Are you struggling to find the perfect packaging solution that protects your products while keeping costs low? Many manufacturers face the challenge of balancing product protection, visual appeal, and budget constraints when selecting packaging methods. Flow-wrap packaging offers a versatile, cost-effective solution that addresses all these concerns while providing excellent product protection and professional presentation.

Flow-wrap, also known as horizontal form-fill-seal (HFFS), is a packaging process where products are placed on polypropylene or polyethylene film, moved horizontally through specialized machinery, and sealed at both ends plus longitudinally. This creates an airtight, continuous film tube around products that provides superior protection compared to overwrapping while using 20% less material. The global flow-wrap packaging market, valued at $22.0 billion in 2024, reflects its growing importance across industries.

Let’s dive deeper into how flow-wrap packaging can revolutionize your product presentation and protect your bottom line.

Table of Contents

ToggleHow Does Flow-Wrap Packaging Work?

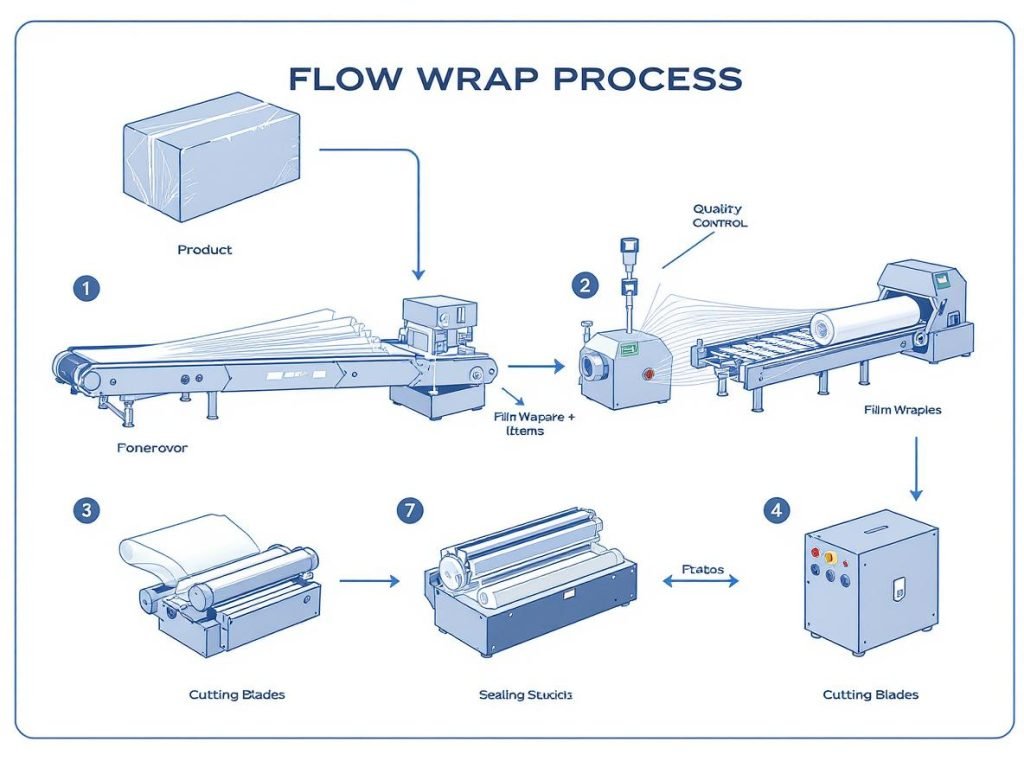

Understanding the sophisticated seven-step flow-wrap process helps you appreciate its efficiency and reliability for high-volume production.

Flow-wrap packaging operates through precise horizontal machinery that creates professional pillow-pack style packages at remarkable speeds.

The flow-wrapping process operates through a sophisticated sequence: product feeding onto conveyor belts, film formation around products creating tube shapes, edge alignment along the bottom, heat and pressure sealing at edges and ends, cutting individual packages, quality control inspection, and discharge of completed packages. Entry-level machines process 50-150 packages per minute, while high-end systems handle 300-1,500 packages per minute.

The technical precision of modern flow-wrap equipment ensures consistent, high-quality results across all production runs:

Product Feeding and Positioning: Infeed conveyor systems guide products into the forming area with precise timing and placement controls that accommodate various shapes and sizes.

Film Formation Process: Packaging film unwinds from rolls and forms around products, creating continuous tube shapes that conform to individual item dimensions while minimizing material waste.

Advanced Sealing Technology: Heat and pressure create three critical seals – the longitudinal fin seal along the package bottom and two end seals that provide complete airtight protection.

