Flexible pouch packaging failures cost manufacturers millions annually through product recalls, customer complaints, and damaged brand reputation. A single compromised seal can lead to contamination, reduced shelf life, and regulatory violations that devastate business relationships.

Ensuring flexible pouch seal integrity requires a systematic approach combining precise heat sealing parameters (temperature 115°C+ at interface), comprehensive testing methods including ASTM F3004-approved airborne ultrasound and vacuum decay testing, contamination prevention protocols, and validated equipment maintenance programs. Modern non-destructive testing methods can detect defects down to single-digit micron ranges while preserving product value.

Let’s explore the proven strategies that protect your products and maintain customer trust throughout the global supply chain.

Table of Contents

ToggleWhat Are the Primary Causes of Flexible Pouch Seal Failures?

Understanding failure mechanisms enables proactive prevention strategies that eliminate costly defects before they reach customers. Even microscopic defects can compromise entire production batches.

The primary causes of flexible pouch seal failures include contamination in seal areas (fat, water, particulate matter), insufficient heat sealing temperatures below 115°C interface requirements, equipment-related issues like pressure imbalances, and material incompatibilities. Contamination represents the most prevalent cause, with curved-bar sealing systems showing superior performance over flat-bar systems in contaminated conditions.

Contamination-Related Failures

Seal area contamination creates the majority of packaging integrity issues across all industries:

- Fat and water contamination significantly reduces seal strength reliability

- Particulate matter creates microscopic channels compromising hermetic integrity

- Post-fill drip from overhead fillers introduces contaminants into critical sealing zones

- Incorrect vacuum levels during filling can draw contaminants toward seal areas

Steam-flushing techniques effectively remove both particulate contamination and excess moisture while reducing headspace gas volume, creating optimal conditions for subsequent sealing operations.

Process Parameter Deviations

Temperature control challenges arise from film thickness variations within standard batches:

| Film Specification | Thickness Range | Temperature Adjustment | Impact |

|---|---|---|---|

| 80μm Nominal | 72-88μm (±10%) | +15-20°C for thick films | Critical for interface heating |

| PET/AL/LLDPE | Variable layers | Layer-specific optimization | Requires sealant layer focus |

| Bio-derived Sealants | New formulations | Adjusted parameters needed | Process revalidation required |

Equipment-Related Issues

Mechanical factors create intermittent failures that compromise batch integrity:

- Foreign material entrapment between sealing surfaces

- Inadequate sealing pressure distribution (minimum 20N/cm² for medical pouches)

- Uneven mold surfaces causing localized pressure imbalances

- Temperature inconsistencies across sealing areas

- Misalignment during equipment installation or maintenance

Which Testing Methods Provide the Most Reliable Seal Integrity Detection?

Modern seal integrity testing combines multiple approaches to catch defects before products reach customers. The industry has shifted toward quantitative, deterministic methods that preserve product value while providing reliable results.

Vacuum decay testing has emerged as the gold standard, applying precise vacuum levels between -980 and -20 millibars absolute to detect leaks down to single-digit micron ranges. Airborne ultrasound technology (ASTM F3004-approved and FDA-recognized) provides rapid testing with pass/fail results within 15 seconds, making it ideal for high-volume production environments.

Advanced Non-Destructive Methods

Vacuum Decay Testing

This method places containers in precisely fitted test chambers where controlled vacuum levels monitor pressure changes over predetermined intervals:

- Detects leaks in both flexible packaging containing air or liquids

- Specialized sensors monitor product deformation to prevent false readings

- Provides quantitative results with statistical confidence levels

- Preserves 100% of tested products for sale

Airborne Ultrasound Technology

ASTM F3004-approved method transmits ultrasound waves through package seals:

- Analyzes signal strength variations to identify both visible and invisible defects

- Detects incomplete seals, partial weak areas, and process-related anomalies

- Provides rapid screening suitable for 100% inspection on high-speed lines

- Identifies defects that appear visually acceptable but compromise quality

Helium Leak Testing

Mass spectrophotometry offers the highest sensitivity, measuring seven orders of magnitude smaller than other methods by tracking helium migration through sealed packages.

