Fresh produce packaging can make or break your products’ quality and shelf life. Poor ventilation leads to moisture buildup, accelerated spoilage, and disappointed customers who receive wilted or moldy produce.

Fresh produce requires strategic ventilation through microperforated films, precisely positioned vent holes, or breathable packaging materials that maintain optimal gas concentrations. Proper ventilation prevents anaerobic conditions by keeping oxygen levels at 2-5% and carbon dioxide at 3-10%, extending shelf life by 50-200% compared to non-ventilated packaging.

Let’s explore the proven methods that keep your produce fresh from harvest to customer.

Table of Contents

ToggleWhat Makes Proper Ventilation Critical for Fresh Produce?

Understanding why ventilation matters helps you choose the right packaging approach for different types of produce.

Proper ventilation maintains optimal gas exchange, prevents anaerobic conditions, and controls respiratory heat buildup to extend shelf life while preventing off-flavors, premature ripening, and quality loss.

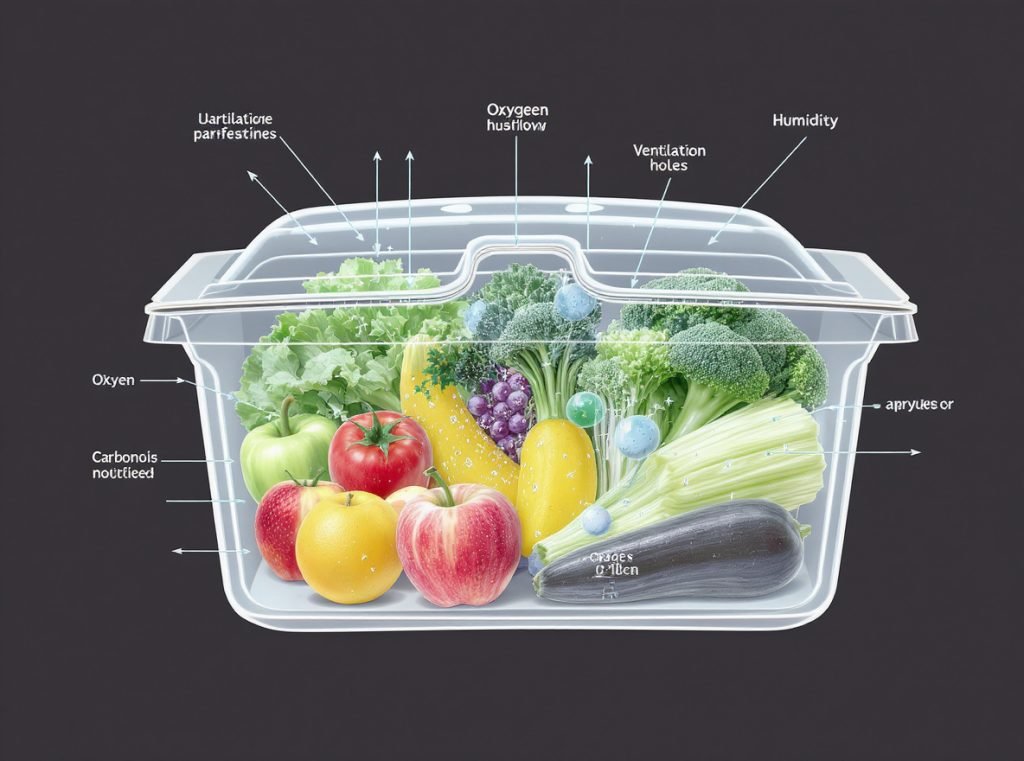

Fresh produce continues to respire after harvest, consuming oxygen and producing carbon dioxide, water vapor, and ethylene gas. The optimal respiration environment requires maintaining oxygen levels between 2-5% and carbon dioxide levels between 3-10%, significantly different from ambient air which contains approximately 21% oxygen and 0.03% carbon dioxide.

When oxygen levels drop below 2%, fermentation occurs instead of normal respiration. This produces alcohol and unpleasant flavors that compromise produce quality and make products unmarketable.

