Understanding the difference between score lines and cuts in corrugated boxes is crucial for packaging professionals seeking optimal box performance. While both processes shape your packaging, they serve completely different purposes and impact your box’s structural integrity in distinct ways.

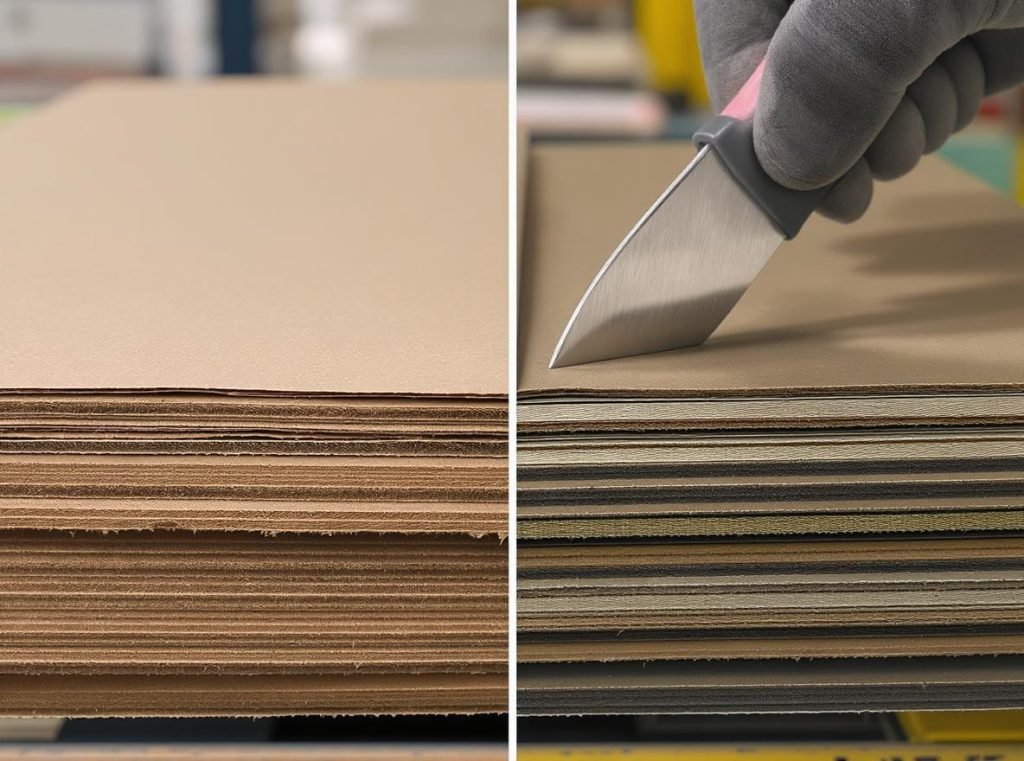

A score line is a controlled impression that only goes partway through the corrugated material, designed to facilitate precise folding without weakening the overall structure. A cut goes completely through the material, separating it into distinct pieces and creating openings necessary for box assembly.

This fundamental distinction affects everything from box durability to manufacturing costs, making it essential knowledge for anyone involved in custom packaging decisions.

Table of Contents

ToggleWhat Exactly is a Score Line in Corrugated Packaging?

Many packaging buyers confuse scoring with cutting, but understanding this difference can dramatically improve your box design effectiveness and cost control.

A score line is an impression or crease made in corrugated board to position and facilitate folds without rupturing surface fibers, creating a controlled weakening that enables precise folding while maintaining structural integrity.

Score lines work by creating a controlled stress point that allows corrugated board to fold cleanly along predetermined lines. This process involves pressing a creasing rule into the board, creating a shallow depression without cutting through the material.

The scoring process serves multiple critical functions in professional packaging:

- Facilitates precise folding by creating predetermined fold lines that prevent random creasing

- Prevents ink and coating from cracking during the folding process, maintaining professional appearance

- Ensures clean, straight fold lines that contribute to consistent box assembly and functionality

- Positions flaps and panels for proper alignment during automated or manual assembly

Score lines appear as indented lines on your corrugated box where the material has been compressed but not penetrated. The depth and width can be adjusted based on material thickness and desired fold characteristics.

| Score Line Characteristics | Function | Manufacturing Impact |

|---|---|---|

| Controlled impression depth | Creates precise fold points | Maintains fiber continuity |

| Adjustable pressure settings | Accommodates different board weights | Prevents material damage |

| Single stress point creation | Enables clean folding | Preserves structural strength |

| No material removal | Maintains full board thickness | Optimizes material utilization |

How Do Cuts Differ from Score Lines in Box Manufacturing?

