Parents and manufacturers face growing concerns about keeping potentially harmful products away from children while maintaining convenient access for adults. Traditional rigid containers don’t always meet modern packaging efficiency demands, yet safety remains the top priority.

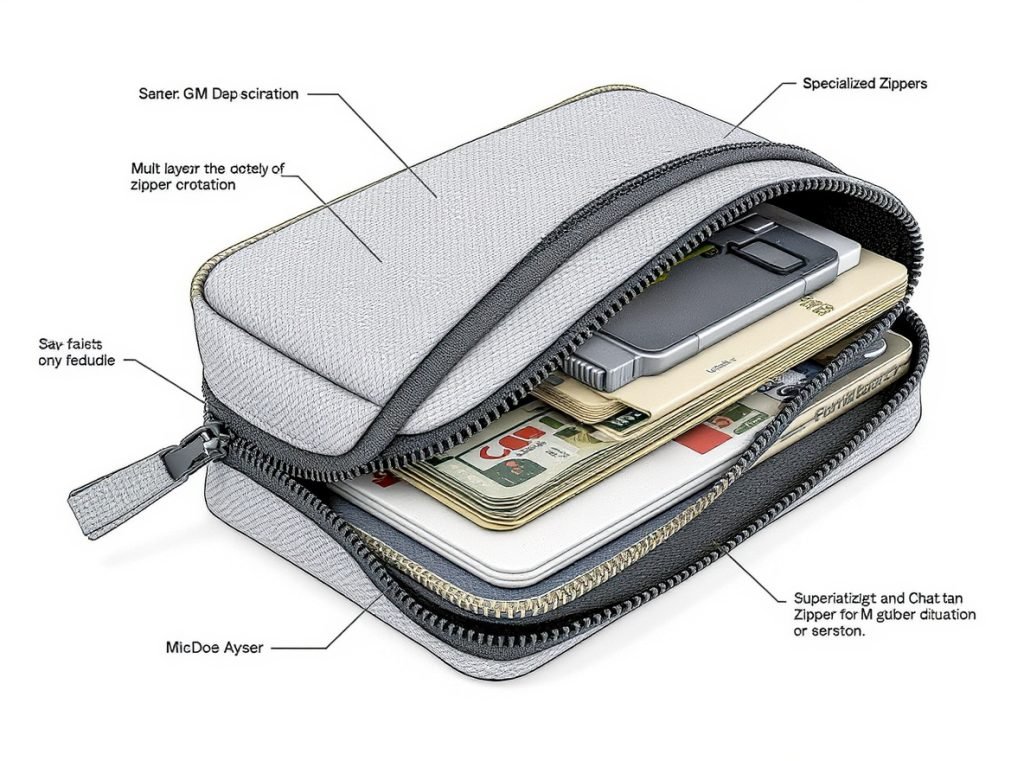

Child-resistant technology in flexible pouches uses specialized closure mechanisms like the Child-Guard® track & slider system and Safety-Lok™ press-to-close zippers that require coordinated motions children under 5 cannot perform. These systems must prevent 85% of children aged 42-51 months from opening packages while allowing 90% of adults aged 50-70 to access contents easily.

These innovative packaging solutions are transforming industries from pharmaceuticals to cannabis while meeting strict regulatory requirements and consumer safety expectations.

Table of Contents

ToggleWhat Makes a Flexible Pouch Child-Resistant?

Many assume only rigid bottles can provide adequate child protection. However, flexible pouches have evolved sophisticated mechanisms that meet or exceed traditional container safety standards.

Child-resistant flexible pouches achieve safety through multi-step opening sequences, specialized material construction, and physical dexterity requirements that exploit developmental limitations in children under five. The Consumer Product Safety Commission defines child-resistant packaging as “significantly difficult for children under 5 years of age to open or obtain a toxic or harmful amount of the substance contained therein within a reasonable time”.

The core technology centers on creating packaging that requires multiple coordinated motions, fine motor skills, or two-handed dexterity that young children typically lack. These mechanisms are embedded directly into the pouch structure during manufacturing, ensuring child-resistant features function as integral components rather than add-ons.

