If you’ve ever opened a jewelry box to find your precious silver pieces covered in dark, unsightly tarnish, you understand the frustration of metal deterioration. This common problem costs businesses thousands in damaged inventory and disappointed customers worldwide.

Anti-tarnish paper is sulfur-free paper with neutral pH that actively absorbs hydrogen sulfide, sulfur dioxide, and other corrosive gases to prevent metal tarnishing. It’s essential for protecting silver, gold, copper, brass, bronze, nickel, and tin objects during storage, display, and shipping.

Let’s explore everything you need to know about this specialized packaging solution and how it can protect your valuable metal products.

Table of Contents

ToggleHow Does Anti-Tarnish Paper Actually Work?

Understanding the science behind tarnishing helps explain why anti-tarnish paper is so effective for protecting your valuable metal products.

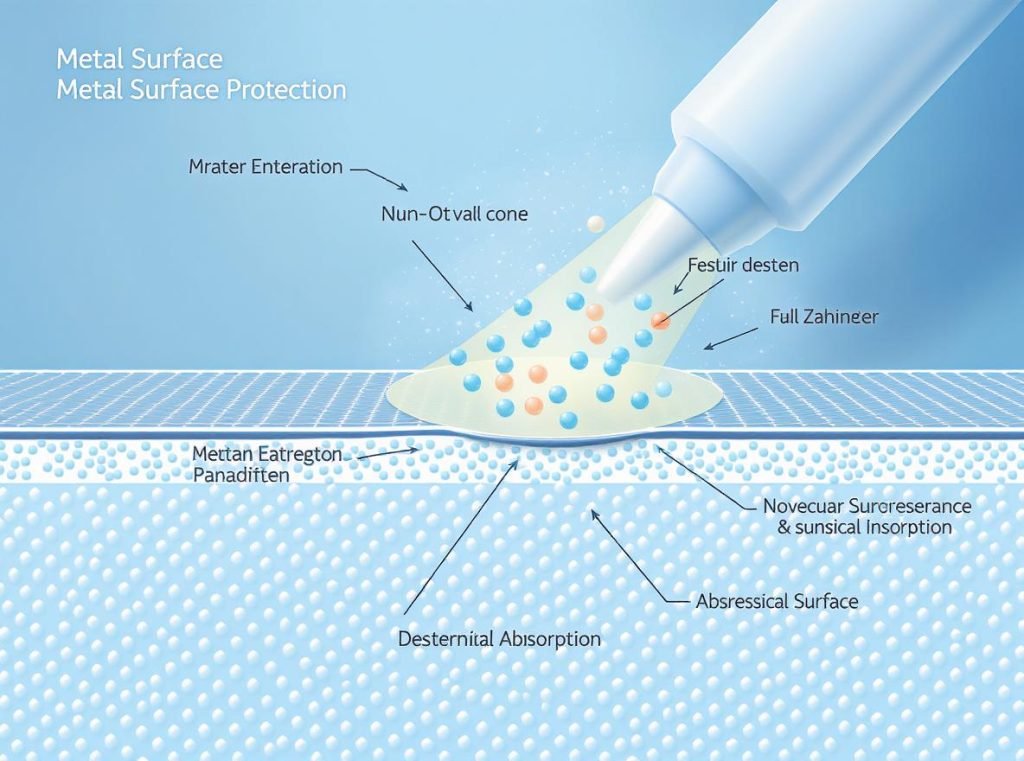

Anti-tarnish paper works through chemical absorption and neutralization of tarnish-causing gases. It contains compounds that actively absorb hydrogen sulfide (H2S), sulfur dioxide (SO2), chlorine, and other corrosive gases, then chemically neutralizes them to prevent metal oxidation.

The Science Behind Metal Tarnishing

Tarnishing occurs when metals react with sulfur compounds naturally present in the atmosphere. These harmful gases come from various sources:

- Environmental pollutants and industrial emissions

- Organic materials like fingerprints and skin oils

- Natural atmospheric compounds

- Off-gassing from packaging materials and storage environments

Silver, for example, combines with hydrogen sulfide to form silver sulfide, creating that familiar black coating that diminishes both appearance and value.

