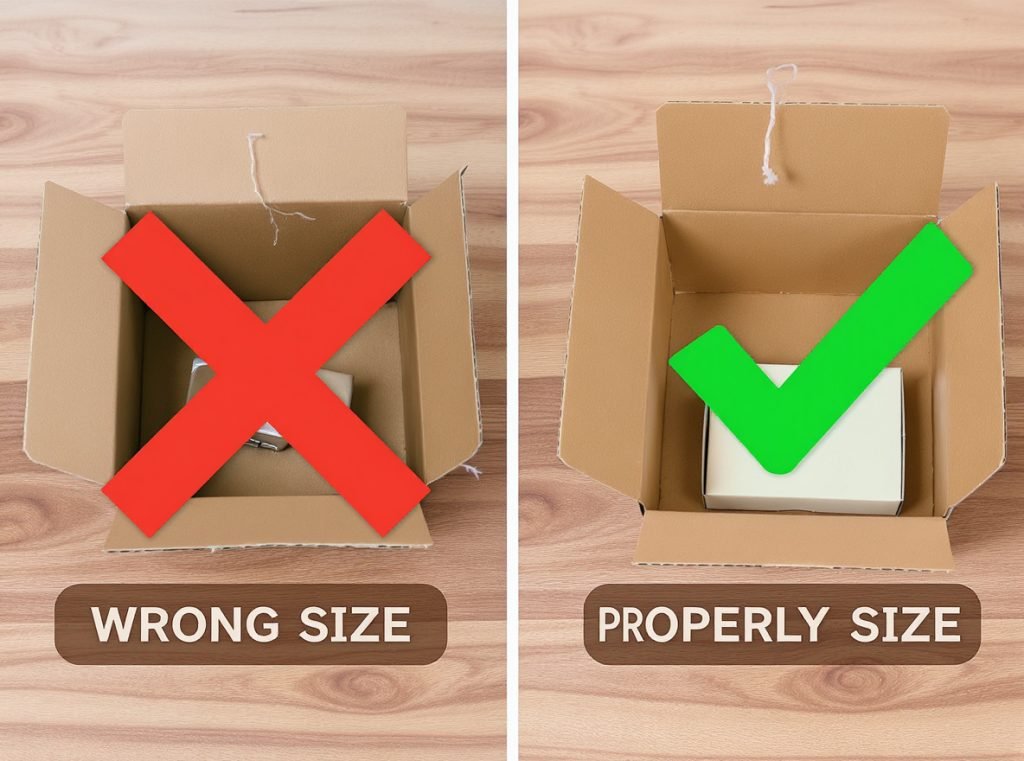

Choosing the wrong box size for your e-commerce shipments can quietly drain your profits through inflated shipping costs and unhappy customers. Research shows that 40% of e-commerce packages are oversized, with the average package containing 40% wasted space.

The most common e-commerce shipping box sizes are 4x4x4 inches and 8x6x4 inches for small items, 12x9x6 inches and 15x15x6 inches for medium products, and 18x18x16 inches for larger goods. These standard dimensions help minimize shipping costs while ensuring adequate product protection during transit.

Let’s explore everything you need to know about selecting the perfect box sizes for your e-commerce business.

Table of Contents

ToggleWhat Are the Standard Small Box Sizes for E-commerce?

Small boxes form the backbone of most e-commerce shipping operations. They’re perfect for lightweight items that need secure packaging without wasting space or triggering dimensional weight charges.

Standard small e-commerce boxes include 4x4x4 inches for jewelry and accessories, 6x6x6 inches for cosmetics and beauty products, 8x6x4 inches for books and electronics, and 8x8x8 inches for fragile items requiring extra padding. These compact dimensions keep shipping costs minimal while providing adequate protection.

Most Popular Small Box Specifications

The 4x4x4 inch box serves as the ultra-compact option for jewelry, small accessories, candles, and promotional items. This cube design maximizes protection for delicate products in the smallest possible footprint.