Established Destructive Testing Standards

ASTM F88/F88M-23 Seal Strength Testing

Recent updates include improved guidance for tray applications and comprehensive appendices covering inter-laboratory studies:

- Measures force required to separate 1-inch wide sealed strips

- Controlled rates of 10-12 inches per minute for consistent results

- Provides both maximum and average seal strength measurements

- Essential for process validation and regulatory compliance

| Test Method | Detection Capability | Sample Preservation | Regulatory Recognition |

|---|---|---|---|

| Vacuum Decay | Single-digit microns | 100% preserved | FDA consensus standard |

| Airborne Ultrasound | Micro-defects | 100% preserved | ASTM F3004 approved |

| Helium Leak | Ultra-fine detection | 100% preserved | Highest sensitivity |

| ASTM F88 Tensile | Quantitative strength | Destructive | Primary regulatory standard |

How Do You Optimize Heat Sealing Parameters for Maximum Seal Integrity?

Achieving optimal seal integrity requires precise control of the critical triad: time, temperature, and pressure, applied to clean, compatible materials. Modern microprocessor-controlled systems achieve ±1°C thermal uniformity with 0.1-second timing resolution.

Optimal heat sealing requires interface temperatures above 115°C for robust polyolefin sealing, balanced with precise pressure (minimum 20N/cm² for medical applications) and optimized dwell times that follow square root relationships with seal strength. Temperature calibration must account for ±5°F equipment tolerance while maintaining consistency across sealing areas.

Advanced Temperature Control Strategies

The ideal temperature window spans from seal initiation temperature (Tsi) through plateau initiation (Tpi) to final plateau temperature (Tpf):

Critical Temperature Zones

- Seal Initiation (Tsi): Polymer surfaces begin softening

- Plateau Initiation (Tpi): Optimal fusion window opens

- Final Plateau (Tpf): Maximum safe temperature before degradation

This operational window provides flexibility for equipment variations while maintaining seal quality without polymer degradation.

Film-Specific Parameter Optimization

Different material combinations require tailored approaches:

- PET/AL/LLDPE structures: Focus heat application on polyethylene sealant layer

- Coffee packaging films: Account for aluminum foil barrier protection requirements

- Ready meal applications: Consider nylon puncture resistance in retort processing

- EVOH barrier films: Position barrier layers away from direct heat contact

Pressure and Timing Integration

Sealing pressure facilitates molecular interpenetration between sealant layers:

- Medical pouches require minimum 20N/cm² pressure for reliable closure

- Insufficient pressure creates incomplete bonding and air entrapment

- Dwell time correlates with seal strength through square root relationships

- Longer times enable complete fusion while risking material degradation

Process Control Implementation

| Parameter | Target Range | Monitoring Frequency | Critical Tolerance |

|---|---|---|---|

| Interface Temperature | >115°C | Continuous | ±1°C |

| Sealing Pressure | 20-40 N/cm² | Per cycle | ±5% |

| Dwell Time | 0.5-2.0 seconds | Per cycle | ±0.1 seconds |

| Cooling Time | Material dependent | Continuous | Process specific |

What Quality Control Measures Most Effectively Prevent Seal Defects?

Systematic quality control integrates contamination prevention, real-time process monitoring, and statistical sampling to reduce defect rates by up to 95% compared to reactive approaches.

Effective seal integrity quality control combines clean filling systems that prevent product “tailing,” steam-flushing contamination removal, real-time temperature and pressure monitoring across sealing areas, and comprehensive statistical process control tracking seal strength trends to identify process drift before defective products reach consumers.

