Choosing safe packaging materials for your food products isn’t just about protection—it’s about consumer health and regulatory compliance. The wrong paper choice could contaminate your products, damage your brand reputation, and lead to costly recalls.

The best paper materials for direct food contact include virgin kraft paper, food-grade coated papers, glassine paper, and certified paperboard. These materials must comply with FDA regulations under 21 CFR and meet strict safety standards for migration limits, chemical composition, and manufacturing processes.

Let’s explore exactly which paper materials will keep your food products safe while meeting all regulatory requirements.

Table of Contents

ToggleWhat Makes Paper Safe for Direct Food Contact?

Understanding food safety standards is crucial before selecting any packaging material. Not all papers are created equal when it comes to food contact applications.

Food-grade paper must be manufactured from virgin materials, be free from harmful chemicals like bleaches and dyes, and undergo rigorous migration testing to ensure substances don’t transfer to food products beyond acceptable limits under FDA 21 CFR regulations.

Food-grade paper refers to materials specifically designed to meet stringent safety standards established by regulatory agencies, ensuring they don’t transfer harmful substances or contaminants to food items.

The safety of paper for food contact depends on several critical factors:

Virgin Material Requirement: Only virgin-grade paper is approved for food-grade applications, as recycled paper is not considered safe for direct food contact. Virgin paper made from fresh wood or cotton pulp provides contamination-free material, making it ideal for food packaging.

Chemical-Free Production: Food-grade paper must be free from harmful chemicals such as bleaches and dyes that could pose health risks. The production process involves minimal chemical additives, making it safer than alternatives like Teflon-coated materials.

Migration Testing Compliance: Materials must undergo rigorous testing to ensure harmful substances don’t migrate into food products. The FDA requires that materials not endanger human health, change food composition unacceptably, or affect taste and smell.

| Safety Factor | Requirement | Testing Standard |

|---|---|---|

| Migration Limits | <10 ppb for most substances | FDA 21 CFR 176.170 |

| Chemical Composition | Only approved substances | FDA 21 CFR Database |

| Manufacturing Process | GMP compliance | ISO 22000 Standards |

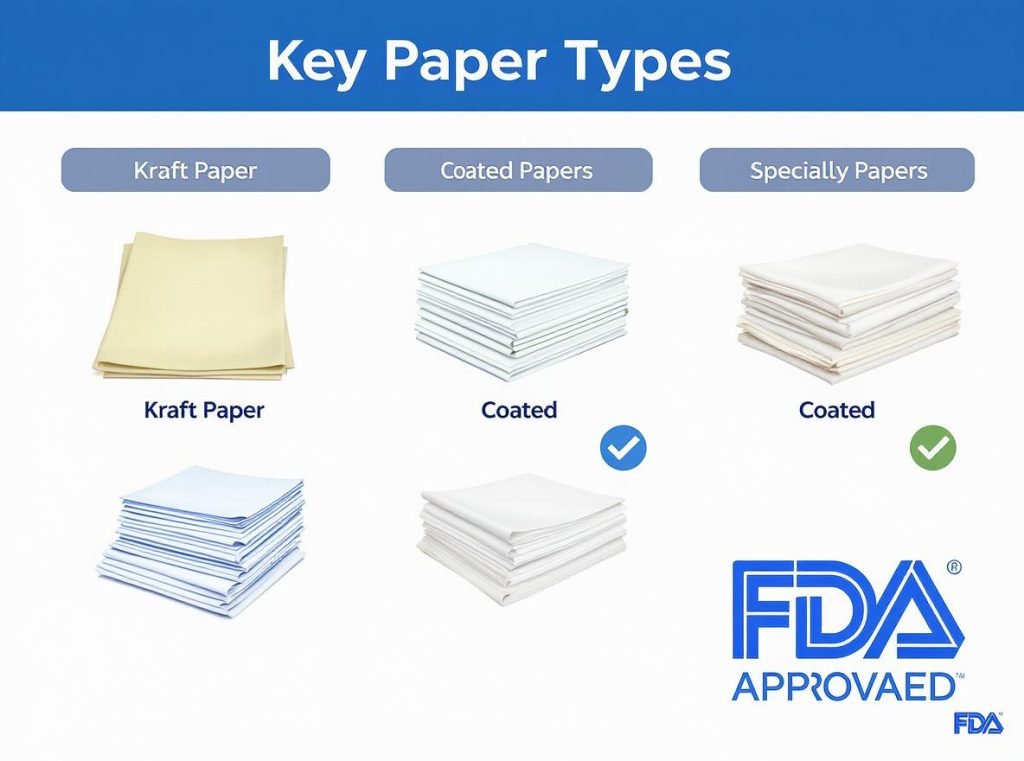

Which Types of Virgin Paper Work Best for Food Packaging?

