Choosing the right packaging filler can make or break your customer’s unboxing experience. You want something that protects your products, looks professional, and doesn’t break your budget or harm the environment.

Crinkle-cut paper offers excellent eco-friendly cushioning with vibrant presentation options, making it ideal for gift packaging and light products under 15 pounds. However, it weighs more than air-based alternatives, requires significant storage space, and provides limited protection for heavy items or moisture-sensitive products.

Let’s explore the specific advantages and disadvantages to help you make the best decision for your packaging strategy.

Table of Contents

ToggleWhat Makes Crinkle-Cut Paper Different from Other Fillers?

Understanding crinkle-cut paper’s unique characteristics helps you evaluate whether it fits your packaging requirements compared to bubble wrap, foam peanuts, or air pillows.

Crinkle-cut paper features specialized accordion-like zigzag strips that compress and expand naturally, conforming to irregular product shapes while maintaining springy cushioning properties. Unlike synthetic alternatives with rigid structures, this flexible design creates both functional protection and enhanced aesthetic appeal for packaging applications.

The material stands out due to its unique accordion-like texture created through specialized cutting techniques, allowing it to function differently than bubble wrap’s air-filled chambers or foam peanuts’ rigid pieces. This distinctive design allows it to conform to irregular shapes while maintaining springy cushioning properties.

The manufacturing process involves cutting recyclable paper into strips with deliberate accordion folds that give the material its signature spring-like quality. Unlike synthetic alternatives, crinkle-cut paper provides a natural, organic feel that enhances the unboxing experience while serving practical protection needs.

Unlike foam peanuts that can shift during shipping, crinkle-cut paper’s interlocking design helps it stay positioned around products throughout transit, providing more consistent protection than loose-fill alternatives.

What Are the Main Advantages of Crinkle-Cut Paper?

Crinkle-cut paper offers several compelling benefits that make it increasingly popular among businesses seeking attractive, sustainable packaging solutions.

Crinkle-cut paper delivers exceptional environmental sustainability made from recyclable paper sources that are biodegradable and compostable. It provides lightweight cost efficiency, vibrant aesthetic appeal for branding, versatile protection for various products, and requires no specialized equipment for easy storage and handling.

Environmental Sustainability Benefits

Crinkle-cut paper offers significant environmental benefits compared to plastic alternatives. Made from recyclable paper content, it’s biodegradable and compostable, supporting sustainable packaging practices. This eco-friendly nature addresses growing consumer demand for environmentally responsible packaging solutions.

Unlike plastic bubble wrap or foam peanuts that persist in landfills, crinkle-cut paper decomposes naturally without leaving harmful residues. For businesses prioritizing green initiatives, this material supports corporate sustainability goals while appealing to environmentally conscious customers.

Lightweight Cost Efficiency

One of the key advantages is its minimal weight impact on shipping costs. Unlike bulky alternatives that add unnecessary weight, crinkle-cut paper strikes an optimal balance between protection and shipping efficiency, helping businesses reduce transportation expenses compared to heavier foam alternatives.

This weight efficiency becomes particularly valuable for high-volume shippers who need consistent protection without pushing packages into higher shipping cost brackets.

Aesthetic Appeal and Branding Opportunities

| Feature | Benefit | Business Impact |

|---|---|---|

| Multiple colors available | Brand coordination opportunities | Enhanced brand recognition |

| Premium unboxing experience | Increased customer satisfaction | Higher perceived product value |

| Social media appeal | Encourages sharing | Free marketing exposure |

The material significantly enhances product presentation, creating a premium unboxing experience. Available in multiple colors, crinkle-cut paper can be coordinated with brand aesthetics, making packages more visually appealing and memorable.

Versatile Protection Capabilities

Crinkle-cut paper provides effective cushioning for various product types, from fragile glassware to electronics. Its ability to conform to product shapes prevents movement during transit while absorbing shock and vibrations.

The accordion structure creates natural cushioning zones that adapt to different product configurations, making it suitable for irregularly shaped items that rigid foam inserts can’t accommodate effectively.

Easy Storage and Handling

The material requires minimal storage space compared to pre-formed packaging alternatives and doesn’t need specialized equipment for application. It comes ready to use without fluffing or assembly requirements, streamlining packaging operations for busy fulfillment centers.

