Are you looking for a cost-effective way to upgrade your product packaging without a complete redesign? Paper belly bands offer an elegant solution that transforms ordinary packages into premium-looking products while providing practical benefits for your business.

A paper belly band is a printed strip of paper or cardstock that wraps around the middle of a product or packaging, serving as a decorative wrap that adds visual appeal while providing space for key information without covering the entire package. These bands create a minimalistic yet eye-catching enhancement that instantly elevates perceived value and sophistication.

Let’s explore how these versatile packaging accessories can revolutionize your product presentation and boost your brand’s market appeal.

Table of Contents

ToggleWhat Exactly is a Paper Belly Band in Packaging?

Understanding the fundamentals helps you make informed decisions about implementing this sophisticated packaging solution for your products.

A paper belly band is essentially a printed strip of paper or cardstock that wraps around the middle of a product or packaging—much like a belt around the waist. Unlike full-coverage packaging solutions, belly bands typically cover only part of the front and back surfaces, allowing the product itself to remain the focal point.

Paper belly bands function as decorative wraps that go around products and add visual appeal while providing space for key information without covering the entire package. The bands are designed to be minimalistic yet eye-catching, offering brands an elegant way to enhance their product presentation without requiring complete packaging redesigns.

These versatile packaging elements can be constructed from various materials:

- Standard cardstock: 12pt to 24pt thickness for durability

- Kraft paper: Eco-friendly option with rustic appeal

- Recycled materials: 100% recycled content for sustainability

- Specialty papers: Premium coated stocks for vibrant colors

| Material Type | Thickness | Best For | Environmental Impact |

|---|---|---|---|

| Standard Cardstock | 12pt-24pt | General applications | Recyclable |

| Kraft Paper | 100gsm | Eco-conscious brands | Biodegradable |

| Recycled Stock | Varies | Sustainable packaging | Minimal footprint |

| Specialty Papers | Custom | Premium products | Depends on coating |

Most belly bands are equipped with self-adhesive strips or double-sided tape to ensure secure application around products, making them practical for both manual and automated packaging processes.

How Do Paper Belly Bands Instantly Elevate Product Appeal?

The visual impact of belly bands extends far beyond their simple appearance, creating immediate impressions that influence purchasing decisions.

Paper belly bands instantly elevate the perceived value and sophistication of any product through their elegant appearance and refined presentation style. The partial coverage design generates intrigue and sophistication, implying something extraordinary within the product.

The psychological impact shouldn’t be underestimated. Customers perceive banded products as more premium and secure, which often results in consumers’ willingness to pay premium prices. This enhanced presentation adds a touch of elegance and sophistication to a wide variety of product packaging solutions.

Premium Positioning Benefits:

- Creates immediate impression of quality and craftsmanship

- Suggests exclusivity and special attention to detail

- Builds anticipation during the unboxing experience

- Differentiates products from competitors on retail shelves

The bands serve as eye-catching accents that elevate the overall presentation of packaged products, whether used to showcase limited-edition releases or bundle multiple items together. A properly designed belly band can transform ordinary packaging with instant brand identification—imagine a plain white box changed by a band carrying your company’s unique symbol.

Smart retailers report that products with belly bands often command 15-30% higher price points compared to standard packaging, demonstrating the real financial impact of perceived premium positioning.

What Industries Benefit Most from Paper Belly Band Packaging?

Different sectors leverage belly bands for specific advantages that align with their unique packaging challenges and consumer expectations.

