Direct printing on corrugated packaging seems like a cost-effective solution, but many businesses discover hidden challenges that compromise their brand presentation and operational efficiency. These technical limitations can result in poor print quality, increased production costs, and damaged brand reputation.

Direct printing on corrugated materials faces significant limitations including excessive ink absorption causing color degradation, flute crushing that compromises both print quality and structural integrity, poor contrast and color reproduction issues, surface irregularities preventing fine detail reproduction, reduced production efficiency, and substantially higher costs than anticipated.

Understanding these fundamental challenges helps you make informed packaging decisions and explore more effective printing alternatives for professional brand presentation.

Table of Contents

ToggleWhy Does Ink Absorption Create Critical Quality Problems?

Ink absorption represents the most persistent challenge in direct corrugated printing, affecting both visual quality and production costs significantly.

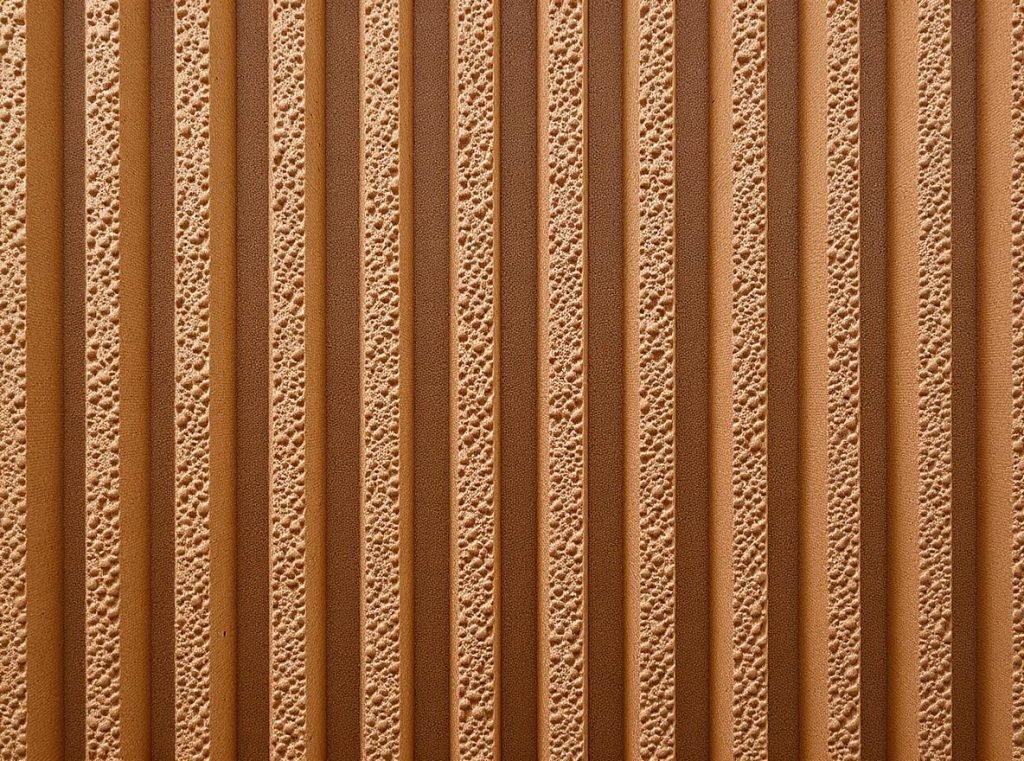

High ink penetration occurs rapidly due to the porous and semi-porous nature of corrugated surfaces, causing ink to be absorbed into the substrate rather than remaining on the surface. This fundamental issue creates multiple interconnected problems that compromise print quality.

The absorbent characteristics of corrugated materials significantly reduce color intensity and vibrancy. As ink penetrates deep into the board structure, colors appear faded and washed out compared to printing on non-porous substrates. This porosity causes ink to disperse rather than maintaining sharp, defined images.

Ink bleeding and blurred markings occur when excessive penetration causes printed elements to spread beyond their intended boundaries. This effect particularly compromises critical information like barcodes, expiry dates, and product codes, potentially causing scanning errors and supply chain disruptions.