Quality Assurance Integration: Modern machines include integrated inspection systems that verify seal integrity, package dimensions, and overall quality before products exit the system.

| Process Stage | Technical Function | Speed Capability | Quality Benefit |

|---|---|---|---|

| Product Feed | Precise positioning control | Up to 1,500/min | Consistent placement |

| Film Formation | Automated tube creation | Continuous operation | Perfect conformity |

| Sealing System | Heat/pressure application | Microsecond timing | Airtight protection |

| Quality Check | Real-time inspection | 100% verification | Zero defects |

Speed and Automation Advantages: The continuous, automated process eliminates manual handling while maintaining exceptional quality standards that exceed traditional packaging methods.

What Products Commonly Use Flow-Wrap Packaging?

Flow-wrap packaging’s versatility makes it indispensable across numerous industries, from food production to medical devices and consumer goods.

The food industry represents the largest application area, accounting for the majority of flow-wrap usage worldwide due to its freshness preservation capabilities.

Flow-wrap packaging dominates food applications including bakery items like cookies, bread, and pastries, plus snack bars, chocolate bars, candy, fresh produce, frozen meats, biscuits, and confectionery products. The airtight sealing preserves freshness and extends shelf life significantly, making it ideal for perishable goods requiring contamination protection.

Beyond food applications, flow-wrap serves diverse industries with specialized requirements:

Medical and Pharmaceutical Applications:

• Surgical instruments requiring sterile packaging

• Syringes and medical devices needing tamper-evident protection

• Pharmaceutical products requiring moisture and contamination barriers

• Individual-dose medications for precise dispensing

Consumer and Industrial Products:

• Toiletries and personal care items

• Tissues and hygiene products

• Scratch cards and promotional materials

• Consumer goods requiring retail-ready presentation

Specialty Applications: From greeting cards to electronic components, flow-wrap accommodates irregularly shaped objects that traditional rigid packaging cannot handle efficiently.

The technology’s ability to package diverse product shapes and sizes without frequent machine adjustments makes it perfect for manufacturers with varied product lines or seasonal variations.

What Are the Key Benefits of Flow-Wrap Packaging?

Flow-wrap packaging delivers multiple strategic advantages that directly impact operational efficiency, cost control, and market success.

Cost efficiency and material optimization represent flow-wrap’s most compelling business advantages for manufacturers.

Flow-wrap provides superior cost efficiency through automated continuous processes that reduce labor costs while minimizing material waste through precise film usage – unlike overwrapping which uses approximately 20% more film. The hermetic sealing creates complete barriers against moisture, contaminants, oxygen, and tampering while significantly extending product shelf life.

Production and Operational Benefits:

• High-Speed Automation: Rapid packaging suitable for high-volume manufacturing with speeds reaching 1,500 packages per minute

• Versatile Product Accommodation: Handles wide ranges of shapes and sizes without frequent equipment adjustments

• Reduced Labor Requirements: Automated systems minimize manual handling while maintaining consistent quality

• Material Optimization: Precise film usage eliminates excess waste common in other packaging methods

Product Protection and Quality:

• Airtight Protection: Creates hermetic seals protecting against environmental factors that degrade product quality

• Tamper Evidence: Once sealed, any opening attempt becomes immediately apparent to consumers

• Extended Shelf Life: Superior barrier properties maintain freshness longer than alternative packaging methods

| Benefit Category | Specific Advantage | Quantifiable Impact | Business Result |

|---|---|---|---|

| Cost Control | 20% less material than overwrap | Lower per-unit costs | Improved margins |

| Production Speed | Up to 1,500 packages/minute | Higher output capacity | Increased revenue |

| Quality Protection | Airtight hermetic sealing | Extended shelf life | Reduced waste/returns |

| Labor Efficiency | Automated operation | Minimal manual handling | Lower operational costs |

Brand Enhancement Opportunities: Clear or printed films provide excellent product visibility while offering ample space for branding, logos, and product information that enhances shelf appeal and consumer recognition.

Sustainability Advantages: Precise material usage and recyclable film options support environmental responsibility goals while maintaining superior product protection.

How Does Flow-Wrap Compare to Other Packaging Methods?

Understanding flow-wrap’s advantages over alternative packaging methods helps you make informed decisions for specific applications and business requirements.

Flow-wrap offers distinct advantages over overwrapping, shrink wrap, and other packaging alternatives in multiple performance areas.