Here are the top small box dimensions used by successful e-commerce businesses:

- 4x4x4 inches: Perfect for jewelry, small accessories, candles, and promotional items

- 6x6x6 inches: Ideal for cosmetics, beauty products, small tools, and tech accessories

- 8x6x4 inches: Popular choice for books, electronics accessories, cosmetics, and phone cases

- 8x8x8 inches: Cube shape provides extra protection for fragile items like glassware and collectibles

Why Small Box Selection Impacts Your Bottom Line

The 6x4x4 inch box has become an industry standard, supporting up to 4 pounds while maintaining cost efficiency. For slightly larger products, the 8x6x4 inch option accommodates up to 9 pounds and works perfectly for books, electronics, picture frames, and apparel.

Small boxes help you avoid dimensional weight penalties that can dramatically increase shipping costs. USPS applies dimensional weight pricing to packages exceeding 1,728 cubic inches, while UPS and FedEx use this pricing for packages 6x6x6 inches or larger.

Using appropriately sized small boxes also creates better customer experiences. Nobody wants to receive a tiny item rattling around in an oversized box filled with excessive padding material.

Which Medium Box Sizes Work Best for Most Products?

Medium-sized boxes handle the majority of e-commerce shipments across diverse product categories. They offer the sweet spot between versatility and shipping cost efficiency.

The most effective medium box sizes are 10x8x6 inches for household goods, 12x9x6 inches for apparel and subscription boxes, 15x15x6 inches for clothing and electronics, and 18x18x16 inches as the most versatile medium option. These dimensions accommodate various product types while maintaining reasonable shipping costs.

Top Medium Box Applications

| Box Size (L x W x H) | Weight Capacity | Best Product Categories | Key Advantages |

|---|---|---|---|

| 10x8x6 inches | Up to 5 lbs | Mugs, phone accessories, pet supplies | Efficient for moderate protection needs |

| 12x9x6 inches | Up to 10 lbs | Apparel, boxed retail products, subscription items | Popular for clothing and packaged goods |

| 15x15x6 inches | Up to 15 lbs | Clothing, small electronics, home goods | Square footprint optimizes pallet space |

| 18x18x16 inches | Up to 25 lbs | Household goods, medium appliances | Most versatile medium size option |

Strategic Benefits of Medium Box Standardization

The 18x18x16 inch box stands out as the most commonly used medium size, providing approximately 3 cubic feet of space for household goods and medium appliances. This popularity stems from its versatility across multiple product categories.

Medium boxes offer several operational advantages:

They reduce inventory complexity by handling diverse product types with fewer box variations. Your warehouse operations become more efficient when you can standardize on three to four medium sizes rather than stocking dozens of different dimensions.

The 12x9x4 inch and 14x10x3 inch dimensions work particularly well for subscription box companies and apparel retailers. These compact profiles minimize dimensional weight charges while accommodating folded clothing and packaged consumer goods.

What Large Box Dimensions Should E-commerce Businesses Consider?

Large boxes serve specific strategic purposes for bulky items, consolidated shipments, and oversized products. While they cost more to ship, they’re essential for certain business models and product categories.

Common large e-commerce box sizes include 18x14x8 inches for large appliances and padded items, 18x18x24 inches providing 4.5 cubic feet for tall products, 24x20x12 inches for extra-large items, and specialized long boxes like 36x6x6 inches for posters and sporting goods.

Large Box Category Applications

Different large box dimensions serve distinct business needs:

18x18x24 inches boxes provide 4.5 cubic feet of space and handle tall, bulky items like desk lamps, heavy blankets, speakers, and small electronics. This dimension works well for products that need height clearance.

24x18x24 inches boxes offer 6 cubic feet and support items up to 65 pounds, making them ideal for furniture parts, large appliances, and consolidated orders. These maximize shipping efficiency for heavy, bulky products.

20x15x15 inches boxes suit mid-range bulk orders and irregularly shaped items that don’t fit standard medium dimensions.

Managing Large Box Shipping Economics

Large boxes require careful cost management due to dimensional weight pricing. A lightweight 7-pound pillow in a 24x18x12 inch box results in a billable weight of 38 pounds rather than the actual 7 pounds when using standard DIM factors.

