Packaging electronics incorrectly leads to damaged products, angry customers, and expensive returns that destroy your profit margins. One mishandled smartphone or tablet can cost you hundreds of dollars and damage your reputation permanently.

The best approach to packaging electronics in rigid boxes combines ESD-safe materials, custom foam inserts, proper cushioning layers, and strategic box-in-box design. Use anti-static bags, maintain at least 6cm clearance on all sides, and ensure components never touch anything but protective materials.

Let’s explore the complete system for packaging electronics that protects your valuable inventory and builds customer trust.

Table of Contents

ToggleWhy Do Electronics Need Special Packaging Considerations?

Electronics face multiple serious threats that standard packaging simply cannot handle. Your customers invest significant money expecting perfect working condition upon arrival.

Electronics are vulnerable to electrostatic discharge (ESD), physical impact, moisture, temperature fluctuations, and electromagnetic interference. These devices contain delicate circuits that can fail from static electricity as low as 30 volts, making specialized rigid box packaging absolutely essential.

High-value electronics contain sensitive components that require special care, as shock, vibration, moisture, static electricity, and temperature fluctuations can all cause irreparable damage. Electronics face multiple risks during transit including extreme temperatures, moisture exposure, electrostatic discharge (ESD), and physical impact.

The financial impact is severe. Movement, temperature changes, and g-forces can wreak havoc on sensitive electronic components, leading to costly warranty claims and damaged brand reputation.

Consider these critical protection areas:

- Static Electricity: Even invisible static charges can permanently destroy microchips and circuit boards

- Physical Impact: Screens, connectors, and internal components crack easily without proper cushioning

- Environmental Factors: Temperature swings cause condensation that leads to corrosion and short circuits

- Vibration Damage: Constant shipping vibration loosens connections and damages delicate parts

The investment in proper electronic packaging delivers measurable returns through reduced return rates, enhanced customer satisfaction, protection of high-value inventory, and compliance with international shipping standards.

What Materials Should You Use for Electronics Packaging?

Selecting the right materials determines whether your electronics arrive safely or become expensive losses. Electronics packaging requires a multi-layer protection approach combining structural strength with specialized protective properties.

The ideal materials combination includes high-grade chipboard (1.5-3mm thickness) for rigid box construction, anti-static bags with surface resistivity of 10^6 to 10^9 Ω/sq, and custom foam inserts designed for electronics protection.

Structural Foundation Materials:

High-grade greyboard or chipboard paperboard with a minimum thickness of 1.5mm to 3mm is recommended for enhanced performance. This material provides the necessary sturdiness to support the box’s form and maintain shape under pressure.

Corrugated cardboard is widely used for electronic packaging boxes due to being lightweight, sturdy, and highly customizable. Fiberboard boxes made of high-quality cardboard are very durable and often used for heavy and fragile electronic products, offering excellent water resistance and shock absorption.

ESD Protection Materials:

The most critical aspect of electronics packaging addresses electrostatic discharge. ESD-treated packaging considers the electrostatic problems on the product to be protected. Effective ESD materials should have surface resistivity ranging from 10^6 Ω/sq to 10^9 Ω/sq.

Anti-static bags and foam are readily available and can help protect devices during transportation. These specialized materials prevent static buildup and create controlled charge dissipation rather than allowing dangerous accumulation.

Advanced Cushioning Systems:

Foam inserts are best for fragile items such as jewelry, glass or electronics. Different foam types serve specific electronics protection purposes:

| Foam Type | Properties | Best Use Cases |

|---|---|---|

| Polyurethane (PU) | Open-cell, excellent vibration dampening | Circuit boards, delicate components |

| Polyethylene (PE) | Closed-cell, superior impact resistance | Heavy electronics, shock protection |

| EPS Foam | Outstanding insulation properties | Temperature-sensitive devices |

Anti-static foam inserts are available in either PU (open-cell) or PE (closed-cell) foam, specifically engineered to protect electronic components from both physical damage and static discharge simultaneously.

Anti-static bubble wrap specially designed to safeguard electronic components from static electricity and physical damage provides additional versatile cushioning. This specialized bubble wrap typically comes in distinctive pink coloring to distinguish it from standard varieties that can actually generate static electricity.

