Rising shipping costs are eating into your e-commerce profits, and dimensional weight pricing is likely the culprit. Your lightweight products are being charged as if they weigh much more, creating an invisible tax on every shipment that’s costing you thousands annually.

The best practices for reducing dimensional weight in e-commerce include right-sizing packaging with custom solutions, switching to lightweight mailers, eliminating void fill, negotiating higher divisors with carriers, and implementing automated cartonization systems. These strategies can reduce shipping costs by 15-30% while improving operational efficiency.

Let’s dive deeper into proven strategies that successful e-commerce businesses use to slash their dimensional weight charges and boost profitability.

Table of Contents

ToggleWhy Does Dimensional Weight Matter More Than Ever in 2025?

Understanding dimensional weight’s growing impact helps you prioritize the right cost-saving strategies for your business.

Dimensional weight pricing now drives parcel spend more than actual weight. In August 2025, FedEx and UPS began rounding every fraction of an inch up to the next whole inch before calculating DIM, instantly inflating billable weight for millions of shipments. Combined with aggressive 139 divisors, more parcels than ever price on volume.

Carriers monetize space, not mass. Large, light parcels crowd trailers and planes, forcing carriers to optimize revenue per cubic inch. The recent rule changes have made dimensional weight optimization critical for survival:

Fractional Inch Rounding: The August 2025 change means a package measuring 12.1″ × 9.3″ × 6.8″ now bills as 13″ × 10″ × 7″, adding significant dimensional weight.

Aggressive Divisors: UPS Daily and FedEx use a 139 divisor domestically, while USPS uses 166. Missing this shift erodes margins, distorts freight forecasts, and triggers costly post-invoice adjustments.

Space Competition: Carriers prioritize dense shipments that maximize trailer utilization. Shipping lightweight items in oversized packaging now carries a premium penalty that can triple your actual shipping costs.

The impact extends beyond individual shipments. Brands failing to adapt see 20-50% shipping cost increases while competitors using optimized packaging gain competitive pricing advantages.

How Can Right-Sized Packaging Dramatically Cut Your DIM Charges?

Right-sizing represents the most effective strategy for controlling dimensional weight costs across your entire operation.

Right-sized packaging through custom solutions, multi-depth boxes, and on-demand cutting systems can reduce dimensional weight by 15-30% while cutting damage claims by 20%. Every inch trimmed from package dimensions creates compound savings across millions of shipments.

Maintaining a broad library of cartons or implementing on-demand box-cutting ensures each SKU ships in the smallest safe container. Modern fulfillment operations use these proven approaches:

Multi-Depth Box Systems: Boxes with perforated score lines allow height adjustment without maintaining separate SKU inventories. A single box design can accommodate 3-4 different product heights efficiently.

On-Demand Corrugated Systems: Companies like Packsize create boxes in real time from fanfold blanks, slashing void by 15-30% and shipping spend by 15-30% in documented programs. Brands report 20% fewer damage claims thanks to precise fits.

| Custom Packaging Solution | Void Reduction | Cost Savings | Implementation Time |

|---|---|---|---|

| Multi-depth boxes | 15-25% | 10-20% | 2-3 weeks |

| On-demand cutting | 25-30% | 15-30% | 4-8 weeks |

| Product-specific inserts | 20-30% | 12-25% | 3-6 weeks |

ABC Sizing Matrix: Pair high-volume SKUs with dedicated cartons while using variable-depth or on-demand solutions for long-tail items. This approach optimizes inventory costs while maximizing dimensional efficiency.

Working with experienced packaging manufacturers like Acreet ensures your custom solutions balance cost reduction with product protection. Their expertise in dimensional weight optimization identifies opportunities that generic packaging solutions miss.

Which Lightweight Materials Offer the Best Protection-to-Weight Ratio?

Strategic material selection directly impacts both dimensional weight and actual weight charges while maintaining product protection.

Switching from rigid corrugated packaging to lightweight alternatives like poly mailers and bubble mailers can reduce package weight by 80-90% while cutting dimensional footprint significantly. The key is matching material properties to product protection requirements.

Material comparison for dimensional weight optimization:

| Packaging Option | Typical Added Weight | Protection Level | Best Applications | DIM Impact |

|---|---|---|---|---|

| Poly mailer | <0.1 lb | Low | Apparel, soft goods | Minimal – flexible |

| Bubble mailer | 0.15-0.25 lb | Medium | Cosmetics, books | Low – semi-rigid |

| E-flute corrugated | 0.3-0.6 lb | Medium-high | Small electronics | Moderate |

| B-flute corrugated | 0.6-1.2 lb | High | Fragile, bulky items | High |

Environmental Benefits: Light mailers cut both DIM and scale weight while reducing environmental impact. Brands switching from 0.7 lb boxes to 0.05 lb poly mailers cut CO₂ emissions six-fold and energy use 23×.