Virgin paper materials offer the highest safety standards for direct food contact applications. These papers provide consistent quality and eliminate contamination risks associated with recycled content.

Kraft paper from FDA-approved sources, virgin wood pulp papers, and FSC-certified papers are the top choices for direct food contact. They offer superior strength, natural barrier properties, and consistent food safety compliance.

Kraft paper stands out as one of the most reliable choices for food packaging, made from chemically treated wood pulp to enhance strength while maintaining safety standards.

Virgin kraft paper excels in multiple applications:

Natural Brown Kraft: Perfect for dry food products like nuts, coffee beans, and baked goods. Its unbleached nature provides natural grease resistance while maintaining food safety standards with superior tear resistance.

Bleached White Kraft: Ideal for applications requiring high-quality printing and clean appearance. Food service bags, sandwich wraps, and retail packaging benefit from its bright white surface and excellent printability.

Virgin Wood Pulp Benefits: Papers made from virgin wood pulp have no risk of contamination, are safe for contact with food, and don’t transfer harmful ingredients. Virgin wood pulp fibers offer much higher resistance to punctures and tears compared to recycled alternatives.

- Excellent moisture and grease resistance for dry goods

- Superior mechanical strength prevents package failure

- Natural antimicrobial properties from lignin content

- Cost-effective solution for large-volume applications

- Better stiffness and enhanced aesthetic appeal

FSC-Certified Papers: Forest Stewardship Council certified papers guarantee sustainable sourcing from responsibly managed forests while meeting both environmental and safety standards, ensuring complete supply chain traceability.

How Do Coated Papers Enhance Food Safety?

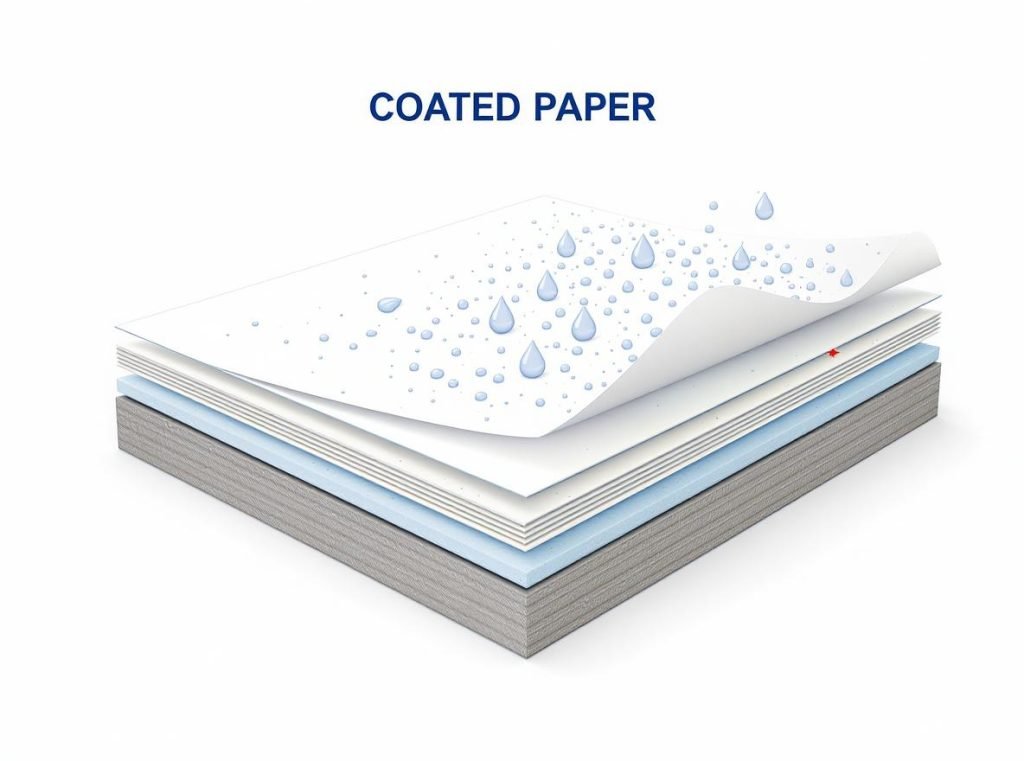

Coating technologies significantly improve paper’s barrier properties and food safety performance. Various coating types address specific food packaging challenges.

Food-grade silicone coatings, polyethylene (PE) coatings, and biodegradable PLA coatings create superior moisture and grease resistance while maintaining FDA compliance for direct food contact applications.

Coating technologies significantly improve paper’s barrier properties essential for food packaging applications, with various coating types addressing specific packaging challenges.

