Partnering with a Chinese factory can be a game-changer for your business, but poor technical support can turn your manufacturing dreams into costly nightmares. You need reliable partners who understand your products, respond quickly to issues, and provide expert guidance throughout your project.

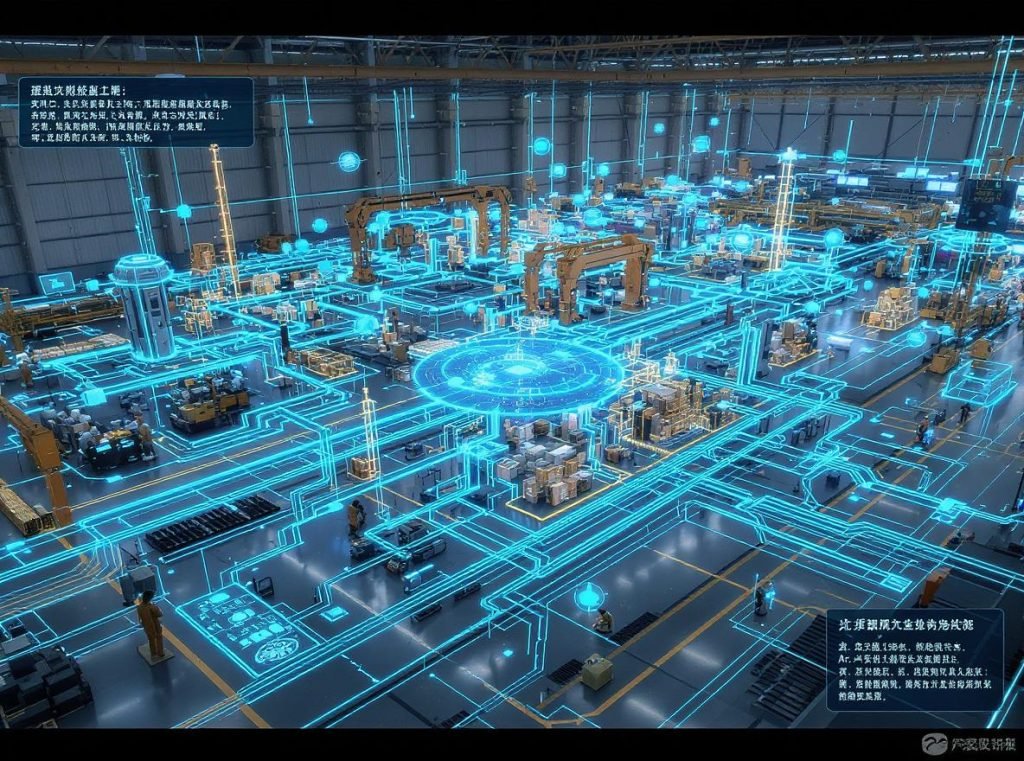

Top-tier Chinese factories provide comprehensive technical support including dedicated multilingual technical teams with over 21 years of experience, 24/7 customer service systems, real-time production monitoring with AI-powered quality control, Design for Manufacturing (DFM) consultation, systematic change management processes, and extensive post-delivery warranty services. Leading manufacturers implement smart factory technologies achieving 28.4% faster development cycles and 50.2% defect reduction.

Let’s dive deeper into what separates exceptional Chinese factories from mediocre ones when it comes to technical support.

Table of Contents

ToggleWhat Technical Team Qualifications Should You Demand?

The backbone of exceptional technical support lies in having qualified engineers who can bridge language barriers and provide expert guidance throughout your manufacturing journey.

Professional Chinese factories maintain dedicated technical support teams with bilingual capabilities in Chinese and English, featuring engineers with backgrounds in mechanical, electrical, and process engineering. Top-tier facilities employ product engineers with over 21 years of experience in product design, development, prototyping, and manufacturing, ensuring comprehensive technical assistance for international clients.