What Are the Key Disadvantages of Crinkle-Cut Paper?

While crinkle-cut paper offers numerous benefits, understanding its limitations ensures you make informed packaging decisions that align with your specific requirements.

Crinkle-cut paper weighs significantly more than air-based alternatives, potentially adding thousands in annual shipping costs. It provides inadequate protection for heavy items over 15 pounds, requires substantial storage space, creates messy handling situations, and offers minimal moisture protection for sensitive products.

Significant Weight Impact on Shipping

Despite being lightweight, crinkle-cut paper still weighs significantly more than air-based alternatives like bubble wrap or air pillows. For high-volume shippers, this weight difference can result in thousands of dollars in additional shipping costs annually, particularly when packages cross weight thresholds that trigger higher shipping rates.

This weight consideration becomes critical for e-commerce businesses shipping hundreds or thousands of packages monthly, where even small weight increases compound into substantial cost differences.

Inadequate Heavy-Duty Protection

Crinkle-cut paper performs poorly with heavy items (15+ lbs) or high-impact situations. The material compresses under weight and doesn’t provide sufficient protection for dense or fragile items requiring substantial cushioning.

• Electronics over 10 pounds need additional protection

• Dense items like tools or hardware compress the filler

• High-value fragile products require foam or bubble wrap alternatives

• Multiple heavy items in one package overwhelm paper cushioning

Storage Space Requirements

Unlike deflated air pillows or compressed bubble wrap, crinkle-cut paper maintains its volume, requiring more warehouse storage space. This can create logistical challenges for businesses with limited storage capacity.

The bulky nature means businesses need dedicated storage areas and careful inventory management to prevent running out of filler material during peak shipping periods.

Messy Handling and Cleanup Issues

The material can create cleanup challenges for recipients, with loose paper pieces potentially causing dust and debris issues. This is particularly problematic for electronics or products where paper particles could cause operational problems.

Customer complaints about messy unpacking experiences can negatively impact brand perception, especially for premium products where clean presentation matters.

Limited Moisture Protection

Paper-based fillers offer minimal protection against moisture and humidity compared to plastic alternatives. This limitation makes crinkle-cut paper unsuitable for products sensitive to environmental conditions, requiring additional barrier protection for moisture-sensitive items.

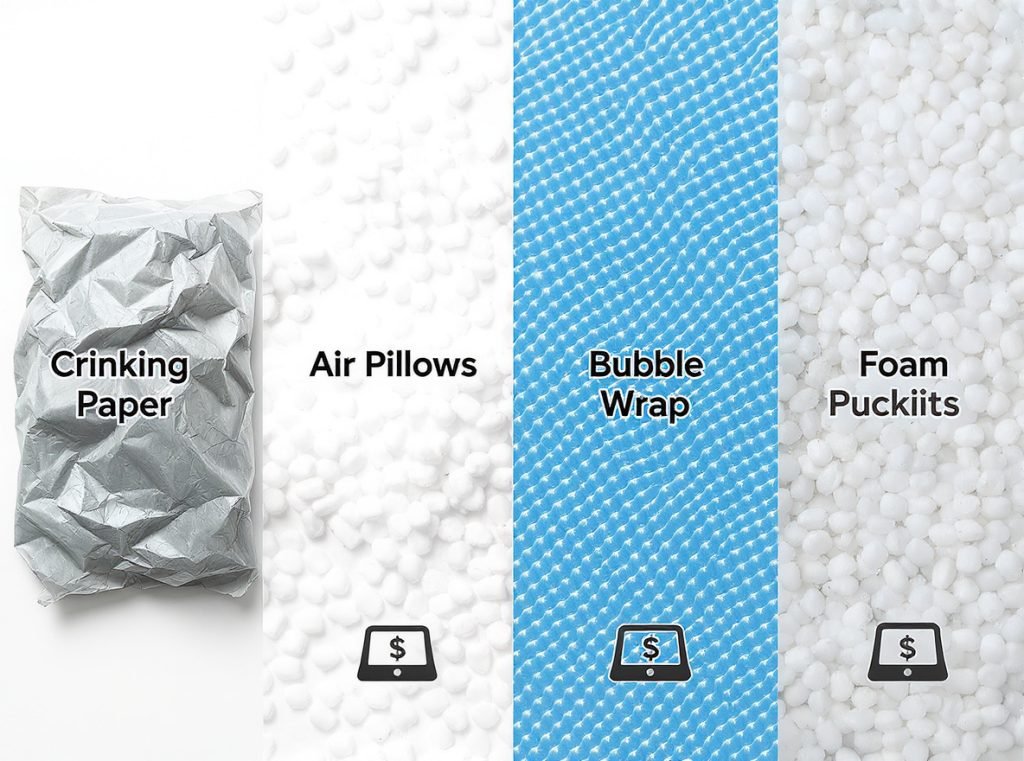

How Does Crinkle-Cut Paper Compare to Other Packaging Fillers?

