Packaging dairy products presents a complex web of interconnected challenges that can make or break your product’s market success. Without proper packaging solutions, even the highest quality cheese and yogurt face rapid spoilage, safety risks, and costly waste throughout the supply chain. The dairy industry faces mounting pressures from precise temperature requirements, evolving consumer demands, and stringent regulatory standards that demand sophisticated packaging expertise.

Dairy packaging must overcome critical challenges including temperature control between 34°F-40°F, advanced barrier properties for moisture and oxygen control, food safety compliance under FDA regulations, and balancing sustainability goals with product protection. These challenges require specialized materials, precise engineering, and industry expertise to ensure product integrity throughout the supply chain.

Understanding these packaging challenges is essential for dairy manufacturers, distributors, and retailers who want to protect their investment while delivering quality products that meet modern market demands.

Table of Contents

ToggleWhy Is Temperature Control the Most Critical Challenge in Dairy Packaging?

Temperature control stands as the foundation of successful dairy packaging, with even minor fluctuations threatening product safety and quality. The complexity of maintaining cold chain integrity creates multiple vulnerability points throughout distribution.

Most dairy products require precise storage temperatures between 34°F and 40°F to prevent bacterial growth and maintain quality. Bacterial growth accelerates dramatically at temperatures above 40°F, making temperature control absolutely essential for product safety and shelf life.

Temperature fluctuations pose the greatest risk to dairy product integrity, with precise refrigeration being essential for maintaining product quality and safety. The cold chain management throughout the supply chain presents multiple vulnerable points where temperature control can fail.

Transportation creates particularly high-risk scenarios. Refrigeration unit breakdowns, improper loading techniques, extended door openings during deliveries, and extreme weather conditions all threaten temperature stability. Industry research shows that packages are dropped nearly twenty times before reaching their final destination, highlighting how physical handling compounds temperature control challenges.

Advanced packaging materials must withstand low-temperature storage while maintaining protective properties:

- Flexible films that remain pliable in refrigerated conditions

- Rigid containers that resist cracking from thermal stress

- Seal integrity that maintains effectiveness across temperature ranges

- Barrier properties that don’t degrade in cold environments

The packaging itself must function as part of the temperature control system. Materials that provide insulation properties help buffer against temperature fluctuations during brief exposure periods, while specialized thermal barrier films can extend the time products remain safe during cold chain disruptions.