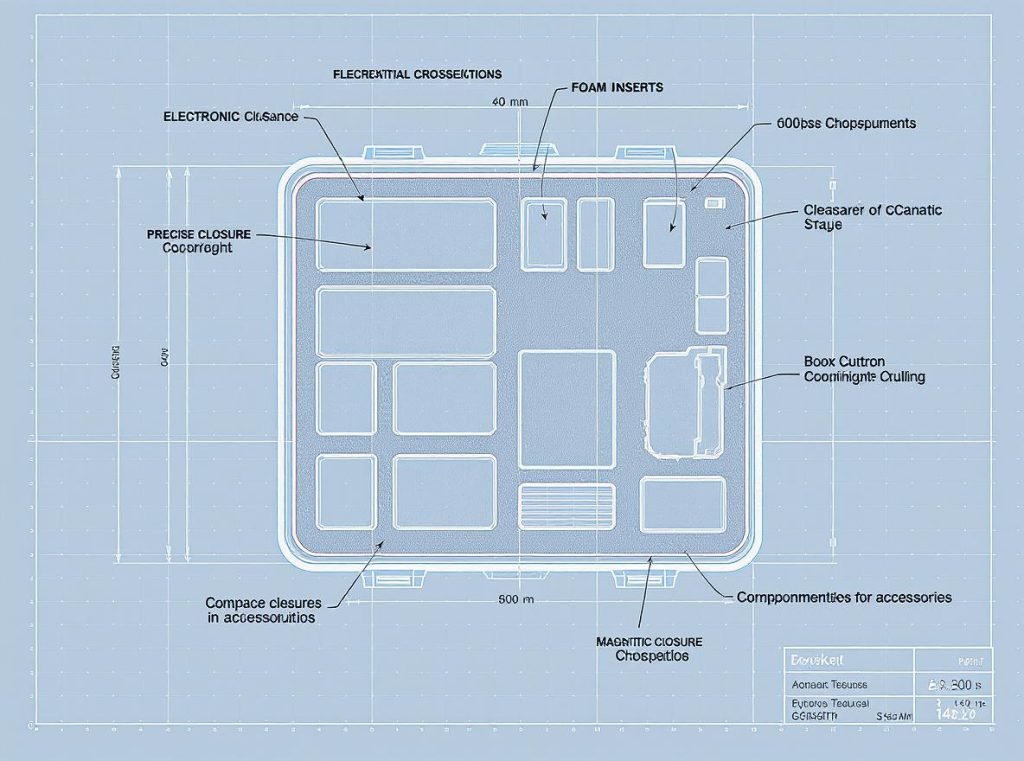

How Do You Design the Perfect Rigid Box Layout?

Strategic rigid box design ensures electronics arrive safely while creating impressive unboxing experiences that enhance your brand value. The layout must balance maximum protection with practical accessibility.

Effective rigid box design uses the box-in-box technique with at least 14cm larger outer dimensions, custom foam inserts that prevent component contact, and strategic compartmentalization for accessories and documentation.

Structural Design Options:

Two-piece rigid boxes consist of a separate base and lid that fit together seamlessly, offering versatility for electronics packaging. Hinged rigid boxes (flip-top boxes) feature a hinged lid that adds elegance and functionality, commonly used for high-end electronics.

Magnetic rigid boxes use magnetic mechanisms perfect for high-value electronic items, providing both security and elegance. The premium feel justifies higher pricing and enhances perceived product value.

Critical Design Principle:

The box-in-box technique is specifically recommended for all electronic goods, where the outer box should be at least 14cm larger than the inner box in all dimensions. This creates essential buffer zones that absorb impacts before reaching your valuable electronics.

Interior Layout Strategy:

Custom-cut foam inserts should create compartments that fit the electronic device snugly. The layout must ensure component separation – each electronic item should touch nothing but packing material and movement prevention – ensuring devices fit securely to minimize movement during transit.

Inserts keep products safe and stylishly in place, with options including foam inserts for fragile items like tech, cardboard or molded pulp for eco-friendly options, and custom-cut shapes to fit unique products snugly.

Consider these advanced design elements:

- Multi-level compartments for organizing main devices and accessories separately

- Cable management systems with individual slots preventing tangling

- Documentation pockets for manuals and warranty information

- Window cutouts for product display while maintaining protection

The design should reflect your product’s value proposition. High-end electronics deserve premium packaging that customers want to keep and reuse, creating lasting brand impressions.

What Are the Step-by-Step Packaging Procedures?

Following systematic packaging procedures ensures consistent protection across all electronic products while maintaining quality control standards. Each step builds comprehensive protection layers.

The correct packaging sequence begins with component preparation and ESD precautions, includes proper wrapping with anti-static materials, strategic placement within rigid boxes using the 6cm rule, and final sealing with quality verification.

