Are you confused about whether to use corrugated or regular cardboard for your packaging needs? You’re not alone. Many businesses struggle with this decision, unsure which material will best protect their products while staying cost-effective. Making the wrong choice could lead to damaged goods, frustrated customers, and lost profits.

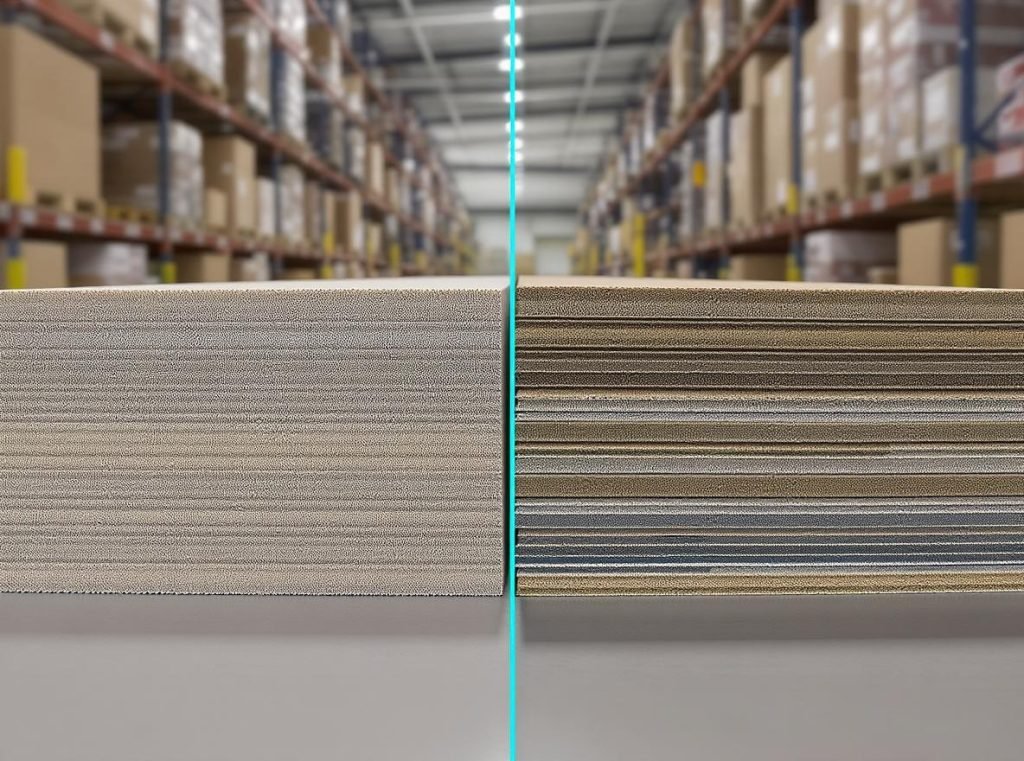

Corrugated cardboard consists of multiple layers with a fluted middle section between two flat liners, providing superior strength and durability. Regular cardboard is a single-layer thick paper material that’s lighter and less protective, making it suitable only for lightweight applications like cereal boxes or greeting cards.

Understanding these differences will help you make the right packaging choice for your business, ensuring your products arrive safely while optimizing your costs.

Table of Contents

ToggleWhat Are the Main Structural Differences Between Corrugated and Regular Cardboard?

Understanding the construction of these materials is crucial for making informed packaging decisions. The structural differences directly impact performance, cost, and application suitability.

Regular cardboard is a thick paper-based material made from a single layer of paper stock or heavy paper pulp. Corrugated cardboard features a complex three-layer construction with two flat outer linerboards and a wavy, fluted middle layer called the corrugated medium.

Regular cardboard is essentially thick paper that has been pressed and processed to create a rigid, flat sheet. The manufacturing process involves pressing paper pulp into flat sheets and drying them using standard papermaking techniques.

Corrugated cardboard requires a significantly more complex manufacturing process. It uses specialized machinery called corrugators, which employ heat, steam, and pressure to create the fluted medium and bond it to the linerboards with starch-based adhesive. This “sandwich” construction creates a material that is both lightweight and remarkably strong.

The fluted layer forms air pockets that provide cushioning and structural integrity. These air pockets act as natural shock absorbers while the multiple layers distribute weight effectively across the entire surface.

Key structural differences include:

- Layer construction: Corrugated has 3+ layers vs. regular cardboard’s single layer

- Fluted medium: Corrugated features wavy inner structure creating air pockets vs. cardboard’s flat design

- Manufacturing complexity: Corrugated requires specialized corrugator machinery vs. standard paper pressing

- Adhesive bonding: Corrugated uses starch-based adhesives to bond layers vs. cardboard’s single-piece construction

How Do Strength and Durability Compare Between These Materials?