Carbon dioxide accumulation creates equally serious problems. When CO₂ concentrations rise between 1-5% in the atmosphere, it quickly ruins produce by causing bad flavors, internal breakdown, failure of fruit to ripen, and other physiological disorders.

Ethylene gas management represents another critical factor. Many fruits naturally produce ethylene, a plant hormone that accelerates ripening and senescence. Ethylene-sensitive produce like leafy greens, broccoli, and cabbage can be damaged by exposure to ethylene-producing fruits such as apples and bananas.

| Gas Type | Optimal Range | Problems if Exceeded | Common Sources |

|---|---|---|---|

| Oxygen | 2-5% | Oxidation, rapid aging | Ambient air (21%) |

| Carbon Dioxide | 3-10% | Off-flavors, internal breakdown | Produce respiration |

| Ethylene | <0.1 ppm | Premature ripening, yellowing | Apples, bananas, tomatoes |

Which Ventilation Methods Work Best for Different Produce Types?

Different fruits and vegetables require specific ventilation approaches based on their respiration rates, ethylene sensitivity, and moisture requirements.

High-respiration produce needs microperforated films with 0.1-0.5% perforation area, medium-respiration items benefit from strategic vent holes, while low-respiration produce requires mesh bags or minimal ventilation to prevent moisture loss.

High-Respiration Produce (Leafy Greens, Herbs, Broccoli):

These products have extremely high respiration rates and require immediate access to oxygen while needing protection from moisture loss. Breathable packaging with precise oxygen transmission rates prevents anaerobic conditions while maintaining optimal humidity levels of 90-95%.

Laser-perforated breathable films can extend shelf life by 50-200% compared to non-perforated alternatives. The perforation density and size can be customized based on specific produce respiration rates, ensuring optimal gas exchange without excessive moisture loss.

Use microperforated films with hole sizes of 0.5-1mm for delicate leafy greens. These provide precise gas control while requiring specialized equipment for creation.

Medium-Respiration Produce (Berries, Root Vegetables, Citrus):

Root vegetables like carrots, potatoes, and beets require moderate ventilation to prevent sprouting while maintaining firmness. These products benefit from controlled airflow that removes respiratory heat without causing dehydration.

Berries and soft fruits need balanced ventilation through microporous films that allow controlled gas exchange. Strategic placement of 4-6 vent holes on opposite sides of containers, each measuring 6-8mm in diameter, creates cross-ventilation that removes excess moisture.

Citrus fruits produce moderate levels of ethylene and benefit from ventilation that allows gas exchange while maintaining protective barriers against physical damage during transport.

Low-Respiration Produce (Onions, Garlic, Winter Squash):

These alliums and storage crops require dry, well-ventilated conditions with air circulation but should never be stored in plastic bags or airtight containers. They need lower humidity levels (70-75%) and good air circulation to prevent decay during long-term storage.

- Open mesh bags with 2-4mm openings provide adequate airflow

- Polypropylene leno bags offer excellent breathability through their open weave construction

- Ventilated crates with 12-15mm vent holes on multiple sides create three-dimensional airflow

How Do You Design Optimal Vent Patterns and Sizes?

Scientific research shows that vent hole design significantly impacts cooling efficiency and airflow distribution throughout packages.

