You’ve just opened your favorite tea, only to find it tastes flat and lifeless. Poor packaging is the silent killer of tea’s delicate flavor profile. Without proper protection, your premium tea transforms into expensive dust within weeks, leaving customers disappointed and your brand reputation damaged.

The key to packaging tea bags for maximum flavor and aroma preservation lies in creating an airtight, light-resistant, and moisture-proof barrier system. Use multi-layer materials like aluminum foil laminates, oxygen absorbers, and ultrasonic sealing to maintain tea quality for 12-24 months.

Let’s explore the complete packaging strategies that will keep your tea products fresh, flavorful, and profitable.

Table of Contents

ToggleWhat Are the Main Enemies of Tea Freshness?

Understanding what destroys tea quality helps you choose the right packaging approach. Tea degradation happens faster than most people realize.

Tea’s five primary enemies are oxygen, light, moisture, heat, and strong odors. Oxygen exposure causes oxidation that degrades flavor compounds within 2-4 weeks, while moisture levels above 65% can trigger mold growth in just 3-7 days.

Oxygen exposure is tea’s most significant threat, causing chemical changes that dull taste and reduce antioxidants. When tea leaves contact air, they undergo oxidation that destroys the delicate compounds responsible for fresh flavor and nutritional benefits.

Light exposure, particularly UV rays, breaks down essential oils in tea leaves. Direct sunlight causes visible discoloration and accelerated deterioration, especially damaging green and white teas that rely on delicate flavor compounds.

Even small amounts of moisture can be devastating. Humidity levels above 65% significantly accelerate spoilage, creating ideal conditions for bacterial contamination and mold growth that can ruin entire batches.

| Enemy Factor | Primary Damage | Time to Noticeable Loss | Critical Threshold |

|---|---|---|---|

| Oxygen | Flavor oxidation, antioxidant loss | 2-4 weeks | Any exposure |

| Light/UV | Essential oil breakdown | 1-3 months | Direct sunlight |

| Moisture | Mold growth, contamination | 3-7 days | Above 65% RH |

| Heat | Accelerated degradation | 1-2 weeks | Above 77°F (25°C) |

| Strong Odors | Flavor contamination | Immediate | Any exposure |

Heat exposure speeds up degradation of beneficial compounds and volatile oils. Temperatures above 77°F (25°C) accelerate chemical changes that create bitter flavors and nutrient loss.

Strong odors pose a unique threat because tea leaves readily absorb surrounding aromas. Coffee, spices, cleaning products, and perfumes can permanently alter tea’s intended flavor profile through contamination.

Which Packaging Materials Best Protect Tea Bags?

Material selection determines how long your tea maintains its quality and market appeal. Advanced barrier materials provide comprehensive protection against multiple threats.

