Whether you’re a pizzeria owner or packaging distributor, choosing the right pizza box directly impacts customer satisfaction and operational success. Poor-quality boxes lead to soggy crusts, structural failures, and disappointed customers who won’t return.

A good pizza box must feature premium corrugated cardboard construction, PFAS-free grease resistance, precise sizing, strategic ventilation, stackable design, thermal insulation, branding space, FDA compliance, and sustainable materials. The ideal pizza box balances durability, functionality, and cost-effectiveness while serving as a powerful marketing tool.

Let’s explore each essential feature that separates professional-grade pizza boxes from inferior alternatives.

Table of Contents

ToggleWhat Material Should Pizza Boxes Be Made From?

The foundation of any quality pizza box starts with premium material selection. Your choice directly impacts structural integrity, food safety, and customer experience.

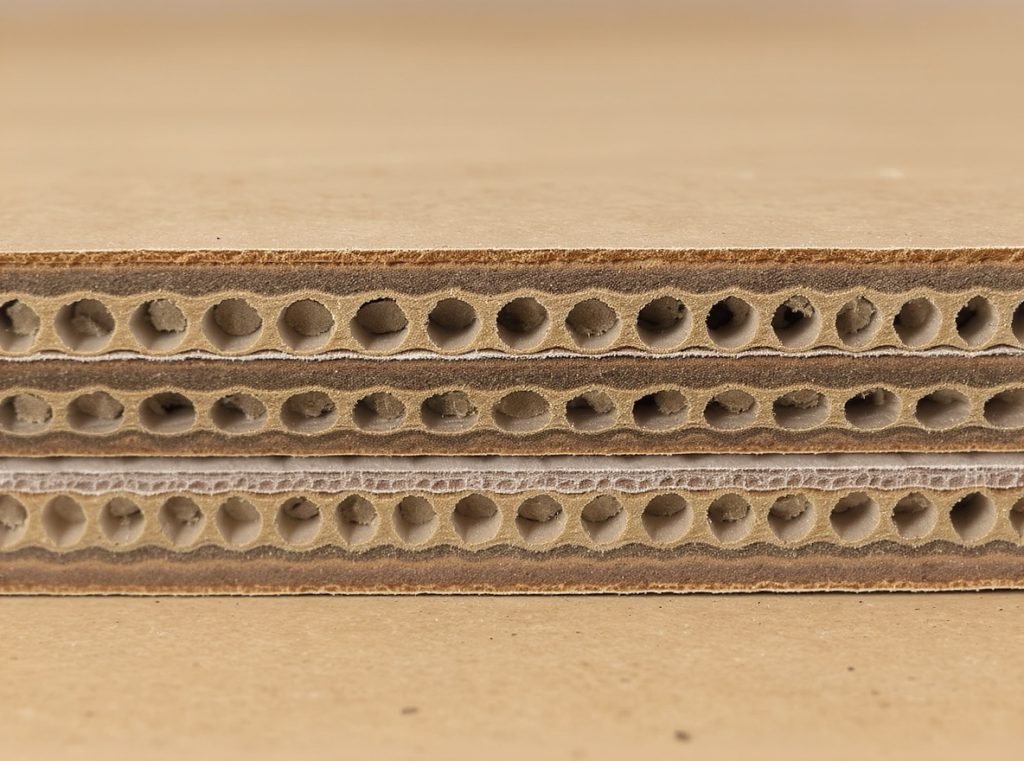

Premium corrugated cardboard stands as the industry standard for pizza boxes, offering optimal balance of functionality, cost-effectiveness, and environmental responsibility. This three-layer construction provides essential structural integrity while creating air pockets that serve as natural insulation.

Understanding Corrugated Construction

Single-Wall vs. Double-Wall Performance

Single-wall corrugated cardboard typically measures 1.5mm (1/16th of an inch) in thickness and works effectively for most standard pizzas. However, larger or heavier pizzas require double-wall corrugated construction for enhanced structural support.