Key design elements that create effective barriers include:

Multi-step opening sequences requiring children to perform coordinated actions like pressing down while simultaneously pulling or sliding. The Safety-Lok™ child-resistant press-to-close zipper exemplifies this approach with its unique tabbed profile that provides resistance for younger children while remaining accessible to adults.

Specialized material construction using 4-6 mil thick multi-layer barrier films that combine moisture protection with child-resistant functionality. These pouches typically feature constructions like 48ga MetPET/LLDPE combinations offering oxygen transfer rates below 0.95.

Visual instruction dependencies that rely on reading comprehension or understanding complex diagrams – abilities that children under five typically lack. Instructions are printed directly on packaging to guide proper opening procedures.

Physical dexterity requirements such as precise finger placement in thumb pockets or alignment of slider components with specific track positions exploit developmental limitations in fine motor control that characterize young children.

Which Industries Require Child-Resistant Flexible Pouches?

Understanding regulatory requirements helps businesses navigate mandatory child-resistance standards across different sectors. Multiple industries face legal obligations for child-resistant packaging implementation.

Pharmaceutical, cannabis, household chemical, and agricultural industries are mandated by law to use child-resistant packaging. The global child-resistant packaging market is projected to reach $48 billion by 2032, with child-resistant locking pouches specifically expected to grow at 6.2% CAGR from 2025-2035.

| Industry | Regulatory Body | Common Products | Market Growth |

|---|---|---|---|

| Pharmaceuticals | FDA/CPSC | Prescription drugs, OTC medications, vitamins | Largest market segment |

| Cannabis & Hemp | State Regulations | Flower, edibles, concentrates, THC products | Fastest growing sector |

| Household Chemicals | CPSC/EPA | Detergent pods, cleaners, pool chemicals | Established requirement |

| Agricultural Products | EPA | Pesticides, lawn chemicals, nicotine products | Steady demand |

| Consumer Health | Various | Medicinal herbs, cosmetics with actives | Emerging segment |

Pharmaceutical Industry represents the largest market segment, encompassing prescription medications, over-the-counter drugs, vitamins, and dietary supplements. Companies adopted child-resistant flexible pouches to meet Poison Prevention Packaging Act requirements while reducing packaging weight and material usage.

Cannabis and Hemp Products drive significant market expansion as legalization spreads. State regulations often mandate child-resistant packaging for flower products, edibles, concentrates, and THC-containing items. Cannabis companies particularly favor flexible pouches for their discrete appearance and compliance with “exit bag” requirements.

Household Chemical Products including detergent pods, cleaning agents, and pesticides must use child-resistant packaging under both CPSC and EPA regulations. The similarity of detergent pods to candy created particular urgency for secure packaging solutions.

The regulatory landscape continues evolving, with companies increasingly adopting child-resistant packaging voluntarily for liability protection and enhanced brand reputation.

How Do Child-Resistant Zipper Systems Work?

Zipper technology represents the most widely adopted approach for child-resistant flexible packaging. These systems employ sophisticated mechanisms far beyond traditional zipper functionality.

Child-resistant zipper systems require specific manipulation techniques beyond young children’s capabilities, using press-to-engage mechanisms, pin-and-tab systems, and thumb pocket designs. Testing demonstrates these systems prevent access for 85% of children under five during initial five-minute testing periods, while 90% of adults can successfully operate them.

The most effective zipper systems employ several proven design approaches:

Press-to-Engage Systems like the Child-Guard® closure require users to align the slider tongue with a groove, press down on the slider’s top side, and then pull the slider across the track. This “point, press and pull” motion challenges children’s coordination while remaining intuitive for adults. The slider locks into a secure notch when closed, preventing accidental reopening.

Pin-and-Tab Mechanisms feature sliding zippers with pins that must be inserted to unlock contents. The Child-Guard® push-pin zipper requires lifting a latch to unlock the bag, then pulling the slider zipper while the latch remains lifted. This two-handed operation typically exceeds young children’s capabilities.

Press-to-Close Systems utilize special tab mechanisms for opening and access. The Safety-Lok™ zipper requires identifying specific tab locations and pulling them to separate from the existing closure. Multiple tabs may be present, requiring users to locate the correct operational sequence.