Several specific problems result from excessive ink absorption:

- Color saturation decreases by 30-50% compared to smooth substrates

- Sharp text and fine lines become blurred and illegible

- Barcode scanning reliability drops significantly

- Higher ink consumption increases material costs by 40-60%

- Inconsistent absorption creates patchy, uneven appearance

| Absorption Issue | Quality Impact | Cost Implication |

|---|---|---|

| Deep Penetration | Faded colors | 40-60% more ink usage |

| Ink Spreading | Blurred details | Reprints and waste |

| Uneven Absorption | Patchy appearance | Quality control costs |

In food packaging applications, high ink penetration poses additional contamination risks when ink comes into direct contact with products. The deep absorption can also affect the structural integrity of the corrugated board itself, creating weakened areas that may fail under stress.

Professional packaging requires consistent color reproduction and sharp detail definition that direct corrugated printing simply cannot deliver reliably due to these fundamental absorption issues.

How Does Flute Crushing Destroy Both Print Quality and Structural Integrity?

Flute crushing represents a critical limitation that simultaneously damages print appearance and compromises the protective function of corrugated packaging.

Understanding why flute crushing occurs helps explain why direct printing often fails to meet professional packaging standards for both visual appeal and functional performance.

Excessive printing pressure required to achieve adequate ink coverage on uneven corrugated surfaces often crushes the internal flute structure. This is particularly problematic when printing large solid areas or when operators increase pressure to compensate for poor initial ink coverage.

Flute damage during printing severely affects both print quality and box strength. The corrugated structure that provides cushioning and stacking strength becomes compromised, reducing the package’s ability to protect contents during shipping and storage.

Equipment-related crushing occurs from several mechanical factors:

The interaction between printing equipment and corrugated structure creates unavoidable pressure points. Improperly set infeed rollers, contaminated or misaligned components, and overly hard rubber rollers all contribute to localized crushing damage.

Striping and washboard effects result from the contact between printing plates and the three-dimensional corrugated surface. Digital printing plates tend to create worse fluting effects than analog counterparts due to their rounded geometry and contact angles with uneven surfaces.

Flute crushing creates multiple interconnected problems:

- Reduced compression strength by up to 40% in damaged areas

- Uneven print density creating striped appearance

- Compromised stacking stability for warehouse storage

- Decreased protection for packaged products

- Professional appearance degradation affecting brand perception

The fundamental conflict between achieving adequate print pressure and preserving flute integrity makes direct printing unsuitable for applications requiring both high-quality graphics and reliable structural performance.

What Severe Color and Contrast Limitations Affect Brand Presentation?

Color reproduction challenges in direct corrugated printing create substantial barriers to effective brand communication and professional packaging presentation.

These limitations become particularly problematic when attempting to maintain consistent brand standards across different packaging materials and production runs.

Research demonstrates that printing on various corrugated types results in color differences (ΔE) ranging from 10-45, far exceeding permissible standards for quality color reproduction. This variation makes brand color matching virtually impossible with direct printing methods.

Poor contrast between ink and the natural brown kraft substrate particularly affects scanability of printed codes and readability of important product information. The inherent brown color of corrugated surfaces reduces available contrast for text and graphics, making designs appear flat and unprofessional.

Color reproduction limitations manifest in several critical ways:

The natural brown background of corrugated material creates fundamental challenges for lighter colors and pastels. These colors often appear muddy or completely disappear against the brown substrate, severely limiting design possibilities.

Limited color gamut represents another significant constraint. Unlike smooth surfaces that can achieve vibrant, saturated colors, corrugated substrates inherently restrict the range of achievable colors due to absorption and surface irregularities.

Dark colors like black, dark blue, purple, and green show better contrast on brown backgrounds, but even these suffer from:

- Reduced saturation and vibrancy

- Inconsistent density across printed areas

- Poor reproduction of subtle color variations

- Difficulty achieving accurate brand color matching

- Higher ink consumption required for acceptable density

| Color Category | Visibility | Brand Impact |

|---|---|---|

| Light Colors | Very Poor | Major brand inconsistency |

| Pastel Colors | Poor | Invisible on brown background |

| Dark Colors | Fair | Limited design flexibility |

| Bright Colors | Poor | Appear dull and muted |

Professional packaging often requires white base layers to achieve acceptable color reproduction, but this solution significantly increases production time, material costs, and process complexity while still failing to match the quality achievable with alternative methods.

Why Do Surface Irregularities Severely Restrict Design Complexity?

The three-dimensional structure and surface irregularities of corrugated materials create fundamental barriers to reproducing detailed graphics and complex designs.

These physical characteristics make it impossible to achieve the fine detail reproduction that modern packaging design requires for effective brand communication.