The corrugated design offers superior strength and durability compared to single-layer cardboard:

- Two flat outer surfaces with corrugated fluted middle layer

- Prevents boxes from collapsing under heavy pizza weight

- Maintains shape integrity during transport and stacking

- Creates natural insulation through trapped air pockets

Alternative Sustainable Materials

| Material Type | Thickness | Strength | Cost | Environmental Impact |

|---|---|---|---|---|

| Single-Wall Corrugated | 1.5mm | Good | Low | Recyclable |

| Double-Wall Corrugated | 3.0mm | Excellent | Medium | Recyclable |

| Sugarcane Bagasse | Variable | High | Medium-High | Compostable |

| FSC-Certified | 1.5-3.0mm | Good-Excellent | Medium | Sustainable sourcing |

How Important Is Grease Resistance in Pizza Boxes?

Grease resistance represents one of the most crucial features in pizza box design, directly impacting both food quality and structural integrity throughout transport.

Proper grease resistance is absolutely critical for maintaining pizza quality and box structural integrity. Modern PFAS-free barrier coatings prevent oil penetration that would weaken cardboard, create unsightly stains, and compromise the protective food barrier.

Modern Grease-Resistant Solutions

PFAS-Free Alternatives

The FDA confirmed that fluorochemical-based grease barriers are no longer used in U.S. food packaging as of 2024. Modern pizza boxes achieve grease resistance through safer alternatives:

- Styrene-butadiene emulsion polymers for comparable performance without health concerns

- Clay-coated surfaces offering enhanced grease resistance with food safety compliance

- Bio-based waxes eliminating “forever chemicals” that persist environmentally

Performance Benefits

- Structural protection: Preventing oil penetration that weakens cardboard and causes box failure

- Aesthetic maintenance: Avoiding unsightly grease stains that create negative customer impressions

- Food safety: Ensuring packaging maintains protective barriers throughout transport

Testing Standards

Quality manufacturers conduct rigorous grease resistance testing including penetration resistance over time, moisture vapor transmission rates, and structural integrity under load conditions.

What Size Standards Should Pizza Boxes Follow?

Precision sizing ensures optimal transport conditions, prevents pizza movement, and maintains heat retention while optimizing storage and shipping efficiency.

Pizza box dimensions must precisely match pizza sizes to ensure optimal performance. Industry-standard sizing follows direct correlation between pizza diameter and box dimensions, preventing pizza movement during transport while maintaining topping integrity.

Standard Size Categories

Industry-Standard Dimensions

| Pizza Size | Pizza Diameter | Box Dimensions | Typical Use |

|---|---|---|---|

| Personal | 6-8 inches | 7″ × 7″ × 2″ | Individual servings |

| Small | 8-10 inches | 10″ × 10″ × 2″ | Lunch specials |

| Medium | 12-14 inches | 14″ × 14″ × 2″ | Family meals |

| Large | 16-18 inches | 18″ × 18″ × 2″ | Party orders |

| Extra Large | 20+ inches | 20″ × 20″ × 2″ | Specialty pizzas |

Square Design Advantages

The square box design, despite most pizzas being round, optimizes manufacturing efficiency and storage space utilization compared to round alternatives. This design choice maximizes:

- Manufacturing cost-effectiveness

- Storage density and stackability

- Shipping efficiency and handling convenience

- Structural integrity during transport

Custom Sizing Considerations

When working with packaging manufacturers, consider your oven capacity, storage limitations, delivery vehicle constraints, and customer handling preferences for optimal sizing solutions.

Why Is Proper Ventilation Essential for Pizza Boxes?

Strategic ventilation design represents a critical balance between maintaining temperature and preventing moisture buildup that creates soggy crusts and compromises texture.

Effective pizza box ventilation prevents moisture accumulation that leads to soggy crusts while preserving intended texture and crispness. Advanced ventilation systems allow steam escape while maintaining structural integrity and temperature retention.

Advanced Ventilation Technologies

Strategic Perforation Placement

Standard ventilation features include small holes positioned strategically to facilitate airflow even when boxes are stacked. These perforations prevent moisture accumulation while preserving pizza quality.

VENTiT System Innovation

The most advanced designs feature misaligned holes in top and bottom surfaces while maintaining an intact middle corrugated layer. This creates steam pathways through corrugated grooves without direct holes that could compromise temperature retention.

Design Principles

- Allow steam escape without compromising structural integrity

- Facilitate airflow in stacked configurations

- Balance temperature retention with moisture control

- Prevent condensation buildup on pizza surfaces

How Does Stackability Affect Pizza Box Design?

Efficient stackability directly impacts operational costs, storage requirements, and transport efficiency throughout the entire supply chain from manufacturer to customer.

