Running a wholesale business means constantly seeking sustainable packaging solutions that don’t compromise on quality or cost-effectiveness. With environmental regulations tightening and consumer demand for eco-friendly products soaring, you’re probably wondering how recycled paper packaging actually gets made and whether it’s right for your business.

The recycled paper packaging process involves seven key stages: collection and sorting of waste paper into over 50 different grades, cleaning and screening through coarse and fine filtration systems, pulping at 160°F to create fiber suspension, de-inking and bleaching to achieve commercial brightness levels, paper formation using hydraulic headbox technology, drying through heated cylinders at up to 200°C, and comprehensive quality control testing. This sustainable manufacturing method transforms used paper products into high-quality packaging materials while reducing environmental impact.

Understanding this process will help you make informed decisions about sustainable packaging solutions that meet both performance requirements and environmental goals for your wholesale operations.

Table of Contents

ToggleHow Does the Collection and Sorting Stage Work?

The foundation of quality recycled paper packaging starts with a sophisticated collection and sorting system that determines the final product’s quality and performance characteristics.

The collection and sorting process involves gathering various paper types from residential homes, businesses, and recycling sites, then categorizing materials into over 50 different grades across four main groups: low grade, de-inking grade, kraft grade, and high grade materials. Advanced automated sorting systems using ballistic separators, optical scanners, magnetic systems, and eddy current separators ensure only suitable materials proceed to recycling.

Collection methods vary by region but typically include curbside recycling programs, drop-off centers, commercial collection from businesses, and specialized collection from supermarkets and office buildings. This multi-channel approach ensures consistent raw material supply for packaging manufacturers.

The four main material groups require different processing approaches:

- Low grade materials: Mixed paper and corrugated board requiring extensive cleaning

- De-inking grade: Newspapers, magazines, and office paper suitable for ink removal processes

- Kraft grade: Unbleached brown packaging materials with high strength properties

- High grade materials: Printer cut-offs and unprinted paper providing premium fiber quality

Quality control during sorting is critical for packaging performance. Paper must be clean and free from biological waste, liquid substances, wet or dirty paper, food residues, plastics, metals, and non-paper materials. Contamination at this stage significantly affects processing efficiency and final packaging quality.

| Sorting Technology | Function | Contamination Removed | Processing Efficiency |

|---|---|---|---|

| Ballistic Separators | Sort plastic, metal, card, paper | Mixed materials | 85-90% |

| Optical Scanners | Identify materials by color | Non-paper items | 90-95% |

| Magnetic Systems | Remove steel and tin | Ferrous metals | 99%+ |

| Eddy Current | Separate aluminum | Non-ferrous metals | 95-98% |

Modern facilities process thousands of tons daily, with automated systems achieving contamination removal rates exceeding 95%. This precision sorting ensures consistent raw material quality essential for reliable packaging production.

What Happens During the Cleaning and Screening Phase?

Once sorted materials enter the facility, they undergo intensive cleaning and screening through sophisticated equipment designed to remove impurities and prepare materials for optimal pulping conditions.

The cleaning and screening phase employs coarse and fine screening systems including up-flow pressure screens, fiber separators, high density cleaners, and low density cleaners to remove contaminants. Fine screening systems feature gap-adjustable rotors, multi-stage configurations, and slotted screen baskets that successfully separate impurities from good pulp while maintaining fiber integrity.

Coarse screening operations utilize specialized equipment designed for different contamination types. Up-flow pressure screens remove larger contaminants, while fiber separators distinguish between usable fibers and waste materials. High density cleaners eliminate heavy impurities through centrifugal force separation.

The selection of screening equipment depends on waste paper characteristics and performance requirements. Coarse screens operate at higher speeds to handle larger contaminant loads, while fine screens use lower operating speeds for precise separation.

Fine screening processes follow coarse screening operations, employing low density cleaners before materials enter fine sieves. These systems offer superior performance characteristics:

- Gap-adjustable rotors with optimized operating speeds for different paper grades

- Multi-stage systems achieving highest efficiency with lowest fiber losses

- Slotted screen baskets providing optimal impurity removal rates

- Efficient removal of both heavy and lightweight contaminants

Modern screening technology incorporates generously sized screens with optimized slot passing speeds, specially designed screen bars with optimized profiles, and chromium-plated baskets for high wear resistance. The screening process sets specific hole sizes and shapes based on differences between impurities and fibers, achieving separation efficiency rates exceeding 98%.