Thumb Pocket Designs incorporate special indentations requiring specific finger placement and pressure application. The Thumb-Pocket® Zipseal pouches require users to place thumbs in registered marks as far as possible, then execute pulling motions from precise positions.

These mechanisms exploit fundamental differences in motor development between young children and adults, creating effective safety barriers while maintaining user-friendly operation for intended users.

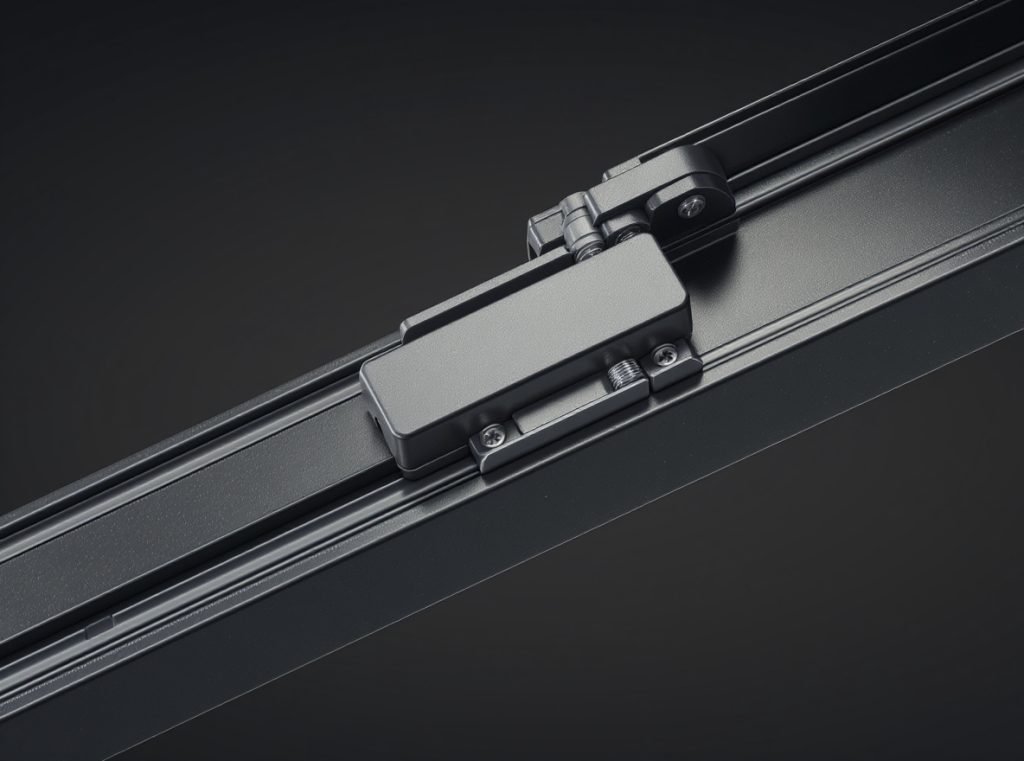

What Are Track and Slider Closure Technologies?

Track and slider systems represent the most sophisticated child-resistant closure technology available for flexible packaging, combining mechanical complexity with intuitive adult operation.

Track and slider systems require precise alignment and coordinated manipulation that exceeds young children’s capabilities. The Child-Guard® Track & Slider Technology pioneered this category, becoming the first child-resistant slider available for pouch packaging that met Title 16 CFR 1700 of the Poison Prevention Packaging Act.

These advanced systems incorporate several key technological features:

Child-Guard® Track & Slider Technology features a specialized track system with integrated slider components requiring precise alignment before activation. Users must press down on designated areas while simultaneously sliding the mechanism across predetermined paths. The system achieved certification under CFR 16, Part 1700, and ISO 8317 test requirements.

Slide-Rite® Technology provides the underlying platform for many track and slider systems, converting traditional packaging machinery to accommodate child-resistant features without requiring completely new equipment. This machinable approach allows manufacturers to integrate child-resistant capabilities into existing production lines.