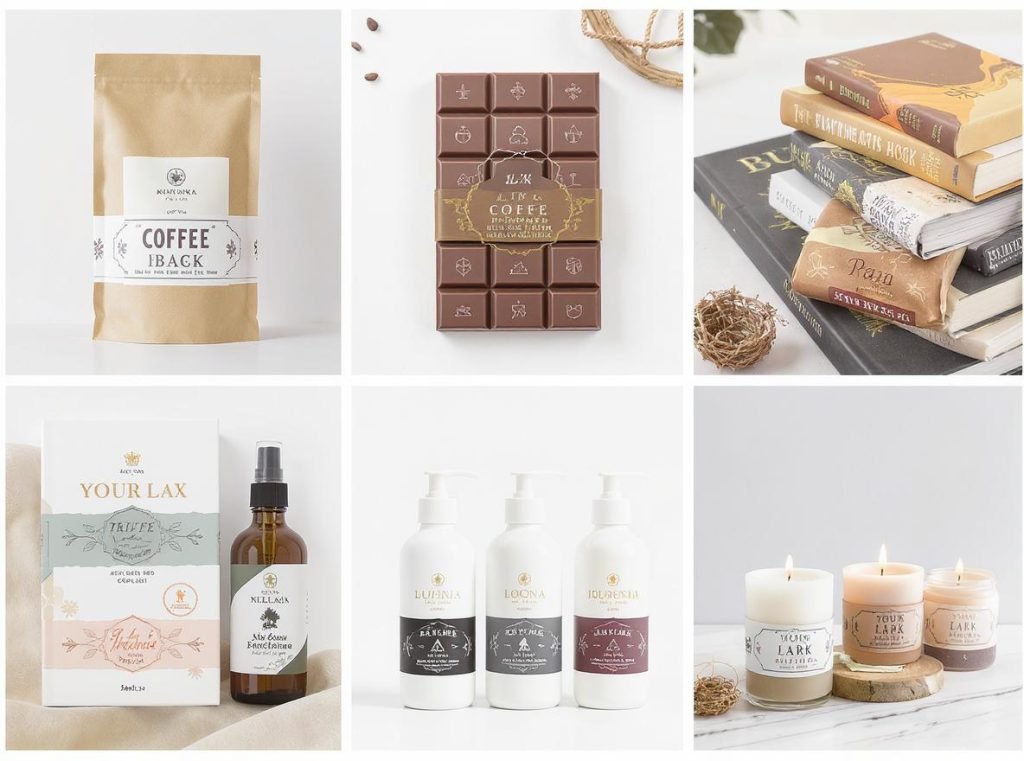

Belly band packaging is widely used across food and beverage, publishing and stationery, health and beauty, retail and e-commerce industries. Each sector utilizes these bands to address particular needs while enhancing brand presentation.

Food and Beverage Applications

The food sector extensively utilizes belly bands for gourmet baked items, tea boxes, coffee bags, bottles of wine, and handmade chocolates. Coffee roasters particularly benefit from combining custom belly sleeves with stock coffee bags to create seasonal designs and promotional campaigns while maintaining cost efficiency.

Food service operations use belly bands to provide tamper-evident seals for candy boxes and bakery containers, with self-adhering stickers creating protective layers for various food containers. The bands are especially valuable for meal kits, food tubs, and trays where branding and product information need prominent display.

Publishing and Stationery Excellence

The publishing industry has long recognized belly bands’ value for books, magazines, and printed collections. They serve multiple purposes including marketing promotion, highlighting limited editions, awards, or promotional messages without altering the book cover.

Stationery applications include notebooks, diaries, journals, wedding invitations, and gift wraps. The bands add an elegant touch to print materials while keeping multiple pieces organized, making them particularly popular for special occasions and premium stationery presentations.

Health and Beauty Sector

Cosmetics and personal care products benefit significantly from belly band packaging, including candles, cosmetic boxes, soap bars, skincare kits, and beauty accessories. The bands provide essential space for ingredient listings, usage instructions, and regulatory compliance information without compromising the product’s visual appeal.

Handmade soap manufacturers particularly favor belly bands as plastic-free alternatives for wrapping products, often using sustainable kraft paper options that align with eco-conscious consumer preferences.

How Do Paper Belly Bands Provide Superior Product Protection?

Beyond aesthetics, belly bands serve crucial functional roles in product security, integrity, and tamper evidence.

