You’ve probably handled countless gusseted pouches without realizing it – from your morning coffee bag to pet food packaging. These expandable pouches seem to hold way more than flat bags, but what’s the secret behind their space-saving magic?

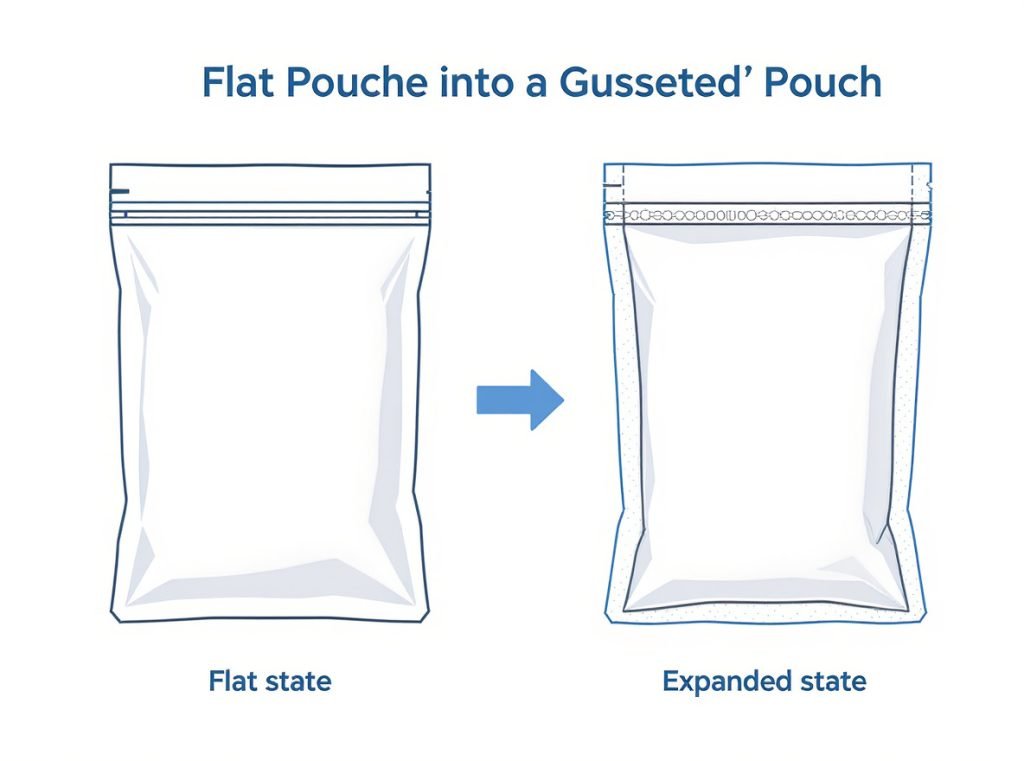

A gusset is an expandable fold or pleat of additional material strategically placed on flexible packaging to increase storage capacity and structural strength. This extra material transforms flat bags into three-dimensional packages, allowing them to accommodate more product while maintaining stability and creating superior shelf presentation.

Understanding how gussets work can revolutionize your packaging choices and dramatically impact your product’s market success.

Table of Contents

ToggleWhat Exactly is a Gusset in Packaging Terms?

The term “gusset” originally comes from medieval armor, where it protected knights’ underarms during battle – and today it serves a similarly protective function in packaging.

A gusset serves as a depth-creating panel that allows pouches to expand from their flat state when filled with product. The key principle is straightforward: more gusset equals more depth and volume, transforming two-dimensional bags into three-dimensional packages.

This additional material is engineered to fold flat during storage and transportation but opens up to create volume when needed. When products are placed inside, the gusseted areas unfold and expand, allowing the pouch to accommodate irregularly shaped items, bulk products, or simply more volume than traditional flat bags.

The fundamental engineering behind gussets involves creating strategic weak points that fold in controlled ways. During manufacturing, precise pleats are created along predetermined lines that remain compressed when empty but gradually unfold as the package fills with product.

Primary Functions of Gussets

Modern gussets serve multiple critical functions:

- Volume expansion: Dramatically increases storage capacity without enlarging the package footprint

- Structural integrity: Provides stability and prevents bursting under pressure

- Weight distribution: Spreads product weight evenly across the package structure

- Shelf stability: Enables packages to stand upright independently

How Do Side Gussets Work in Practice?