Advanced systems can process mixed paper grades simultaneously while maintaining separate quality streams for different packaging applications. This flexibility allows manufacturers to optimize raw material utilization while meeting diverse customer requirements.

How Does the Pulping Process Transform Paper Waste?

The pulping stage represents the heart of recycled paper manufacturing, where solid waste paper transforms into workable fiber suspension through carefully controlled mechanical and chemical processes.

Pulping combines cleaned paper waste with processed water in large stainless steel containers called pulpers operating at approximately 160°F. The mechanical pulping process breaks down paper into individual fibers through vigorous stirring while removing small pieces of plastic and metal, creating a homogeneous pulp suspension containing 1% fiber and 99% water.

Bales of recycled paper are fed into pulpers where they mix with processed water under controlled temperature and agitation conditions. The elevated temperature helps burn off greases and other contaminants while mechanical action separates individual fibers from the paper structure.

The pulping process varies depending on quality requirements and intended applications. Mechanical pulping provides cost-effective fiber separation for basic packaging applications, while chemical pulping methods utilize sodium hydroxide and sodium sulfide to dissolve lignin and achieve superior fiber separation.

Chemical pulping produces higher quality pulp suitable for fine paper products and premium packaging materials. The process requires careful chemical balance to maximize fiber recovery while maintaining strength properties essential for packaging performance.

Key pulping parameters affecting final packaging quality include:

- Temperature control: 160°F optimal for contaminant removal without fiber degradation

- Consistency management: Fiber-to-water ratio affecting processing efficiency

- Agitation intensity: Mechanical force levels balancing fiber separation and preservation

- Residence time: Duration in pulper optimizing fiber recovery rates

Quality control during pulping removes various impurities through screens and filters while maintaining fiber integrity. The resulting pulp suspension provides optimal conditions for subsequent processing stages, with fiber length distribution directly affecting packaging strength characteristics.

| Pulping Method | Temperature (°F) | Fiber Recovery (%) | Quality Grade | Typical Applications |

|---|---|---|---|---|

| Mechanical | 140-160 | 85-90 | Standard | Corrugated packaging |

| Thermomechanical | 160-180 | 88-92 | Enhanced | Folding cartons |

| Chemical | 180-200 | 92-96 | Premium | High-end packaging |

Modern pulping systems incorporate advanced screening technology to remove contaminants continuously, ensuring consistent pulp quality for downstream processing. This integration eliminates quality variations that could affect packaging performance in wholesale applications.

What Role Does De-inking and Bleaching Play?

Removing residual inks and achieving consistent brightness requires sophisticated de-inking and bleaching processes that preserve fiber strength while improving packaging aesthetics and performance.

De-inking utilizes flotation and washing methods to separate ink particles from pulp fibers, achieving brightness levels around 51.75% ISO, while controlled bleaching processes using hydrogen peroxide can increase brightness to 64.05% ISO under optimal conditions. These processes remove 85-95% of ink contamination while maintaining fiber integrity essential for packaging applications.

The de-inking process employs multiple sophisticated methods designed for different ink types and contamination levels. Flotation de-inking passes air through pulp creating foam that absorbs ink particles, which are then skimmed from the surface. This method effectively removes most printing inks while preserving fiber length and strength characteristics.

Washing processes use chemicals to separate ink from paper fibers, followed by water washing to remove dissolved ink. Advanced de-inking cells feature specialized machines with connected sections using air injection and suction forces to create bubbles that help remove unwanted particles.

The choice of de-inking method depends on several factors:

- Ink type and age: Fresh inks respond better to flotation, aged inks to washing

- Paper grade: Newspapers require different treatment than office papers

- Contamination level: Heavy ink loads need multi-stage processing

- End-use requirements: Packaging applications requiring specific brightness levels

Modern bleaching technology primarily uses hydrogen peroxide due to environmental advantages and effectiveness under alkaline conditions. Single-stage peroxide bleaching achieves brightness levels up to 64.05% ISO under optimal conditions including 2% hydrogen peroxide concentration, 80°C temperature, 20% consistency, and 60-minute treatment time.