Advanced Protection Technology

Modern anti-tarnish papers use copper-based polymers that provide dual-action protection. Unlike traditional charcoal-based papers with limited effectiveness, these advanced materials both absorb and permanently neutralize harmful gases.

The paper creates a controlled micro-environment around stored items, maintaining optimal conditions and preventing the concentration of tarnish-causing agents from reaching damaging levels.

What Types of Products Need Anti-Tarnish Protection?

Anti-tarnish protection is essential across multiple industries for preserving valuable metal items and maintaining customer satisfaction.

Jewelry, musical instruments, electronics, silverware, collectible coins, and any products containing precious metals require anti-tarnish protection. This includes both finished goods and components used in manufacturing processes.

Jewelry and Precious Metals

The jewelry industry represents the primary market for anti-tarnish protection:

| Metal Type | Tarnishing Risk | Protection Priority |

|---|---|---|

| Sterling Silver | Very High | Critical – requires comprehensive protection |

| Gold/Gold-Plated | Medium | Important for maintaining appearance |

| Copper/Brass | High | Essential for long-term storage |

| Bronze/Nickel | High | Necessary for professional presentation |

Musical Instruments

Professional musicians and instrument manufacturers rely on anti-tarnish protection for:

- Silver flutes, piccolos, and wind instruments

- Brass instruments including trumpets, trombones, and French horns

- Copper and bronze musical components

- Valuable vintage and professional-grade instruments

Electronics and Industrial Applications

Electronic components containing precious metals suffer performance degradation from tarnishing:

- Printed circuit boards (PCBs) and electronic components

- Silver-plated electrical contacts and connectors

- Aerospace and automotive components requiring precision performance

- Static-sensitive electronics requiring specialized anti-static protection

Collectibles and Household Items

High-value items requiring long-term preservation include:

- Silver flatware and serving pieces

- Collectible coins and medallions

- Trophies, awards, and decorative items

- Antique silver pieces and family heirlooms

When Should You Use Anti-Tarnish Paper?

Timing is crucial when implementing anti-tarnish protection to maximize effectiveness and prevent irreversible damage.

Use anti-tarnish paper for any storage period longer than a few weeks, in high-humidity environments, for infrequently used items, and always for high-value or irreplaceable pieces. Prevention is significantly more cost-effective than restoration.

Critical Timing Factors

Storage Duration: Items stored for months or years require immediate protection. Even short-term storage of 3-4 weeks can benefit from anti-tarnish protection in challenging environments.

Environmental Conditions: Essential protection in:

- High humidity areas (above 50% relative humidity)

- Locations with air pollution or industrial emissions

- Coastal environments with salt air exposure

- Areas with sulfur compounds in the atmosphere

Usage Frequency Considerations

Items that are infrequently accessed need the most protection. Regular handling and cleaning can remove early tarnishing, but stored items develop permanent damage without proper protection.

Value-Based Protection Strategy

- High-value items: Always protect regardless of storage duration

- Irreplaceable pieces: Antiques and heirlooms require premium protection

- Commercial inventory: Essential for maintaining product quality and customer satisfaction

- Professional equipment: Musical instruments and precision tools need consistent protection

What Are the Different Types of Anti-Tarnish Products?

Various anti-tarnish solutions are available to meet different packaging needs, protection durations, and application requirements.

Anti-tarnish products include traditional absorption papers, advanced polymer-based solutions, strips and tabs, bags and pouches, and specialized formats. Each type offers different coverage areas, protection duration, and application methods.

Traditional Anti-Tarnish Papers

Silver Saver Paper: Industry standard using hydrogen sulfide absorption technology, available in various weights from lightweight tissue to heavy Bristol board.

Tissue Paper Types: Lightweight wrapping papers perfect for individual items and delicate surfaces.

Heavy-duty Papers: Bristol board weight for larger items requiring robust protection.

Advanced Polymer-Based Products

Intercept Technology: Revolutionary copper-based polymer strips and bags providing up to 30 years of protection through permanent neutralization of harmful gases.

Static Intercept: Specialized anti-static versions designed for electronics protection, combining tarnish prevention with static electricity control.