Comparing crinkle-cut paper against alternatives helps determine the optimal choice for your specific packaging needs, budget constraints, and performance requirements.

Crinkle-cut paper excels in presentation and environmental impact but weighs more and costs more than air-based alternatives. It provides moderate protection suitable for light items while requiring significantly more storage space than compressed alternatives like air pillows or deflated bubble wrap.

Comprehensive Filler Comparison

The following comparison shows how different filler types perform across key business criteria:

| Filler Type | Weight | Cost | Protection Level | Environmental Impact | Storage Space | Best Use Cases |

|---|---|---|---|---|---|---|

| Crinkle-Cut Paper | Moderate | Medium | Good for light items | Excellent (recyclable) | High | Gift boxes, light products, presentations |

| Air Pillows | Very Light | Low | Good void fill, poor heavy items | Poor (plastic) | Very Low | Light products, void fill |

| Bubble Wrap | Light | Medium | Excellent all-around | Poor (plastic) | Medium | Fragile items, versatile wrapping |

| Packing Peanuts | Light | Low | Moderate | Variable (foam vs. starch) | High | Loose fill, multiple items |

| Foam Inserts | Light | High | Excellent | Poor | Medium | Heavy/fragile items, custom shapes |

Key Performance Differences

Air pillows offer the most storage efficiency and lowest shipping weight impact, making them ideal for high-volume operations prioritizing cost control over presentation.

Bubble wrap provides superior all-around protection but lacks the environmental benefits and aesthetic appeal of crinkle-cut paper.

Foam inserts deliver maximum protection for valuable items but require custom manufacturing and higher costs per package.

When Should You Use Crinkle-Cut Paper as Filler?

Understanding optimal applications maximizes crinkle-cut paper’s benefits while avoiding situations where it falls short of requirements.

Use crinkle-cut paper for gift packaging, subscription boxes, light products under 15 pounds, and situations where sustainable branding and premium presentation matter. Avoid for heavy items, moisture-sensitive products, electronics requiring clean environments, or high-volume operations prioritizing shipping cost efficiency.

Perfect Applications for Crinkle-Cut Paper

Gift packaging and subscription boxes where presentation matters significantly represent ideal use cases because customers expect attractive, memorable unboxing experiences.

Light to medium-weight products under 15 pounds work well because the material provides adequate cushioning without compression issues that affect heavier items.

E-commerce businesses prioritizing sustainable packaging and brand experience benefit from the environmental messaging and visual impact that supports premium positioning.

Seasonal and Themed Applications:

• Holiday gift baskets coordinated with seasonal colors

• Wedding favors and special occasion packaging

• Product launches where memorable unboxing drives social sharing

• Subscription box services building brand loyalty through presentation

Applications to Avoid

Heavy items exceeding 15 pounds that could compress the filler require more robust cushioning materials to prevent product damage during shipping.

Highly fragile electronics where paper particles could cause issues need clean, static-free environments that paper filler cannot provide.

Moisture-sensitive products requiring barrier protection must use plastic or specialized protective materials instead of paper-based options.