Flow-wrap provides superior sealing properties compared to overwrapping and offers better branding opportunities than shrink wrap, while maintaining faster automation capabilities than vacuum packaging. The complete barrier protection and material efficiency give flow-wrap clear competitive advantages for most applications.

Flow-Wrap vs. Overwrapping:

Flow-wrap creates airtight seals with complete barrier protection, while overwrapping is not completely airtight and uses 20% more material. Flow-wrap operates at higher speeds with better automation, while overwrapping is slower and less automated.

Flow-Wrap vs. Shrink Wrap:

Flow-wrap accommodates any solid shape or size, while shrink wrap works best for bulk or bundled items. Flow-wrap provides professional pillow-pack appearance, while shrink wrap creates tight-fitted looks around products.

Comprehensive Comparison Analysis:

| Performance Factor | Flow-Wrap | Overwrapping | Shrink Wrap | Vacuum Pack |

|---|---|---|---|---|

| Barrier Protection | Complete airtight seal | Partial protection | Moderate protection | Excellent protection |

| Material Efficiency | Optimal usage | 20% excess material | Moderate waste | Minimal waste |

| Production Speed | 300-1,500/min | Slower process | Moderate speed | Slower process |

| Product Versatility | Any shape/size | Flat-sided items only | Bulk items preferred | Limited shapes |

| Cost Effectiveness | Lowest operational cost | Higher material costs | Moderate costs | Higher equipment costs |

| Brand Presentation | Professional appearance | Gift-wrap aesthetic | Shrink-fitted look | Industrial appearance |

Application-Specific Advantages: Flow-wrap excels when you need individual product protection with high-speed production capabilities, making it ideal for food products, pharmaceuticals, and consumer goods requiring retail-ready presentation.

What Materials Work Best for Flow-Wrap Packaging?

Material selection significantly impacts packaging performance, product protection, and cost-effectiveness across different flow-wrap applications.

The choice of film material determines barrier properties, visual appeal, sealing effectiveness, and environmental impact of your packaging solution.

Polyethylene (PE) serves as the most widely used material, offering excellent flexibility, clarity, and sealing properties, with low-density polyethylene (LDPE) suiting lighter products like bread and vegetables, while high-density polyethylene (HDPE) works better for heavier items. Different PE formulations provide specific benefits for various application requirements.

Primary Material Categories:

Polypropylene Options:

• BOPP (Biaxially Oriented Polypropylene): Enhanced strength and glossy appearance, commonly used for confectionery and greeting cards

• Cast Polypropylene (CPP): Superior flexibility and sealing characteristics for diverse product shapes

• Standard PP Films: Excellent clarity, strength, and chemical resistance for general applications

Polyethylene Varieties:

• LDPE: Optimal for lighter products requiring softer, more conformable packaging

• HDPE: Better strength and barrier properties for heavier or sharper-edged items

• Linear Low-Density Polyethylene (LLDPE): Enhanced puncture resistance and optical clarity

Specialized Film Solutions:

• Composite Films: Multi-layer combinations offering enhanced properties like improved strength and barrier protection

• Metalized Films: High-end aesthetics with excellent barriers against water and oxygen

• Cold-Sealing Films: Protect heat-sensitive products like chocolates without thermal damage

| Material Type | Key Properties | Optimal Applications | Performance Benefits |

|---|---|---|---|

| PE (Various) | Flexibility, clarity, sealing | Food, consumer goods | Cost-effective, versatile |

| BOPP | Strength, gloss, clarity | Confectionery, cards | Premium appearance |

| Composite Films | Enhanced barriers | Sensitive products | Superior protection |

| Metalized Films | Barrier + aesthetics | Premium products | Luxury presentation |

Sustainable Material Trends: Biodegradable films, recyclable materials, and paper-based wraps with plastic coatings address growing environmental consciousness while maintaining product protection standards.

At Acreet, we work with leading film suppliers to match materials perfectly to your specific product requirements, protection needs, and brand standards.

When Should You Choose Flow-Wrap Packaging?

Determining whether flow-wrap fits your specific application requires evaluating product characteristics, production requirements, and business objectives.

Flow-wrap packaging represents the optimal choice for manufacturers requiring efficient, protective, and cost-effective packaging solutions.

Flow-wrap packaging works exceptionally well when you need high-volume production requiring rapid, consistent packaging of large quantities, products needing airtight seals and freshness preservation, versatile applications packaging diverse shapes and sizes, cost control minimizing material waste and labor costs, and quality assurance for industries with strict hygiene requirements. The technology excels in food, pharmaceutical, and medical device manufacturing where contamination protection is critical.