Two-stage oxidative-reductive bleaching sequences can increase brightness by up to 9.7% ISO beyond single-stage treatment. Sodium dithionite treatment provides reductive bleaching for specialized applications requiring enhanced brightness or color correction.

The bleaching process optimization involves multiple critical parameters:

- Temperature control maintaining 80°C for optimal peroxide efficiency

- pH management ensuring alkaline conditions for hydrogen peroxide activation

- Consistency levels balancing chemical contact and fiber mobility

- Treatment time allowing complete chemical reaction without fiber degradation

Beyond brightness improvement, bleaching sterilizes pulp and eliminates taste and odor, making it suitable for food packaging applications where safety and hygiene are paramount considerations for wholesale distribution.

How Is New Packaging Paper Formed?

The paper formation stage transforms clean, de-inked pulp into continuous paper sheets through sophisticated papermaking technology requiring precise control of multiple variables to ensure consistent quality and performance.

Paper formation utilizes hydraulic headbox systems like the TurboJetter that distribute uniform fiber suspension onto forming wire sections. The process involves gravitational drainage, foil systems, and suction boxes that reduce water content from 99% to 75-80% while creating interlocked fiber networks with controlled basis weight, thickness, and strength properties.

The formation process begins at the headbox, which distributes a uniform jet of diluted fiber suspension onto the forming section. Modern hydraulic headboxes incorporate lamella technology creating perfect formation through dedicated turbulent shearing forces that ensure uniform fiber distribution across paper width and optimal fiber orientation for strength properties.

The headbox ensures several critical formation characteristics:

- Uniform fiber distribution preventing basis weight variations

- Optimal fiber orientation maximizing packaging strength properties

- Consistent cross-directional profiles eliminating weak spots

- Proper fiber deflocculation achieving superior sheet formation

The forming section consists of a continuously moving mesh belt extending 30-40 meters where multiple water removal mechanisms operate simultaneously. As the fiber suspension contacts the wire, progressive dewatering transforms the liquid into a formed paper web through gravitational drainage, foil systems that improve fiber uniformity, and suction boxes that vacuum out water.

Advanced forming systems create multi-layer packaging papers using specialized equipment like the TT TopFormer, providing uniform stock activity with symmetrical and progressive drainage. This technology optimizes paper formation while maintaining symmetry, enhances mechanical characteristics, increases basis weight range capabilities, and improves dimensional stability compared to simple dewatering methods.

| Formation Parameter | Single Layer | Multi-layer | Advanced Systems |

|---|---|---|---|

| Water Removal Rate | 75-80% | 80-85% | 85-90% |

| Formation Uniformity | Standard | Enhanced | Superior |

| Strength Properties | Good | Better | Optimal |

| Production Speed | 800 m/min | 1000 m/min | 1200+ m/min |

Quality control during formation monitors fiber length distribution, basis weight uniformity, and moisture content profiles. These parameters directly affect packaging strength, printability, and machine runnability in customer operations. Modern forming systems achieve coefficient of variation levels below 2% for basis weight, ensuring consistent packaging performance across entire production runs.

The transformation from liquid suspension to solid paper web occurs within the forming section length, with fiber bonding beginning immediately upon water removal. This process creates the foundational structure determining final packaging characteristics including tensile strength, burst resistance, and dimensional stability.

