stacking | Light warehouse pallets, regional shipping |

| 66-80 lb | 48 ECT double-wall / 275# DW | Automotive parts, machinery | Regional LTL freight, high stacking |

| 81-140 lb | 60-90 ECT double/triple-wall | Industrial equipment, export | Maximum protection for heavy items |

For fragile products like glassware or electronics, prioritize higher Mullen ratings over ECT to prevent puncture damage during handling.

How Do You Calculate and Minimize Dimensional Weight Charges?

Modern shipping carriers charge based on dimensional weight rather than actual weight for larger packages. Understanding these calculations is crucial for cost optimization.

Dimensional weight equals length × width × height ÷ carrier divisor. UPS and FedEx use divisor 139, while USPS uses 166 for packages over 1 cubic foot. You pay whichever is higher – actual weight or dimensional weight.

The dimensional weight formula:

Dim Weight (lb) = (L × W × H in inches) ÷ Divisor

Carrier-Specific Divisors

- UPS/FedEx: 139 for most services

- USPS Priority: 166 when package exceeds 1 cubic foot

Practical Example

18″ × 12″ × 12″ box = 2,592 cubic inches

Dimensional weight = 2,592 ÷ 139 = 18.6 lb (rounds to 19 lb)

If your product weighs 12 pounds, you’ll pay shipping for 19 pounds unless you reduce one dimension.

Optimization Strategies

- Minimize void space: Use appropriately sized boxes rather than excessive padding

- Consider product orientation: Rotating the product might allow smaller dimensions

- Use structured inserts: Custom foam inserts often take less space than loose fill

- Switch packaging styles: Mailers or Five-Panel Folders work better for flat items under 2″ thick

- Avoid unnecessary double-wall: Use only where weight or drop risk demands it

What Are the Most Expensive Packaging Mistakes to Avoid?

Even experienced businesses make costly sizing errors that dramatically impact shipping costs and product damage rates. Understanding these pitfalls prevents expensive mistakes.

The most costly mistakes include over-boxing (choosing cartons 2+ inches larger than needed), under-specifying board grades, ignoring carrier size limits, and failing to account for internal product movement during shipping.

Critical Mistakes That Drive Up Costs

Over-Boxing

Choosing boxes more than 2 inches larger than necessary “just in case” triggers higher dimensional weight charges. This single mistake can increase shipping costs by 20-40%.

Under-Specifying Board Grade

Using 32 ECT for 60-pound items leads to box collapse in pallet stacks. The cost of damaged products and returns far exceeds the material savings.

Ignoring Carrier Limits

UPS limits packages to 165 inches (length + 2×width + 2×height), while USPS limits to 108 inches. Exceeding these triggers expensive oversize fees.

Allowing Internal Movement

Products that can rattle inside boxes suffer higher damage rates and fail ISTA drop tests. Proper internal fitment prevents movement without excessive padding.

Print Orientation Errors

Forgetting artwork orientation when rotating box dimensions results in sideways branding, requiring costly reprints.

Prevention Strategies

- Always measure with minimal but adequate clearance

- Match ECT ratings to actual product weight and stacking requirements

- Check carrier dimension limits before finalizing designs

- Use structured inserts or form-fitting cushioning to prevent movement

- Consider print orientation when optimizing box dimensions

How Do You Balance Cost, Protection, and Brand Presentation?

Successful packaging optimization requires balancing material costs, product protection, and brand impact. This balance varies significantly based on your business model and customer expectations.

Start with minimum protection requirements based on product weight and fragility, then evaluate cost-effective upgrades that enhance brand perception. Often, strategic investments in custom printing or premium materials pay for themselves through improved customer satisfaction.

E-Commerce Considerations

Online retailers need packaging that survives shipping while creating memorable unboxing experiences. The packaging often provides the first physical brand interaction.

Key optimization strategies:

- Use 32 ECT white board for lightweight apparel – saves weight while printing cleanly

- Upgrade selected panels only with honeycomb or foam corner blocks instead of switching to double-wall

- Embed brand colors inside mailers (uncoated kraft outside) for upscale reveals without extra ink costs

- Consider rigid mailers for flat items – saves up to 50% in postage compared to boxes

Wholesale Operations

B2B customers prioritize functionality and cost-effectiveness over premium presentation. Focus on protection and standardization.

Essential elements:

- Durability over appearance: Boxes must withstand multiple handling points

- Standardized sizing: Consistent dimensions improve warehouse efficiency

- Cost optimization: Lower per-unit costs often outweigh premium materials

Multi-Channel Strategies

Products serving both retail and direct-to-consumer channels need dual-purpose packaging.

Consider these approaches:

- Modular designs that work for both shipping and retail display

- Removable sleeves for retail presentation over standard shipping boxes

- Convertible formats that transform from shipping to display configuration

What Role Does ISTA Testing Play in Packaging Validation?

