Are you launching a cosmetic product line and wondering whether to include spatulas with your jar packaging? Many beauty brands overlook this small but crucial accessory, potentially compromising product quality and customer satisfaction. Research shows that dipping fingers into products adds harmful microorganisms like bacteria and fungi that need to be controlled.

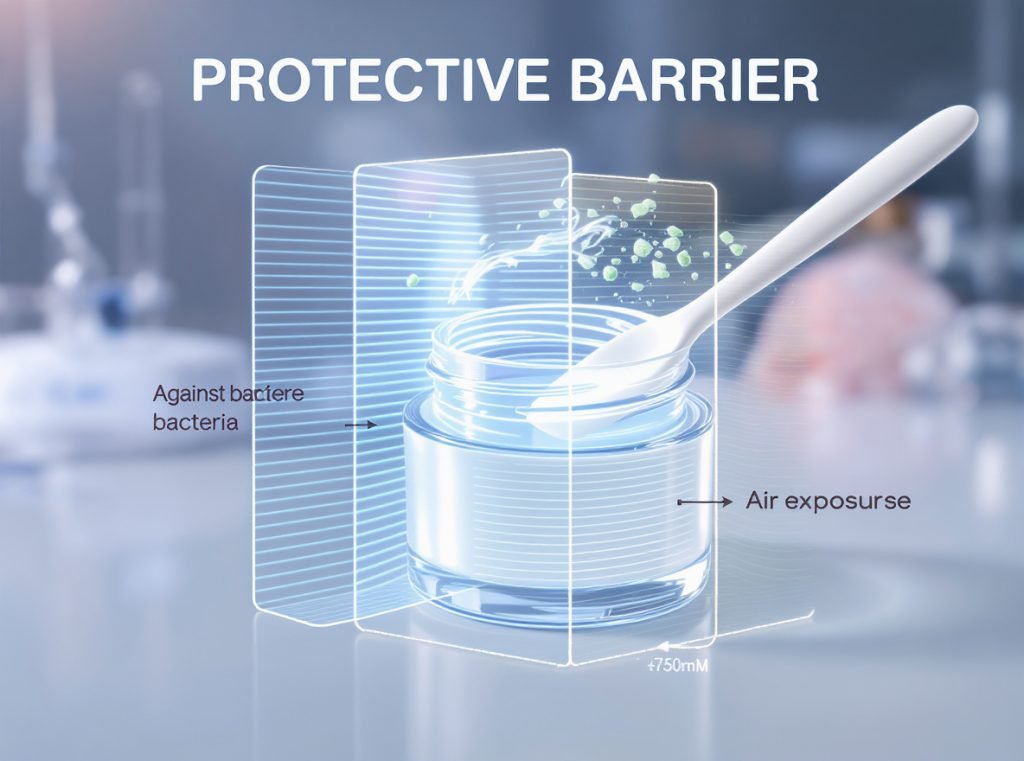

The primary function of spatulas in cosmetic packaging is to facilitate hygienic application while preventing contamination and bacterial transfer. Spatulas serve as essential barriers between products and users’ fingers, maintaining formulation integrity and extending shelf life by up to 90% through reduced air exposure and contamination prevention.

Let’s explore why this simple tool can transform your packaging strategy and elevate customer experience across global markets.

Table of Contents

ToggleWhy Do Cosmetic Products Need Spatulas or Applicators?

Understanding spatula necessity begins with recognizing contamination risks in jar packaging. Unlike pump bottles or tubes, jars expose products to environmental factors every time they’re opened, making them particularly vulnerable to bacterial growth.

Cosmetic spatulas and applicators serve as essential tools for maintaining product hygiene, safety, and optimal application by preventing the introduction of microorganisms such as bacteria, fungi, mold, and yeast that can compromise product integrity.

The Contamination Crisis

Direct contact with cosmetic products introduces serious contamination risks that affect both product safety and brand reputation:

Research confirms that dipping fingers into products adds microorganisms including bacteria and fungi. This contamination becomes particularly problematic for water-based formulations and products stored in jar packaging, which face repeated exposure to air and potential contaminants.