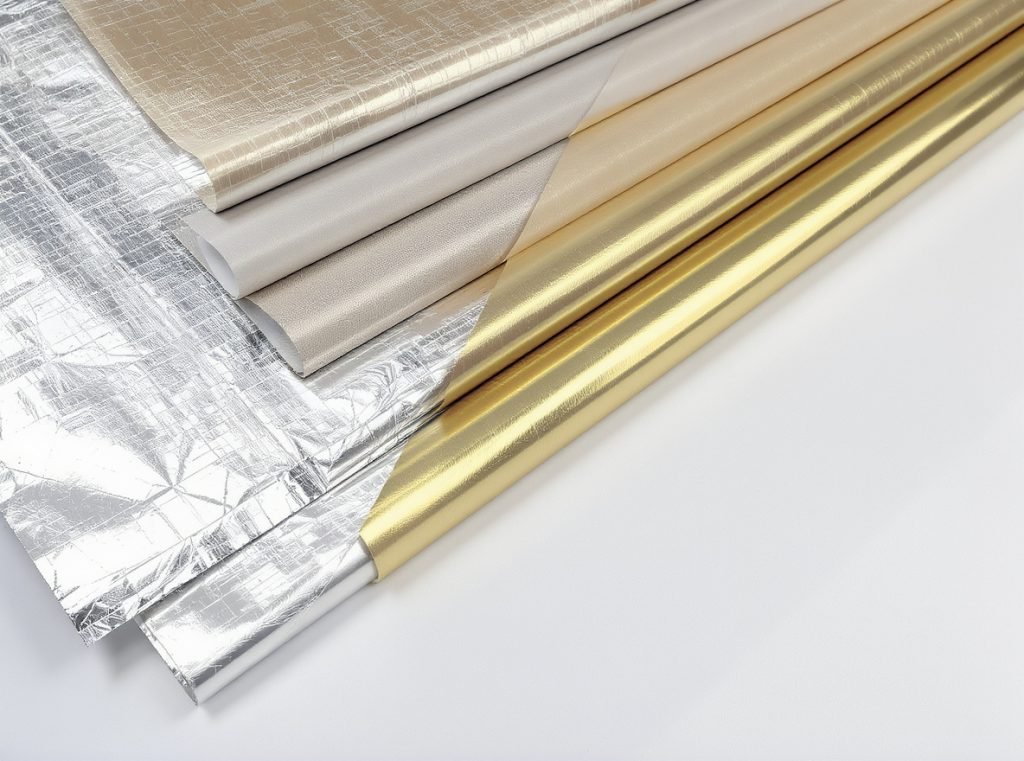

Aluminum foil laminates offer the most comprehensive protection, providing excellent barriers against light, moisture, oxygen, and odors. Common high-performance structures include PET/AL/PE and OPP/AL/PE configurations that maintain tea quality for extended periods.

Tinplate containers deliver superior barrier properties against all environmental threats while providing recyclable, premium packaging. These metal containers offer excellent protection and attractive presentation for high-end tea products.

Metallized films such as PET/VMPET/PE provide enhanced oxygen barriers through specialized metallization processes. These lightweight materials remain food-safe while delivering professional protection.

High-barrier material options by protection level:

- Premium Protection: Aluminum foil laminates, tinplate containers

- Enhanced Barriers: Metallized films, composite multi-layer materials

- Moderate Protection: Foil-lined bags with resealable features

- Eco-Friendly Options: PLA (plant starch), kraft paper with liners

Composite materials combine multiple layers to maximize protection. These typically integrate paper, plastic, and aluminum foil combinations that provide design flexibility while maintaining excellent barrier properties.

Biodegradable materials like PLA offer environmentally conscious alternatives with moderate barrier properties. Paper-based materials provide eco-friendly options but require appropriate liners for complete protection.

| Material Type | Oxygen Barrier | Moisture Barrier | Light Protection | Typical Applications |

|---|---|---|---|---|

| Aluminum Foil Laminate | Excellent | Excellent | Complete | Premium tea, long-term storage |

| Tinplate Containers | Excellent | Excellent | Complete | Gift packaging, loose leaf |

| Metallized Films | Very Good | Good | Very Good | Mid-range products |

| Foil-lined Bags | Good | Very Good | Good | Resealable retail packaging |

How Do You Create Effective Moisture Control?

Moisture management requires both preventive packaging materials and active protection systems working together.

Oxygen absorbers and desiccant packets provide active moisture control by continuously removing excess humidity from sealed packages. Combined with low water vapor transmission rate (WVTR) materials, these systems maintain optimal storage conditions throughout shelf life.

Oxygen absorbers work double-duty by removing both oxygen and moisture. These FDA-approved packets contain iron powder that can absorb approximately three times their weight in oxygen while reducing moisture to safe levels below 0.1%.

Proper environmental controls maintain storage conditions between 40-60% relative humidity. Temperature management between 68-77°F (20-25°C) minimizes moisture-related degradation risks.

Advanced sealing techniques prevent moisture infiltration:

- Ultrasonic sealing creates molecular-level bonds without heat damage

- Hermetic sealing establishes completely airtight environments

- Heat sealing provides reliable closure for thermoplastic materials

- Induction sealing offers tamper-evident moisture barriers

Package design considerations optimize moisture control by minimizing internal air space to reduce condensation risk. Rounded corners prevent stress concentration while tear notches enable easy opening without package damage.

Humidity indicators provide valuable monitoring throughout the supply chain. These color-changing cards alert handlers when moisture levels become dangerous, preventing quality failures before they occur.

What Role Does Oxygen Control Play in Tea Preservation?

Oxygen elimination extends shelf life by preventing the oxidation reactions that destroy tea’s fresh taste and aromatic compounds.

Nitrogen flushing is the most popular modified atmosphere packaging (MAP) technique for tea products, replacing oxygen with inert nitrogen gas to create preservation environments that can extend freshness by 6-24 months depending on package size.

Nitrogen flushing injects inert nitrogen gas to replace oxygen before sealing. This harmless, abundant gas doesn’t react with tea compounds and significantly extends shelf life without affecting flavor.

Vacuum packaging removes air from containers, dramatically slowing degradation processes. This method works exceptionally well for bulk tea storage and premium products where maximum freshness is essential.

Sophisticated gas mixture applications combine nitrogen with small amounts of carbon dioxide for enhanced antimicrobial properties. However, pure nitrogen remains preferred for tea packaging due to its completely inert nature.

Oxygen absorber capacity should match package volume for optimal effectiveness:

| Package Size | Recommended Absorber | Expected Shelf Extension | Oxygen Level Achieved |

|---|---|---|---|

| 50g tea bags | 100cc capacity | 6-12 months | <0.1% |

| 250g pouches | 300cc capacity | 12-18 months | <0.1% |

| 1kg bulk packs | 1000cc capacity | 18-24 months | <0.1% |

Modified atmosphere packaging creates controlled environments that maintain optimal gas compositions throughout storage. These systems can be customized for different tea varieties and storage requirements.