Strength and durability are critical factors when choosing packaging materials. The wrong choice can result in product damage, customer complaints, and increased shipping costs.

Corrugated cardboard demonstrates superior strength across all metrics, withstanding 30-60% more top-load pressure and providing 2-3 times higher burst resistance than regular cardboard.

The strength difference is dramatic and measurable through industry-standard tests. The fluted structure creates vertical columns that distribute weight effectively, making corrugated ideal for stacking applications.

Compression Strength Performance:

Corrugated boxes can withstand significantly more top-load pressure than regular cardboard. The fluted structure creates natural reinforcement that prevents crushing under weight.

Impact and Burst Resistance:

The fluted medium acts as a shock absorber, providing substantially higher burst resistance. This makes corrugated essential for protecting fragile items during shipping and handling.

Edge Crush Test (ECT) Standards:

| ECT Rating | Weight Support | Typical Applications |

|---|---|---|

| 23 ECT | 23 lbs pressure | Light shipping boxes |

| 32 ECT | 32 lbs pressure | Standard shipping |

| 44 ECT | 44 lbs pressure | Heavy-duty applications |

Regular cardboard lacks standardized strength measurements due to its single-layer construction. It’s more vulnerable to tearing, puncturing, and crushing, making it unsuitable for protective packaging applications.

Moisture Resistance:

While both materials are susceptible to moisture, corrugated cardboard’s multi-layer structure provides better protection. The absolute humidity of corrugated cardboard should be maintained between 6-9% for optimal performance.

For businesses requiring reliable protection during shipping and storage, corrugated cardboard is the clear winner. Its superior durability justifies the higher cost through reduced damage rates and improved customer satisfaction.

What Are the Cost Differences and When Is Each More Economical?

Budget considerations play a major role in packaging decisions. Understanding the true cost implications helps businesses optimize their packaging investments while maintaining product protection.

Regular cardboard costs 20-40% less initially than corrugated material, but corrugated often provides better long-term value through reduced damage costs and reusability.

The upfront cost difference is significant and reflects the manufacturing complexity. Simple cardboard boxes can cost as little as $0.50 for small sizes, while corrugated boxes range from $0.60-$0.70 for extra-small sizes to $1.75-$2.00 for medium sizes.

Volume Pricing Benefits:

Both materials benefit from bulk discounts, but corrugated shows more dramatic savings. Medium-sized corrugated boxes can drop from $2.00 each to $1.50 each (25% savings) when ordered in quantities of 1,000 or more.

Total Cost Analysis:

- Regular Cardboard: Lower material costs but potential hidden expenses for additional protective materials

- Corrugated Cardboard: Higher material costs offset by reduced product damage and insurance claims

- Reusability Factor: Corrugated can often be reused multiple times, improving cost-effectiveness

Economic Considerations:

| Cost Factor | Regular Cardboard | Corrugated Cardboard |

|---|---|---|

| Initial Cost | $0.50-1.00 | $0.60-2.00 |

| Damage Rate | 5-15% | 1-3% |

| Reusability | Single use | Multiple uses |

| Additional Protection | Often required | Built-in protection |

For businesses shipping valuable or fragile items, corrugated cardboard’s damage prevention often outweighs its higher cost. A single prevented damage claim can justify the extra expense for hundreds of packages.

Choose regular cardboard when cost is the primary concern and protection isn’t critical. Opt for corrugated when product safety, professional appearance, and customer satisfaction are priorities.

Which Applications Are Best Suited for Each Type of Cardboard?

Matching the right material to your specific application ensures optimal performance and cost-effectiveness. Each type of cardboard excels in different scenarios based on protection requirements and usage conditions.

Regular cardboard excels in retail packaging and lightweight applications, while corrugated dominates shipping and protective packaging, with 95% of North American products shipping in corrugated containers.

Regular Cardboard Applications:

Regular cardboard serves consumer-facing applications where appearance and cost matter more than protection:

- Retail packaging (cereal boxes, cosmetic containers)

- Lightweight consumer goods packaging

- Food service containers and takeaway boxes

- Arts and crafts projects

- Greeting cards and stationery

- Display materials where printability is prioritized

Corrugated Cardboard Applications:

Corrugated cardboard dominates protective and shipping applications:

- E-commerce shipping boxes (industry standard)

- Heavy-duty packaging for electronics and appliances

- Automotive parts shipping

- Medical equipment transportation

- Fresh produce packaging

- Industrial storage and warehouse solutions

- Protective inserts and dividers

Industry-Specific Requirements:

Different industries have unique demands that influence material selection:

| Industry | Preferred Material | Key Requirements |

|---|---|---|

| E-commerce | Corrugated | Shipping protection, stacking strength |

| Food Service | Regular | Cost-effectiveness, food safety |

| Electronics | Corrugated | Static protection, impact resistance |

| Automotive | Corrugated | Heavy-duty strength, reusability |

| Retail Display | Regular | Print quality, visual appeal |

The choice depends on the product’s weight, fragility, and shipping requirements. Items requiring protection during long-distance transport or rough handling benefit from corrugated’s superior cushioning properties.