Well-designed pizza boxes must maintain structural integrity when stacked, preventing crushing damage while maximizing storage efficiency. Proper stackability features optimize operational costs and storage requirements throughout the supply chain.

Engineering Stackable Solutions

Structural Reinforcement Features

- Corner reinforcement that distributes weight evenly across stacked boxes

- Consistent dimensions allowing stable stacking configurations

- Adequate strength-to-weight ratios supporting multiple box layers without deformation

Operational Benefits

Effective stackability enables:

- Maximized warehouse storage density

- Efficient delivery vehicle loading

- Reduced transportation costs per unit

- Streamlined handling procedures

Load Distribution Technology

Professional-grade boxes incorporate strategic design elements that maintain structural integrity under stacking loads while preserving accessibility and handling convenience.

What Role Does Thermal Insulation Play?

Temperature retention directly affects customer satisfaction and pizza quality upon delivery. Proper insulation technology maintains optimal eating temperatures throughout transport.

Corrugated cardboard’s natural insulation properties stem from trapped air pockets within the fluted middle layer, creating barriers that slow heat transfer. This insulation typically maintains pizza warmth for 30-60 minutes after delivery.

Insulation Performance Factors

Natural Corrugated Benefits

The corrugated structure’s effectiveness relies on air-trapping design, which acts as natural insulation while maintaining breathability to prevent condensation.

Enhanced Thermal Solutions

- Thicker corrugated walls providing superior heat retention

- Aluminum-lined interiors reflecting heat back toward pizza

- Proper box sizing minimizing air space and heat loss

Performance Metrics

| Insulation Type | Heat Retention | Duration | Cost Impact |

|---|---|---|---|

| Standard Corrugated | Good | 30-45 minutes | Baseline |

| Double-Wall | Better | 45-60 minutes | +15-20% |

| Aluminum-Lined | Excellent | 60+ minutes | +30-40% |

How Important Is Branding Space on Pizza Boxes?

Pizza boxes provide substantial branding real estate that functions as mobile advertising platforms, creating marketing opportunities that extend far beyond the initial purchase.

Pizza boxes offer excellent branding opportunities as mobile advertising platforms. Effective logo placement and high-quality graphics enhance brand recognition, encourage social media sharing, and function as powerful marketing tools that reach customers at their most receptive moment.

Maximizing Marketing Impact

Strategic Design Elements

- Logo placement prominently displayed for maximum brand recognition impact

- High-quality images showcasing appetizing pizzas encouraging repeat business

- Contact information and social media handles for customer engagement

- QR codes linking to digital promotions and loyalty programs

Design Balance Considerations

Effective designs balance aesthetic appeal with functional requirements while avoiding excessive complexity that might detract from legibility or increase printing costs.

Brand Positioning Opportunities

- Create Instagram-worthy unboxing experiences

- Communicate quality and professionalism

- Showcase unique value propositions

- Build emotional connections with customers

What Food Safety Standards Must Pizza Boxes Meet?

FDA regulations govern all materials that come into direct contact with food, making compliance essential for protecting customers and avoiding regulatory issues.

FDA regulations mandate that all inks, adhesives, and coatings used in pizza box manufacturing must be food-grade and free from harmful substance migration. Compliance with 21 CFR 176.170 specifically addresses paper and paperboard components in food contact applications.

Regulatory Compliance Requirements

Material Safety Standards

- All components must meet FDA food-contact regulations

- Inks, adhesives, and coatings require food-grade certification

- Migration testing ensures no harmful chemical transfer

- Good Manufacturing Practices (GMP) ensure sanitary production environments

PFAS Elimination Requirements

Modern pizza boxes must achieve grease resistance through PFAS-free alternatives that maintain food safety standards, eliminating “forever chemicals” from food packaging.

Documentation Requirements

Professional packaging suppliers should provide:

- Material safety data sheets

- FDA compliance certificates

- Third-party testing results

- Manufacturing quality control records

Working with certified manufacturers ensures regulatory compliance while maintaining cost-effectiveness and performance standards.

How Do You Balance Cost and Quality in Pizza Box Selection?

Understanding total cost of ownership, not just unit price, enables informed decisions that optimize both budget and performance over time.