How Does Light Protection Impact Tea Quality?

Light exposure rapidly degrades tea’s visual appeal and flavor compounds, making comprehensive protection essential for quality maintenance.

UV-blocking materials like aluminum foil pouches and PET/AL/PE laminates provide complete light protection while maintaining product integrity. These materials block harmful rays completely, ensuring optimal preservation of essential oils and preventing discoloration.

Advanced packaging systems incorporate UV-blocking materials as part of comprehensive five-layer protection systems. These include air-tight seals, moisture barriers, and aroma protection that work together for maximum effectiveness.

Opaque containers such as steel tins and dark-tinted glass offer effective light barriers when properly stored. However, clear glass should be avoided unless products remain in completely dark environments.

Strategic packaging design balances protection with marketing requirements:

- Opaque primary packaging with clear promotional sleeves

- UV-protective coatings applied to transparent display areas

- Package orientations that minimize light exposure during storage

- Light-blocking inserts for retail display packaging

Color stability testing helps determine optimal protection levels for specific tea varieties. Green teas typically require more comprehensive protection than darker fermented teas due to their delicate compound structures.

Retail display considerations affect light protection requirements. Products stored under fluorescent lighting need different protection strategies than those in dark warehouse environments.

What Are the Best Sealing Methods for Tea Packages?

Advanced sealing technologies ensure all barrier properties function effectively throughout the product lifecycle.

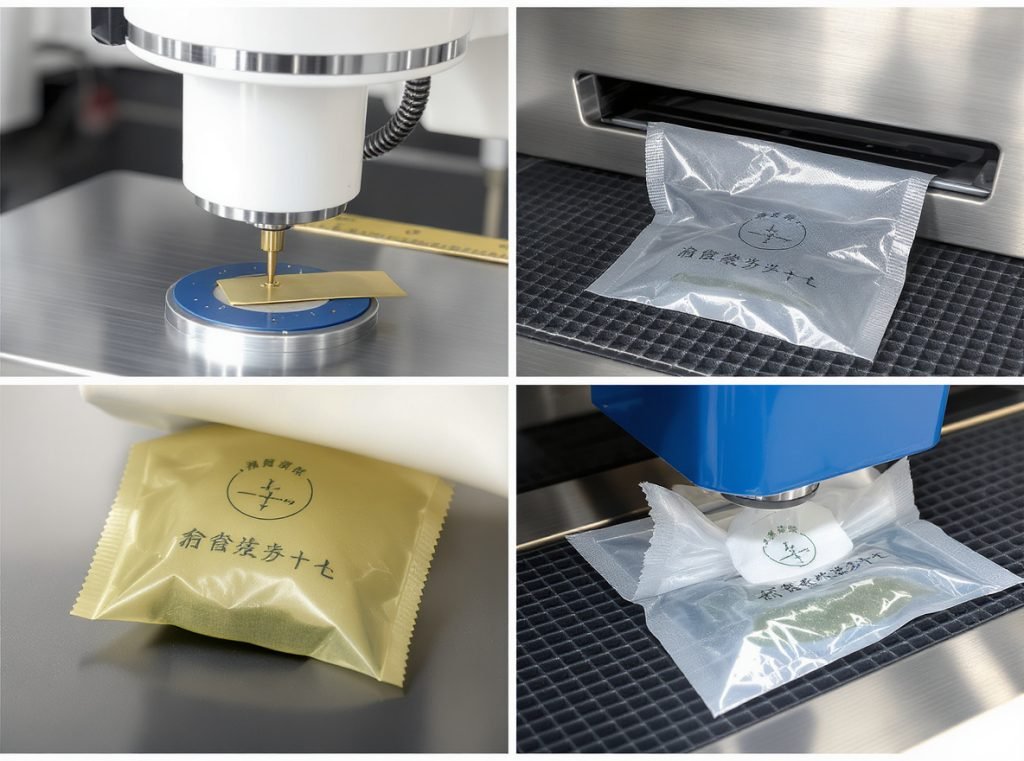

Ultrasonic sealing has emerged as the superior method for tea bag packaging, using high-frequency vibrations to create molecular-level bonds without external heat. This technology offers higher accuracy, narrow sealing edges, and no heat damage to temperature-sensitive materials.

Ultrasonic sealing provides multiple advantages over traditional methods. It creates smooth, tight seals with minimal material waste while processing faster with no cooling time requirements. This technology works effectively with various materials including nylon, PLA, and non-woven fabrics.

Heat sealing remains widely used for basic applications but has limitations including longer setup times and potential product damage. Temperature and pressure control ensure consistent quality without compromising package integrity.