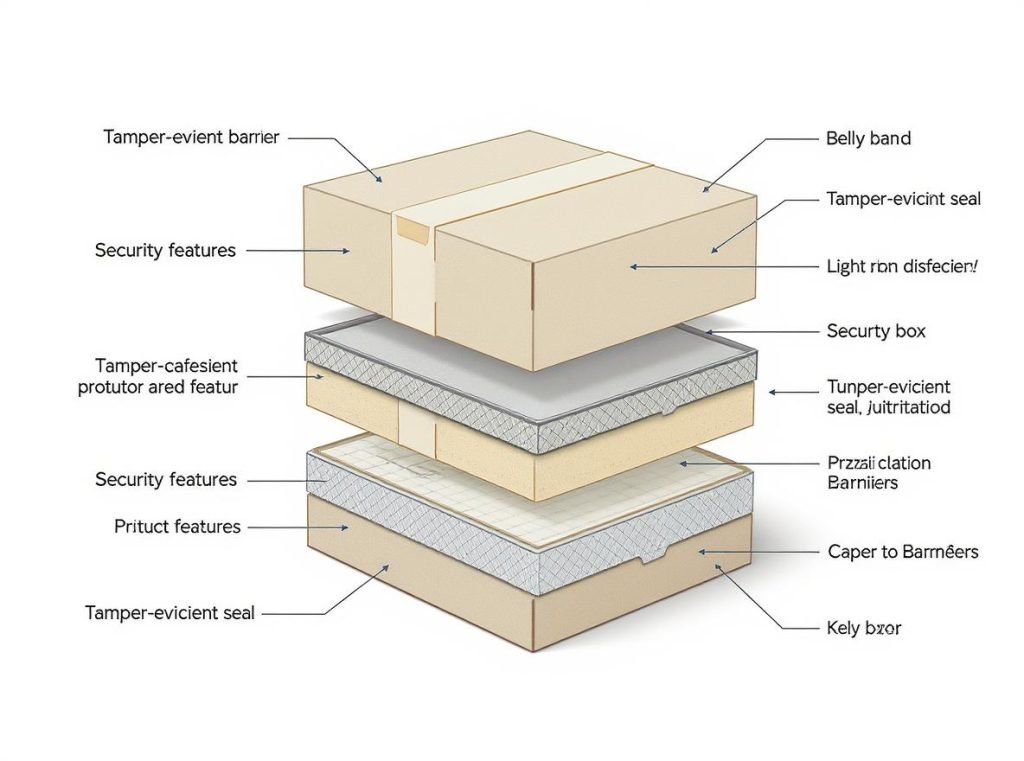

Paper belly bands provide multiple layers of product protection through protective barriers that shield products from environmental factors while maintaining easy access for consumers. They create an extra layer of security, assuring consumers of product integrity and safety through their tamper-evident properties.

Physical Protection Features

Moisture and contamination prevention represents a key benefit. While not providing complete environmental sealing, belly bands help protect products from dust, light exposure, and minor moisture contact during storage and transport.

For bundled items or multi-component products, belly bands provide structural integrity that keeps components together and prevents separation during handling. The bands work exceptionally well to hold multiple items together, especially when dealing with product bundles that would need complex packaging otherwise.

Tamper Evidence and Security

Tamper-evident properties represent one of the most valuable protection features of paper belly bands. Self-adhesive designs help create tamper-evident seals, ensuring the security and integrity of contents. Once applied, strong adhesives ensure bands don’t peel back or unravel, providing visible evidence if products have been accessed.

Security applications extend beyond basic tamper evidence. Belly bands can incorporate security features such as special adhesives, perforations, or tear-away sections that clearly indicate if tampering has occurred. This functionality is crucial for pharmaceutical products, food safety compliance, and consumer confidence building.

| Protection Type | Benefit | Application |

|---|---|---|

| Environmental | Dust, light, moisture barrier | All products |

| Structural | Keeps components together | Multi-part items |

| Tamper Evidence | Security and integrity | Food, pharma, cosmetics |

| Transport Safety | Prevents damage during shipping | Fragile items |

What Are the Significant Cost Benefits of Paper Belly Bands?

Budget-conscious businesses need packaging solutions that deliver maximum impact while maintaining financial efficiency.

Paper belly bands offer significant cost advantages compared to traditional full-coverage packaging solutions by reducing material usage, manufacturing complexity, and inventory requirements. This approach provides substantial cost savings over complete packaging overhauls.

Material and Production Efficiency

Printing on a flat sheet for a sleeve, rather than producing fully custom-printed boxes, reduces manufacturing complexity. This approach enables brands to buy unbranded or standard boxes in bulk, applying distinct sleeves to differentiate product lines.