Multi-Point Engagement Systems require activation at multiple track positions before opening becomes possible. The Arm and Hammer Sure Lock system exemplifies this approach, requiring users to align sliders to specific locations where unlocking mechanisms can be engaged and pressed into the zipper before sliding open.

Key advantages include:

- Reusability: Multiple open-close cycles without performance degradation

- Visual feedback: Clear indication of open versus closed position

- Tamper evidence: Obvious signs if packaging has been compromised

- Manufacturing efficiency: Integration into existing pouch production lines

Ergonomic Design Features ensure adult accessibility while maintaining child resistance. Fresh-Lock designed their systems with visible cues for consumer confidence and ergonomic profiles that accommodate users with limited dexterity, including elderly consumers who represent a significant user demographic.

How Do Press-to-Close Systems Enhance Safety?

Press-to-close mechanisms offer manufacturing simplicity while maintaining child-resistance effectiveness through coordinated pressure application requirements that challenge young children’s motor development.

Press-to-close systems provide child resistance through mechanisms requiring coordinated pressure application and manipulation techniques that challenge young children’s motor development. Testing protocols demonstrate press-to-close systems achieve 94-98% child resistance rates while maintaining 100% adult accessibility during certification testing.

The engineering behind these systems focuses on several critical elements:

Safety-Lok™ Technology represents the leading press-to-close innovation, featuring unique tabbed profiles that create resistance barriers. The system requires users to identify correct tab locations, apply precise pressure, and execute pulling motions in coordinated sequences. This complexity typically exceeds the problem-solving and motor coordination capabilities of children under five.

Thumb Pocket Integration creates specialized indentations requiring specific finger placement. The Thumb-Pocket® Zipseal pouches require users to place thumbs in registered marks as far as possible, then execute pulling motions from precise positions. Attempting to open from other areas demonstrates the system’s resistance to random manipulation.

Two-Handed Operation Requirements force users to coordinate bilateral motor functions. Many press-to-close systems require simultaneous pressure application and pulling motions that young children cannot easily coordinate. This bilateral coordination requirement serves as a fundamental barrier to child access.

Benefits for manufacturers include:

- Lower production costs compared to complex slider systems

- Faster packaging line speeds

- Reduced maintenance requirements

- Compatibility with existing pouch manufacturing equipment

- Simplified quality control testing procedures

Tamper-Evident Integration combines child resistance with tamper detection. Many press-to-close systems incorporate tear notches or perforation lines that provide visual evidence of opening attempts while maintaining child-resistant functionality throughout multiple use cycles.