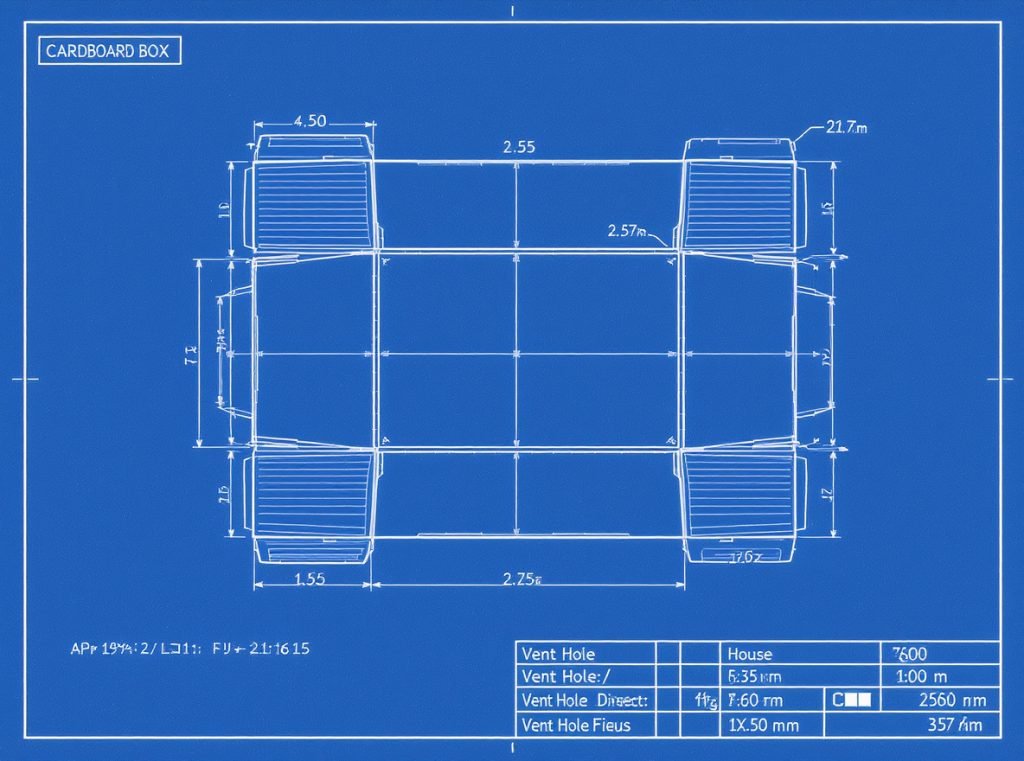

Optimal vent patterns require 7-8% of total package surface area for ventilation, with bottom vent placement providing superior airflow distribution compared to side or top vents, reducing cooling energy consumption by 37-49%.

Calculating Optimal Vent Area:

Research demonstrates that optimized vent patterns can reduce forced-air cooling energy consumption by 37-49% compared to poorly designed alternatives. Opening areas below 10% significantly increase cooling time and reduce preservation effectiveness.

Use this approach for calculating perforation requirements:

- High-respiration produce: 2-5% surface area

- Medium-respiration items: 1-3% surface area

- Low-respiration vegetables: 0.5-2% surface area

The “Multivent” design, featuring multiple small holes distributed across the package surface, showed superior performance compared to traditional large hole patterns in controlled studies.

Strategic Vent Placement Principles:

Bottom ventilation is critical for refrigerated transport, with bottom vent holes providing better airflow distribution than side or top vents. This placement works with natural convection patterns and refrigeration airflow systems.

Position primary vents on opposite sides to encourage cross-ventilation. Add secondary vents on top and bottom panels for three-dimensional airflow in deeper packages, ensuring no dead zones where moisture can accumulate.

Balancing Structural Integrity:

Ventilation holes reduce carton compression strength by 10-40%. The Edgevent and Multivent designs offer the best compromise between ventilation performance and structural integrity.

| Hole Diameter | Structural Impact | Best Applications | Performance Benefits |

|---|---|---|---|

| 0.5-1mm | Minimal (5-10% strength loss) | Delicate produce | Precise gas control |

| 2-4mm | Low (10-15% strength loss) | Berries, soft fruits | Good moisture control |

| 6-8mm | Moderate (15-25% strength loss) | Medium vegetables | Easy cooling access |

| 10-15mm | High (25-40% strength loss) | Root vegetables | Maximum airflow |

Strategic placement of vents near edges rather than centers helps maintain package strength while providing adequate airflow for optimal preservation.

What Packaging Materials Provide Natural Breathability?