Additional Situations to Avoid:

• Industrial shipping where protection outweighs presentation

• Products with sharp edges that could damage paper filler

• High-volume operations where shipping weight significantly impacts profitability

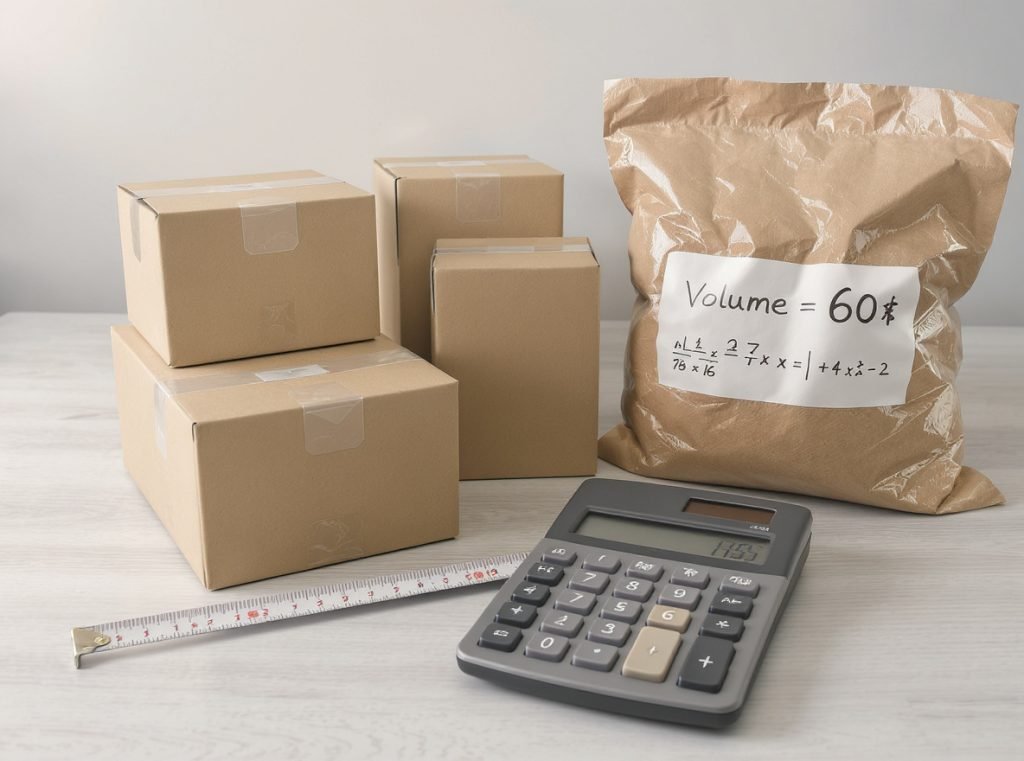

How Much Crinkle-Cut Paper Do You Need?

Calculating the appropriate quantity prevents over-ordering while ensuring adequate protection for your products during transit.

Industry guidelines suggest using the box volume formula: Length × Width × Height ÷ 40,000 = kg of crinkle paper needed. Alternatively, 1 lb of crinkle paper covers approximately 500 cubic inches, with optimal fill density at 3/4 capacity for balanced protection and cost efficiency.

Standard Calculation Methods

Box Volume Formula: Length × Width × Height (in cm³), Paper Requirement: Volume ÷ 40,000 = kg of crinkle paper needed

Alternative Method: 1 lb of crinkle paper covers approximately 500 cubic inches

Practical Usage Examples

10 lb box typically fills 15-20 medium gift baskets, providing businesses with clear quantity planning guidelines.

Small gift boxes (6×4×3 inches): Approximately 120 boxes per 10 lb carton, Medium boxes (12×10×4 inches): Approximately 12 boxes per 10 lb carton

Optimization Guidelines

| Box Size Category | Paper Amount Needed | Cost per Box | Optimal Applications |

|---|---|---|---|

| Small (under 100 cubic inches) | 1-2 oz | $0.15-0.30 | Jewelry, cosmetics, small accessories |

| Medium (100-500 cubic inches) | 3-4 oz | $0.45-0.60 | Books, gift sets, clothing items |

| Large (over 500 cubic inches) | 6-8 oz | $0.90-1.20 | Multiple items, large gifts, bulk products |

Fill boxes to approximately 3/4 capacity for optimal protection without over-packing. Account for product displacement when calculating filler needs, as items will compress the paper and reduce required volume.

What Are the Best Practices for Using Crinkle-Cut Paper?

Implementing proper techniques maximizes protection while maintaining the aesthetic benefits that make crinkle-cut paper attractive for premium packaging applications.

Layer crinkle-cut paper strategically with bottom cushioning, side support, and top protection. Avoid overpacking which increases costs and reduces spring action. Combine with complementary materials for enhanced protection and maintain proper storage conditions to preserve paper quality and performance.