The fluted structure corresponds to uneven pressure distribution during printing, making it difficult to achieve consistent ink transfer across the entire surface. Grooves and ridges create microscopic valleys and peaks that prevent uniform ink application.

Fine detail reproduction becomes nearly impossible with direct printing methods. Traditional flexographic processes struggle with intricate designs, small text, fine lines, and halftone dots that are essential for professional packaging graphics.

Surface irregularity problems include several specific technical limitations:

Small halftone dots (1-2%) are easily lost during plate washing and printing processes, while 3% dots tend to expand to 10% during printing, making smooth gradients impossible to achieve. Even better-printed products can only reproduce 8-10% dots reliably.

The uneven substrate surface makes it extremely difficult to maintain consistent print quality across different areas of the same sheet. Areas over flute peaks receive different pressure than areas over valleys, creating unavoidable variations in print density and appearance.

Design elements that work well on other packaging materials fail completely when applied to corrugated surfaces:

- Fine serif fonts become illegible due to ink spreading and surface irregularities

- Detailed logos lose critical visual elements and brand recognition features

- Photographic images appear grainy, unprofessional, and lack detail definition

- Barcodes may not scan properly due to line quality inconsistencies

- Gradient effects appear banded rather than smooth and professional

Registration accuracy becomes challenging when printing multiple colors due to the flexible nature of corrugated material. The substrate can shift or compress differently across its surface, causing color separations to misalign and creating blurry or off-register prints.

These limitations severely restrict the complexity and sophistication of designs possible with direct corrugated printing, making it unsuitable for premium packaging applications that require detailed graphics, fine text, or photographic imagery.

How Do Production Speed and Efficiency Problems Impact Operations?

Direct corrugated printing creates significant operational bottlenecks that affect productivity, delivery schedules, and overall cost-effectiveness compared to alternative methods.

These efficiency challenges become particularly apparent when dealing with tight deadlines, variable job sizes, or the need for quick design modifications that modern packaging markets demand.

Extended setup times represent a major efficiency limitation, with traditional flexographic and offset processes requiring substantial makeready periods ranging from 20-30 minutes compared to 1-3 minutes for digital alternatives. Each color change, design modification, or job changeover requires new plates and extensive mechanical adjustments.

Higher waste generation occurs during setup and color registration processes. Traditional direct printing methods produce significant material waste during plate changes, color adjustments, and quality testing runs that can account for 15-25% of total material usage.

Multiple operational factors contribute to reduced production efficiency:

Setup complexity increases substantially when preparing for direct corrugated printing. Operators must carefully calibrate pressure settings to avoid flute crushing, adjust for material thickness variations, and perform multiple test runs to achieve acceptable quality levels.

Reduced overall equipment effectiveness (OEE) results from frequent production stops for plate changes, pressure adjustments, and quality control inspections. The harsh printing environment of corrugated production creates numerous mechanical challenges that reduce uptime.

Quality control requirements become more intensive due to various issues associated with direct printing:

- Individual inspection needed for crushed flutes

- Color consistency monitoring across sheets

- Registration accuracy verification for multi-color work

- Barcode scanning quality testing

- Structural integrity assessment after printing

Limited flexibility for short runs and quick turnarounds becomes problematic as market demands shift toward smaller quantities and faster delivery. Traditional processes are economically inefficient for shorter print runs or custom orders, leading to longer lead times and increased operational costs.

| Production Factor | Traditional Method | Efficiency Impact |

|---|---|---|

| Setup Time | 20-30 minutes | 300-500% longer |

| Waste Rate | 15-25% | Significant material loss |

| Changeover Time | Extended | Reduced daily throughput |

| Flexibility | Limited | Poor short-run economics |

The need for specialized equipment maintenance and skilled operator training further impacts operational efficiency, with many facilities struggling to find experienced personnel familiar with complex traditional corrugated printing processes.

What Hidden Cost Factors Create Budget Overruns?

The total cost of direct corrugated printing typically exceeds initial projections by 20-40% due to multiple hidden expenses that become apparent only during production.

Understanding these comprehensive cost implications helps businesses make realistic budget assessments and evaluate alternative approaches more accurately.

High capital investment requirements for traditional corrugated printing equipment often exceed millions of dollars for complete systems. Specialized flexographic presses, rotary die cutters, and associated maintenance infrastructure create substantial financial barriers, particularly for smaller operations.

Plate costs represent substantial ongoing expenses, with each color requiring separate plates costing hundreds to thousands of dollars depending on size and complexity. Design changes necessitate completely new plates, making customization and short runs economically unfeasible.