Smart strategies for large box optimization include:

- Consolidating multiple items into single shipments when logistics allow

- Using these boxes only when product dimensions truly require the space

- Negotiating volume discounts with carriers for consistent large shipment patterns

- Implementing regional fulfillment centers to reduce shipping distances and costs

How Do Carrier-Specific Box Sizes Affect Your Shipping Strategy?

Each major shipping carrier offers specific box programs with different pricing structures and size restrictions. Understanding these options helps optimize both shipping costs and delivery reliability.

USPS offers Small (8-11/16″ × 5-7/16″ × 1-3/4″), Medium (11-1/4″ × 8-3/4″ × 6″), and Large (12-1/4″ × 12-1/4″ × 6″) flat rate boxes. FedEx provides Small (10-7/8″ × 1-3/4″ × 12-3/8″), Medium (13-1/4″ × 11-1/2″ × 2-3/8″), and Large (17-1/2″ × 12-3/8″ × 3″) express boxes with different weight limits and pricing models.

USPS Flat Rate Box Strategy

USPS Priority Mail boxes come in standardized sizes with specific weight limits and flat-rate pricing regardless of destination. Small boxes support lightweight documents and accessories, while larger options accommodate various product categories up to 70 pounds.

USPS flat rate advantages include:

- Predictable pricing for cross-country shipments where zone pricing would be expensive

- Cost-effective shipping for heavy items in compact packages

- Simplified shipping cost calculations for customer checkout processes

- No dimensional weight penalties within the provided box dimensions

FedEx and UPS Premium Options

Both carriers use a DIM factor of 139 for domestic shipments and apply dimensional weight pricing to packages 6x6x6 inches or larger. FedEx offers free packaging with weight limits ranging from 20 to 50 pounds depending on box size.

These premium carriers excel when:

You need guaranteed delivery times for time-sensitive products. Business customers often prefer faster delivery options even at higher costs.

Your products require special handling capabilities, tracking features, or insurance coverage that these carriers provide.

International shipping needs demand the global networks and customs expertise these carriers offer.

Amazon FBA Box Requirements

Amazon maintains strict box size limits for FBA shipments that directly impact packaging strategy. Standard boxes cannot exceed 25 inches on any side and must weigh no more than 50 pounds.

| Shipping Method | Size Restrictions | Weight Limits | Best Use Cases |

|---|---|---|---|

| USPS Flat Rate | Provided dimensions only | Up to 70 lbs | Heavy, compact items |

| FedEx/UPS Standard | 6x6x6+ triggers DIM weight | Varies by service | Time-sensitive shipments |

| Amazon FBA | 25″ maximum any side | 50 lbs maximum | Marketplace sellers |

What Box Sizing Mistakes Cost E-commerce Businesses Money?

Poor box selection decisions create multiple expensive problems including increased shipping costs, higher return rates, regulatory penalties, and operational inefficiencies.

The most costly box sizing mistakes include using oversized boxes that trigger dimensional weight charges, choosing inadequately sized boxes leading to product damage, miscalculating DIM weight formulas, and wasting materials through poor size optimization. These errors can cost businesses $60,000+ annually per 1,000 monthly shipments.

Dimensional Weight Penalty Analysis

Research reveals that businesses shipping 1,000 packages monthly with boxes 20% larger than necessary waste approximately $60,000 annually through dimensional weight penalties alone.

Understanding dimensional weight calculations prevents these costly errors:

USPS applies DIM pricing to packages exceeding 1,728 cubic inches (equivalent to 12x12x12 inches). UPS and FedEx use a DIM factor of 139, meaning a package’s dimensional weight equals Length × Width × Height ÷ 139.

Common dimensional weight mistakes include:

- Using standard large boxes for small, lightweight items without calculating billable weight

- Failing to optimize box dimensions for your most frequently shipped products

- Ignoring carrier-specific DIM factors and thresholds in packaging decisions

- Not testing different box sizes to identify cost-effective alternatives

Product Protection and Return Cost Issues

Inadequate protection creates equally expensive problems through product damage and returns. Poor sizing decisions result in 10% damage rates, forcing companies to use excessive filler materials to compensate for improper fit.