Format Variations and Applications

| Product Type | Coverage Area | Best Applications | Duration |

|---|---|---|---|

| 1″ x 1″ Tabs | 30 cubic inches | Small jewelry boxes, individual pieces | 6-12 months |

| 2″ x 7″ Strips | 100+ cubic inches | Larger packaging, multiple items | 6-12 months |

| Tissue Paper | Variable wrap | Individual wrapping, irregular shapes | 3-6 months |

| Polymer Bags | Pre-sized | Ready-to-use storage solutions | Up to 30 years |

Specialized Solutions

Charcoal-Based Papers: Older technology with limited effectiveness at normal atmospheric conditions, being phased out in favor of more advanced solutions.

Fabric Products: Anti-tarnish cloths and linings for jewelry boxes, combining protection with presentation.

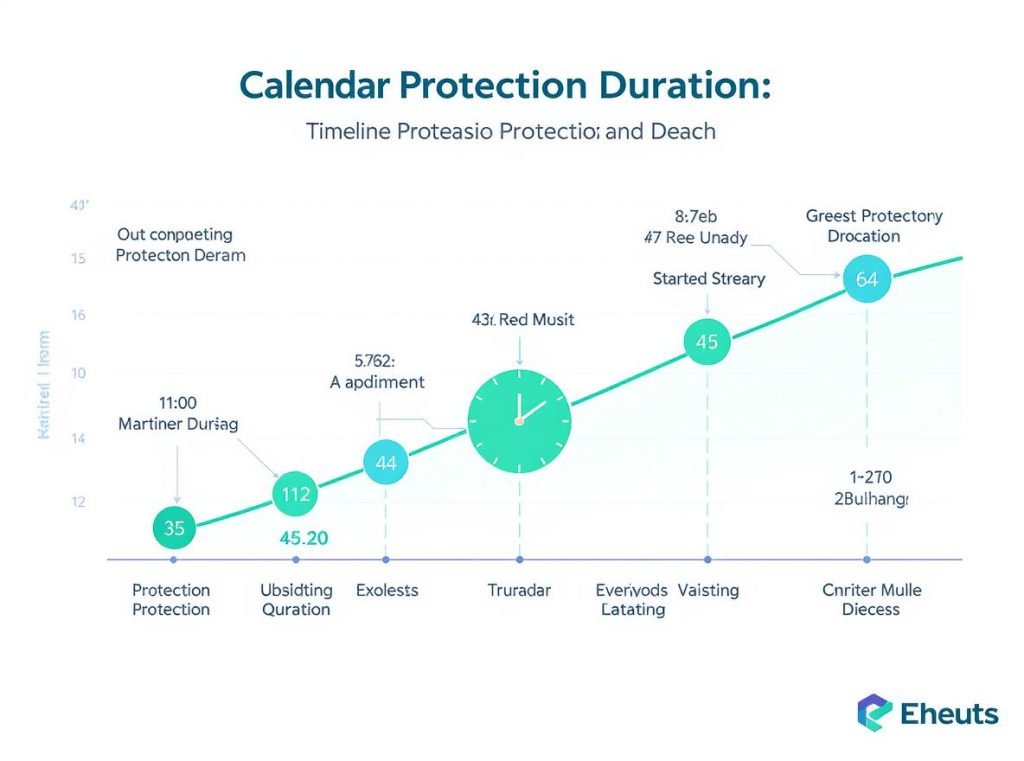

How Long Does Anti-Tarnish Protection Last?

Protection duration varies significantly based on product technology, environmental conditions, and storage methods.

Standard anti-tarnish papers provide 3-6 months of protection, while 3M Anti-Tarnish Strips offer 6-12 months. Advanced Intercept Technology products can provide up to 30 years of continuous protection under optimal conditions.

Protection Duration by Product Type

Standard Anti-Tarnish Papers:

- General paper products: 3-6 months in normal conditions

- Premium paper solutions: 6-8 months with proper storage

3M Anti-Tarnish Strips:

- Normal conditions: 6 months continuous protection

- Airtight containers: Up to 12 months extended protection

Advanced Polymer Products:

- Intercept Technology: 12 months to 30 years depending on application

- Premium polymer systems: 5+ years for specialized applications

Environmental Impact on Duration

Container Seal Quality: Airtight containers significantly extend protection duration by preventing fresh contaminated air from entering the storage space.