Strategic Application Techniques

Layer strategically around products to prevent shifting during transit, starting with a foundation layer that prevents downward movement during transport.

Create cushioning nests for irregularly shaped products by molding the paper around contours before placing items. This technique provides custom-fit protection without requiring expensive molded inserts.

Combine with other materials for enhanced protection of fragile items, using bubble wrap for corners and crinkle paper for general cushioning and presentation.

Storage and Handling Best Practices

Use appropriate containers like snap boxes or corsage cases for organized storage to maintain paper quality and facilitate efficient packaging operations.

Implement portion control systems to prevent waste and ensure consistent usage across different packaging staff and shift changes.

Quality Control Measures:

• Monitor consistent texture and color batch-to-batch

• Maintain dry storage conditions to prevent degradation

• Track usage rates to optimize ordering quantities

• Test packing methods with drop tests before full implementation

Professional Presentation Tips

Select consistent texture materials for professional appearance and avoid mixing different paper grades or textures within the same package.

Choose appropriate colors that align with brand identity and seasonal themes to maximize the marketing impact of your packaging investment.

How Can Custom Packaging Enhance Your Crinkle-Cut Paper Strategy?

Integrating crinkle-cut paper with thoughtfully designed custom packaging creates synergistic effects that amplify both protection and brand impact.

Custom packaging maximizes crinkle-cut paper effectiveness through coordinated branding, enhanced customer experiences, seasonal adaptability, and cost-effective brand messaging. Professional packaging design optimizes box dimensions and features to work efficiently with paper filler while supporting sustainability messaging and marketing goals.

Brand Integration and Coordination

Custom packaging elements can significantly amplify crinkle-cut paper’s impact. Coordinating paper colors with branded boxes, tissue paper, and packaging tape creates a cohesive visual experience that reinforces brand identity.

This coordination approach allows businesses to create premium presentation experiences without custom printing every packaging component, making professional presentation accessible to smaller businesses.

Enhanced Customer Experience Strategy

Custom packaging transforms standard shipping into memorable unboxing experiences. When crinkle-cut paper colors complement custom printed boxes or branded inserts, it elevates perceived product value and encourages social media sharing.

The combination of thoughtful box design with attractive filler creates Instagram-worthy moments that customers want to share, providing free marketing exposure and building brand recognition.

Seasonal and Promotional Applications

Custom packaging allows for easy adaptation to seasonal themes or special promotions. Businesses can coordinate crinkle-cut paper colors with limited-edition packaging designs, holiday themes, or special events to create compelling marketing moments.

• Valentine’s Day: Red and pink paper with heart-themed custom boxes

• Halloween: Orange and black combinations with seasonal graphics

• Christmas: Traditional red and green or elegant gold and silver themes

• Brand anniversaries: Custom colors matching special edition branding

Cost-Effective Professional Branding

Unlike expensive custom printing on every component, coordinating crinkle-cut paper colors with existing branded elements provides cost-effective visual impact. This approach allows smaller businesses to achieve professional presentation without significant packaging investment.

Strategic use of colored paper filler can make standard brown shipping boxes appear custom-designed when combined with branded tape, stickers, or inserts.

Sustainable Brand Messaging Integration

Combining eco-friendly crinkle-cut paper with sustainable custom packaging reinforces environmental commitment. This alignment between packaging materials and brand values resonates with environmentally conscious consumers and supports broader sustainability marketing efforts.

Businesses can highlight their environmental responsibility by prominently featuring the recyclable nature of both custom packaging materials and paper filler, creating compelling sustainability stories.

Summary

Crinkle-cut paper provides an excellent balance of sustainability, presentation, and functionality for businesses prioritizing customer experience and environmental responsibility. It excels for light products under 15 pounds, gift packaging, and subscription boxes where aesthetic appeal matters. However, the material’s weight impact on shipping costs, storage space requirements, and limited protection for heavy items require careful consideration. Success depends on matching the material’s strengths to appropriate applications while understanding cost implications and performance limitations.

Ready to create packaging solutions that maximize crinkle-cut paper’s benefits while addressing its limitations? Contact Acreet today for custom packaging designs that work seamlessly with your chosen filler materials. Our experienced team can help you develop integrated packaging systems that protect products, enhance brand presentation, and optimize costs for your specific business requirements.