Different coating types serve specialized purposes:

Silicone Coatings: Most parchment papers use food-safe silicone coatings that provide non-stick and heat-resistant properties. Silicone remains stable at high cooking temperatures, doesn’t leach chemicals, and is generally safe for food contact applications.

Polyethylene (PE) Coatings: These provide excellent moisture barriers for frozen foods, dairy products, and beverages. The PE coating creates a heat-sealable surface perfect for cartons and cups while maintaining food safety standards.

PLA and Biodegradable Coatings: Modern sustainable options include polylactic acid (PLA) and other biodegradable coatings that provide moisture barrier properties while allowing packaging to be composted both industrially and at home.

| Coating Type | Best Applications | Key Benefits |

|---|---|---|

| Silicone Coating | Baking papers, heat applications | Heat resistant up to 425°F, non-stick |

| PE Coating | Liquid containers, frozen foods | Heat sealable, excellent moisture barrier |

| PLA Coating | Sustainable packaging, cold foods | Compostable, biodegradable, moisture resistant |

The coating process must use only FDA-approved materials. The FDA does not “approve” food-contact materials and it is up to the formulator–supplier to make that determination, with coatings needing compliance with regulations like 176.170 and 176.180.

What About Specialty Papers Like Glassine and Parchment?

Specialty papers offer unique properties for specific food packaging applications. These materials undergo specialized manufacturing processes to achieve desired characteristics.

Glassine paper and parchment paper are FDA-approved specialty options offering superior grease resistance and heat tolerance. Glassine is specifically FDA-approved for direct food contact, while parchment paper provides heat resistance up to 425°F/220°C.

Both materials undergo specialized manufacturing processes to achieve unique properties for specific food packaging applications.

Glassine Paper Properties: Made from highly refined wood pulp through supercalendering, glassine is considered food-safe and FDA-approved for direct food contact. This smooth, dense paper offers excellent grease resistance and natural translucency for product visibility.

Parchment Paper Safety: Generally considered safe for cooking and baking when used within recommended temperature limits. Made from cellulose fibers with silicone coating, it provides non-toxic protection with no harmful chemical release when heated properly.

Specialty Paper Applications: These materials excel in specific food service applications where standard papers cannot perform adequately.

- Superior grease and oil resistance without chemical treatments

- Heat tolerance for cooking and baking applications

- Natural transparency for enhanced product visibility

- Biodegradable properties supporting sustainability goals

- Non-stick surfaces eliminating need for release agents

| Paper Type | Temperature Limit | Best Applications | Key Properties |

|---|---|---|---|

| Glassine | Standard temperatures | Candy wrapping, bakery items | Grease resistant, translucent |

| Parchment | Up to 425°F/220°C | Baking, hot food packaging | Heat resistant, non-stick |

Are There Sustainable Paper Options for Food Contact?

Environmental concerns drive demand for sustainable food packaging materials. Several eco-friendly paper options maintain food safety while reducing environmental impact.

FSC-certified papers, biodegradable papers made from sugarcane bagasse and bamboo fiber, and compostable coated papers offer environmentally responsible alternatives while meeting FDA food contact requirements.

The demand for sustainable food packaging has led to innovative eco-friendly solutions that maintain strict safety standards while reducing environmental impact.

Sustainable options include several proven materials:

FSC-Certified Papers: Forest Stewardship Council certification ensures responsible forestry practices and sustainable forest management. These papers maintain all food safety properties while supporting environmental protection, social benefits for communities, and economic viability.

Plant-Based Alternatives: Modern biodegradable papers made from sugarcane bagasse, bamboo fiber, and other agricultural waste materials offer sustainable alternatives. These materials break down naturally in industrial composting environments while providing excellent food protection.

Recyclable Solutions: Many food-grade papers are designed to be 100% recyclable, supporting circular economy principles. These papers can be processed through standard paper recycling streams while maintaining food safety standards.

| Sustainable Option | Growth/Harvest Cycle | Food Safety Status | Environmental Benefit |

|---|---|---|---|

| FSC Kraft Paper | Managed forest rotation | Fully FDA compliant | Responsible forestry |

| Bamboo Paper | 3-4 years to harvest | FDA compliant | Rapid renewable resource |

| Bagasse Paper | Agricultural waste utilization | Emerging compliance | Waste stream reduction |

Compostable Innovations: New developments include compostable coatings that allow packaging for both hot and cold foods to be composted industrially and at home, supporting comprehensive sustainability goals.

How Should You Choose Paper Based on Food Type?

Different food products require specific paper characteristics for optimal safety and performance. Matching paper properties to food requirements ensures both safety and quality.

Choose paper based on your food’s moisture content, fat content, temperature requirements, and storage conditions. High-moisture foods need barrier coatings, while dry goods can use uncoated kraft papers.