Side gussets are positioned along the vertical edges of pouches, creating expandable sides that form a tubular or box-like shape when filled.

Side gussets work by allowing the pouch to expand outward from its center, distributing the weight of contents evenly across the structure. These designs are particularly effective for heavy products weighing 5-10 pounds or more, creating packages that can stand upright even when the product settles.

The mechanics involve a single seal that runs the entire width and continues through the bottom, making this design especially suitable for accommodating large volumes of heavy products. When filled, the gussets create a stable base while maintaining an attractive retail presentation.

Coffee Industry Leadership

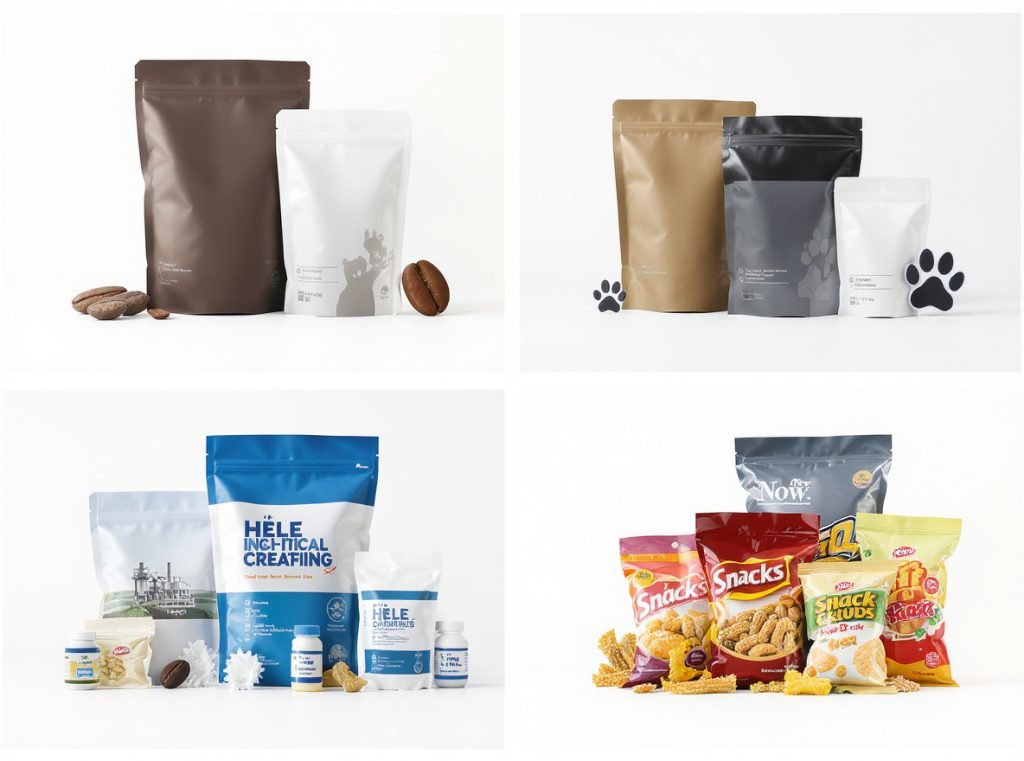

The coffee industry represents the largest adopter of side gusseted packaging, with this format being the recognized standard globally. Coffee pouches demonstrate the perfect application – the filled pouch can stand upright even when beans settle, creating optimal retail display while maintaining product freshness.

Key advantages of side gussets include:

- Superior strength for heavy products due to continuous sealing

- Cost-effectiveness – typically 10-20% less expensive than bottom gusset alternatives

- Storage efficiency – better space utilization in refrigerators and tight spaces

- Versatility across multiple product categories from coffee to pet food

| Product Category | Typical Weight Range | Primary Benefits |

|---|---|---|

| Coffee beans | 6 oz – 25 lbs | Freshness preservation, standing stability |

| Pet food | 5 – 25 lbs | Durability, puncture resistance |

| Industrial powders | 10 – 50+ lbs | Strength, bulk accommodation |

What Makes Bottom Gussets Different and Special?