Contamination Prevention Systems

Clean filling represents the first line of defense against seal contamination:

Automated Dosing Control

- Well-designed systems prevent product “tailing” into seal areas

- Consistent speeds with controlled acceleration/deceleration patterns

- Superior contamination control compared to manual operations

- Reduced operator variability in filling consistency

Steam-Flushing Implementation

- Removes particulate contamination and excess moisture simultaneously

- Reduces headspace gas volume for improved product preservation

- Creates optimal surface conditions for subsequent sealing

- Dual benefit approach improving both integrity and shelf life

Real-Time Process Monitoring

Advanced monitoring systems track critical parameters continuously:

- Temperature Distribution: Identify hot spots or cold zones across sealing bars

- Pressure Monitoring: Detect pneumatic system variations affecting seal quality

- Environmental Conditions: Track humidity and temperature affecting material behavior

- Input Voltage: Monitor power fluctuations impacting heating element performance

Statistical Process Control Implementation

Control charts enable proactive process management:

- Monitor seal strength trends identifying gradual process drift

- Establish control limits based on validated acceptance criteria

- Trigger corrective actions before defective products are produced

- Document process capability for regulatory compliance

Sampling Protocol Optimization

| Production Phase | Sampling Rate | Test Methods | Response Time |

|---|---|---|---|

| Startup | Every 10th package | Multiple methods | Immediate |

| Routine Production | Every 100th package | Risk-based selection | Within 1 hour |

| Material Changes | Every 5th package | Comprehensive testing | Real-time |

| Equipment Maintenance | First 50 packages | Full validation suite | Before release |

How Do Material Selection and Design Choices Impact Seal Performance?

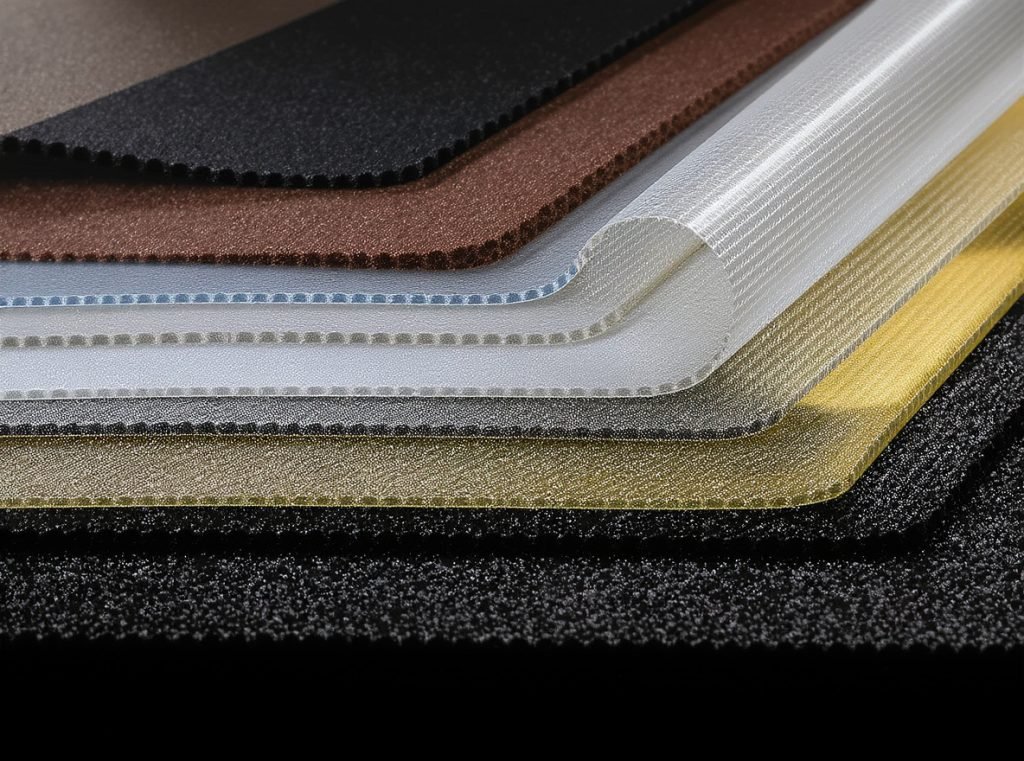

Strategic material selection and design optimization determine seal success before production begins. Modern multi-layer structures require sophisticated understanding of polymer compatibility and thermal behavior.