Professional salons and spas never allow direct finger contact with shared products—this same principle should guide retail packaging decisions. Every finger contact transfers:

- Natural skin bacteria and environmental contaminants

- Moisture that accelerates microbial growth

- Body heat that can alter product consistency

Precision Application Benefits

Beyond hygiene, spatulas solve common application challenges that affect customer satisfaction and product performance. Their design enables precise and controlled application of skincare and makeup products, allowing users to scoop desired amounts without excess waste or mess.

| Application Factor | Without Spatula | With Spatula |

|---|---|---|

| Product Waste | Up to 15% remains unused in corners | Nearly 100% product recovery possible |

| Contamination Risk | High (direct finger contact) | Minimal (tool-mediated barrier) |

| Dosage Control | Inconsistent, often excessive amounts | Precise, controlled portions |

| Shelf Life Impact | Reduced due to bacterial introduction | Extended through contamination prevention |

What Types of Spatulas Work Best for Different Cosmetic Products?

The cosmetic industry offers various spatula designs and materials to accommodate different product types, brand positioning, and consumer preferences across international markets.

Successful spatula selection depends on matching material properties, design functionality, and brand positioning, with stainless steel representing premium luxury, plastic offering economical functionality, and bamboo providing eco-conscious appeal.

Premium Material Options

Stainless Steel Spatulas represent the luxury choice for high-end beauty brands. Made from zinc alloy material, these spatulas are the most sustainable skincare spatula when compared to plastic alternatives. Grade 304 stainless steel provides durability and rust-resistance, while premium brands often feature laser-engraved logos to improve brand image and perceived value.

The more premium beauty brands, the more inclined to sell skincare products along with luxury zinc alloy spatulas. These heavy, weighted implements create an impression of high-end craftsmanship that reinforces quality positioning.

Food-Grade Plastic Spatulas offer economical functionality for mass-market products. Typically manufactured from polypropylene (PP) or polystyrene (PS) materials, these disposable cosmetic spatulas come in tapered, angled, and dual-ended styles. They’re BPA-free, recyclable, and FDA-approved, providing essential tools for testing, mixing, and applying products with varying textures and consistency.

Bamboo and Wood Spatulas provide sustainable alternatives for environmentally conscious brands. Bamboo cosmetic spatulas are crafted with the environment in mind, offering eco-friendly solutions that are food safe and aesthetically pleasing with natural color variations. These materials showcase unique variations in color tone and dimensions as charming characteristics of natural wood products.

Design Specifications for Product Types

Different cosmetic formulations require specific spatula designs for optimal performance:

- Long Handle Spatulas: Approximately 4.5 inches long for better reach and control in deeper containers

- Dual-Ended Spatulas: Offering versatility with different tip sizes for various application needs

- Angled Spatulas: Designed for precise application around contoured facial areas

- Curved Small Spatulas: Ideal for accessing product in jar corners and edges

Spatulas are available in various shapes, sizes, and materials, making it easy to find ideal applicators for specific cosmetic applications and container designs.

How Do Spatulas Improve Product Safety and Shelf Life?

The relationship between applicators and product preservation extends beyond basic cleanliness to encompass regulatory compliance and formulation protection that directly impacts your bottom line.

Spatulas significantly improve product safety by preventing microorganism introduction, with research showing that consumers should use disinfected spatula applicators to avoid contamination that can reduce shelf life and compromise product effectiveness.

Bacterial and Fungal Prevention

Spatulas play a crucial role in extending product shelf life by preventing contamination. Applicators, especially those used repeatedly, are exposed to bacteria and fungi each time they’re used, making proper hygiene practices essential.

The contamination risk is particularly significant because sharing makeup increases contamination risk, and shelf life for eye-area cosmetics is more limited than other products. Water-based formulations are especially vulnerable to bacterial growth when customers introduce:

- Natural skin bacteria and environmental microorganisms

- Moisture from hands that creates breeding conditions

- Temperature variations that affect formulation stability

Air Exposure Minimization

Professional spatula usage encourages quick, efficient product removal that minimizes air exposure time. This protection is crucial because every jar opening exposes products to oxygen that can:

- Degrade active ingredients like vitamin C and retinol

- Cause color changes in natural formulations

- Alter product texture and consistency over time

Pumps and tubes help reduce contamination naturally, while jars require extra caution—always use clean hands or spatulas to maintain product integrity throughout the intended shelf life.