Protection Without Bulk: Modern packaging engineering focuses on structural integrity through design rather than material thickness. Folded reinforcement patterns and strategic scoring provide strength without adding dimensions.

Material Transition Strategy: Start with non-fragile, soft goods for mailer conversion, then gradually expand to harder goods as you build confidence in protection levels.

How Does Eliminating Void Fill Reduce Dimensional Weight?

Void elimination represents one of the fastest ways to achieve immediate dimensional weight savings.

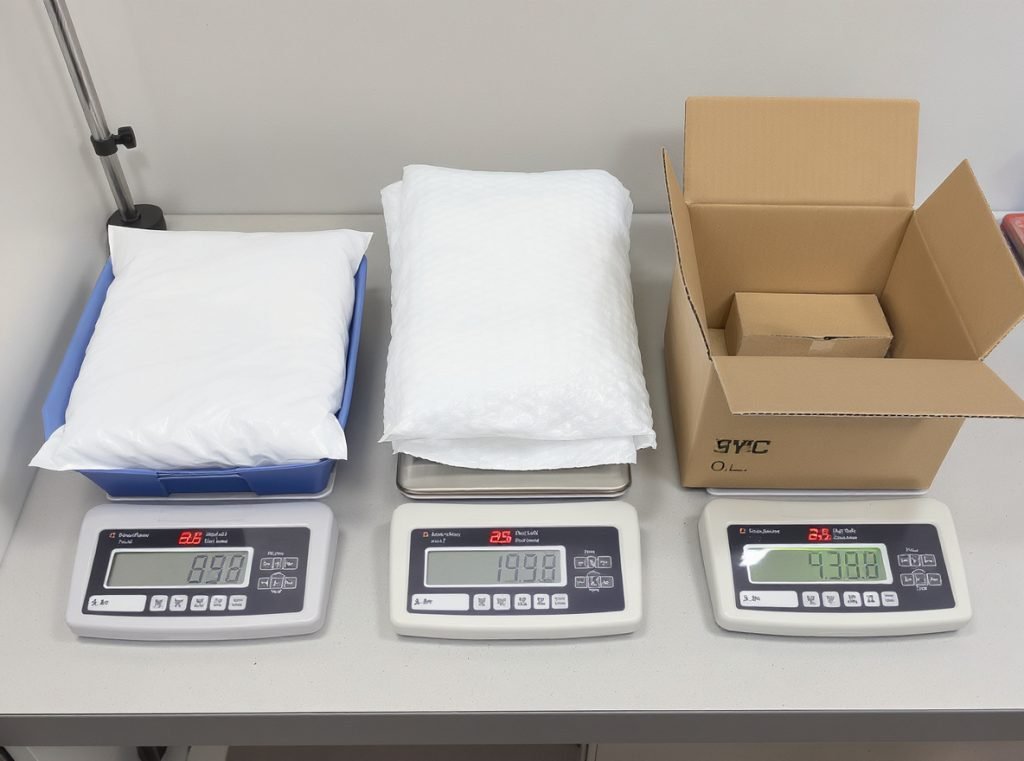

Every inch trimmed from each side of a standard shipping box saves significant cubic volume. Removing 1 inch from each dimension of a 12″ × 9″ × 7″ box saves approximately 180 cubic inches, dropping DIM weight by 1-2 pounds under a 139 divisor.

Effective void elimination strategies include:

Custom Inserts and Molded Pulp: Replace loose fill materials with precisely fitted inserts that hold products securely without adding bulk. Molded pulp inserts can reduce package volume by 30-40% compared to traditional bubble wrap or foam peanuts.

Scored Carton Design: Internal folding mechanisms create product compartments without additional materials. These designs eliminate movement while maintaining minimal package dimensions.

Smart Fill Alternatives: When protection materials are necessary, choose options that add minimal dimensional impact:

• Paper padding: 60% lighter than bubble wrap with similar protection

• Cornstarch packing: 40% lighter than foam peanuts, biodegradable

• Tissue paper: 20% lighter than newspaper, better presentation

Pre-Pack Optimization: Design retail packaging that nests efficiently or folds flat to lower cubic volume at the source. Products designed with shipping in mind often require no additional packaging.