Modern Chinese manufacturers have evolved far beyond basic production facilities:

Multi-Level Support Structure:

Leading factories implement sophisticated technical hierarchies that include junior engineers for routine support, senior engineers for complex problem-solving, and specialist consultants for advanced technical challenges. This structure ensures you receive appropriate expertise for each situation.

Educational Requirements and Certifications:

Professional facilities require their technical staff to hold relevant engineering degrees and maintain current industry certifications. Many top-tier factories invest in continuous education programs, sending their engineers to international training sessions and technical conferences.

Language Proficiency Standards:

| Support Level | English Requirement | Technical Expertise | Typical Responsibilities |

|---|---|---|---|

| Junior Engineers | Conversational English | 2-5 years experience | Daily production support, basic troubleshooting |

| Senior Engineers | Professional English | 5-15 years experience | Complex problem solving, design optimization |

| Lead Engineers | Fluent English | 15+ years experience | Strategic planning, advanced technical consultation |

| Technical Directors | Native-level English | 20+ years experience | Partnership management, innovation leadership |

Quality factories understand that technical expertise without communication skills creates dangerous gaps in understanding. They invest heavily in English training and often employ technical translators to ensure complex concepts are communicated accurately.

How Should Pre-Production Technical Consultation Work?

The foundation of any successful manufacturing project lies in thorough pre-production planning. Exceptional Chinese factories don’t just take your order – they become strategic partners in optimizing your design for manufacturing success.

Premier Chinese factories provide comprehensive pre-production consultations including Design for Manufacturing (DFM) feedback, product development consultation covering materials selection and tooling requirements, feasibility analysis, engineering drawing development, prototype development with multiple iterations, and Route to Market Planning (RTMP) that outlines exact development steps, costs, timelines, and deliverables.

Professional pre-production support has become increasingly sophisticated:

Design for Manufacturing (DFM) Analysis:

Experienced factories conduct thorough DFM reviews that identify potential manufacturing challenges before production begins. They analyze your design for material efficiency, production complexity, assembly requirements, and quality control considerations.

Comprehensive Feasibility Studies:

Top-tier manufacturers don’t accept projects blindly. They perform detailed feasibility analysis examining technical requirements, production capacity, material availability, and timeline constraints to ensure successful project completion.

Advanced CAD Capabilities:

Professional factories utilize industry-standard software including SolidWorks, AutoCAD, and UG for design development and modification. Their engineering teams can optimize your designs, create detailed technical drawings, and develop comprehensive manufacturing specifications.

Route to Market Planning Excellence:

- Detailed project timeline with milestone markers and contingency planning

- Resource allocation analysis preventing production bottlenecks

- Risk assessment with mitigation strategies for potential challenges

- Quality checkpoint integration throughout the development process

- Comprehensive cost analysis with optimization recommendations

Prototype Development Process:

Smart manufacturers emphasize prototype development with multiple iterations to refine design and functionality. They understand that investing time in prototyping prevents costly mistakes during mass production.

What Communication Infrastructure Indicates Serious Operations?

Modern business operates across time zones, requiring communication systems that provide immediate access to technical expertise when issues arise.

Leading Chinese factories provide 24/7 technical query support through multiple communication channels including WeChat for instant messaging, email for formal documentation, video conferencing for complex explanations, and project management platforms for tracking technical issues. Professional manufacturers establish clear communication protocols with designated points of contact to maintain efficient information flow.

Communication infrastructure reveals a factory’s commitment to international partnerships:

Multi-Channel Communication Strategy:

Professional factories recognize that different situations require different communication approaches. Emergency technical issues need instant messaging, while complex design discussions require video conferencing with screen sharing capabilities.

Structured Response Systems:

Quality manufacturers implement formal response protocols ensuring urgent technical issues receive immediate attention while routine inquiries follow standard timelines. They use ticketing systems to track all technical queries and maintain resolution records.