Cuts serve an entirely different purpose in corrugated manufacturing, requiring different equipment and creating different structural characteristics.

Cuts completely separate the corrugated material, going entirely through all layers to create slots, flaps, openings, and separate panels necessary for box formation and functionality.

The cutting process uses sharp blades or steel rule dies that slice completely through all layers of corrugated board. This creates clean edges but removes material entirely, which affects the structural support in those areas.

Key manufacturing terminology distinguishes between different types of cuts. A slit refers to a cut made without material removal, while a slot involves cutting away a narrow strip to accommodate folding without material interference.

Manufacturing equipment handles cuts differently than scores:

- Steel rule dies incorporate cutting knives that penetrate completely through the board

- Flexo folder gluer machines use slotting stations to create cuts in sequence with other operations

- Die-cutting machines can perform both cutting and scoring simultaneously in a single pass

- Rotary die cutters enable high-speed cutting of complex shapes for custom applications

Common cut applications include die-cut handles for carrying convenience, ventilation holes for perishable products, display windows for retail visibility, perforated tear strips for easy opening, and slots between flaps to prevent material interference during assembly.

The precision of cuts directly impacts box assembly quality and manufacturing efficiency, making proper tooling and setup critical for successful production runs.

Why Does the Difference Between Scoring and Cutting Matter for Your Business?

The distinction between these processes directly impacts your packaging performance, manufacturing costs, and product protection capabilities.

Choosing the wrong process can result in box failure during shipping, increased production costs, compromised structural integrity, or poor presentation that damages your brand reputation.

Structural integrity represents the most critical difference between these processes. Score lines maintain the continuous fiber structure of corrugated board while creating controlled fold points, preserving box strength during shipping and stacking operations.

Cuts necessarily create potential weakness points where stress can concentrate, though they’re essential for box functionality. Strategic placement of cuts relative to load-bearing areas becomes crucial for maintaining adequate structural performance.

Manufacturing efficiency varies significantly between processes:

| Process Factor | Score Lines | Cuts |

|---|---|---|

| Production Speed | High-speed continuous operation | Moderate speed, depends on complexity |

| Tool Wear | Minimal wear on creasing rules | Higher wear on cutting blades |

| Setup Time | Quick pressure adjustments | More complex die alignment required |

| Material Waste | Zero waste generation | Creates trim waste requiring disposal |

Quality control considerations differ substantially. Score lines provide consistent results once properly calibrated, while cut quality can vary with blade sharpness and material characteristics. Edge crush test (ECT) ratings can be affected by score line patterns, with higher-rated boards maintaining better performance even with multiple scores.

Cost implications extend beyond immediate processing to include material utilization, waste disposal, and tooling requirements for your custom packaging projects.

When Should You Use Score Lines vs Cuts in Your Packaging Design?

Strategic selection between scoring and cutting depends on specific functional requirements, structural needs, and production volume considerations.

Use score lines when you need controlled folding capabilities while maintaining structural continuity. Use cuts when complete material separation is necessary for functionality, even though it creates weakness points.

Score line applications work optimally for fold tabs that require clean assembly, closure flaps needing secure sealing, display angles for professional presentation, and interior divider installation points.

Your product characteristics should guide process selection. Heavy items require maximum structural integrity, favoring score lines wherever possible. Fragile products might need ventilation cuts despite the structural compromise.

Manufacturing method considerations significantly impact your decision:

- Flexo folder gluer systems excel at standard box styles (RSC, HSC, FOL) requiring straight-line scoring and basic slotting

- Die-cutting processes become necessary for complex shapes, custom designs, or non-standard scoring patterns

- Volume requirements affect equipment selection, with high-volume runs benefiting from folder gluer efficiency

Optimal score line scenarios include:

| Application Type | Primary Benefit | Best Use Cases |

|---|---|---|

| Assembly fold tabs | Clean, consistent folding | RSC boxes, shipping containers |

| Closure flaps | Secure sealing capability | E-commerce packaging, mailers |

| Display presentation | Professional appearance | Retail packaging, point-of-sale |

| Interior dividers | Product organization | Multi-product shipping boxes |

Cutting becomes essential when functionality requires material removal, such as carrying handles for consumer convenience, ventilation openings for perishable goods, or display windows for retail presentation.