The compound effect of void elimination across thousands of shipments creates substantial cost savings while improving sustainability metrics.

What Advanced Technology Solutions Automate DIM Optimization?

Modern technology eliminates human error and optimizes dimensional weight calculations in real-time.

Automated dimensioning scanners, cartonization software, and integrated shipping platforms can reduce dimensional weight charges by 15-40% through precise measurements, optimal box selection, and real-time carrier rate shopping. The technology pays for itself within 6-12 months for most operations.

Essential technology stack components:

| Technology Solution | Function | Typical Impact | ROI Timeline |

|---|---|---|---|

| Dimensioning scanners (Cubiscan) | Capture exact SKU & carton dims to 0.1 cm accuracy | 15-20% more precise data | 3-6 months |

| Cartonization software (Optioryx, Shipium) | 3D bin-packing calculates cheapest box & carrier | 6-17% lower freight costs | 6-12 months |

| On-demand box makers (Packsize) | Cuts corrugated to size on-site | 15-30% packaging savings | 12-18 months |

| Shipping analytics dashboards | Track DIM vs. scale weight performance | Actionable KPI insights | 1-3 months |

Dynamic Cartonization: Advanced warehouse management systems choose optimal boxes before pick/pack, considering SKU dimensions, carrier rules, and fill rate targets. This eliminates guesswork and ensures consistent optimization.

Cross-Dock Pick-to-Carton: Workers pick directly into pre-verified final boxes, eliminating repack labor while ensuring optimal dimensional efficiency.

Real-Time Rate Shopping: Modern platforms automatically compare dimensional weight costs across carriers and select the most cost-effective option for each shipment profile.

How Do 2025 Carrier Rules Impact Your Shipping Strategy?

Understanding current carrier-specific dimensional weight policies helps optimize shipping strategies and avoid costly surprises.

Major carriers have tightened dimensional weight rules significantly in 2025. FedEx and UPS now round every fraction of an inch up before calculating DIM weight, while maintaining aggressive 139 divisors. These changes require immediate strategy adjustments to maintain profitability.

Current carrier dimensional weight rules:

| Carrier | Domestic DIM Divisor | 2025 Rounding Rule | Notable Exceptions |

|---|---|---|---|

| UPS Daily | 139 | Each fraction up to next inch & pound | Retail counter: 166 |

| FedEx Ground/Express | 139 | Same rounding as UPS | One Rate flat packs exempt |

| USPS | 166 | Whole-inch rounding standard | Cubic pricing for ≤0.5 ft³ bypasses DIM |

| DHL Express | 139 in³/lb | Whole-cm rounding | Heavier of scale vs. volumetric |

Strategic Implications: The fractional rounding rule change means packages previously billed at actual dimensions now round up significantly. A 10.1″ dimension becomes 11″, creating immediate cost increases.

Negotiation Opportunities: High-volume shippers can negotiate higher divisors (166 or more) with carriers, saving 16%+ on billed weight for identical cartons. Volume commitments often unlock better dimensional weight treatment.

Multi-Carrier Strategy: Different carriers excel with different package profiles. USPS cubic pricing benefits small, dense packages while FedEx/UPS may be better for larger shipments.

What Bundling Strategies Maximize Dimensional Efficiency?

Strategic product bundling optimizes space utilization while potentially increasing average order values.

Effective bundling reduces per-item shipping costs by maximizing package density. Shipping three items separately at 2 lb DIM each costs approximately $24, while bundling the same items in one 4 lb DIM parcel costs around $9, saving 62% on shipping while raising average order value.

Successful bundling approaches include:

Complementary Product Pairing: Group frequently purchased items into efficient configurations. Phone cases with screen protectors, or skincare sets with travel bags create natural bundling opportunities that customers value.

Density Balancing: Combine heavy, compact items with lightweight, bulky products to optimize space utilization. This approach balances actual weight against dimensional weight calculations.

Seasonal Bundle Planning: Design promotional bundles around predictable purchasing patterns during holidays and sales events. Pre-planned combinations allow for optimized packaging design and inventory management.

Volume-Based Incentives: Structure pricing to encourage larger orders that justify larger packages. Free shipping thresholds should account for dimensional weight economics, not just order value.

The key is analyzing your product catalog to identify natural pairing opportunities that enhance customer value while reducing per-item fulfillment costs.

How Can You Measure and Track DIM Weight Performance?

Effective measurement ensures optimization efforts deliver quantifiable results and guide continuous improvement.