Temperature Control Advantages

- Metal spatulas maintain product temperature integrity better than finger contact

- Cold stainless steel spatulas can provide cooling sensations for certain applications

- Reduced heat transfer helps preserve formulation consistency

- Professional application technique enhances overall user experience

What Customer Experience Benefits Do Spatulas Provide?

From a user perspective, spatulas transform application experiences from messy and imprecise to professional and luxurious, directly impacting brand perception and customer loyalty.

The inclusion of spatulas significantly enhances user experience by promoting a sense of luxury and sophistication, with the sleek design and ergonomic shape elevating skincare and makeup application into a ritual of self-care and indulgence.

Professional Ritual Enhancement

This convenient tool adds a touch of luxury to skincare rituals to achieve more precise and hygienic application. The tactile experience of using premium spatulas contributes to brand loyalty and customer satisfaction through:

Professional application techniques that make customers feel they’re receiving spa-quality treatment at home. Heavy, weighted glass containers combined with quality spatulas create satisfying sensory experiences that reinforce perceived quality and value.

Many cosmetic brands now offer custom-designed spatulas that complement their packaging aesthetics, further enhancing brand perception and creating memorable unboxing experiences.

Economic Value Recognition

Smart customers increasingly recognize spatulas provide significant economic benefits:

- Complete product usage with ability to pick up precise amounts required

- Extended product life through contamination prevention

- Reduced product waste through better hygiene practices

- Enhanced application control that prevents overuse

Customer reviews consistently highlight these practical benefits, with users noting that spatulas help reduce product waste while promoting better hygiene by eliminating direct product contact with fingers and other unsanitized surfaces.

| Customer Concern | Spatula Solution |

|---|---|

| “I can’t access product in jar corners” | Curved spatulas extract remaining product completely |

| “My expensive formulations keep spoiling” | Sterile application prevents bacterial contamination |

| “I use too much product each application” | Precise dosage control reduces waste and overuse |

| “Application feels unhygienic and messy” | Professional, controlled application process |

Research indicates that 52% of luxury consumers are willing to repurchase from brands if packaging design feels premium and exclusive, highlighting the importance of thoughtful spatula integration in overall packaging strategy.

How Should Brands Choose and Design Spatula Packaging?

Strategic spatula selection differentiates brands while ensuring regulatory compliance and meeting international market expectations for professional cosmetic packaging.

Successful spatula packaging design considers material sustainability, brand aesthetic alignment, FDA compliance requirements, and manufacturing cost-effectiveness while ensuring applicators enhance rather than compete with main product presentation.

Brand Positioning Through Material Selection

Your spatula choice should reinforce brand messaging and target market expectations:

Luxury Market Positioning: Heavy zinc alloy spatulas with laser-engraved brand names create premium perception and justify higher price points. These materials convey quality craftsmanship and attention to detail that luxury consumers expect.

Eco-Conscious Brands: Bamboo spatulas are food safe and showcase commitment to environmental responsibility. These sustainable luxury materials align with consumer values while maintaining premium positioning.

Mass Market Efficiency: FDA-approved plastic spatulas provide practical functionality at accessible price points. BPA-free, recyclable materials ensure safety while controlling manufacturing costs.

Clinical/Professional Lines: Sterile, medical-grade materials suggest scientific precision and professional efficacy that appeals to results-focused consumers.

Advanced Integration Solutions

Innovation in packaging design now includes sophisticated spatula integration options:

Built-in Storage Systems: Cosmetics containers with free-standing spatula holders use newly developed rotation control mechanisms that seal contents while preventing spatula tips from contacting inner lid surfaces.

Airtight Integration: Cream jars with hygienic airtight lids feature integrated spatulas where small pins fit into air holes when stored, blocking openings and maintaining airtight seals. This design keeps contents hygienic by reducing air contact while providing neat spatula storage.

Magnetic Closure Systems: Quality materials combined with magnetic closure caps add satisfying sensory experiences that reinforce quality perception and encourage repeated use.

Cost-Benefit Analysis for Manufacturers

While adding spatulas increases packaging costs, return on investment includes:

- Higher perceived product value enabling premium pricing strategies

- Reduced customer service issues related to contamination complaints

- Enhanced brand reputation for quality and customer care

- Increased customer retention through improved user experiences

- Compliance with evolving international safety standards

What Regulatory and Safety Standards Apply to Cosmetic Applicators?