Protection failures that impact profitability:

Undersized boxes that compress products or prevent proper padding. Forcing items into inappropriate spaces frequently causes damage claims and costly returns.

Mixed product incompatibility in single shipments. Combining fragile and heavy items without proper separation increases damage rates significantly.

Insufficient consideration for packaging material space requirements. Your actual product dimensions plus necessary bubble wrap, air pillows, or paper padding must fit comfortably within chosen box dimensions.

Regulatory and Environmental Costs

Extended Producer Responsibility regulations in states like California and Maine now penalize businesses for excessive packaging waste. These emerging costs add financial pressure to optimize packaging efficiency.

Environmental considerations also impact customer perception and brand reputation, with consumers increasingly preferring businesses that minimize packaging waste.

How Can Custom Box Sizing Optimize Your E-commerce Operations?

Custom-sized boxes designed specifically for your product mix can dramatically improve shipping efficiency, reduce costs, and enhance customer experience while supporting sustainable business practices.

Custom box sizing optimizes operations by eliminating wasted space, reducing dimensional weight charges, minimizing packaging material costs, creating consistent brand presentation, and improving customer unboxing experiences. Businesses implementing right-sized packaging report ROI ratios ranging from 9.8 to 34.2 depending on customization level.

Custom Sizing ROI and Break-Even Analysis

Studies show that custom packaging delivers measurable returns through cost reduction and revenue enhancement. The break-even point requires only a 0.4% increase in sales, while high customization can drive up to 20% revenue increases.

| Business Metric | Standard Boxes | Custom Optimized | Annual Impact (1000 packages) |

|---|---|---|---|

| Average shipping cost | $8.50 | $6.75 | $21,000 savings |

| Damage rate | 10% | 3% | $14,000 in reduced returns |

| Material costs | $2.10 | $1.65 | $5,400 savings |

| Customer satisfaction | 85% | 92% | Improved retention rates |

Implementation Strategy with Professional Partners

Working with experienced packaging manufacturers streamlines the custom box development process:

Product analysis phase: Professional manufacturers measure your most frequently shipped items to determine optimal dimensions and identify opportunities you might overlook.

Prototype development: Creating sample boxes to test with actual products and shipping processes prevents costly mistakes in final production runs.

Material optimization: Selecting appropriate corrugated cardboard weights and construction styles that balance protection requirements with cost efficiency.

Branding integration: Incorporating your logo, brand colors, and marketing messages into box design for enhanced customer experience and brand recognition.

Operational Efficiency Through Standardization

Custom-sized boxes reduce packing time by eliminating excessive filler materials and creating predictable packing workflows. Standardized custom dimensions enable automated packaging systems to operate more efficiently while reducing training requirements for warehouse staff.

Start implementation with your highest-volume products to maximize immediate impact. Analyze shipping data to identify which products would benefit most from custom sizing based on frequency, value, and current shipping costs.

Consider seasonal variations in your product mix when designing custom solutions. Custom boxes work best when you have consistent shipping patterns rather than constantly changing product dimensions and volumes.

Ready to optimize your packaging strategy and reduce shipping costs? Contact Acreet today for custom box solutions designed specifically for your products and shipping requirements. Our packaging experts can analyze your current shipping data and develop cost-effective custom boxes that improve both your bottom line and customer satisfaction.

Summary

Selecting optimal shipping box sizes is crucial for e-commerce profitability and customer satisfaction. Standard small boxes (4x4x4″ to 8x8x8″), versatile medium boxes (12x9x6″ to 18x18x16″), and specialized large boxes (18x14x8″ to 24x20x12″) handle most shipping needs cost-effectively. Understanding carrier-specific requirements and avoiding common sizing mistakes protects profit margins while ensuring reliable delivery performance.

Partner with Acreet to develop custom packaging solutions that eliminate wasted space, reduce shipping costs, and create memorable unboxing experiences for your customers.