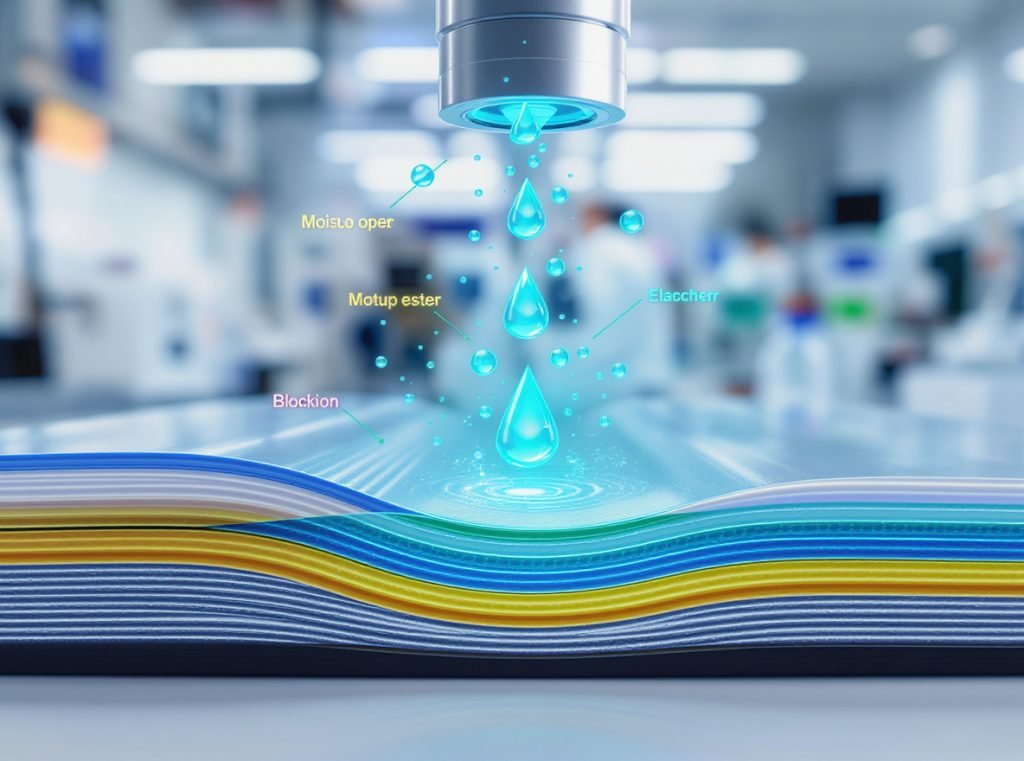

How Do Moisture and Oxygen Barriers Determine Product Success?

Barrier properties control the transmission rates that directly impact dairy product shelf life and quality preservation. Understanding these scientific measurements helps manufacturers select appropriate packaging materials.

Effective dairy packaging requires controlling moisture vapor transmission rate (MVTR) and oxygen transmission rate (OTR). Different dairy products need customized barrier solutions: high-barrier products like cream require EVOH incorporation, while refrigerated items with shorter shelf life may need lower barrier properties.

MVTR measures water vapor permeation through packaging materials over time, while OTR quantifies oxygen permeation rates, both directly impacting product shelf life and quality preservation.

Advanced barrier materials now provide remarkable improvements in protection. XPP Enhanced Barrier Polypropylene delivers up to 90% improvement in OTR/MVTR properties compared to traditional polypropylene without requiring specialty barrier materials or coatings.

Specific barrier requirements vary dramatically by product type:

| Dairy Product | Primary Barrier Need | OTR Requirement | MVTR Requirement | Protection Duration |

|---|---|---|---|---|

| Fresh cheese | Controlled moisture | Medium | Low-Medium | 2-4 weeks |

| Aged cheese | Oxygen protection | Very Low | Medium | 6-12 months |

| Yogurt | Oxygen barrier | Low | Low | 3-6 weeks |

| Cream products | Oxygen barrier | Very Low | Very Low | 2-3 months |

Multi-layer coextrusion processes incorporating EVOH materials achieve the necessary barrier requirements for high-protection applications. These sophisticated structures prevent oxidation that causes flavor degradation and reduces nutritional value in dairy products.

The challenge lies in achieving superior barrier properties while maintaining cost-effectiveness and sustainability goals. Innovation continues focusing on simplified, recyclable barrier structures that meet performance requirements without compromising environmental responsibility.

What Food Safety Regulations Must Dairy Packaging Navigate?

Food safety compliance creates a complex regulatory framework that dairy packaging must satisfy. Multiple federal agencies oversee different aspects of dairy packaging safety and labeling requirements.

The FDA maintains primary jurisdiction over dairy product packaging under the Federal Food, Drug, and Cosmetic Act. Current Good Manufacturing Practices (CGMP) regulations in 21 CFR part 117, subpart B, specifically apply to food packaging manufacturing, requiring comprehensive contamination prevention measures.

Food packaging manufacturers must implement adequate precautions to reduce allergen cross-contact potential and prevent contamination with microorganisms, chemicals, filth, and other extraneous materials.

Regulatory compliance involves multiple layers of requirements. Quality control operations must ensure food-packaging materials are safe and suitable for their intended use. This includes material composition approval, migration testing for chemical safety, and microbiological barrier validation.

Standards of Identity add another compliance dimension. Yogurt must contain both Lactobacillus bulgaricus and Streptococcus thermophilus, while Cheddar cheese must have maximum 39% moisture content and minimum 50% fat in remaining solids.

The Model Grade “A” Pasteurized Milk Ordinance (PMO) influences packaging decisions across 46 states. While not federally enforceable, this ordinance establishes food safety standards for production methods, processes, and packaging requirements that significantly impact industry practices.