Bottom gussets create a flat, stable base that allows pouches to stand upright independently, even when empty, unlike side gussets that require product weight for stability.

Bottom gusseted pouches (also known as stand-up pouches) have their expandable area at the base, creating a foundation that supports the package’s weight. This design provides superior shelf stability and maximum branding opportunities with large, flat surface areas.

There are three distinct types of bottom gussets, each engineered for specific weight ranges:

Round Bottom Gussets (Doyen Gussets)

These are optimal for lightweight products under 2 pounds. The rounded bottom creates sturdy shelf presentation by keeping products elevated off surfaces, making them ideal for premium products requiring protection from ground contact.

K-Seal Gussets

Designed for midweight products, K-seal gussets also maintain elevation from shelf surfaces while providing enhanced stability compared to round bottom designs. They’re suitable for products requiring moderate structural support.

Plow Bottom Gussets (W-Fold)

Featuring no bottom seal, plow bottom gussets allow the shelf surface to support most of the product weight. This makes them ideal for products weighing 2 pounds and above, where the packaging structure alone cannot bear the full load.

The choice between these types depends primarily on product weight and display requirements, with heavier products benefiting from designs that transfer weight to the supporting surface.

Which Industries Benefit Most from Gusseted Pouches?

Multiple industries have embraced gusseted packaging, each leveraging different advantages of this versatile format.

The pet food industry extensively utilizes gusseted pouches for their durability and capacity to handle sharp-edged items like kibble. The packaging typically ranges from small treat sizes to 25-pound bulk bags, with side gusseted bags commonly used for weights exceeding 10 pounds.

Food and Beverage Applications

Beyond coffee, the food packaging sector benefits from gusseted solutions across numerous categories:

Bulk products like breakfast cereals, grains, powders, and spices require large volume accommodation while maintaining freshness. Gussets provide the necessary capacity without compromising barrier properties.

Frozen foods benefit from the durability and long-term storage capabilities of gusseted pouches, while snack foods leverage the attractive shelf presentation for consumer appeal.

Heavy products such as flour, sugar, and rice utilize the superior strength characteristics of side gusseted designs.

Industrial and Specialty Applications

Industrial applications leverage gusseted pouches for hardware items, powdered chemicals, and agricultural products due to their puncture resistance and sealing strength. The global gusseted bags market, valued at $4.4 billion in 2024 with projected growth through 2034, demonstrates increasing adoption across industries.

Chemical packaging requires robust barrier properties and puncture resistance that gusseted designs provide effectively.

Agricultural products benefit from the bulk capacity and weather resistance of industrial-grade gusseted pouches.

Hardware and fasteners utilize gusseted bags for their ability to accommodate irregular shapes while preventing punctures from sharp edges.

How to Choose Between Side and Bottom Gussets?

The decision between side and bottom gussets depends on product weight, volume requirements, display preferences, and cost considerations.

Choose side gussets when product weight exceeds 5-10 pounds, storage efficiency is critical, cost is a primary concern, or products are irregularly shaped. Choose bottom gussets when shelf presentation and aesthetics are priorities, products are lightweight, maximum branding surface area is needed, or independent standing capability is essential.

Decision Matrix for Gusset Selection

Product Weight Considerations:

- Under 2 pounds: Round bottom gussets optimal

- 2-10 pounds: K-seal or plow bottom gussets recommended

- Over 10 pounds: Side gussets provide superior strength

Display and Marketing Factors:

- Premium positioning: Bottom gussets offer superior shelf appeal

- Cost-sensitive markets: Side gussets provide 10-20% cost savings

- High-traffic retail: Bottom gussets create better product visibility

Storage and Logistics:

- Limited retail space: Side gussets require less refrigerator/storage space

- Warehouse efficiency: Both types offer good stacking capabilities

- Transportation costs: Similar efficiency for both designs

Application-Specific Recommendations

Coffee and beverage products typically benefit from side gussets due to weight considerations and industry standards. Pet food manufacturers often choose side gussets for products over 5 pounds due to strength requirements and cost efficiency.

Snack foods and premium consumer products frequently utilize bottom gussets for enhanced shelf presence and branding opportunities. Industrial applications usually favor side gussets for their superior strength characteristics.

What Are the Technical Specifications You Should Know?