Advanced materials offer inherent ventilation properties that reduce the need for mechanical perforation while maintaining product protection.

Microporous films, calcium carbonate-filled polymers, and natural fiber materials provide controlled breathability, while advanced polymer systems offer temperature-responsive permeability that adapts to environmental conditions.

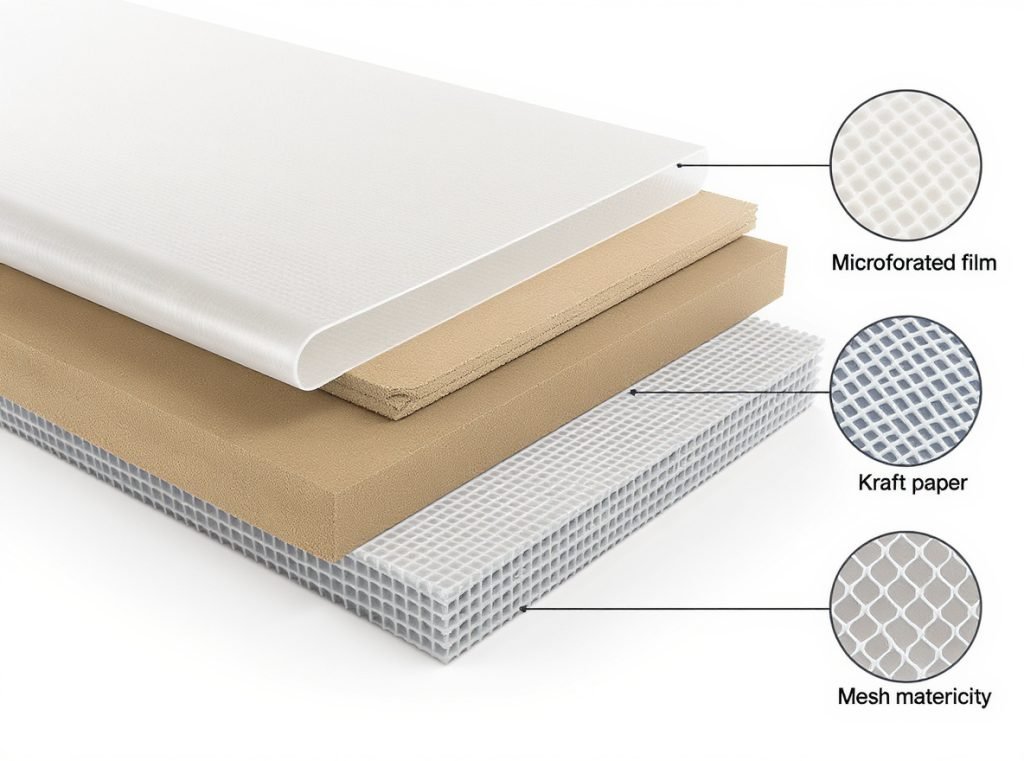

Advanced Microporous Films:

Laser-perforated films use precision laser technology to create consistent micro-perforations that control oxygen and moisture transmission rates. The perforation density and size can be customized based on specific produce respiration rates.

Calcium carbonate films incorporate calcium carbonate fillers that create microporous structures when stretched during manufacturing. These films allow water vapor and gases to pass through while blocking liquids and contaminants, providing ideal conditions for fresh produce.

Thermoplastic Polyurethane (TPU) represents non-porous breathable films that allow moisture vapor transmission through the polymer matrix without visible perforations. These materials provide controlled permeability based on molecular structure.

Natural Breathable Solutions:

Corrugated cardboard with optimized vent hole patterns remains the most common packaging for fresh produce transport. Single-wall corrugated provides moderate breathability perfect for apples, pears, and citrus fruits, while the fluting creates natural air channels.

Paper and cardboard materials offer inherent breathability while providing structural protection. Natural fiber materials provide gas exchange through their fibrous structure without requiring mechanical perforation.

Temperature-Responsive Systems:

Advanced materials adjust their permeability based on temperature changes, automatically responding to environmental conditions during transport. These systems help maintain optimal conditions even when temperatures fluctuate during distribution.