Material selection significantly impacts seal integrity through polymer compatibility for molecular bonding, barrier layer positioning away from direct heat contact, and engineered structures like PET/AL/LLDPE for coffee packaging or PET/AL/Nylon/PP for retort applications. Bio-derived sealants and recyclable high-barrier papers demonstrate improved adhesion kinetics while requiring adjusted processing parameters and comprehensive validation.

Advanced Multi-Layer Engineering

Modern flexible pouches employ sophisticated combinations tailored to specific applications:

Coffee Packaging Systems

- PET Layer: Provides structural strength and moisture resistance

- Aluminum Foil: Creates complete oxygen, moisture, and light barriers

- LLDPE Sealant: Ensures reliable heat sealing at optimized temperatures

- Thermal Management: Protects aluminum from direct heat exposure

Ready Meal Applications

- PET/AL/Nylon/PP Structures: Engineered for retort processing requirements

- Nylon Enhancement: Adds puncture resistance for high-temperature processing

- Polypropylene Sealant: Maintains integrity through thermal cycling

- Barrier Integration: Multiple barrier layers for extended shelf life

Sustainable Material Innovation

Bio-derived sealants represent emerging alternatives with unique characteristics:

- Improved adhesion kinetics compared to traditional petroleum-based films

- Reduced carbon footprint supporting sustainability initiatives

- Require adjusted processing parameters for optimal performance

- Demand comprehensive process validation when transitioning from conventional materials

Design Optimization Factors

Strategic design choices improve reliability and reduce stress concentrations:

| Design Element | Specification | Performance Benefit | Critical Consideration |

|---|---|---|---|

| Seal Width | Minimum 5mm | Increased strength margin | Wider allows parameter tolerance |

| Corner Radius | 3mm minimum | Prevents stress concentration | Reduces tear initiation points |

| Material Thickness | Process-optimized | Optimal heat transfer | Must match sealing requirements |

| Barrier Positioning | Away from heat | Prevents degradation | Critical for multi-layer integrity |

Polymer Compatibility Requirements

Successful sealing demands molecular-level compatibility:

- Match polymer types for optimal adhesion and chain entanglement

- Consider surface treatment levels affecting bondability between layers

- Verify thermal compatibility across full operating temperature ranges

- Test long-term bond stability under actual storage and transport conditions

What Role Does Equipment Maintenance Play in Consistent Seal Quality?

Preventive maintenance programs directly impact seal consistency, with proper protocols reducing seal defects by 60-80% compared to reactive maintenance approaches. Equipment degradation creates gradual quality deterioration often unnoticed until failure rates spike.

Equipment maintenance directly impacts seal integrity through consistent temperature control, uniform pressure application, and contamination-free sealing surfaces. Critical maintenance includes daily temperature and pressure verification, PTFE cover replacement every 4,000-5,000 seals, weekly belt and pneumatic system inspection, and comprehensive calibration using traceable standards.

Critical Maintenance Protocols

Daily Maintenance Requirements

- Temperature and pressure setting verification against calibrated standards

- Sealing jaw inspection for damage, wear, or contamination buildup

- Complete residue removal using non-abrasive cleaning solutions

- Debris removal from mechanical systems preventing operational jams

- Documentation of all maintenance activities with operator signatures

Weekly Comprehensive Inspection

- Lubrication of moving parts according to manufacturer specifications

- Belt inspection for wear, tracking, and proper tension

- Pneumatic system leak detection and pressure verification

- Consumable part assessment and replacement scheduling

- Control system backup and parameter verification

PTFE Cover Management

PTFE cover replacement represents critical maintenance often overlooked:

- Covers typically provide 4,000-5,000 reliable seals before replacement

- Discoloration indicates approaching replacement requirements

- Premature replacement prevents seal quality degradation

- Element wire inspection prevents catastrophic failures damaging control systems