Material and operational costs accumulate from multiple sources:

Setup waste during job changes can account for 15-25% of total material usage, representing significant direct cost increases. Quality rejects due to printing problems, flute crushing, and color inconsistencies further increase waste-related expenses.

Specialized ink formulations required for corrugated substrates command premium pricing compared to standard printing inks, often costing 50-100% more than conventional alternatives. These inks must balance absorption control, drying speed, and color vibrancy requirements.

Labor costs increase substantially due to several factors:

- Extended setup and changeover times requiring skilled operators

- Intensive quality control procedures demanding additional personnel

- Specialized training requirements for complex equipment operation

- Higher maintenance costs due to substrate-related equipment wear

Working capital implications include inventory carrying costs for pre-printed materials, obsolescence risks from design changes, and the economic pressure to produce larger quantities to justify plate costs, often resulting in excess inventory.

| Cost Category | Standard Printing | Direct Corrugated | Percentage Increase |

|---|---|---|---|

| Equipment Investment | Base | Specialized | 200-400% |

| Plate Costs | Not Required | Per Color/Design | $500-5000+ per job |

| Ink Costs | Standard | Specialized | 50-100% |

| Labor Hours | Base | Extended | 140-180% |

| Material Waste | 3-5% | 15-25% | 300-500% |

Long-term financial impacts include higher reprinting rates due to quality issues, customer complaints about unprofessional appearance, potential loss of business due to poor brand presentation, and the opportunity costs associated with longer production cycles and reduced flexibility.

Which Alternative Solutions Deliver Superior Results?

Several proven alternatives to direct corrugated printing address the fundamental limitations while delivering superior quality, efficiency, and cost-effectiveness for professional packaging applications.

Modern alternative approaches eliminate most technical constraints associated with direct printing while offering improved flexibility and brand presentation capabilities.

Digital printing technology has emerged as the most transformative alternative, offering multiple advantages including elimination of plate requirements, setup time reduction to minutes instead of hours, and true on-demand production capabilities that match modern market demands.

Pre-printing techniques provide superior print quality by applying graphics to linerboard before corrugation, then laminating to create the final product. While adding process steps, pre-printing achieves much higher resolution and color accuracy than direct printing methods.

The most effective alternative solutions include:

Litho-lamination combines offset printing quality with corrugated functionality by printing high-resolution graphics on separate sheets, then laminating them to corrugated boards. This method produces exceptional visual results with full photographic reproduction capability.

Hybrid production approaches optimize different technologies for specific applications. Digital printing excels for short runs, variable data, and quick turnarounds, while traditional methods remain cost-effective for large volumes with simple designs when quality requirements are minimal.

Advanced digital corrugated printing systems offer several breakthrough capabilities:

- Setup times reduced from 20-30 minutes to 1-3 minutes

- No plate costs or design change penalties

- Variable data printing for personalization

- Photographic quality reproduction

- Consistent color matching across runs

- Minimal waste generation during production

| Solution Type | Quality Level | Setup Time | Best Application |

|---|---|---|---|

| Digital Direct | Excellent | 1-3 minutes | Short runs, variable data |

| Pre-printing | Superior | Moderate | High-volume quality work |

| Litho-lamination | Premium | Extended | Luxury packaging |

| Hybrid Approach | Optimized | Variable | Flexible production needs |

Working with experienced packaging manufacturers like Acreet ensures access to the most appropriate printing solutions based on specific design requirements, volume needs, budget constraints, and delivery timelines. Professional packaging partners can recommend optimal methods and provide samples demonstrating quality differences between approaches.

Modern alternative printing methods eliminate the fundamental limitations of direct corrugated printing while offering superior brand presentation, operational efficiency, and total cost-effectiveness for businesses seeking professional packaging solutions.

Summary

Direct printing on corrugated material presents severe limitations including excessive ink absorption reducing color quality, flute crushing compromising structural integrity, poor color reproduction with ΔE values of 10-45, surface irregularities preventing fine detail reproduction, extended production times, and hidden costs increasing total expenses by 20-40%. Alternative solutions like digital printing, pre-printing, and litho-lamination deliver superior quality and efficiency.

Ready to overcome these printing limitations and achieve professional packaging results? Contact Acreet today for expert consultation on optimal printing methods for your custom packaging needs. Our experienced team can help you select the most cost-effective solution that delivers outstanding visual impact while meeting your production requirements and delivery schedules.