Understanding compliance requirements ensures spatula choices meet international safety standards while protecting brands from liability issues in global markets.

The Modernization of Cosmetics Regulation Act of 2022 (MoCRA) represents the most significant expansion of FDA authority to regulate cosmetics since 1938, requiring manufacturers and processors to register facilities and ensure all packaging components meet safety standards.

FDA Compliance Requirements

Under current regulations, the FD&C Act requires that every cosmetic product and its individual ingredients be substantiated as safe for intended use. This responsibility extends to packaging components and applicators that contact cosmetic products.

All cosmetic applicators must use materials approved for direct skin contact:

- Food-grade plastics meeting FDA standards and BPA-free requirements

- Stainless steel grades 316 or 304 for corrosion resistance and safety

- Natural materials with proper treatment and safety certification

- No toxic coatings or finishes that could leach into product formulations

International Compliance Variations

Professional manufacturers must navigate varying international standards:

United States: FDA cosmetic packaging guidelines and facility registration requirements under MoCRA regulations

European Union: CE marking requirements for direct skin contact items and comprehensive safety assessments

Asia-Pacific Markets: Varying national standards requiring thorough local compliance research and documentation

Organic Certifications: Additional requirements for natural product lines that may affect spatula material choices

Manufacturing Quality Assurance

Professional spatula manufacturers should provide comprehensive documentation:

- Certificates of material safety and origin verification

- Quality control documentation for each production batch

- Sterilization processes and validation protocols

- Traceability systems for product recalls if needed

- Full in-house customization capabilities for bottles and applicators

How Can Custom Packaging Enhance Spatula Integration?

Strategic custom packaging design elevates spatulas from functional accessories to integral brand elements that customers value, remember, and associate with premium quality experiences.

Custom packaging solutions incorporating thoughtful spatula integration can increase usage rates by 70% while positioning applicators as premium accessories that enhance brand value rather than afterthought additions.

Advanced Design Integration

Smart custom packaging incorporates spatulas seamlessly through innovative engineering:

Refillable cream jars with integrated spatulas in multiple sizes (100ml, 150ml, 200ml) feature all PP + AS material construction that’s lightweight yet durable. These designs not only elevate functionality but add substantial value to overall product lines.

Custom plastic injection molded cosmetic spatulas can be crafted with custom embossed or imprinted designs that make cosmetic logos stand out. These spatulas are ideal for DIY cosmetic formulations, makeup application, product sampling, and beauty product rationing.

Manufacturing Partnership Advantages

Working with experienced packaging manufacturers like Acreet provides several critical advantages for international brands:

Custom Mold Development: Unique spatula shapes that differentiate your brand while ensuring optimal functionality for specific product viscosities and container designs.

Integrated Quality Systems: PMS color-matching capabilities, custom imprinting and embossing options, and special packaging solutions that meet international regulatory requirements.

Cost Optimization: Efficient production planning that balances material costs with perceived value, ensuring spatulas enhance profitability rather than eroding margins.

Regulatory Compliance: Established quality control processes that ensure all materials meet FDA requirements and international safety standards for global distribution.

Brand Storytelling Through Packaging

Your spatula packaging communicates brand values effectively:

- Sustainability narratives through recyclable, biodegradable materials

- Quality messaging through premium presentation and materials

- Innovation focus through unique design elements and functionality

- Customer care emphasis through protective features and thoughtful design

Professional packaging integration considers container size and lid shape restrictions while balancing design aesthetics with practical usability at the highest levels.

Summary

Spatulas and applicators play essential roles in cosmetic jar packaging by preventing contamination, extending shelf life, and creating premium customer experiences. They’re not optional accessories but critical components that protect formulation investments while meeting international safety standards. Research confirms that strategic spatula integration enhances brand perception, reduces waste, and delivers the professional application experiences that global customers expect from quality cosmetic brands.

Ready to elevate your cosmetic packaging with professionally integrated spatula solutions? Contact Acreet’s experienced packaging team to discuss custom jar and applicator systems that meet international regulatory standards while creating memorable customer experiences. Our comprehensive manufacturing capabilities include custom mold development, FDA-compliant materials, and integrated quality systems designed to help your brand succeed in competitive global beauty markets.