How Do Environmental Impact and Sustainability Compare?

Environmental considerations increasingly influence packaging decisions. Both materials offer sustainability benefits, but their environmental profiles show important differences that affect eco-conscious purchasing decisions.

Corrugated cardboard achieves a 97% recycling rate and produces 0.94 kg CO2e per kilogram, while regular cardboard has a higher carbon footprint at 1.53 kg CO2e per kilogram.

Corrugated Cardboard Environmental Profile:

Corrugated cardboard leads in sustainability metrics across multiple categories. The corrugated industry achieved a 50% reduction in greenhouse gas emissions between 2006 and 2020, demonstrating continuous improvement in environmental performance.

Recycling Performance:

- Recovery Rate: 97% of corrugated packaging is recovered for recycling

- Recycled Content: Contains 43% recycled content on average

- Forest Impact: Every ton of recycled corrugated saves approximately 17 trees

- Fiber Reuse: Can be recycled 5-7 times before fiber degradation

Regular Cardboard Environmental Profile:

Regular cardboard offers good recyclability but with some limitations:

- Energy Consumption: Paper production uses about 3 times more energy than plastic production

- Recyclability Challenges: Can be compromised by heavy inks, waxes, or plastic coatings

- Processing Requirements: Simpler structure allows easier recycling in some applications

Sustainability Comparison:

| Environmental Factor | Corrugated | Regular Cardboard |

|---|---|---|

| Carbon Footprint | 0.94 kg CO2e/kg | 1.53 kg CO2e/kg |

| Recycling Rate | 97% | 70-80% |

| Decomposition Time | 2 months | 2-4 months |

| Recycled Content | 43% average | Varies widely |

Biodegradability Benefits:

Both materials decompose in approximately 2 months under proper composting conditions, making them excellent alternatives to plastic packaging for environmentally conscious businesses.

For companies prioritizing sustainability, corrugated cardboard offers superior environmental performance while providing better product protection.

What Key Factors Should Guide Your Material Selection Decision?

Making the right choice requires evaluating multiple factors specific to your business needs. A systematic approach ensures optimal results that balance cost, protection, and performance requirements.

Consider product characteristics, shipping requirements, environmental conditions, and budget constraints when choosing between corrugated and regular cardboard for optimal packaging performance.

Product Characteristics Assessment:

Weight and Fragility:

Heavy items require corrugated’s superior strength and compression resistance. Delicate products benefit from corrugated’s cushioning properties and impact protection.

Value Considerations:

High-value items justify corrugated’s additional protection costs through reduced damage claims and customer satisfaction improvements.

Shipping and Handling Requirements:

Distance and Duration:

Long-distance shipping favors corrugated’s durability and structural integrity. Extended storage requires corrugated’s resistance to environmental factors.

Handling Environment:

Rough handling environments require corrugated’s impact resistance and puncture protection. Warehouse stacking demands corrugated’s compression strength.

Environmental Conditions:

- Temperature Variations: Corrugated handles temperature changes better than regular cardboard

- Humidity Control: Both materials are sensitive, but corrugated offers better moisture protection

- Storage Duration: Extended storage requires corrugated’s structural integrity

Budget and Volume Considerations:

Initial Cost vs. Total Cost:

Consider potential damage costs when evaluating material options. Volume discounts apply to both materials but show more dramatic savings with corrugated.

Reusability Factor:

Corrugated can often be reused multiple times, improving long-term cost-effectiveness for businesses with return logistics.

Decision Framework:

- Assess Protection Needs: Evaluate product fragility and value

- Review Shipping Stress: Consider distance, handling, and environmental conditions

- Calculate Total Costs: Include potential damage prevention savings

- Evaluate Volume Requirements: Determine bulk pricing advantages

- Consider Sustainability Goals: Both materials support environmental objectives

For businesses requiring expert guidance on material selection, consulting with packaging professionals ensures optimal decisions that balance all critical factors.

Summary

The choice between corrugated and regular cardboard depends on your specific packaging needs, protection requirements, and budget considerations. Corrugated cardboard offers superior strength, durability, and environmental performance, making it ideal for shipping and protective applications. Regular cardboard provides cost-effective solutions for lightweight retail packaging and display applications where protection isn’t critical.

Ready to optimize your packaging strategy with the right material choice? Contact Acreet today for expert guidance on custom packaging solutions that protect your products while enhancing your brand image. Our experienced team specializes in creating tailored corrugated and cardboard packaging designs that meet your specific requirements and budget. Send us an inquiry to discover how our custom packaging solutions can improve your shipping success and customer satisfaction.