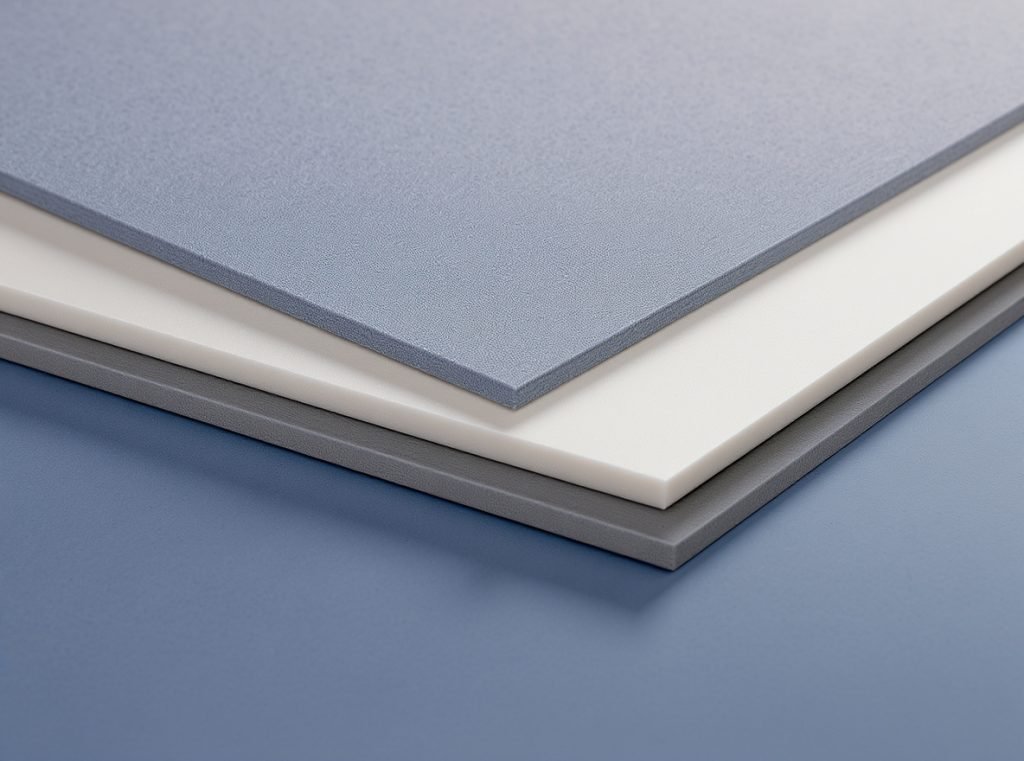

Which Materials Work Best for Child-Resistant Pouches?

Material selection significantly impacts both safety performance and manufacturing feasibility. Child-resistant pouches require specialized constructions that maintain closure integrity under repeated stress while providing product protection.

Child-resistant flexible pouches require multi-layer barrier films that balance durability, functionality, and closure system integration. Common constructions include 48ga MetPET/LLDPE combinations offering oxygen transfer rates below 0.95, with 4.3-4.6 mil total thickness providing adequate strength for repeated opening cycles.

| Material Type | Barrier Properties | Applications | Sustainability Options |

|---|---|---|---|

| MetPET/LLDPE | OTR <0.95, excellent moisture barrier | Pharmaceuticals, cannabis | 25-50% PCR content available |

| PVDC/LLDPE | Superior oxygen barrier, clear visibility | Food products, vitamins | Limited recycling options |

| Metallized Films | UV protection, mirror finish | Light-sensitive products | Aluminum recovery possible |

| Paper/PE Combinations | Good printability, moderate barrier | Dry goods, supplements | Fully recyclable options |

Multi-Layer Barrier Films provide the foundation for effective child-resistant pouches. These structures resist tearing while maintaining flexibility for closure system operation. Clear barrier films allow product visibility while maintaining child resistance, while metallized barrier films provide superior UV protection.

High-Barrier Constructions using PVDC outer layers with LLDPE inner layers create optimal protection against moisture, oxygen, and light penetration. FDA-approved materials create safe contact surfaces while maintaining compatibility with various product formulations.

Sustainable Material Options increasingly incorporate post-consumer recycled content while maintaining performance standards. AccredoFlex and similar technologies achieve over 50% PCR content in pouches while preserving child-resistant effectiveness. Fresh-Lock’s collaboration with TIPA produced home compostable closures that biodegrade within 90-180 days while maintaining child-resistant performance.

Specialized Coating Systems provide additional functionality such as easy-tear properties for single-use applications or enhanced grip surfaces for improved adult handling. Gloss lamination creates attractive surfaces for branding while providing smooth operation of sliding mechanisms.

Material selection must consider interaction with specific closure systems, as child-resistant effectiveness depends on proper integration between film structure and mechanical components.

How Do You Test Child-Resistant Pouch Effectiveness?

Testing child-resistant pouch effectiveness requires rigorous protocols established by regulatory agencies to ensure reliable safety performance across diverse user populations and usage scenarios.

Child-resistant packaging testing uses standardized CPSC protocols requiring 85% of children aged 42-51 months cannot open packages within initial five-minute periods, while 90% of adults aged 50-70 can access contents successfully. Third-party certification through accredited testing laboratories provides independent validation of regulatory compliance.

The comprehensive testing process includes several critical components:

CPSC Testing Protocol (16 CFR 1700) establishes the gold standard for child-resistant packaging validation. Testing involves panels of 50 children aged 42-51 months with specific age distribution requirements attempting to open packages during controlled five-minute periods. If unsuccessful initially, children receive demonstrations before second five-minute attempts.