Ideal Flow-Wrap Applications:

• High-Volume Manufacturing: Production runs requiring speeds of 300-1,500 packages per minute with consistent quality

• Diverse Product Lines: Manufacturers handling various shapes and sizes without frequent equipment changes

• Freshness-Critical Products: Food items, pharmaceuticals, and perishables requiring extended shelf life

• Retail-Ready Packaging: Products needing attractive presentation with branding opportunities

• Cost-Sensitive Operations: Applications where material efficiency and labor reduction drive profitability

Quality and Compliance Considerations:

Flow-wrap provides essential benefits for industries requiring sterile packaging, tamper evidence, and regulatory compliance. The hermetic sealing meets stringent food safety standards while providing consumer confidence through visible tamper indication.

Production Flexibility Requirements:

The technology accommodates seasonal variations, product mix changes, and varying production volumes without significant retooling or setup time, making it ideal for dynamic manufacturing environments.

Consider alternatives when products require rigid protection, premium gift presentation, or complex multi-component packaging that flow-wrap cannot accommodate effectively. However, for most solid products requiring individual protection and retail presentation, flow-wrap offers superior benefits.

How Can Custom Flow-Wrap Packaging Boost Your Brand?

Custom flow-wrap packaging transforms basic product protection into powerful marketing tools that drive sales, build brand recognition, and create competitive advantages.

Professional packaging design creates immediate visual impact that influences purchasing decisions and builds long-term customer loyalty.

Custom flow-wrap packaging serves as a powerful marketing tool extending far beyond basic product protection through enhanced shelf appeal, brand recognition, marketing communication, memorable unboxing experiences, sustainability messaging, and market differentiation. Clear films showcase products effectively while custom printing enables eye-catching graphics, logos, and branding elements that stand out on retail shelves.

Strategic Branding Opportunities:

Visual Impact and Recognition:

• Enhanced Shelf Appeal: High-quality graphics and clear product visibility attract consumer attention in crowded retail environments

• Brand Consistency: Uniform packaging design across product lines creates instant brand recognition and builds consumer trust

• Premium Positioning: Professional packaging communicates quality and justifies premium pricing strategies

Marketing Communication Platform:

• Product Information: Packaging surfaces provide valuable space for nutritional details, usage instructions, and regulatory compliance data

• Promotional Messaging: Seasonal promotions, contests, and interactive elements like QR codes engage consumers beyond the initial purchase

• Sustainability Communication: Custom packaging allows brands to showcase environmental commitments and recycling information

Consumer Experience Enhancement:

• Unboxing Experience: High-quality custom packaging creates memorable moments that encourage social media sharing and word-of-mouth marketing

• Convenience Features: Easy-open designs and resealable options improve user experience and encourage repeat purchases

• Trust Building: Professional presentation builds consumer confidence in product quality and brand reliability

| Marketing Element | Brand Benefit | Consumer Impact | Business Result |

|---|---|---|---|

| Visual Design | Shelf differentiation | Increased attention | Higher sales conversion |

| Clear Information | Trust building | Confident purchasing | Reduced returns |

| Premium Appearance | Quality perception | Value justification | Improved margins |

| Sustainability Message | Brand values alignment | Loyalty building | Long-term relationships |

Market Growth and Positioning: The global flow-wrap packaging market’s growth to $22.0 billion in 2024 with 7.77% CAGR through 2030 reflects increasing recognition of packaging as a strategic business asset rather than merely functional necessity.

Competitive Differentiation: Unique packaging designs help products stand out in crowded marketplaces, potentially influencing purchasing decisions at critical point-of-sale moments when consumers make final buying choices.

Working with experienced packaging partners like Acreet ensures your custom flow-wrap designs maximize visual impact while maintaining production efficiency and cost-effectiveness that supports your business growth objectives.

Summary

Flow-wrap packaging represents the optimal solution for manufacturers seeking efficient, protective, and cost-effective packaging that enhances brand presence. This horizontal form-fill-seal technology delivers airtight protection, uses 20% less material than overwrapping, and operates at speeds up to 1,500 packages per minute across diverse applications from food products to medical devices. The combination of superior barrier properties, production efficiency, custom branding capabilities, and growing market demand makes flow-wrap an intelligent investment for companies prioritizing operational excellence and market competitiveness.

Ready to transform your product presentation while reducing packaging costs and improving efficiency? Contact Acreet today for expert consultation on custom flow-wrap solutions tailored to your specific requirements. Our experienced team will help you select optimal materials, design compelling custom graphics, and implement packaging strategies that protect your products while strengthening your brand presence in competitive global markets.