Understanding technical specifications ensures optimal performance and cost-effectiveness in your gusseted pouch applications.

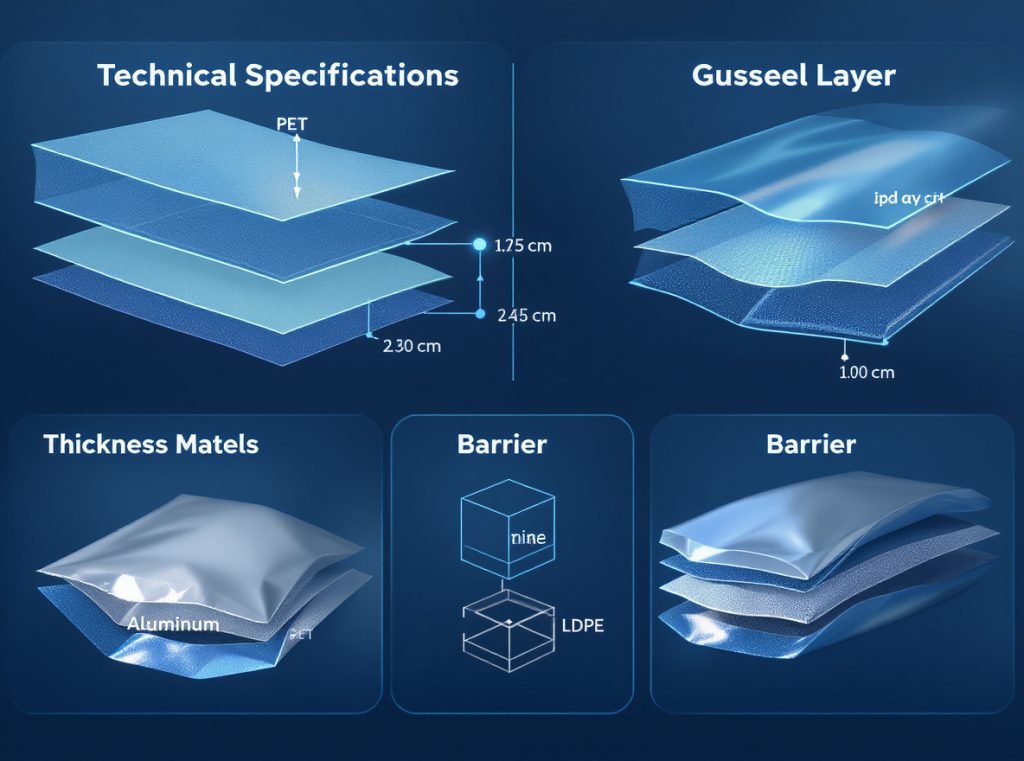

Standard gusseted pouches utilize multi-layer barrier films with typical constructions including PET (polyethylene terephthalate), aluminum, and LDPE (low-density polyethylene) layers. Coffee applications commonly use 5-mil structures providing excellent oxygen and moisture barriers.

Material Construction Standards

Thickness Specifications:

- Light-duty applications: 2-3 mils

- Standard commercial use: 4-5 mils

- Heavy-duty industrial: 6-7.5 mils

- Specialized applications: Up to 10+ mils

Temperature Performance:

- Standard range: -20°C to +60°C

- Premium constructions: -40°C to +80°C

- Specialized applications: Extended ranges available

Barrier Properties:

- Water vapor transmission: ≤0.05 to 0.1 g/m²/day for high-barrier applications

- Oxygen transmission: Variable based on product sensitivity

- Puncture resistance: ~68N for premium materials

Size Parameters and Customization

Size capabilities range from small consumer portions to industrial bulk applications:

- Coffee pouches: 6 ounces to 25 pounds capacity

- Pet food applications: 1 pound to 50+ pounds

- Industrial applications: Up to 51″ x 49″ x 73″ for bulk packaging

- Custom sizing: Virtually unlimited within manufacturing constraints

Feature Integration Options

Modern gusseted pouches can incorporate multiple functional features:

- Degassing valves for coffee and similar products requiring CO2 release

- Resealable zippers for consumer convenience and product preservation

- Clear windows for product visibility and consumer appeal

- Tear notches for easy opening without tools

- Hang holes for retail display flexibility

How Do Gussets Impact Your Product’s Market Success?