Pass/Fail Criteria require that at least 85% of tested children cannot open packages during the first five minutes, and at least 80% cannot open them following demonstrations. If fewer than 85% are prevented from opening initially, additional testing with up to 200 children may be required to establish statistical significance.

Adult Accessibility Testing uses panels of 100 adults aged 50-70 years to ensure packages remain functional for intended users. At least 90% of adults must successfully open and properly reclose packages within five-minute periods, followed by one-minute replication tests to verify continued functionality.

Testing phases include:

- Initial child panel testing with 50 children aged 42-51 months

- Demonstration phase showing proper opening technique

- Second child testing period after demonstration

- Adult usability testing with 100 subjects aged 50-70

- Durability testing through 20-50 opening cycles

Durability Testing subjects packages to multiple opening and closing cycles to ensure child-resistant effectiveness persists throughout product lifecycles. Administrators examine closure mechanisms for wear, degradation, or performance changes that might compromise safety over time.

ISO 8317 and International Standards provide additional testing frameworks for global market compliance, incorporating different age ranges, testing procedures, or performance criteria depending on regional regulatory requirements.

What Are the Cost Considerations for Child-Resistant Pouches?

Understanding cost implications helps businesses make informed packaging investment decisions. Child-resistant features add complexity but provide significant value through risk mitigation and market positioning.

Child-resistant flexible pouches typically cost 15-40% more than standard pouches but remain 30-60% less expensive than rigid child-resistant containers. The global child-resistant packaging market’s projected growth to $48 billion by 2032 reflects both increasing demand and premium pricing structures across industries.

Cost factors break down across several key categories:

Initial Development Investment

- Closure mechanism tooling: $50,000-200,000

- CPSC testing and certification: $15,000-50,000 per design

- Additional international compliance testing: $20,000-75,000

- Product development timeline: 6-18 months

Per-Unit Production Costs

- Specialized closure components: $0.05-0.25 per pouch

- Higher-grade barrier materials: $0.03-0.15 per unit

- Additional quality control testing: $0.01-0.05 per pouch

- Reduced production speeds: 10-20% labor cost increase

Volume and Scale Economics

Minimum order quantities typically range from 5,000-25,000 pieces for custom child-resistant pouches. Volume significantly impacts pricing, with orders over 100,000 units achieving optimal pricing tiers. Smaller companies face higher per-unit costs due to inability to achieve manufacturing scale efficiencies.

Sustainability Premium

Eco-friendly child-resistant pouches incorporating PCR content or compostable materials typically add 20-40% to base costs. However, sustainable options may provide marketing advantages and regulatory benefits that offset increased expenses.

Total Cost of Ownership Benefits

- Reduced liability exposure and insurance premiums

- Enhanced brand protection and consumer confidence

- Avoided regulatory penalties and potential recalls

- Potential premium pricing opportunities

- Market differentiation advantages

Many businesses find the investment worthwhile when considering potential liability costs from accidents involving inadequately protected products, with some companies reporting insurance premium reductions that help offset higher packaging costs.

How Do You Choose the Right Child-Resistant Pouch Solution?

Selecting appropriate child-resistant packaging requires systematic evaluation of multiple factors to ensure optimal safety, functionality, and business performance across your specific application requirements.

Choose child-resistant pouch technology based on product characteristics, regulatory requirements, user demographics, and manufacturing constraints. Successful selection typically involves collaboration between packaging engineers, regulatory specialists, and product development teams to balance competing requirements and optimize overall solution effectiveness.

Critical decision criteria include:

Product Compatibility Assessment

Different products require specific barrier properties, chemical compatibility, and storage conditions that influence material choices. Pharmaceutical products may need moisture protection and light barriers, while food products require FDA-approved contact surfaces. Cannabis products often need odor containment and discrete appearance features.

Regulatory Requirement Analysis

CPSC requirements under the Poison Prevention Packaging Act apply to pharmaceuticals and household chemicals, while state cannabis regulations may impose additional requirements. International markets may require ISO 8317 or EN 14375 compliance. Understanding applicable regulations prevents costly redesigns and delays.