Key performance indicators for dimensional weight management include average package cube per order, percentage of shipments using lightweight packaging, achieved dimensional divisors, and monthly freight cost trends. Proper tracking quantifies savings and identifies additional optimization opportunities.

Essential tracking framework:

Baseline Analysis: Export six months of shipment data, calculate billable DIM versus scale weight, and identify the percentage where DIM pricing applies. This establishes your optimization opportunity.

Monthly KPI Dashboard:

- Average package cube (in³) per order

- Percentage of shipments using poly/bubble mailers versus boxes

- Dimensional divisor achieved through carrier contracts

- Freight cost per order and per pound of merchandise shipped

Technology Integration: Feed carrier invoices and WMS data into business intelligence tools or specialized logistics analytics platforms to visualize trends and verify savings after packaging changes.

Quarterly Audits: Re-measure top 100 SKUs with dimensioning equipment to catch supplier changes that inflate package requirements. Product dimensions can change without notice, affecting optimization efforts.

Performance Verification: Track the percentage reduction in average dimensional weight, total shipping cost savings, and damage claim improvements following optimization initiatives.

Regular measurement creates accountability and identifies emerging opportunities as your product mix evolves.

What Critical Mistakes Should You Avoid in DIM Weight Management?

Avoiding these common errors prevents unnecessary costs and operational inefficiencies that can eliminate optimization gains.

The most costly dimensional weight mistakes include using the closest available box instead of optimal sizing, forgetting to include packaging materials in measurements, and failing to audit carrier billing for dimensional weight accuracy. These oversights can increase shipping costs by 20-50% above optimized levels.

Critical mistakes and prevention strategies:

Limited Box Variety: Using the “closest” available carton because of restricted inventory options. Solution: Invest in comprehensive box libraries or on-demand cutting systems to ensure optimal sizing for every order.

Measurement Inconsistencies: Forgetting packaging materials when recording dimensions, or rounding down decimal inches during manual measurement. Solution: Implement automated dimensioning systems and standardized measurement protocols.

Carrier Audit Neglect: Skipping weekly billing audits that catch carrier adjustments and overcharges. Solution: Regular invoice reviews identify discrepancies and ensure you’re receiving contracted rates.

Single-Carrier Dependency: Relying on one carrier without rate-shopping cube-friendly options or USPS cubic pricing tiers. Solution: Multi-carrier strategy with automated rate shopping.

Rule Change Ignorance: Missing annual rate guide updates like the 2025 fractional-inch rounding changes. Solution: Quarterly contract reviews and proactive communication with carrier representatives.

Training Gaps: Inadequate staff training on dimensional weight impact and proper measurement techniques. Solution: Regular training sessions and clear standard operating procedures.

Prevention requires systematic approach combining technology, training, and regular performance reviews.

How Does Custom Packaging from Acreet Solve DIM Weight Challenges?

Professional packaging design specifically addresses dimensional weight optimization while maintaining brand presentation and product protection.

Custom packaging solutions from experienced manufacturers like Acreet can reduce dimensional weight by 25-40% compared to standard shipping boxes through right-sizing, material optimization, and innovative design features. The investment typically pays for itself within 3-6 months through reduced shipping costs.

Acreet’s dimensional weight optimization approach includes:

Precision Engineering: Custom boxes designed around exact product dimensions eliminate wasted space while maintaining structural integrity. Advanced design software calculates optimal dimensions considering carrier rules and protection requirements.

Material Selection Expertise: Professional guidance on lightweight materials that maintain protection standards. Options include lightweight corrugated grades, innovative cushioning systems, and hybrid packaging solutions.

Scalable Solutions: From prototype development to high-volume production, custom packaging scales with business growth while maintaining dimensional efficiency.

The comprehensive approach addresses both immediate cost reduction and long-term operational optimization, making custom packaging a strategic investment rather than just a cost center.

Summary

Reducing dimensional weight in e-commerce requires a comprehensive strategy combining right-sized packaging, lightweight materials, void elimination, technology automation, and performance tracking. With 2025’s stricter carrier rules, businesses can achieve 20-40% shipping cost reductions through systematic dimensional weight optimization while improving customer satisfaction and environmental impact.

Ready to slash your dimensional weight charges with custom packaging solutions? Contact Acreet today for a comprehensive dimensional weight analysis and custom packaging consultation. Our packaging engineers specialize in creating right-sized solutions that reduce shipping costs while enhancing your brand presentation. Send us your current package specifications and shipping data for a free optimization assessment – discover exactly how much you could save with professional packaging design.