International markets add complexity through varying regulatory requirements. European standards often differ from US regulations, requiring packaging solutions that meet the most stringent requirements for global distribution capabilities.

Compliance testing and documentation represent substantial investments. Material certification, migration studies, and ongoing quality monitoring require specialized expertise and significant time commitments that many dairy manufacturers lack internally.

How Do Sustainability Demands Transform Packaging Strategies?

Environmental responsibility is fundamentally reshaping dairy packaging decisions as manufacturers balance sustainability goals with performance requirements. Consumer pressure and regulatory trends drive adoption of recyclable and biodegradable materials.

Major dairy companies are implementing comprehensive sustainability strategies: FrieslandCampina aims for 100% recyclable packaging by 2025, while Lactalis has reduced plastic usage by 9.5% on milk bottles through strategic material optimization.

Bioplastic alternatives like PLA (polylactic acid) and PHA (polyhydroxyalkanoate) are gaining adoption as renewable alternatives to petroleum-based plastics, offering similar functionality while providing natural biodegradation advantages.

Circular economy principles are driving innovative approaches to material selection and design. Lactalis partnered with INEOS to introduce HDPE milk bottles made from circular polyethylene derived from post-consumer recycled materials, demonstrating successful integration of recycled content into food-grade packaging.

Sustainability challenges create complex trade-offs:

- Recyclability vs. Barrier Performance: Multi-layer films provide excellent protection but complicate recycling processes

- Biodegradability vs. Shelf Life: Eco-friendly materials often compromise barrier properties, potentially increasing food waste

- Cost vs. Environmental Impact: Sustainable materials typically cost more, affecting competitiveness in price-sensitive markets

Paper-based packaging is experiencing renewed interest as biodegradable alternatives. Multi-layer paper solutions combined with appropriate barrier coatings provide necessary protection while maintaining recyclability and compostability characteristics.

The key lies in finding sustainable solutions that don’t compromise food safety or significantly increase costs. Innovation in this area continues evolving as manufacturers seek materials that satisfy environmental concerns while meeting dairy protection requirements.

What Cost Factors Drive Dairy Packaging Investment Decisions?

Packaging costs significantly impact dairy product profitability through both direct material expenses and hidden operational costs. Understanding the full cost structure helps manufacturers make informed packaging decisions.

Research indicates that average total processing and packaging costs decrease by 7.66% for plants processing more than 9 million pounds per month compared to smaller operations. Container size directly affects economics, with half-gallon containers offering the lowest average costs across all plant sizes.

Gallon containers cost approximately 6.72% more than half-gallons, while smaller formats like quarts and half-pints can cost 22-53% more per unit volume. These cost variations significantly impact pricing strategies and market positioning.

Hidden costs often exceed material expenses:

- Quality Failures: Poor packaging causing spoilage generates expensive recalls and brand damage

- Inventory Losses: Inadequate protection leads to product waste and reduced margins

- Transportation Efficiency: Packaging design affects shipping costs and storage requirements

- Labor Requirements: Complex packaging systems increase handling time and operational costs

Advanced packaging technologies require substantial capital investment but provide significant returns. Aseptic processing and barrier materials enable extended shelf life and reduced product loss, justifying higher upfront packaging costs through expanded distribution capabilities.

Volume commitments dramatically affect pricing structures. Large dairy operations negotiate better rates through annual contracts, while smaller producers face premium pricing for limited quantities.

Return on investment calculations must consider long-term benefits including reduced waste, extended distribution reach, and improved brand reputation. Quality packaging often pays for itself through reduced losses and enhanced market opportunities.

How Do Different Dairy Products Require Specialized Packaging Approaches?

Each dairy product category presents unique packaging challenges requiring tailored solutions based on specific preservation needs and consumer usage patterns. Generic packaging approaches rarely optimize protection and functionality.

Soft cheeses are sensitive to pressure deformation and require breathable packaging that allows continued maturation while preventing oxygen intake. Hard cheeses develop protective rinds requiring aroma protection, typically achieved through vacuum packaging in barrier shrink films.