Belly bands use considerably less material than conventional full-wrap packaging, helping to minimize overall packaging costs and reduce environmental impact. This efficiency translates to lower shipping weights and reduced transportation expenses.

Flexible Inventory Management

The cost-effective nature of belly bands allows businesses to produce different designs for various campaigns without significant inventory investments. Brands can quickly redesign bands for promotions, limited-edition runs, or product rebrands with minimal downtime and less leftover inventory.

Scalable Pricing Models

Bulk pricing advantages make belly bands particularly attractive for businesses of all sizes. Pricing typically starts as low as $0.10 per piece for basic designs, with significant volume discounts available for larger orders.

| Order Quantity | Price Range | Ideal For |

|---|---|---|

| 100-1,000 units | $0.15-$0.30 each | Small businesses, testing |

| 1,000-5,000 units | $0.08-$0.15 each | Growing brands |

| 5,000+ units | $0.03-$0.08 each | Established companies |

| Custom specifications | Quote-based | Premium applications |

Small minimum order quantities make belly bands accessible for startups, boutique companies, and specialized packaging projects, while commercial quantities offer substantial per-unit savings for larger operations.

How Simple is the Application Process for Paper Belly Bands?

Implementation simplicity often determines whether packaging solutions succeed in real-world production environments.

Whether applied manually or automatically, belly bands are relatively simple to put on, making them suitable for both small-scale artisan operations and high-volume commercial applications. The application process for paper belly bands is remarkably straightforward, requiring minimal specialized equipment or training.

Manual Application Process

Manual application is ideal for smaller production runs and artisan products, requiring only basic tools including rulers, cutting mats, and adhesive materials. The process typically involves:

- Measure the product circumference and add 1/4 to 1/2 inch for overlap

- Wrap the band around the product ensuring proper alignment

- Secure the ends using adhesive strips, stickers, or double-sided tape

- Apply consistent pressure to ensure secure adhesion

Automated Integration Options

For higher volume operations, specialized banding machines can apply belly bands with precise tension and secure packaging automatically. These systems equipped with sensors can adapt to slight variations in product dimensions, guaranteeing a secure fit every time.

Quality Control Considerations

Pre-production testing involves creating physical samples before finalizing designs to ensure proper fit and functionality. Cut a strip of paper four inches wide and the length of the product, wrap it around to mark where ends meet for accurate measurements.

Using templates and measurement guides ensures consistent application across production runs. Professional finishing includes proper creasing, accurate cutting, and secure adhesive application, maintaining quality standards throughout production.

Training requirements are minimal because the process is intuitive. New employees can learn proper application techniques quickly, reducing onboarding time and potential errors while maintaining consistent packaging standards.

What Extensive Customization Options Are Available?

Customization capabilities determine how well belly bands can align with your specific brand requirements and product characteristics.

Paper belly bands offer extensive material customization options and design possibilities to match specific brand requirements, including various paper types, specialty finishes, custom printing, and interactive elements. This flexibility enables businesses to create genuinely distinctive and memorable packaging.

Material Selection and Finishes

Standard material choices provide versatility for different applications and budgets:

- White uncoated stock: Provides clean, sturdy, and versatile options for high-quality packaging

- White silk: Enhances packaging with elegant finish for smooth, premium appearance

- Brown kraft: Durable and eco-friendly option for robust, sustainable packaging

- Recycled materials: 100% recycled content options support environmental goals

Specialty Finishing Options

Advanced finishing techniques create premium effects and enhanced brand impact:

- Lamination options: Gloss, matte, sandy matte, soft touch, and pattern coatings

- Metallic effects: Foil stamping, embossing, debossing, and metallic inks

- Surface treatments: Spot UV, flood UV, varnish, and custom coatings

Design Flexibility and Branding

Custom printing capabilities support full-color designs using CMYK processes or Pantone matching for specific brand colors. High-quality UV inks ensure vibrant, durable printing that maintains color integrity throughout product lifecycle.

Size customization is available in various dimensions to fit different products, from small items like candles to larger boxes. Custom dimensions can often be requested to meet specific needs, with standard widths ranging from 1-3 inches and lengths from 8-30 inches.