Professional packaging testing prevents costly failures and ensures your chosen packaging performs under real-world shipping conditions. ISTA (International Safe Transit Association) testing simulates the actual parcel network.

ISTA 6 and ASTM D4169 testing simulate drop, vibration, and compression stresses that packages experience during shipping. This testing cuts damage-related returns, identifies over-engineered areas for cost savings, and ensures Amazon SIOC compliance.

Standard Testing Procedures

ISTA testing follows a standardized sequence:

- Drop tests: One corner, three edges, and six faces from heights based on package weight

- Vibration testing: Simulates vehicle transport conditions

- Compression testing: Evaluates stacking strength in warehouse conditions

Business Benefits

- Reduced returns: Prevents damage-related customer complaints and returns

- Cost optimization: Identifies over-engineered areas where material can be reduced

- Compliance requirements: Required for Amazon SIOC/FFP programs to avoid chargebacks

- Risk mitigation: Validates packaging before large-scale production

Drop Test Heights by Weight

Testing heights increase with package weight:

- Under 20 lbs: 18-inch drops (typical conveyor height)

- 20-40 lbs: 24-inch drops

- 40-60 lbs: 30-inch drops (standard sorting facility)

- Over 60 lbs: 36-48-inch drops (maximum expected handling)

Professional testing typically costs $500-2,000 per SKU but can save thousands in damage claims and returns.

How Can Packaging Consultants Optimize Your Results?

Professional packaging expertise can deliver significant cost savings while improving product protection and brand presentation. Independent consultants and supplier design teams offer specialized knowledge that most businesses lack internally.

Packaging consultants typically deliver 5-15% total packaging cost reduction while improving on-time delivery and customer satisfaction. They provide finite-element analysis, sustainability guidance, and access to pre-qualified testing laboratories.

Key Services Packaging Consultants Provide

Cost Audit and Optimization

- Audit current SKUs to identify hidden freight and material waste

- Analyze dimensional weight penalties and recommend size optimizations

- Evaluate ECT/Mullen specifications against actual requirements

Technical Expertise

- Finite-element compression analysis to right-size strength specifications

- ISTA testing coordination with pre-qualified laboratories

- Regulatory compliance guidance for different markets

Sustainability Solutions

- Navigate regional recycling regulations and sustainability mandates

- Recommend eco-friendly materials without compromising protection

- Optimize for circular economy principles

Speed to Market

- Provide ready dielines for common product categories

- Accelerate new product launches with proven packaging solutions

- Access to supplier networks and volume pricing

When to Engage Consultants

Consider professional packaging consultation when:

- Shipping costs exceed 8-10% of product value

- Damage rates exceed 2-3% of shipments

- Launching new product lines or entering new markets

- Facing regulatory compliance requirements

- Seeking sustainability improvements without cost increases

The investment in professional packaging consultation typically pays for itself within 6-12 months through reduced shipping costs, fewer returns, and improved operational efficiency.

What Emerging Trends Are Reshaping Custom Packaging Selection?

The packaging industry is evolving rapidly with new materials, sustainability requirements, and e-commerce demands. Understanding these trends helps future-proof your packaging decisions.

Sustainability mandates are driving increased use of recyclable materials, while e-commerce growth demands packaging that balances protection with unboxing experience. Smart packaging technologies and right-sizing algorithms are becoming standard tools for optimization.

Sustainability Requirements

- Recyclable materials: Increased demand for mono-material designs

- Reduced material usage: Lightweighting without compromising protection

- Circular economy principles: Designing for end-of-life recycling

- Regional regulations: Varying requirements across different markets

E-Commerce Optimization

- Unboxing experience: Packaging as marketing tool and brand differentiator

- Size standardization: Fewer SKUs with broader product compatibility

- Automated packing: Designs optimized for robotic fulfillment centers

- Return-friendly formats: Easy-to-reuse packaging for product returns

Technology Integration

- Right-sizing algorithms: Software that optimizes dimensions for each product

- Predictive testing: AI-powered simulation reducing need for physical testing

- Smart packaging: QR codes and NFC tags for enhanced customer engagement

- Supply chain visibility: Track packaging performance throughout distribution

These trends indicate that successful packaging strategies will increasingly require balancing multiple objectives: cost, protection, sustainability, and brand experience.

Summary

Choosing the right custom box requires precise measurement following GS1 guidelines, understanding FEFCO codes and ECT ratings, optimizing for dimensional weight pricing, and validating through professional testing. Start with accurate product measurement, match box style to your fulfillment needs, and select appropriate board grades based on weight and fragility requirements.

Ready to optimize your custom packaging for maximum protection and cost efficiency? Contact Acreet today for expert consultation on box sizing, FEFCO style selection, and ECT rating optimization. Our experienced packaging engineers will help you minimize shipping costs while ensuring product protection. Send us your product specifications and shipping requirements for a customized packaging solution that delivers results.