User Demographics Consideration

Products primarily used by elderly consumers may require more accessible designs, while products with broader demographic appeal can accommodate more complex mechanisms. Senior-friendly designs must maintain child resistance while ensuring 90% of adults aged 50-70 can operate packages successfully.

Manufacturing Integration Requirements

- High-volume applications may justify custom tooling investments

- Existing equipment compatibility reduces implementation costs

- Production speed requirements affect closure complexity choices

- Quality control capabilities influence testing requirements

- Supply chain reliability for specialized closure components

Sustainability and Brand Objectives

Companies prioritizing environmental responsibility may select PCR content options or compostable materials despite premium costs. Brand positioning may favor premium closure systems that enhance perceived quality and consumer confidence.

Key selection factors include:

| Factor | Zipper Systems | Track & Slider | Press-to-Close |

|---|---|---|---|

| Manufacturing Cost | Moderate | High | Low |

| User Accessibility | Good | Excellent | Very Good |

| Child Resistance | High | Very High | High |

| Reusability | Excellent | Excellent | Good |

| Speed to Market | Fast | Moderate | Fast |

Working with experienced flexible packaging manufacturers ensures you receive expert guidance throughout the selection process, from initial concept through production scaling and ongoing compliance management.

What Future Innovations Are Emerging in Child-Resistant Technology?

The child-resistant packaging industry continues evolving with breakthrough technologies that enhance safety while addressing sustainability and user experience challenges across diverse market applications.

Smart packaging integration, sustainable materials, and enhanced accessibility features represent the future of child-resistant technology. Smart packaging systems can incorporate biometric authentication, NFC tags, and digital monitoring capabilities that provide absolute child resistance while maintaining convenient adult access through personal identification.

Emerging innovations transforming the industry include:

Smart Technology Integration

Schreiner MediPharm’s Smart Blister Wallet demonstrates integration of child-resistant features with electronic adherence monitoring, using conductive trace patterns linked to individual cavities that generate real-time data when medications are accessed. These systems can send dosing reminders, track compliance, and prevent unauthorized access through smartphone authentication.

Biometric Authentication Systems are emerging for high-security applications, requiring fingerprint or facial recognition to access package contents. Patents describe smart packaging with touch sensors and communication devices that can verify user identity before allowing access, providing absolute child resistance.

Advanced Sustainable Materials combine child resistance with environmental responsibility through innovations in biodegradable polymers and enhanced recyclability. Fresh-Lock’s collaboration with TIPA produced home compostable closures that biodegrade within 90-180 days while maintaining child-resistant effectiveness. PCR content integration now achieves 50%+ recycled material in packages without compromising safety performance.

Enhanced Closure Mechanisms incorporate multiple activation points, sequential unlocking requirements, and adaptive resistance levels that adjust based on user capabilities. Future Child-Guard® innovations promise wider pouch openings with enhanced child-resistant performance, addressing user feedback while maintaining safety standards.

Future trends include:

- AI-driven predictive analytics for medication adherence and safety monitoring

- Miniaturization and integration of child-resistant features into packaging structures

- Global standards harmonization creating unified testing protocols across international markets

- Cost reduction technologies making child-resistant packaging accessible to smaller manufacturers

Market projections indicate these innovations will drive continued growth, with smart packaging expected to reach $7.8 billion by 2026 and child-resistant specific applications showing sustained expansion through 2035.

Summary

Child-resistant technology in flexible pouches combines specialized closure mechanisms, rigorous testing protocols, and advanced materials to protect children while maintaining adult accessibility. From zipper systems to smart technology integration, these solutions meet regulatory requirements across pharmaceuticals, cannabis, chemicals, and consumer products. Proper selection considers product compatibility, user demographics, and manufacturing requirements to optimize safety and business performance.

Ready to implement child-resistant flexible pouches that meet your industry’s safety standards? Contact Acreet today for expert consultation on custom packaging solutions. Our experienced team specializes in child-resistant technology selection, regulatory compliance guidance, and manufacturing optimization to create packaging that protects children while supporting your business success. Let us help you navigate the complex requirements and deliver packaging solutions that exceed safety expectations.