Modern belly bands can incorporate QR codes, promotional messages, and interactive features that connect physical products to digital experiences. Variable data printing allows for personalized messages and customized information on individual bands, creating unique customer experiences.

How Do Paper Belly Bands Support Environmental Sustainability?

Environmental responsibility increasingly influences packaging decisions as consumers and regulations demand eco-friendly solutions.

Paper belly bands significantly support sustainable packaging initiatives through reduced material consumption, eco-friendly material options, and compatibility with circular economy principles. Using less material than conventional full-wrap packaging, belly bands help minimize carbon footprints and reduce overall environmental impact.

Environmental Impact Reduction

The minimalist design philosophy of belly bands aligns perfectly with sustainable practices. By requiring less paper and energy to produce than traditional packaging, they represent an effective way for businesses to demonstrate environmental commitment.

Material efficiency translates to real environmental benefits. Belly bands use considerably less material than conventional full-wrap packaging, helping to minimize overall packaging costs and reduce environmental impact while maintaining packaging effectiveness.

Recyclable and Biodegradable Options

100% recycled kraft paper options are available with strong, durable construction (100gsm weight). These materials break down naturally and can be recycled through standard kerbside programs, supporting waste reduction initiatives.

Advanced sustainable options include home compostable materials that break down to become part of healthy soil in home compost systems. These materials biodegrade naturally when exposed to light, air, and moisture, offering complete end-of-life sustainability.

Circular Economy Compatibility

Mono-material packaging support represents a key advantage. Paper belly bands naturally support mono-material packaging goals by using single-type materials that simplify recycling and waste sorting. This approach ensures seamless recyclability and supports circular economy principles.

Local production options within 250 miles of delivery help reduce energy use and emissions during transport. Combined with recyclable cardboard cores and plastic-free packaging, belly bands offer comprehensive sustainability solutions that meet increasingly stringent environmental requirements.

What Key Factors Should You Consider for Successful Implementation?

Successful implementation requires careful planning and consideration of various factors that affect both production efficiency and customer satisfaction.

Key implementation factors include product compatibility assessment, brand integration strategy, cost-benefit analysis, supplier selection, and quality control procedures. Getting these elements right ensures smooth adoption and positive customer reception.

Planning and Design Phase

Product compatibility assessment involves evaluating product dimensions, packaging requirements, and target market expectations. Consider factors like product weight, surface texture, and storage conditions that might affect band performance and customer experience.

Brand integration strategy ensures belly band designs align with existing brand identity and packaging aesthetics. Consistent branding elements such as colors, fonts, and imagery help reinforce brand recognition and build consumer trust while maintaining visual coherence across product lines.

Production and Quality Control

Supplier selection requires choosing reputable printing partners with experience in belly band production. Evaluate factors including print quality, turnaround times, minimum order quantities, and customer service capabilities to ensure reliable partnership.

Testing and prototyping involve ordering samples and creating prototypes before full production runs. Test bands with actual products to ensure proper fit, secure adhesion, and desired visual impact under real-world conditions.

Operational Integration Considerations

- Staff training on proper application techniques and quality standards

- Inventory management planning for seasonal demands and promotional campaigns

- Performance monitoring through customer feedback and sales data analysis

- Quality standards establishment for materials, dimensions, and printing specifications

Working with experienced packaging manufacturers ensures your implementation vision becomes reality while maintaining cost-effectiveness and production efficiency throughout the process.

Summary

Paper belly bands provide a sophisticated yet simple packaging solution that transforms ordinary products into premium brand experiences. They offer exceptional value through enhanced branding opportunities, cost efficiency compared to full packaging redesigns, superior product protection, and strong environmental sustainability benefits. From food and cosmetics to publishing and retail, businesses across industries successfully use belly bands to differentiate their products, create memorable customer experiences, and achieve their packaging goals while maintaining budget efficiency.

Ready to elevate your packaging with custom paper belly bands that capture attention and drive sales? Contact Acreet today for expert consultation on designing and manufacturing the perfect belly band solution for your products. Our experienced team specializes in creating cost-effective, premium-quality belly bands that enhance your brand presence while meeting your specific requirements. Send us your product specifications and design ideas to begin your custom packaging transformation journey.