Different cheese varieties require specialized packaging approaches based on their specific characteristics and storage needs. Fresh mozzarella needs moisture retention while preventing mold growth, requiring packaging that allows controlled gas exchange.

Processed cheese products face distinct challenges:

- Sliced cheese: Requires protection against drying while maintaining easy separation

- Grated cheese: Highly susceptible to mold growth from air, heat, and light exposure

- Cheese blocks: Need vacuum packaging or gas-flushed environments for extended storage

Yogurt packaging emphasizes convenience and portability, with stand-up pouches emerging as preferred options due to shelf appeal, resealable features, and transportation advantages.

Liquid dairy products require packaging systems that maintain integrity throughout distribution:

- Fresh milk: Needs excellent light and oxygen barriers with easy-pour functionality

- UHT milk: Requires packaging compatible with high-temperature processing

- Cream products: Demands superior oxygen barriers to prevent rancidity

Specialized applications require custom engineering. Single-serve portions need different barrier properties than bulk packaging. Organic dairy products often require packaging materials that meet organic certification standards.

Understanding product-specific requirements enables manufacturers to select packaging solutions that optimize protection while controlling costs and meeting consumer expectations.

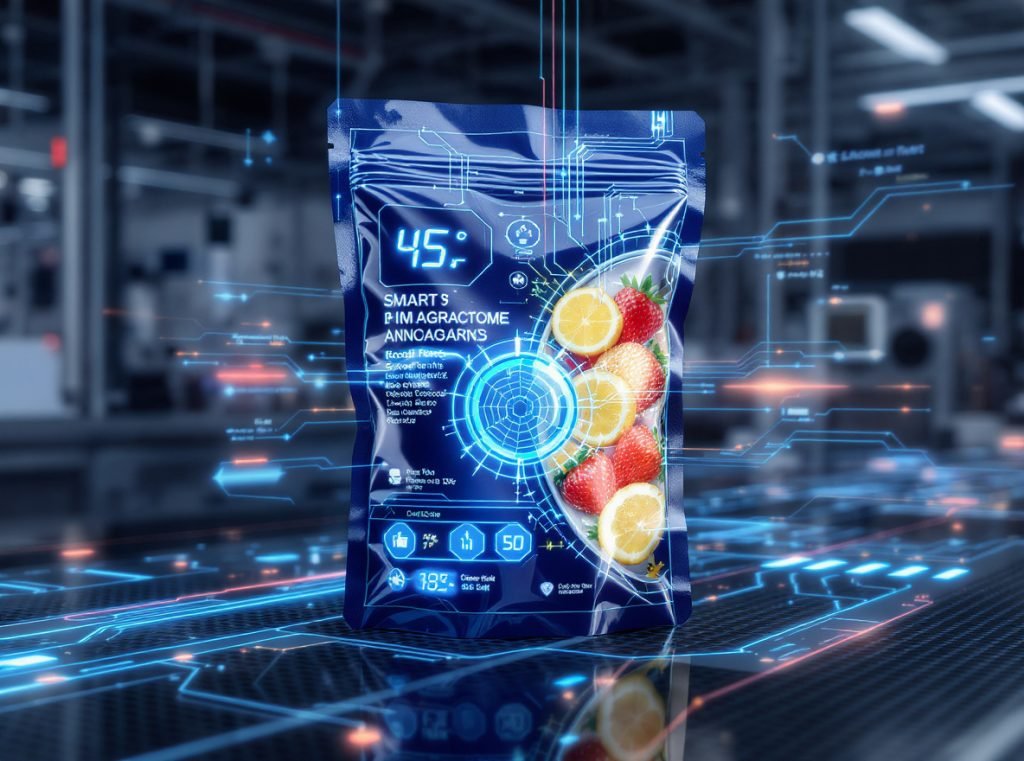

What Are the Latest Innovations Solving Dairy Packaging Problems?

Cutting-edge technologies are revolutionizing dairy packaging through smart systems, advanced materials, and integrated processing solutions. These innovations address traditional challenges while creating new opportunities for market differentiation.