Consider your assembly process requirements as well. Score lines enable automated box assembly because machines can easily fold along predetermined lines, while complex cuts may require manual handling or specialized equipment.

How Do Score Lines and Cuts Affect Box Durability and Performance?

The implementation of both processes significantly impacts your packaging’s longevity, load-bearing capacity, and performance throughout the distribution chain.

Properly executed score lines enhance box functionality without significantly compromising strength, while cuts create necessary openings but must be strategically placed to avoid structural failure points.

Score line impact on durability depends heavily on execution quality and placement. Properly designed scores actually improve box performance by creating controlled stress points that prevent random failure patterns under load.

The orientation of score lines relative to flute direction critically affects performance characteristics. Scoring parallel to flutes provides different strength properties than scoring perpendicular to flutes, with each orientation suitable for different applications.

Environmental factors influence performance differently for each process:

- Score lines maintain consistent performance across temperature and humidity variations

- Cut areas may be more susceptible to environmental damage, particularly at edge locations

- Moisture exposure can affect fold line performance, requiring proper storage conditions

Load-bearing considerations become critical for heavy-duty applications:

| Structural Factor | Score Line Impact | Cut Impact |

|---|---|---|

| Compression Strength | Minimal reduction when properly executed | Proportional reduction based on material removed |

| Edge Crush Performance | Maintains rating with strategic placement | Can significantly compromise ECT ratings |

| Stacking Capability | Preserves vertical load capacity | Creates potential failure initiation points |

| Corner Strength | No impact on corner integrity | Cuts near edges compromise corner performance |

Testing protocols should evaluate both processes under realistic shipping conditions. Boxes with higher ECT ratings (32ECT, 44ECT) maintain better performance even with multiple score lines and strategic cuts, while lower-rated boards show more significant strength reduction.

Full overlap designs (FOL) use additional material and strategic cutting patterns to enhance durability for heavy-duty applications, demonstrating how proper cut placement can maintain structural performance.

What Manufacturing Equipment Creates Score Lines vs Cuts?

Different equipment types are optimized for each process, affecting production capabilities, quality consistency, and cost structures for your packaging projects.

Score lines require specialized creasing equipment that applies controlled pressure without cutting, while cuts need sharp blades, steel rule dies, or laser systems that completely separate material.

Flexo folder gluer systems represent integrated production solutions that handle printing, scoring, slotting, folding, and gluing in continuous operations. These systems feature creasing units with adjustable pressure for consistent score line creation and slotting stations for precise cuts.

Production capabilities vary significantly by equipment type:

- Creasing stations operate at speeds of 100-350 pieces per minute depending on complexity

- Rotary scoring wheels provide high-volume production with minimal setup requirements

- Integrated systems combine multiple operations for efficiency in standard box production

Die-cutting equipment offers different advantages for complex applications. Rotary die cutters use cylindrical dies for high-speed production of intricate shapes, while flatbed die cutters provide precision for complex designs and shorter production runs.

Equipment comparison for manufacturing decisions:

| Equipment Type | Best Applications | Production Speed | Setup Requirements | Flexibility Level |

|---|---|---|---|---|

| Flexo Folder Gluer | Standard box styles, high volume | 100-350 ppm | Minimal for standard jobs | Medium |

| Rotary Die Cutter | Complex shapes, medium volume | 50-200 ppm | Custom die required | High |

| Flatbed Die Cutter | Precision work, short runs | 20-100 ppm | Die and setup time | Very High |

| Laser Systems | Prototyping, specialty materials | 10-50 ppm | Programming required | Maximum |

Quality control requirements differ between equipment types. Scoring systems need regular calibration for consistent compression depth, while cutting tools require blade sharpness monitoring and periodic replacement to maintain edge quality.

Specialized applications may employ laser scoring systems for precision requirements, particularly useful for flexible packaging materials requiring exact score line placement without tool wear considerations.

How Do These Processes Impact Your Custom Packaging Costs?

Cost implications extend throughout the entire project lifecycle, affecting tooling investments, material utilization, production efficiency, and waste management.