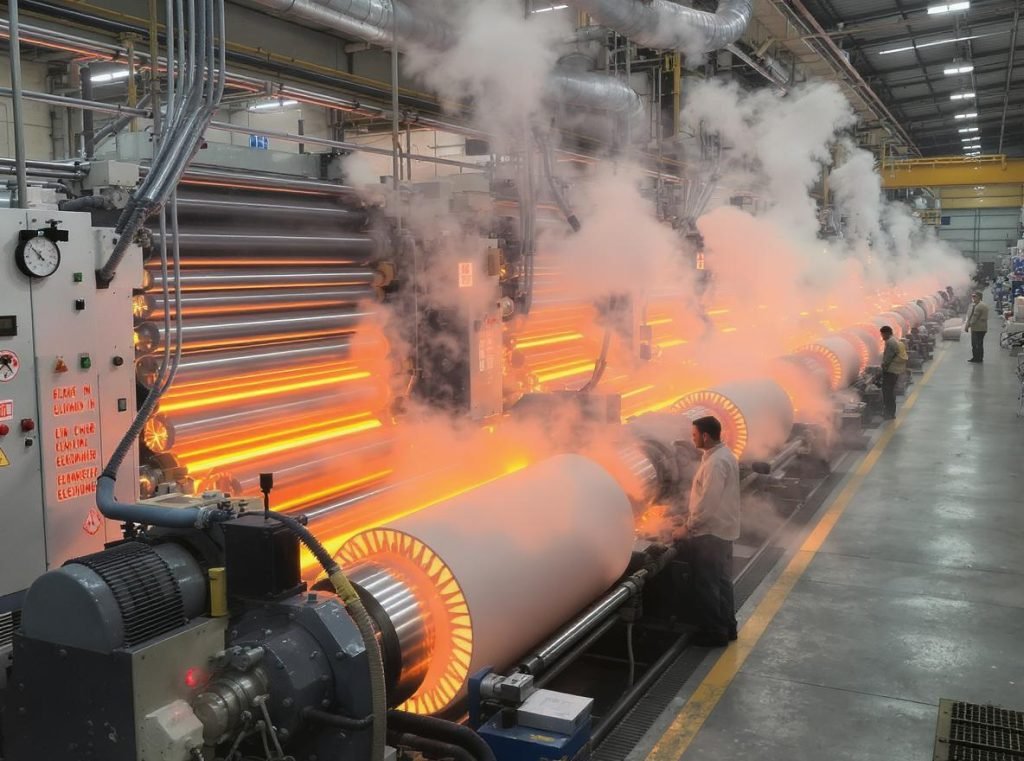

What Happens During Drying and Finishing?

The final manufacturing stages remove remaining moisture and apply surface treatments necessary for packaging performance, printability, and barrier properties required for wholesale applications.

Drying and finishing processes reduce paper moisture content from 75-80% to 6-8% through press section compression followed by thermal drying using heated cylinders reaching up to 200°C. Surface finishing includes calendering through heated steel rollers, coating applications for barrier properties, and surface enhancement treatments improving printability and functional performance.

The press section mechanically removes water before thermal drying, reducing moisture content from 75-80% to approximately 45-55% through compression between press rollers. This mechanical dewatering compresses fibers promoting inter-fiber bonding, creates dense sheet structure, and prepares the web for efficient thermal drying.

Thermal drying utilizes heated cylinders that can reach temperatures up to 200°C for conventional steam drying. Gas-fired dryers achieve even higher temperatures, providing drying rate improvements of 2-4% per high-temperature dryer installation. The thermal system maintains paper temperature around 70-90°C during processing, ensuring controlled moisture removal without thermal degradation.

Modern drying systems incorporate several advanced technologies:

- High-temperature gas-fired dryers for increased drying rates and energy efficiency

- Through-Air-Drying (TAD) systems for specific applications requiring higher bulk and absorbency

- Infrared drying elements providing supplemental heating for enhanced moisture removal

- Heat recovery systems capturing waste heat for improved energy utilization

Following drying, packaging paper undergoes finishing processes enhancing surface properties and functionality. Calendering passes paper through heated, highly polished steel rollers improving smoothness and gloss characteristics essential for high-quality printing applications.

Surface treatments applied during finishing include:

- Barrier coatings: Moisture resistance, grease resistance, and vapor barriers for food packaging

- Print enhancement coatings: Improved ink holdout and print quality for branded packaging

- Functional treatments: Antistatic properties, slip resistance, and handling characteristics

- Protective coatings: UV resistance, chemical resistance, and durability improvements

| Finishing Process | Temperature (°C) | Pressure (kN/m) | Surface Improvement | Application Benefits |

|---|---|---|---|---|

| Calendering | 150-200 | 200-400 | Smoothness, gloss | Print quality, appearance |

| Coating | 80-120 | 50-150 | Barrier properties | Food safety, protection |

| Surface Treatment | 60-100 | 100-200 | Functionality | Handling, performance |

Quality control during finishing monitors surface roughness, gloss levels, barrier performance, and printability characteristics. These measurements ensure packaging materials meet customer specifications for appearance, functionality, and performance in end-use applications.