Smart packaging solutions integrate sensors and communication technologies to monitor product conditions throughout the supply chain. Modified Atmosphere Packaging (MAP) can extend yogurt shelf life by up to 30%, while active packaging with oxygen scavengers can double hard cheese shelf life from 6 to 12 months.

Smart packaging technologies include embedded sensors that track temperature, humidity, and freshness, providing real-time data to consumers and retailers. Time-temperature indicators (TTIs) provide visual confirmation of proper storage conditions throughout distribution.

Active packaging systems represent major advancement opportunities:

- Oxygen scavengers: Reduce oxygen levels to less than 0.1% for extended protection

- Antimicrobial films: Fight bacterial growth on package surfaces using natural agents like nisin

- Moisture regulators: Control humidity levels to prevent condensation and mold growth

Antimicrobial packaging using natural agents can extend fresh milk shelf life by up to 7 days beyond traditional packaging methods.

Advanced processing integration creates powerful solutions. Ultra-High Temperature (UHT) processing combined with aseptic packaging can extend dairy product shelf life from months to over a year without refrigeration requirements.

Nanotechnology improvements enhance barrier properties without adding thickness or weight. Nano-clay particles create tortuous paths preventing gas and moisture transmission while maintaining package flexibility and printability.

These innovations require investment and expertise but provide competitive advantages through improved product quality, extended shelf life, and enhanced consumer appeal.

How Should Manufacturers Choose the Right Packaging Partner?

Selecting the appropriate packaging supplier determines success in addressing dairy packaging challenges. The right partnership brings specialized expertise, advanced technology access, and ongoing support that internal teams often cannot provide.

Successful dairy packaging requires partners with established experience in dairy applications, production flexibility to accommodate demand fluctuations, and technical capabilities in barrier material design, processing equipment expertise, and comprehensive quality control systems.

Key evaluation criteria include production capabilities and flexibility to accommodate varying demand patterns, as dairy sales can experience significant fluctuations due to seasonal factors, promotional activities, or market trends.

Essential partner qualifications include:

Technical Expertise

- Understanding of dairy-specific challenges like probiotic protection and cheese aging requirements

- Experience with FDA compliance and international food safety standards

- Advanced barrier technology capabilities and material science knowledge

Manufacturing Capabilities

- Appropriate production capacity for your volume requirements

- Quality control systems meeting food safety standards

- Geographic coverage supporting your distribution needs

Innovation and Development

- Investment in research and development for emerging technologies

- Ability to provide custom solutions rather than generic options

- Access to latest materials and processing technologies

Partners who invest in research and development, maintain awareness of industry trends, and can adapt to new technologies provide competitive advantages for dairy manufacturers.

Service and support quality affects long-term success. Effective partners provide ongoing consultation, troubleshooting assistance, and collaborative problem-solving to address evolving packaging challenges and opportunities.

Cost optimization requires transparent pricing and value engineering support. Partners should help balance protection requirements with budget constraints through intelligent material selection and design optimization.

At Acreet, we specialize in solving complex dairy packaging challenges through custom solutions tailored to your specific products and markets. Our expertise in barrier technologies, temperature control systems, and international compliance standards helps dairy manufacturers protect product quality while optimizing costs. We understand the unique requirements of cheese aging, yogurt probiotic protection, and liquid dairy distribution challenges.

What Economic Factors Influence Dairy Packaging Decisions?

Economic considerations significantly impact packaging choices, with costs extending far beyond material expenses. Understanding the complete cost structure enables better decision-making and long-term profitability optimization.

Packaging costs typically represent 10-15% of total dairy product costs, but hidden expenses including spoilage, recalls, and shortened shelf life can double the actual packaging investment. Plant size and production volume dramatically affect cost efficiency.

Research shows average total processing and packaging costs decrease by 7.66% for plants processing more than 9 million pounds per month compared to smaller operations. This economy of scale affects packaging material selection and technology adoption decisions.

Container format economics reveal significant cost variations. Half-gallon containers typically offer the lowest average costs across all plant sizes, with gallon containers costing approximately 6.72% more and smaller formats like quarts and half-pints costing 22-53% more per unit volume.