Pre-Packaging Preparation Phase:

Remove removable parts – Carefully disconnect and remove any removable components such as cables, batteries, memory cards, and accessories. Clean components – Ensure used electronic components are clean and free of dust, grease, or foreign materials. Inspect for damage – Check items for any signs of damage before packaging.

Create an ESD-safe workspace with proper humidity levels (45-55% relative humidity) and grounding equipment. This prevents static buildup during the packaging process itself.

Primary Protection Application:

Place electronic components in anti-static bags to minimize the risk of damage from static electricity. Ensure bags are securely sealed to maintain their protective properties throughout shipping.

Wrap the electronic device in several layers of bubble wrap, covering all surfaces including screens, corners, and edges. Use at least 6cm of cushioning layer thickness for adequate impact protection.

For devices with delicate screens, apply a protective film or use specialized screen protectors before adding cushioning materials.

Secondary Packaging Integration:

Position wrapped devices into rigid boxes with pre-installed foam inserts. Fill all available space with filler material such as foam, bubble wrap, or air pillows. Critical requirement: Ensure at least 6cm gap is maintained on all sides.

This spacing creates essential crush zones that absorb impacts before reaching your electronics. Never compromise on this measurement – it’s the difference between safe delivery and expensive damage claims.

Final Assembly and Verification:

Close and seal the box using pressure sensitive tape with H-taping method. Mark packages with appropriate handling instructions including “Fragile” and “Electronic Components”.

Conduct final verification by gently shaking the completed package. No movement or rattling sounds should be detectable – this confirms proper cushioning and secure positioning.

Quality control checkpoints include verifying all components are wrapped, confirming 6cm clearances, checking secure closures, and validating proper labeling compliance.

How Do You Handle Different Types of Electronic Devices?

Different electronic categories require customized packaging approaches based on their unique vulnerabilities and value levels. Understanding these differences optimizes protection while controlling costs.

Electronics packaging strategies must match device sensitivity, weight, and market value. Smartphones need premium unboxing experiences, computer components require maximum ESD protection, and industrial electronics demand robust shipping durability.

Consumer Electronics (Smartphones, Tablets, Laptops):

Specialist packaging is available for mobile phones and tablets. These high-value devices require at least 6cm of suitable filler material such as bubble wrap before placing inside a strong dual-wall corrugated box.

Critical consideration: devices with lithium-ion batteries are subject to strict shipping regulations. Ensure compliance with international battery shipping requirements including proper labeling and documentation.

Premium consumer electronics deserve packaging that reflects their value. Use magnetic closure rigid boxes, custom foam inserts, and elegant interior layouts that create memorable unboxing experiences customers share on social media.

Computer Components and Circuit Boards:

Circuit boards and computer chips require anti-static bubble bags designed specifically for these static-sensitive items. Use the double-boxing method with the computer properly cushioned and padded.

These components are extremely ESD-sensitive and require specialized handling. Use only metallized anti-static bags, conductive foam, and ESD-safe workstations during packaging. Never use standard plastic materials that generate static charges.

Heavy Electronics and Industrial Equipment:

Fiberboard boxes are often used to package heavy and fragile electronic products due to their durability and excellent shock absorption properties. Dual-wall corrugated boxes rated to size and weight are recommended for heavier items.

Industrial electronics face harsh shipping environments requiring robust protection. Use thicker rigid box construction, heavy-duty cushioning, and comprehensive documentation for inventory verification upon delivery.

Fragile Electronic Accessories:

Use dual-wall corrugated boxes rated to size and weight, ensuring contents are well cushioned with at least 6cm separation from external walls. When shipping multiple items in a single box, ensure they are well separated from one another.

Specialized Sensitive Components:

Products sensitive to EMI (electromagnetic interference) require aluminum shielding protection. Certain electronic products with low g-factors between 15-25 need special protection from g-forces during transit.

These ultra-sensitive components may require custom-designed packaging solutions with specialized materials and testing protocols to ensure safe delivery.

What Common Mistakes Should You Avoid?

Learning from packaging failures prevents costly damage and customer dissatisfaction. Many expensive mistakes stem from seemingly minor oversights that have major consequences.

The most dangerous mistakes include using non-ESD materials, inadequate cushioning spacing, improper component contact, and environmental neglect. These errors cause product damage, safety violations, and permanent brand reputation damage.

Critical Packaging Violations:

Never pack a computer on top of the charger or place the charger against the screen – items will break and every item should touch nothing but packing material. Do not have piles of random loose items in a box as this violates common sense packaging principles.

Never ship a laptop computer in a USPS mailer just because it seems snug – there is absolutely no shock absorption. This mistake alone can destroy expensive equipment and relationships with customers.