Food characteristics determine paper selection:

High-Fat Content Foods: Require grease-resistant papers or barrier coatings. Examples include fried foods, nuts, and processed meats. Glassine or wax-coated papers work best.

High-Moisture Foods: Need moisture barriers to prevent package failure. Fresh produce, dairy products, and prepared foods require PE-coated or laminated papers.

Hot Food Applications: Demand heat-resistant materials that won’t break down or release chemicals. Parchment papers and specially treated kraft papers handle these requirements.

Dry Storage Products: Can use uncoated virgin kraft papers for cost-effective protection. Flour, sugar, and grain products benefit from kraft paper’s natural properties.

- Match barrier properties to food characteristics

- Consider temperature exposure during use

- Evaluate storage duration requirements

- Account for distribution and handling conditions

What Regulatory Standards Must Food Contact Papers Meet?

Compliance with food safety regulations is non-negotiable for commercial food packaging. Understanding key regulatory requirements helps ensure proper material selection.

Food contact papers must comply with FDA 21 CFR regulations, specifically sections 176.170 for aqueous and fatty foods and 176.180 for dry food contact, plus undergo migration testing and meet Good Manufacturing Practices requirements.

Compliance with comprehensive food safety regulations is non-negotiable for commercial food packaging, with different regions maintaining specific requirements.

Key regulatory frameworks include:

FDA Requirements (United States): All paper components must use only approved substances listed in the FDA database under 21 CFR regulations. Key sections include 21 CFR 176.170 for components in contact with aqueous and fatty foods, and 21 CFR 176.180 for dry food contact applications.

European Union Standards: EU food contact materials must comply with Regulation (EC) 1935/2004 framework regulation, German BfR XXXVI specific requirements for paper and board, and comprehensive Good Manufacturing Practices requirements.

Core Compliance Requirements: All food contact papers must not endanger human health, not alter food composition unacceptably, not affect taste, smell, or appearance, and meet rigorous migration testing requirements to prove safety for intended use.

Food Contact Substance Notification: The FDA’s FCN program regulates new materials, ensuring thorough safety evaluation before market approval.

| Regulation | Requirement | Testing Standard |

|---|---|---|

| 21 CFR 176.170 | Aqueous/fatty food contact | Migration testing with food simulants |

| 21 CFR 176.180 | Dry food contact applications | Chemical composition analysis |

| EU 1935/2004 | Framework compliance | Good Manufacturing Practices |

The regulatory status of food contact materials depends on the regulatory status of each individual substance that comprises the article, including adhesives, coating components, and paper components.

How Can Professional Packaging Suppliers Help?

Working with experienced packaging suppliers ensures you get the right materials for your specific applications. Professional guidance helps navigate complex regulatory requirements.

Qualified packaging suppliers provide FDA-compliant materials, comprehensive regulatory documentation, and technical expertise for food contact applications. They ensure consistent quality through certified manufacturing processes and ongoing compliance support.

Working with experienced packaging suppliers ensures access to compliant materials and expert guidance throughout the selection and implementation process.

Essential Supplier Capabilities: Look for suppliers with extensive ranges of food-grade materials, certified manufacturing quality standards, complete certification and compliance documentation, and comprehensive testing and quality assurance processes.

Critical Supplier Evaluation Questions: When evaluating potential packaging partners, consider what certifications they maintain (FDA, FSC, BfR XXXVI), whether they can provide migration testing documentation, what quality control measures are in place, if they offer sustainable and eco-friendly options, and their track record with food-grade applications.

Long-term Partnership Benefits: Establishing relationships with qualified suppliers provides consistent material quality and availability, comprehensive regulatory compliance support, cost optimization through volume relationships, access to innovation and new sustainable materials, and effective risk management through supplier diversification.

At Acreet, we understand the critical importance of regulatory compliance in food packaging design. Our comprehensive supplier network and technical expertise ensure your packaging materials meet all safety standards while optimizing performance and costs.

Our Food-Safe Material Services:

- Complete range of FDA-compliant papers and coatings

- Migration testing coordination and documentation

- Sustainable material options including FSC-certified papers

- Custom coating solutions for specific barrier requirements

- Regulatory compliance support for global markets

Contact Acreet today for expert guidance on selecting compliant, cost-effective paper materials that meet your exact food contact requirements while supporting your sustainability goals.

Summary

Selecting appropriate paper materials for direct food contact requires careful consideration of safety standards, regulatory compliance, and food-specific requirements. Virgin kraft papers, food-grade coated papers, and specialty options like glassine provide safe, effective solutions when properly selected and certified.

Ready to ensure your food packaging meets all safety standards? Contact Acreet for expert guidance on selecting the perfect paper materials for your direct food contact applications.