Temperature-responsive polymers provide adaptive ventilation that increases gas transmission rates as temperatures rise, compensating for increased respiration rates in warm conditions.

How Can Modified Atmosphere Packaging Enhance Ventilation?

Modified Atmosphere Packaging (MAP) represents the most sophisticated approach to produce ventilation and preservation through precise gas composition control.

Equilibrium Modified Atmosphere Packaging (EMAP) systems balance produce respiration with packaging permeability to maintain optimal oxygen (2-5%) and carbon dioxide (3-10%) levels, extending shelf life by up to 200% while preventing anaerobic conditions.

Understanding EMAP Principles:

EMAP systems create optimal gas concentrations through the balance between produce respiration and packaging permeability. The Pack-in-MAP software helps calculate optimal packaging parameters by considering produce respiration rates at different temperatures, optimal oxygen and carbon dioxide ranges for specific products, and gas permeability properties of packaging films.

This approach requires precise calculations of perforation area to achieve target gas concentrations. Too little ventilation creates anaerobic conditions, while excessive ventilation prevents atmosphere modification and reduces preservation benefits.

Active Ventilation Control:

Controlled ventilation boxes use miniature blowers and metal tubes to actively control gas exchange. These systems can increase mass transfer coefficients by at least 100 times compared to passive diffusion, maintaining optimal O₂ and CO₂ levels throughout variable temperature conditions.

Active systems automatically adjust ventilation rates based on internal conditions, responding to temperature changes and produce respiration variations during transport and storage.

Specialized Gas Applications:

Nitrogen flushing replaces oxygen with nitrogen to create low-oxygen environments that slow respiration rates. This technique is particularly effective for products sensitive to oxidation and helps prevent quality deterioration.

| Produce Type | Target O₂ (%) | Target CO₂ (%) | MAP Benefits |

|---|---|---|---|

| Leafy Greens | 2-5 | 10-15 | Prevents wilting, maintains color |

| Berries | 3-10 | 15-20 | Reduces mold, extends firmness |

| Stone Fruits | 1-3 | 3-5 | Controls ripening, prevents browning |

| Root Vegetables | 3-5 | 5-10 | Prevents sprouting, maintains texture |

Ethylene absorption systems incorporate specialized additives like potassium permanganate or activated carbon to remove this ripening hormone from the package atmosphere, preventing premature aging.

What Common Ventilation Mistakes Should You Avoid?

Many packaging failures result from ventilation errors that compromise produce quality and reduce shelf life significantly.

Over-ventilation causes rapid moisture loss and dehydration, while under-ventilation leads to anaerobic fermentation, off-flavors, and accelerated decay. Temperature-ventilation imbalances and poor stacking patterns also create significant quality problems.

Over-Ventilation Problems:

Excessive airflow causes rapid moisture loss, leading to wilting and weight reduction. Most fruits and vegetables can tolerate only 3-5% moisture loss before showing visible quality decline that customers associate with poor freshness.

Too much ventilation removes protective humidity levels, causing produce shrinkage and quality loss. Balance is essential between ventilation and humidity retention to maintain optimal relative humidity of 90-95% for most vegetables and 85-95% for fruits.

Monitor weight loss during storage trials. If packages lose more than 2% weight in the first 24 hours, reduce perforation area or adjust hole placement to maintain optimal moisture levels.

Under-Ventilation Issues:

Insufficient ventilation leads to carbon dioxide buildup and oxygen depletion, causing anaerobic respiration and off-flavors. Products packed in non-perforated films without adequate gas transmission rates develop alcoholic or fermented odors that make them unsaleable.

Signs of under-ventilation include package swelling from gas accumulation, condensation on package walls, and accelerated decay in package centers where airflow is most restricted.

Poor air circulation allows respiratory heat to accumulate, accelerating metabolism and reducing shelf life. Proper ventilation removes both heat and metabolic gases to maintain optimal storage conditions.