Cold sealing uses pressure-activated adhesives that bond without heat application. These systems work well for heat-sensitive products or high-speed production lines where temperature control is challenging.

Advanced sealing validation ensures package integrity:

- Seal strength testing measures bond durability under stress

- Pressure decay testing evaluates long-term seal performance

- Visual inspection catches obvious sealing problems

- Dye penetration tests reveal microscopic seal failures

| Sealing Method | Key Advantages | Typical Seal Strength | Best Applications |

|---|---|---|---|

| Ultrasonic | No heat damage, precise control | 20-35 N/15mm | Premium tea bags, heat-sensitive products |

| Heat Sealing | Cost-effective, reliable | 15-30 N/15mm | Standard plastic films, bulk production |

| Induction | Tamper-evident, strong barrier | 25-40 N/15mm | Rigid containers, premium products |

| Cold Sealing | High-speed compatible | 10-25 N/15mm | Temperature-sensitive applications |

How Do You Choose Individual vs Bulk Packaging Options?

Package format decisions impact both preservation effectiveness and market positioning, requiring careful consideration of target markets and usage patterns.

Individual packaging provides maximum freshness protection because each portion remains sealed until use, while bulk packaging offers cost efficiency and environmental benefits when combined with proper resealable features and controlled storage conditions.

Individual packaging delivers enhanced freshness retention since each serving stays sealed separately, preventing repeated air exposure. This format enables premium positioning and provides consistent quality for every use.

Bulk packaging significantly reduces costs per unit with lower material usage and production expenses. Environmental benefits include reduced packaging waste and improved transportation efficiency.

Economic considerations affect packaging decisions beyond material costs. Individual wrapping increases production expenses but may justify higher selling prices through perceived premium value.

Market research reveals consumer preferences vary by tea category:

- Office environments favor individually wrapped convenience portions

- Home users often prefer bulk packaging with measuring features

- Gift markets demand attractive individual presentations

- Food service requires efficient bulk dispensing systems

Quality considerations show bulk tea can be fresher than individually packaged alternatives due to shorter supply chains and faster inventory turnover. However, this requires excellent barrier properties and proper storage conditions.

Consumer convenience factors influence format selection based on usage patterns and storage capabilities. Premium teas often warrant individual packaging protection, while everyday blends suit bulk formats.

What Quality Control Measures Ensure Packaging Effectiveness?

Comprehensive quality control prevents packaging failures that could compromise entire product batches and damage brand reputation.

Barrier property testing including Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR) measurements ensures packaging materials provide adequate protection throughout intended shelf life. Combined with moisture content testing and seal integrity validation, these measures maintain consistent quality.

Moisture content testing using equilibrium relative humidity techniques provides accurate measurements within 0.5% accuracy. While traditional oven-drying methods remain the official standard, modern techniques offer faster, real-time monitoring capabilities.

Accelerated aging tests simulate months of storage in days using elevated temperatures and humidity. These studies predict long-term package performance without waiting for real-time validation data.

Flavor and aroma retention testing employs sensory evaluation panels and gas chromatography-mass spectrometry (GC-MS) to assess volatile compounds. This ensures packaging maintains desired characteristics throughout storage periods.

Essential testing protocols include:

- Seal integrity verification prevents future failure points

- Material thickness measurements maintain barrier properties

- Visual inspections catch cosmetic and functional problems

- Process parameter monitoring ensures consistent results

| Testing Type | Purpose | Frequency | Acceptance Criteria |

|---|---|---|---|

| Moisture Content | Quality maintenance | Every batch | <6% for most teas |

| Barrier Properties | Material validation | New materials/suppliers | Meets specification limits |

| Seal Integrity | Process control | Continuous sampling | 100% seal strength |

| Sensory Testing | Flavor retention | Monthly/quarterly | No detectable changes |

Contamination prevention includes microbial testing for total plate counts, yeast, mold, and specific pathogens. Regular testing throughout production maintains hygienic conditions and product safety.

Chemical safety verification ensures packaging materials don’t transfer harmful substances to tea products. This includes testing for heavy metals, pesticide residues, and material migration under storage conditions.

Customer feedback provides real-world validation of packaging effectiveness. Complaints about staleness, damage, or off-flavors indicate areas requiring immediate attention and process improvements.

Summary

Effective tea bag packaging requires comprehensive protection against oxygen, moisture, light, heat, and odor contamination through carefully selected barrier materials and advanced sealing technologies. Multi-layer constructions, aluminum foil laminates, oxygen absorbers, and ultrasonic sealing provide optimal preservation when combined with rigorous quality control measures.

Ready to elevate your tea packaging quality and extend shelf life? Contact Acreet today for custom packaging solutions that preserve your tea’s exceptional flavor and aroma while enhancing brand appeal. Our packaging experts will help you select optimal materials, sealing methods, and quality control systems for your specific tea products and international markets.