Calibration and Traceability

Equipment calibration maintains accuracy essential for regulatory compliance:

| Component | Calibration Frequency | Standard Requirements | Documentation |

|---|---|---|---|

| Temperature Sensors | Monthly | Traceable standards | Certificate retention |

| Pressure Monitoring | Weekly | Calibrated gauges | Trend analysis |

| Timing Systems | Quarterly | Electronic standards | Drift documentation |

| Control Software | As recommended | Manufacturer updates | Version control |

Predictive Maintenance Implementation

Advanced maintenance programs use data trending to predict failures:

- Track sealing temperature distribution patterns identifying element degradation

- Monitor pressure consistency indicating pneumatic system wear

- Analyze seal strength trends revealing gradual equipment deterioration

- Schedule maintenance based on performance data rather than arbitrary intervals

Maintenance Training and Documentation

Operator training enables early problem recognition:

- Recognize equipment performance changes indicating maintenance needs

- Understand correlation between maintenance activities and seal quality

- Document maintenance effectiveness through quality metrics tracking

- Create historical databases supporting predictive maintenance scheduling

How Do You Validate Seal Integrity Testing Programs for Regulatory Compliance?

Comprehensive validation ensures testing methods provide reliable, reproducible results meeting regulatory requirements. Unlike common misconceptions, using established ASTM methods does not eliminate validation requirements – each facility must validate methods using their specific personnel, equipment, and procedures.

Seal integrity testing validation requires three-phase qualification including Installation Qualification (IQ) verifying correct equipment setup, Operational Qualification (OQ) testing under normal conditions, and Performance Qualification (PQ) demonstrating process stability through three production lots. Validation must demonstrate precision, bias, robustness, repeatability, and linearity with environmental conditioning reflecting actual storage conditions.

Three-Phase Validation Framework

Installation Qualification (IQ)

Foundational phase ensuring testing equipment meets specifications:

- Verify correct equipment installation and environmental conditions

- Confirm appropriate utility connections and calibration records

- Document equipment specifications against purchase requirements

- Establish baseline performance parameters for subsequent testing phases

- Create comprehensive installation documentation for regulatory review

Operational Qualification (OQ)

Testing systems under normal operating conditions:

- Test sealing at lowest and highest parameter ranges

- Simulate real-world equipment fluctuations and variations

- Comprehensive integrity evaluation including visual inspection, seal width measurement, dye leak testing, and aseptic opening assessment

- Document system performance across full operational envelope

- Establish operational limits and alarm conditions

Performance Qualification (PQ)

Demonstrate consistent performance under routine production conditions:

- Test three production lots at nominal parameters with actual products

- Evaluate size and weight impacts on sealing performance consistency

- Document process stability and capability over extended periods

- Establish ongoing monitoring requirements and acceptance criteria

- Create comprehensive performance documentation supporting regulatory submissions

Design of Experiments (DOE) Implementation

Systematic parameter optimization through controlled studies:

Edge-of-Failure Studies

- Establish upper bounds at material melting temperatures

- Define lower bounds at insufficient adhesive transfer temperatures

- Identify safe operating windows with appropriate safety margins

- Document parameter interactions affecting seal quality

Range-Finding Protocols

- Select appropriate temperature/time combinations within safe limits

- Use visual scoring (0-5 scales: 1=poor, 5=perfect adhesion)

- Combine qualitative assessment with quantitative seal strength data

- Create characterization plots establishing sealing windows

| Validation Phase | Duration | Key Deliverables | Regulatory Significance |

|---|---|---|---|

| IQ | 1-2 weeks | Installation documentation | Equipment qualification |

| OQ | 2-4 weeks | Operational limits | Process capability |

| PQ | 4-8 weeks | Performance stability | Commercial readiness |

| DOE Studies | 2-6 weeks | Optimization parameters | Scientific justification |

Method Validation Requirements

Test method validation must demonstrate multiple performance characteristics:

- Precision: Consistent results under controlled conditions

- Bias: Accuracy compared to reference standards or known values

- Robustness: Performance stability under variable conditions

- Repeatability: Consistent results with same operator and equipment

- Linearity: Proportional response across measurement range

What Industry Standards and Regulations Guide Flexible Pouch Testing?