Hidden cost factors include:

Quality-Related Expenses

- Product recalls from packaging failures

- Spoilage losses during distribution

- Customer complaints and brand damage

- Regulatory penalties for safety violations

Operational Impact Costs

- Setup times for different packaging formats

- Changeover costs between product runs

- Waste rates during packaging operations

- Labor requirements for complex packaging systems

Supply Chain Considerations

- International shipping costs and customs delays

- Currency fluctuations affecting material prices

- Inventory carrying costs for packaging materials

- Emergency sourcing premiums during shortages

Investment in advanced packaging technology often provides positive returns through reduced waste and extended distribution capabilities. Products with longer shelf life can reach distant markets and reduce inventory management costs, justifying higher packaging investments.

How Do Specialized Requirements Vary Across Dairy Product Categories?

Different dairy products demand unique packaging approaches based on their specific preservation needs, consumer usage patterns, and distribution requirements. Understanding these distinctions enables optimal packaging selection for each application.

Cheese packaging varies dramatically by type: soft cheeses need breathable packaging allowing continued maturation while preventing oxygen intake, while hard cheeses require aroma protection typically achieved through vacuum packaging in barrier shrink films.

Fresh cheeses like mozzarella need moisture retention while preventing mold growth, requiring packaging that allows controlled gas exchange, while aged varieties develop protective rinds requiring different protection strategies.

Processed cheese categories create additional complexity:

Sliced Cheese Challenges

- Protection against moisture loss and drying

- Maintaining easy slice separation

- Preventing adherence between slices

- Enabling consumer convenience features

Grated Cheese Requirements

- Superior mold prevention from air exposure

- Protection from heat and light damage

- Easy-pour functionality for consumer use

- Extended shelf life for retail display

Grated cheese is particularly susceptible to mold growth promoted by air, heat, and light exposure, typically requiring gas-flushed packaging in foil bags or plastic trays with specialized lid films.

Yogurt packaging prioritizes different factors:

Cultured dairy products benefit from packaging solutions emphasizing convenience and portability. Stand-up pouches have emerged as preferred options for yogurt applications due to their shelf appeal, resealable features, and transportation advantages, offering superior graphics capabilities and convenience features like easy-opening tear notches.

Probiotic protection requires oxygen barriers that preserve beneficial bacteria while preventing contamination. Light protection maintains nutritional value and prevents off-flavor development that reduces consumer acceptance.

Custom packaging design addresses product-specific requirements while optimizing manufacturing efficiency and consumer appeal. Generic solutions rarely provide optimal results for specialized dairy applications.

How Does Shelf Life Extension Impact Packaging Strategy?

Extended shelf life directly influences profitability, distribution capabilities, and waste reduction efforts. Advanced packaging technologies can dramatically improve product longevity while maintaining quality standards.

Modified Atmosphere Packaging (MAP) and active packaging systems represent the most effective techniques for extending dairy shelf life. MAP can extend yogurt shelf life by up to 30%, while oxygen scavengers can double hard cheese shelf life from 6 to 12 months.

MAP creates optimal gas compositions within packages, significantly slowing microbial growth and oxidation processes, with demonstrated success extending yogurt shelf life by up to 30% in some applications.

Active packaging delivers remarkable performance improvements. Oxygen scavengers that reduce oxygen levels to less than 0.1% can achieve doubled shelf life for hard cheeses, while antimicrobial packaging using natural agents like nisin can extend fresh milk shelf life by up to 7 days beyond traditional methods.

Advanced preservation technologies include:

- MAP Systems: Replace air with protective gas mixtures (CO2, nitrogen)

- Oxygen Scavengers: Actively remove harmful oxygen from package environments

- Antimicrobial Films: Incorporate natural preservatives into packaging materials

- Moisture Regulators: Control humidity levels preventing spoilage conditions

UHT processing combined with aseptic packaging can extend dairy product shelf life from months to over a year without refrigeration requirements, providing significant supply chain advantages.

| Technology Type | Shelf Life Improvement | Investment Level | Complexity | Best Applications |

|---|---|---|---|---|

| Standard barriers | Baseline | Low | Simple | Basic refrigerated products |

| MAP systems | 30-50% increase | Medium | Moderate | Yogurt, soft cheese |

| Active packaging | 100-200% increase | High | Complex | Premium products |

| UHT + Aseptic | 500-1000% increase | Very High | Very Complex | Shelf-stable products |

Return on investment analysis shows that shelf life extension often justifies higher packaging costs through reduced waste, expanded distribution reach, and improved inventory management efficiency.