Scoring typically costs less per linear foot with lower setup requirements, while cutting generates material waste and requires more expensive tooling but enables essential functionality.

Tooling cost differences significantly impact project economics. Flexo folder gluer operations require minimal tooling for standard box styles, making them extremely cost-effective for high-volume production runs.

Die-cutting operations demand custom steel rule dies representing substantial upfront investments, but these tools can be reused for repeat orders, amortizing costs over multiple production runs.

Production volume economics create distinct break-even points:

| Production Volume | Optimal Process | Cost Advantage | Typical Applications |

|---|---|---|---|

| Under 1,000 pieces | Manual/flatbed die-cutting | Lower setup costs | Prototypes, specialty packaging |

| 1,000-5,000 pieces | Small die-cutting runs | Balanced cost structure | Short-run custom boxes |

| 5,000-50,000 pieces | Rotary die-cutting | Efficiency gains | Medium production runs |

| Over 50,000 pieces | Flexo folder gluer | Maximum efficiency | High-volume standard boxes |

Material utilization efficiency strongly favors scoring because no corrugated board is removed during processing. Every square inch of purchased material contributes to final packaging structure, optimizing raw material costs.

Cutting inevitably creates waste material requiring disposal or recycling, adding 5-15% to total material costs depending on design complexity. However, strategic cutting can sometimes reduce overall material requirements by enabling more efficient box shapes.

Labor and operational costs vary by process selection. Automated scoring systems operate continuously with minimal operator intervention, while complex cutting patterns may require slower processing speeds or additional quality control measures.

Setup and changeover times directly impact production costs. Flexo folder gluers can change between standard box styles in minutes, while die-cutting operations may require 30-60 minutes for tool changes, affecting overall production efficiency.

Can You Combine Score Lines and Cuts in One Box Design?

Professional corrugated packaging routinely combines both processes strategically to optimize functionality, structural performance, and manufacturing efficiency in a single design.

Combining score lines and cuts allows you to maximize structural integrity through strategic scoring while incorporating essential functional features like handles, ventilation, and display elements through precise cutting.

Integrated die-cutting operations represent the most common approach for combining processes. Die boards incorporate both cutting knives for slots and flaps alongside scoring rules for fold lines, enabling simultaneous processing with perfect registration between all features.

Sequential processing in flexo folder gluer systems handles both operations in carefully planned sequences. Material receives print graphics and score lines first, then moves through slotting stations for cuts, followed by folding and gluing operations.

Design considerations for successful combination include:

- Material grain direction affects both cutting and scoring performance characteristics

- Minimum spacing requirements between cuts and score lines to maintain structural integrity

- Flute orientation relative to score line direction for optimal folding performance

- Registration precision ensures proper alignment between graphics, cuts, and scores

Complex applications demonstrate advanced integration possibilities:

| Application Type | Score Line Function | Cut Function | Combined Benefit |

|---|---|---|---|

| Retail displays | Create display angles | Product visibility windows | Professional presentation with functionality |

| Shipping containers | Enable assembly folding | Carrying handle creation | Structural integrity with user convenience |

| Food packaging | Closure system operation | Ventilation requirements | Product protection with freshness maintenance |

| Electronics packaging | Protective angle formation | Cable access openings | Product security with installation convenience |

Manufacturing considerations for combined designs require careful planning of operation sequences, tool alignment precision, and quality control protocols that address interactions between scored and cut areas.

Testing becomes more sophisticated with combined applications because interactions between different processes can create unexpected performance characteristics under various stress conditions, requiring comprehensive evaluation protocols.

Professional packaging engineers routinely design solutions that leverage both processes strategically, balancing structural requirements with functional needs while optimizing manufacturing efficiency and cost-effectiveness for your specific application requirements.

Summary

Score lines and cuts serve fundamentally different purposes in corrugated packaging manufacturing. Score lines create controlled fold points through compression without material removal, maintaining structural integrity while enabling precise assembly. Cuts completely separate material to create necessary openings, slots, and functional features essential for box operation. Understanding when to apply each process helps optimize your packaging design for durability, functionality, and cost-effectiveness throughout your supply chain operations.

Ready to optimize your corrugated packaging with the perfect combination of score lines and cuts? Contact Acreet today for expert consultation on custom box design that balances structural performance with functional requirements. Our experienced engineering team can help you select the right processes while minimizing production costs for your specific packaging needs.