The calendering process enhances surface characteristics through controlled pressure and heat application, resulting in improved printability and visual appeal essential for branded packaging applications in wholesale markets.

Are There Quality Control Standards for Recycled Packaging?

Quality assurance throughout recycled paper packaging production ensures consistent performance and reliability through comprehensive testing protocols that verify compliance with industry standards and customer specifications.

Recycled paper packaging follows international quality standards including ISO 536 for grammage measurement, ISO 534 for thickness testing, ASTM protocols for strength properties, and EN 13430 for packaging recyclability requirements. Quality control testing covers basis weight, moisture content, burst strength, tensile strength, and tear resistance using standardized methods ensuring packaging meets performance specifications.

Physical property testing verifies packaging performance characteristics through multiple standardized protocols. Key testing parameters include basis weight measured in grams per square meter determining strength and thickness characteristics, caliper measured in micrometers ensuring consistent packaging performance, and strength properties evaluating resistance to various stress conditions.

Standardized testing protocols ensure consistency and reliability across different manufacturing facilities and customer applications. International standards include ISO protocols widely used in European markets, ASTM testing methods standard in North American applications, and specialized packaging standards for specific industry requirements.

Testing frequency and documentation requirements vary by application:

- Basis weight testing: Continuous monitoring using online scanning systems

- Thickness measurement: Regular sampling every 30 minutes during production

- Strength testing: Comprehensive evaluation every 4 hours with full property analysis

- Contamination monitoring: Continuous visual and automated detection systems

For food contact applications, recycled packaging must meet additional safety requirements including Good Manufacturing Practices (GMP) guidelines ensuring product safety, traceability of raw materials, documentation of critical control points, and regular third-party certification assessments.

| Quality Parameter | Test Method | Specification Range | Testing Frequency | Industry Standard |

|---|---|---|---|---|

| Basis Weight | ISO 536 | ±3% target value | Continuous | Global |

| Thickness | ISO 534 | ±5% target value | Every 30 min | Global |

| Burst Strength | ASTM D774 | Min requirements | Every 4 hours | North America |

| Tensile Strength | ISO 1924 | Directional specs | Every 4 hours | Global |

| Tear Resistance | ISO 1974 | Minimum values | Daily | Global |

Modern quality control includes recyclability testing to meet circular economy requirements. Recyclability evaluation includes ease of fiber separation during repulping, proportion of material successfully reprocessed, visual quality of paper produced from recycled content, and overall recyclability scoring using standardized methods such as CEPI and PTS-RH protocols.

Continuous quality monitoring throughout manufacturing ensures consistent product quality through real-time measurement of paper properties, statistical process control identifying and correcting variations, regular calibration of testing equipment, and comprehensive documentation tracking all quality parameters.

The comprehensive quality framework ensures recycled paper packaging materials meet both regulatory requirements and customer expectations while supporting sustainable packaging solutions that contribute to circular economy goals and environmental responsibility in wholesale operations.

Summary

The recycled paper packaging manufacturing process transforms waste paper into high-quality packaging materials through seven sophisticated stages: collection and sorting into over 50 grades, cleaning and screening achieving 98% contamination removal, pulping at 160°F creating optimal fiber suspension, de-inking and bleaching reaching 64% ISO brightness, formation using advanced headbox technology, drying at up to 200°C with precision finishing, and comprehensive quality control meeting international standards.

Understanding this detailed process helps you make informed decisions about sustainable packaging solutions that deliver reliable performance while meeting environmental goals. Ready to explore custom recycled paper packaging options that meet your exact specifications? Contact Acreet today to discuss how our expertise in sustainable packaging manufacturing can support your wholesale operations with high-quality, eco-friendly packaging solutions tailored to your business needs.