Pizza box costs typically range from $0.15 to $0.70 per unit, with most pizzerias paying approximately $0.30 per box on average. Effective cost management requires considering direct costs, indirect impacts, and long-term value creation.

Comprehensive Cost Analysis

Direct Cost Factors

| Size Category | Unit Cost Range | Material Impact | Volume Savings |

|---|---|---|---|

| Small (10″) | $0.20-$0.30 | Baseline | 20-30% bulk discount |

| Medium (14″) | $0.25-$0.40 | +15-20% | 25-35% bulk discount |

| Large (18″) | $0.40-$0.60 | +40-60% | 30-40% bulk discount |

Indirect Cost Considerations

- Customer complaints and refunds from box failures

- Brand reputation impact from poor packaging quality

- Storage space requirements and handling efficiency

- Environmental compliance and sustainability positioning

Volume Purchasing Benefits

Bulk orders provide substantial savings for high-volume operations, with purchasing power significantly reducing per-unit costs across all size categories.

What Sustainability Features Should Modern Pizza Boxes Include?

Environmental responsibility addresses growing consumer concerns while supporting corporate sustainability goals and regulatory compliance requirements.

Modern pizza boxes incorporate recyclability, PFAS-free formulations, compostable alternatives, and recycled content integration. Approximately 73% of the U.S. population has access to pizza box recycling programs, making environmental features increasingly important.

Sustainable Material Options

Recyclability Standards

Most corrugated pizza boxes can be recycled, though grease-contaminated portions must be separated from clean sections before processing. Proper consumer education maximizes recycling program effectiveness.

Compostable Alternatives

Materials like sugarcane bagasse fiber pulp offer complete biodegradability without industrial processing requirements:

- Tree-free production supporting forest conservation

- Complete biodegradability in commercial composting facilities

- Comparable functionality maintaining food safety and performance standards

- Circular economy support reducing waste stream impact

Advanced Sustainable Features

| Feature | Environmental Benefit | Performance Impact | Cost Consideration |

|---|---|---|---|

| Recycled Content | Waste reduction | Maintained | Neutral |

| FSC Certification | Responsible sourcing | Enhanced | +5-10% |

| Compostable Materials | Zero waste | Comparable | +15-25% |

| PFAS-Free Coatings | Eliminates forever chemicals | Maintained | Neutral |

Certification Programs

Forest Stewardship Council (FSC) certifications ensure responsible sourcing of raw materials while supporting sustainable forestry practices and environmental stewardship.

How Do You Choose the Right Pizza Box Manufacturer?

Selecting the right packaging partner affects product quality, cost management, regulatory compliance, and long-term business success.

Choose manufacturers with FDA compliance certification, PFAS-free coating capabilities, customization expertise, volume pricing advantages, and sustainability credentials. The right partner provides technical support, quality assurance, and flexible solutions for growing businesses.

Key Manufacturer Evaluation Criteria

Quality Assurance Standards

- FDA compliance documentation and certifications

- Third-party testing capabilities and quality control systems

- Manufacturing facility inspections and GMP compliance

- Consistent product specifications and performance standards

Customization Capabilities

- Logo printing and branding integration services

- Custom sizing options for specialized pizza offerings

- Color matching and design consultation support

- Prototype development and testing services

Supply Chain Reliability

- Consistent delivery schedules and inventory management

- Geographic distribution capabilities for efficient shipping

- Scalable production capacity for business growth

- Responsive customer service and technical support

Working with experienced manufacturers like Acreet ensures access to the latest innovations, cost-effective solutions, and reliable supply chain management for international wholesale customers.

Summary

Quality pizza boxes require premium corrugated cardboard construction, PFAS-free grease resistance, precise industry-standard sizing, strategic ventilation design, efficient stackability, effective thermal insulation, prominent branding opportunities, FDA regulatory compliance, competitive cost management, and comprehensive sustainability features. The best boxes seamlessly integrate all elements to protect pizza quality, enhance brand recognition, satisfy customers, and support environmental responsibility while meeting operational requirements and regulatory standards.

Ready to upgrade your pizza packaging with professional-grade solutions? Contact Acreet today for custom pizza boxes that perfectly match your brand requirements and operational needs. Our experienced team helps wholesalers, distributors, retailers, and brand manufacturers worldwide create packaging that drives customer satisfaction and business growth. Send us your specifications for a personalized quote and expert design consultation.