Multiple standards organizations provide comprehensive guidance ensuring consistent methodologies and regulatory compliance across global markets. Understanding applicable standards helps manufacturers select appropriate test methods and establish defensible quality systems.

Key industry standards include ASTM F3004 for FDA-recognized airborne ultrasound testing, ASTM F88/F88M-23 for seal strength measurement with recent tray testing updates, ASTM F2338 for vacuum decay testing recognized as FDA consensus standard, and ISO 11607 governing sterile medical device packaging requiring validated test methods for all packaging systems.

Primary ASTM Testing Standards

ASTM F88/F88M-23: Seal Strength Testing

Recent updates provide enhanced guidance and expanded applications:

- Improved guidance for tray applications beyond traditional pouches

- Comprehensive appendices covering inter-laboratory studies

- Sample variation impacts and statistical analysis requirements

- Primary standard for regulatory submissions and process validation

ASTM F3004: Airborne Ultrasound Testing

FDA-recognized standard for non-destructive seal integrity evaluation:

- Approved method for detecting both visible and invisible defects

- Suitable for high-speed production line integration

- Provides rapid pass/fail results supporting real-time quality control

- Growing adoption for pharmaceutical and food applications

ASTM F2338: Vacuum Decay Testing

FDA consensus standard for package integrity testing:

- Quantitative leak detection with statistical confidence levels

- Applicable to both rigid and flexible packaging configurations

- Provides deterministic results supporting regulatory compliance

- Preserves tested products for commercial sale

Specialized Application Standards

| Standard | Application | Key Requirements | Industry Focus |

|---|---|---|---|

| ASTM F1140 | Burst testing | Internal pressure limits | High-stress applications |

| ASTM F1886 | Visual inspection | 0.003-inch defect detection | Quality assurance |

| ASTM F2096 | Bubble emission | Gross leak detection | Preliminary screening |

| ASTM F1929 | Leak detection | Nonporous packages | General packaging |

ISO 11607: Medical Device Packaging

Comprehensive requirements for sterile medical device packaging:

- Mandates validated test methods for all packaging systems

- Requires design controls, verification, and validation documentation

- Specifies risk-based approaches to packaging development

- Establishes requirements for ongoing monitoring and control

FDA Regulatory Framework

FDA guidance emphasizes comprehensive documentation and risk-based validation:

- Special 510(k) Requirements: Detailed design control summaries, risk analyses, and validation results

- Process Validation: Consistent seal quality demonstration under controlled conditions

- Critical Process Parameters: Clear definition and monitoring of parameters affecting seal integrity

- Installation/Operational/Performance Qualification: Structured equipment validation approaches

Global Compliance Considerations

International markets require understanding of regional requirements:

- European Union: Medical Device Regulation (MDR) compliance for medical packaging

- Health Canada: Similar requirements to FDA with specific documentation needs

- Asian Markets: Varying requirements based on product classification and intended use

- Emerging Markets: Growing regulatory sophistication requiring proactive compliance planning

Summary

Ensuring flexible pouch seal integrity requires systematic integration of advanced testing methods, optimized sealing parameters, comprehensive quality control, and validated maintenance programs. Success depends on understanding contamination prevention, implementing appropriate testing technologies, and maintaining regulatory compliance through documented validation programs.

Modern manufacturers who prioritize seal integrity protect product quality, ensure customer satisfaction, and maintain competitive advantages in global markets through reduced recalls and enhanced brand reputation.

Ready to implement world-class seal integrity systems for your flexible packaging? Contact Acreet today for expert consultation on custom pouch design, advanced testing implementation, and comprehensive quality assurance programs. Our experienced engineering team helps global wholesalers, distributors, and brand manufacturers achieve superior seal performance through scientifically validated approaches and proven manufacturing excellence. Send us your specific packaging requirements for a detailed technical assessment and customized solution proposal that ensures your products reach customers with perfect integrity every time.