Environmental Factors: High humidity, temperature fluctuations, and air pollution substantially reduce effectiveness and require more frequent replacement.

Access Frequency: Regular opening of storage containers introduces fresh contaminated air, shortening protection life and requiring more frequent monitoring.

What Are the Benefits of Using Anti-Tarnish Paper?

Anti-tarnish paper offers significant advantages that translate directly into cost savings and improved customer satisfaction.

Benefits include maintaining original appearance, protecting investment value, eliminating regular polishing needs, providing non-toxic safety, and offering cost-effective protection compared to item replacement costs.

Preservation and Financial Benefits

Investment Protection: Maintains both monetary and sentimental value of precious items by preventing permanent tarnishing damage that reduces worth.

Maintenance Reduction: Eliminates the need for frequent cleaning and polishing, reducing labor costs and potential damage from repeated handling.

Extended Lifespan: Prevents corrosion damage that could make items unusable or require expensive professional restoration.

Safety and Environmental Advantages

Modern anti-tarnish products offer superior safety characteristics:

- Non-Toxic Formula: Safe for direct contact with skin and food items

- No Chemical Residue: Leaves no deposits or harmful substances on protected items

- Non-Abrasive Properties: Won’t scratch delicate surfaces during storage

- Environmentally Friendly: Advanced polymers break down into harmless compounds

Economic and Operational Benefits

Cost-Effective Protection: Relatively inexpensive investment compared to potential item replacement or restoration costs.

Reduced Customer Returns: Fewer complaints and returns due to tarnished products arriving in poor condition.

Enhanced Brand Reputation: Products consistently arrive in pristine condition, improving customer confidence and satisfaction.

How to Choose the Right Anti-Tarnish Solution?

Selecting the appropriate anti-tarnish protection requires careful assessment of your specific needs, environmental conditions, and budget constraints.

Consider item type, storage duration, environmental conditions, container size, and budget when choosing anti-tarnish solutions. Match protection technology and format to your specific application for optimal cost-effectiveness and performance.

Product Assessment Strategy

Metal Type Evaluation:

- Silver items require the highest level of protection

- Gold and gold-plated items need medium protection

- Copper, brass, and bronze require high protection for professional presentation

- Electronics need specialized anti-static formulations

Storage Duration Planning:

- Short-term storage (weeks): Basic paper protection adequate

- Medium-term storage (months): Standard strips or premium paper

- Long-term storage (years): Advanced polymer technology recommended

Environmental Considerations

Humidity Control: High-humidity environments require more robust protection and more frequent replacement schedules.

Air Quality Assessment: Polluted environments need stronger protection formulations with higher absorption capacity.

Temperature Stability: Some products perform better across varying temperature ranges and thermal cycling.

Implementation Strategy

Container Size Calculation: Measure storage space cubic inches to determine proper strip quantity and coverage requirements.

Format Selection:

- Strips and tabs: Ideal for existing packaging systems

- Wrapping papers: Best for individual item protection

- Bags and pouches: Convenient for ready-to-use applications

- Custom integration: Built-in protection for packaging design

Quality and Certification Factors

Technology Verification: Choose between traditional absorption and modern neutralization technologies based on protection requirements.

Brand Reputation: Select products from established manufacturers with proven track records and museum-quality certifications.

Testing and Validation: Look for products tested by reputable organizations and used by professional conservators.

Summary

Anti-tarnish paper provides essential protection through chemical absorption and neutralization of harmful gases that cause metal tarnishing. From traditional absorption papers to advanced polymer technologies offering decades of protection, choosing the right solution depends on your specific applications, environmental conditions, and protection requirements.

Ready to protect your valuable metal products with professional anti-tarnish packaging solutions? Contact Acreet today for custom packaging designs that integrate proven anti-tarnish protection, ensuring your products maintain their pristine appearance from manufacturing through customer delivery.