What Role Do Consumer Convenience Features Play in Design Complexity?

Modern consumers demand packaging solutions that offer convenience while maintaining product quality. These requirements add mechanical complexity that must not compromise barrier properties or food safety standards.

Consumer convenience features like resealable closures, easy-open designs, and portion control add significant engineering complexity. Resealable mechanisms must maintain barrier properties after multiple openings while remaining easy for all consumer demographics to operate.

Convenience feature integration creates multiple design challenges. Resealable packaging requires closure mechanisms that preserve barrier properties throughout repeated use cycles. Poor reseal quality leads to rapid product deterioration and consumer dissatisfaction.

Easy-open functionality demands careful engineering balance. Tear strips, pull tabs, and peel-away lids must function reliably without accidentally opening during distribution. Opening force requirements must accommodate elderly users and children while preventing premature activation.

Portion control packaging increases complexity through higher surface-area-to-volume ratios. Individual serving sizes require more packaging material per unit of product while maintaining identical protection standards as larger formats.

Convenience trends driving packaging innovation:

- On-the-go consumption: Spill-proof designs for mobile eating

- Resealable features: Maintaining freshness after opening

- Microwave compatibility: Heat-resistant materials for ready-to-eat products

- Transparent windows: Product visibility without compromising barriers

Consumer research demonstrates that convenience features influence purchasing decisions, but poor execution creates negative brand experiences. Balancing functionality with protection requires extensive testing and development investment.

Successful convenience packaging typically requires custom solutions rather than standard options. Working with packaging specialists ensures convenience features enhance rather than compromise product protection and brand appeal.

How Are Smart Technologies Revolutionizing Dairy Packaging?

Advanced technologies are transforming dairy packaging through intelligent monitoring systems, active protection mechanisms, and integrated supply chain communication. These innovations address traditional challenges while creating new market opportunities.

Smart packaging incorporating sensors, time-temperature indicators, and communication technologies provides real-time monitoring of product conditions throughout the supply chain while offering consumers transparency and quality assurance.

Smart packaging systems include embedded sensors that track temperature, humidity, and freshness, providing real-time data to consumers and retailers while enabling improved supply chain transparency.

Intelligent packaging systems offer multiple value propositions:

Real-Time Monitoring

- Temperature abuse detection during transportation

- Freshness indicators showing product quality status

- Tamper evidence and authentication systems

- Supply chain tracking and traceability

Consumer Communication

- QR codes providing product information and recipes

- Mobile app integration for enhanced engagement

- Freshness indicators preventing consumption of spoiled products

- Nutritional information and usage suggestions

Supply Chain Optimization

- Inventory management through automated tracking

- Quality control monitoring reducing manual inspection

- Predictive analytics for demand planning

- Waste reduction through better rotation management

Blockchain integration provides complete supply chain transparency. Consumers can trace products from farm to store while manufacturers gain valuable data about product performance and handling throughout distribution.

The investment in smart packaging technology continues decreasing as sensor costs drop and integration becomes more standardized. Early adopters gain competitive advantages through enhanced consumer trust and operational efficiency improvements.

Summary

Dairy packaging challenges encompass temperature control precision, advanced barrier requirements, regulatory compliance complexity, sustainability demands, cost optimization, and technology integration. Success requires understanding product-specific needs and partnering with specialized packaging suppliers who can deliver custom solutions addressing these interconnected challenges while meeting market demands and consumer expectations.

Looking for expert dairy packaging solutions? Contact Acreet today to discuss your specific product requirements. Our team designs custom packaging systems that solve temperature control, barrier protection, and convenience challenges while optimizing costs for international distribution. Send us your specifications for a comprehensive packaging consultation tailored to your dairy products.