Material Selection Disasters:

Never use standard plastic bags, newspaper, or regular bubble wrap for direct electronic component contact. These materials generate static electricity that permanently damages sensitive circuits. Only use certified anti-static materials with proper resistivity ratings.

Inadequate packaging is a primary mistake – technology equipment is often delicate and requires specialized packaging materials with secure padding.

Environmental and Compliance Failures:

Ignoring environmental factors such as temperature and humidity can impact sensitive electronics. Choose climate-controlled shipping options to protect equipment.

Improper labeling can lead to delays or mishandling. Ensure all packages are clearly marked with appropriate handling instructions and destination details. Failure to comply with regulations – different countries have varying import/export regulations that must be followed.

Sizing and Design Mistakes:

Avoid over-packing electronics – ensure enough space in the box to accommodate the device and extra padding. Do not wrap an entire box in paper or plastic as it serves no purpose and can cause problems if it tears.

Boxes that are too large allow dangerous movement, while undersized boxes create pressure points that crack screens and damage internal components. Always maintain the critical 6cm clearance rule.

Cost-Cutting Consequences:

Attempting to save money on packaging materials typically costs far more through damage claims, returns, and lost customers. Premium electronics deserve premium protection – the initial investment pays massive dividends through customer satisfaction and reduced liability.

How Do You Ensure Quality Control and Testing?

Systematic quality control prevents packaging failures before products reach customers. Comprehensive testing reveals design weaknesses and optimizes protection levels for different shipping conditions.

Effective quality control combines pre-shipment inspections, physical testing protocols, environmental simulation, and statistical performance tracking. Regular testing cycles identify problems early and verify packaging performance under real-world shipping stresses.

Comprehensive Pre-Shipment Inspection:

Quality control should include checking the physical integrity of the product, inspecting packaging material quality, measuring packaging dimensions, weighing the packaged product, and testing packaging durability.

Product placement inside the package must be verified, along with correct product-label matching and safety seal verification. Ensure packages are easy to open and close and inspect print quality of labels and logos.

Implement random sampling programs where supervisors open and inspect completed packages. Document findings and track trends to identify systemic issues before they become widespread problems.

Physical Performance Testing:

Conduct drop tests to verify product protection and test for potential environmental damages to packaging. Perform mechanical stress testing, thermal cycling to assess package integrity, and electrical testing for electronic components.

Standard testing should include:

- Drop tests from 76cm height for packages under 20kg

- Vibration testing simulating truck transport conditions

- Compression testing for warehouse stacking scenarios

- Edge and corner impact tests for handling damage

Environmental Simulation Testing:

Test packages under temperature extremes from -20°C to 60°C, matching actual shipping conditions. Monitor humidity effects and material degradation, especially adhesives and foam materials that can break down under environmental stress.

Regulatory Compliance Verification:

Check if packaging complies with regulations and ensure all necessary labels are attached to the packaging. Verify that product codes and expiry dates are correctly printed where applicable.

Performance Metrics and Documentation:

| Quality Metric | Target Performance | Measurement Method |

|---|---|---|

| Damage Rate | <0.5% of shipments | Customer return analysis |

| ESD Failures | Zero tolerance | Post-packaging component testing |

| Package Integrity | >99% pass rate | Visual inspection scoring |

| Customer Satisfaction | >4.5/5 rating | Unboxing experience surveys |

Continuous Improvement Process:

Document and record findings from visual and manual testing and maintain detailed records of inspections, tests, and corrective actions for traceability and continuous improvement.

Packaging and shipping inspection is the final step in electronic quality control and crucial for ensuring products are delivered safely and intact to customers. Through strict control over packaging and shipment inspection, losses and risks during transportation can be minimized.

Collect feedback from customers, shipping partners, and internal teams. Regular packaging reviews should incorporate new materials, design innovations, and changing product requirements including seasonal adjustments for environmental conditions and shipping volume changes.

Summary

Successful electronics packaging in rigid boxes requires specialized materials, systematic procedures, and rigorous quality control. The best approach combines ESD-safe anti-static materials, custom foam inserts, strategic box-in-box design with 6cm clearances, and comprehensive testing protocols. Success depends on understanding device-specific vulnerabilities, following proven procedures, and maintaining zero-tolerance quality standards.

Ready to protect your valuable electronics with professional rigid box packaging? Contact Acreet today for custom packaging solutions designed specifically for your electronic products. Our experienced team understands international shipping requirements and can design packaging systems that reduce damage rates while enhancing your brand image. Send us your inquiry for packaging design consultation and discover how proper protection increases customer satisfaction and reduces costly returns.