Gusseted packaging significantly influences consumer purchasing behavior and market performance through enhanced visual appeal and functional benefits.

Research shows that 72% of American consumers are influenced by packaging design in their purchase decisions. Gusseted pouches create superior product visibility and can stand upright, maximizing shelf appeal compared to flat packages, with plastic gusseted bags holding a 57.4% market share demonstrating their consumer acceptance.

Consumer Psychology and Market Impact

Shelf Presence Enhancement:

Gusseted pouches create three-dimensional product visibility that attracts consumer attention more effectively than flat alternatives. The ability to stand upright maximizes shelf appeal and creates premium product perception.

Storage Efficiency Benefits:

Products in gusseted pouches occupy less space in both retail and home environments, making them preferred by retailers and consumers. This space efficiency allows retailers to stock more SKUs in the same footprint while consumers appreciate compact storage.

Brand Differentiation Opportunities:

The large surface area provided by gusseted designs offers extensive branding opportunities, allowing companies to create distinctive shelf presence and communicate product attributes effectively.

Quantifiable Market Advantages

Gusseted packaging delivers measurable business benefits:

- Increased shelf presence compared to flat pouches

- Higher consumer appeal due to three-dimensional structure

- Better space utilization in retail and consumer environments

- Enhanced perceived value through premium packaging appearance

Consumer convenience factors include lightweight, portable nature that appeals to on-the-go consumers, while features like resealable closures enhance user experience and product preservation.

What Should You Consider for Custom Gusseted Pouch Design?

Successful custom gusseted pouch design requires balancing technical requirements, market positioning, cost objectives, and manufacturing constraints.

Barrier requirements represent the primary technical consideration, with options ranging from basic moisture protection to high-oxygen barriers for sensitive products. Production volume significantly impacts cost-effectiveness and customization options, with minimum order quantities typically starting at 10,000 pieces for custom printing.

Technical Design Considerations

Barrier Requirements Analysis:

Your product’s sensitivity to oxygen, moisture, light, and other environmental factors determines the required barrier properties. Coffee applications typically require 5-mil multi-layer constructions with aluminum barriers, while less sensitive products may use simpler structures.

Structural Engineering:

The gusset design must accommodate your product’s physical characteristics including weight, density, shape, and flow properties. Sharp or abrasive products require enhanced puncture resistance, while fine powders need superior seal integrity.

Manufacturing and Economic Factors

Production Volume Impact:

Minimum order quantities vary by manufacturer and customization level. Higher volumes justify more complex features and specialized tooling, while smaller runs may require design compromises.

Feature Integration Strategy:

Align features with product requirements and market positioning:

- Premium products benefit from degassing valves, clear windows, and sophisticated graphics

- Cost-sensitive applications focus on basic functionality and simplified designs

- Industrial products prioritize durability and handling features

Market Positioning Elements

Aesthetic Considerations:

Choose finish options (matte vs. gloss), color schemes, and printing capabilities that align with your brand positioning. Registered-matte finishes can make logos and branding elements stand out prominently on shelves.

Sustainability Requirements:

Eco-friendly options using recyclable materials are increasingly available to meet consumer environmental expectations while maintaining performance standards.

Consumer Experience Design:

Consider how consumers will interact with your package throughout the entire usage cycle, from initial purchase through disposal, ensuring all touchpoints enhance brand perception.

At Acreet, we specialize in engineering custom gusseted pouches that optimize both product protection and market appeal. Our technical team can guide you through material selection, feature integration, and design optimization to create packaging solutions that enhance your product’s competitive position. Contact us to discuss how our expertise in gusseted pouch manufacturing can support your business objectives.

Summary

Gussets are expandable folds of additional material that transform flat pouches into three-dimensional packages capable of greater capacity and stability. Side gussets excel for heavy products and cost-sensitive applications, while bottom gussets provide superior shelf presentation and branding opportunities. The choice between types depends on product weight, display requirements, and cost considerations, with both formats offering significant advantages over traditional flat packaging.

Ready to explore how custom gusseted packaging can enhance your product’s market success? Contact Acreet today for expert consultation on optimized packaging solutions that drive both protection and sales performance.