Design and Stacking Errors:

Using inappropriately sized or spaced perforations can either provide insufficient ventilation or compromise package integrity. Scientific calculation of optimal perforation parameters is essential for effective preservation.

Blocking ventilation holes through improper stacking prevents airflow and creates hot spots within pallets. Strategic pallet arrangement ensures continuous air circulation throughout the cold chain.

Failing to adjust ventilation rates based on temperature changes leads to either excessive moisture loss or inadequate gas exchange, both of which reduce product quality and marketability.

How Do You Test and Optimize Ventilation Performance?

Modern packaging optimization relies on scientific methods including Computational Fluid Dynamics (CFD) analysis and real-time gas monitoring to ensure optimal performance.

Conduct CFD modeling to predict airflow patterns, use automated respirometry for real-time gas monitoring, and perform controlled storage trials measuring weight loss, visual quality, and shelf life under varying temperature conditions.

Computational Fluid Dynamics Analysis:

CFD modeling predicts airflow patterns and heat transfer characteristics within packages. These models can simulate air velocity distribution, temperature uniformity across produce surfaces, pressure drop calculations for different vent configurations, and cooling efficiency comparisons between design alternatives.

CFD models are validated using experimental measurements with specialized equipment like Particle Image Velocimetry (PIV) systems and pressure sensors to ensure accuracy under real-world conditions.

Multi-parameter evaluation considers cooling efficiency, structural integrity, and cost simultaneously, preventing solutions that excel in one area while failing in others.

Real-Time Gas Monitoring:

Advanced systems use automated respirometry to continuously monitor oxygen consumption and carbon dioxide production rates. The Sable Respirometry System allows simultaneous measurement of multiple parameters including gas concentrations, flow rates, and barometric pressure.

Calculating the Respiratory Quotient (RQ) – the ratio of CO₂ production to O₂ consumption – helps identify optimal storage conditions. RQ values around 1.0 indicate healthy aerobic respiration, while values significantly higher suggest anaerobic conditions requiring improved ventilation.

Physical Performance Testing:

Specialized equipment like TVS 1100 data loggers with candle stick sensors accurately measure air velocity and temperature throughout packaging systems, validating design performance under real-world conditions.

Package integrity testing ensures ventilation systems maintain their intended performance through multiple seal testing methods:

- Gas leak tests using helium detection for ultra-fine leak identification

- Vacuum decay tests to measure seal integrity under pressure differentials

- Bubble emission tests for visual leak detection in water baths

Optimization Strategy Implementation:

| Testing Method | Key Measurements | Validation Criteria | Applications |

|---|---|---|---|

| CFD Analysis | Airflow velocity, pressure drop | <150 Pa pressure loss | Vent pattern design |

| Gas Monitoring | O₂, CO₂, ethylene levels | RQ = 0.9-1.1 | Atmosphere optimization |

| Weight Loss Tracking | Moisture retention | <3% loss in 24 hours | Perforation sizing |

| Visual Quality Scoring | Color, firmness, decay | Score >7/10 after 7 days | Overall effectiveness |

Temperature-specific adjustments account for changing ventilation requirements as respiration rates double for every 10°C temperature increase, ensuring consistent performance throughout the cold chain.

Summary

Proper ventilation transforms fresh produce packaging from simple containers into active preservation systems. Strategic approaches including microperforated films, optimal vent patterns, and Modified Atmosphere Packaging can extend shelf life by 50-200% while maintaining premium quality. Success requires matching specific ventilation methods to produce respiration rates, avoiding over- and under-ventilation mistakes, and validating performance through scientific testing methods including CFD analysis and real-time gas monitoring.

Ready to revolutionize your fresh produce packaging with scientifically-optimized ventilation solutions? Acreet combines advanced packaging engineering with proven preservation technologies to create custom solutions that extend shelf life, reduce waste, and maintain premium quality throughout your supply chain. Contact our technical team today to discuss your specific ventilation requirements and discover how our expertise can transform your produce packaging performance.