Communication Platform Integration:

| Platform Type | Primary Use | Response Time Standard | Best Practices |

|---|---|---|---|

| Instant messaging, file sharing | Within 1 hour | Real-time production updates | |

| Formal documentation | Within 4 hours | Technical specifications, contracts | |

| Video Conferencing | Complex discussions | Scheduled meetings | Design reviews, problem solving |

| Project Portals | Progress tracking | Real-time updates | Milestone monitoring, documentation |

Language Bridge Solutions:

Top factories employ technical translators and bilingual project managers who ensure complex technical concepts are communicated accurately across language barriers. They understand that miscommunication in technical details can cause expensive production problems.

How Advanced Are Modern Quality Control Systems?

Quality control has evolved dramatically in Chinese manufacturing, with leading factories implementing AI-powered systems and smart manufacturing technologies that rival international standards.

Top-tier Chinese factories implement AI-powered inspection systems capable of detecting 99% of product defects with precision down to 0.1 millimeters, comprehensive quality management systems including pre-production, during-production, and pre-shipment inspections, statistical process control monitoring, and partnerships with independent third-party quality control organizations for unbiased verification.

The technological revolution in Chinese manufacturing has transformed quality control:

Artificial Intelligence Integration:

Modern Chinese facilities leverage AI-powered inspection systems that dramatically exceed human detection capabilities. These systems identify microscopic defects, measure dimensional accuracy, and maintain consistent quality standards throughout production runs.

Smart Factory Implementation:

China has established over 30,000 basic-level smart factories, with advanced facilities showing remarkable performance improvements including 28.4% reduction in product development cycles, 22.3% increase in production efficiency, 50.2% decrease in defect rates, and 20.4% reduction in carbon emissions.

Multi-Stage Quality Architecture:

- Pre-production inspections verify raw materials and production setup meet specifications

- During-production monitoring with real-time quality checks and immediate corrective action

- Statistical process control tracking quality metrics and trend analysis

- Pre-shipment inspections ensuring final products meet international quality standards

- Independent third-party verification providing unbiased quality confirmation

Manufacturing Execution Systems (MES):

Professional factories implement comprehensive MES platforms that integrate quality control with production management, providing real-time visibility into quality metrics and enabling immediate response to quality deviations.

What Production Monitoring Should Be Standard?

Transparency during production builds trust and prevents unpleasant surprises. Modern Chinese factories have embraced Industry 4.0 technologies to provide unprecedented visibility into production processes.

Leading factories provide comprehensive production monitoring including live production status updates, manufacturing dashboards displaying key performance indicators, remote monitoring systems enabling client tracking without physical presence, digital twin technology for virtual production simulation, and IoT sensors providing real-time production data with predictive maintenance capabilities.

Production monitoring technology has revolutionized international manufacturing relationships:

Real-Time Production Dashboards:

Modern factories provide sophisticated online portals displaying live production data, quality metrics, delivery schedules, and resource utilization. These systems eliminate guesswork about project status and enable proactive decision-making.

Internet of Things (IoT) Integration:

Advanced manufacturers deploy IoT sensors throughout their production lines, collecting data on machine performance, environmental conditions, production speeds, and quality parameters. This data feeds into analytics systems that predict potential issues before they impact production.

Digital Twin Technology:

Cutting-edge facilities use digital twin systems that create virtual replicas of production processes. These systems enable simulation of production changes, optimization of workflows, and prediction of potential bottlenecks.

Production Monitoring Features:

- Real-time machine status and performance indicators

- Automated alerts for quality deviations or production delays

- Photo documentation of critical production milestones

- Integration with inventory management systems

- Predictive maintenance scheduling to prevent equipment failures

- Environmental monitoring ensuring optimal production conditions

How Should Design Modifications Be Managed?

Changes happen in every project, but how your factory handles modifications through systematic Engineering Change Order (ECO) processes reveals their organizational maturity and technical sophistication.

Elite Chinese factories manage design modifications through formal Engineering Change Order (ECO) systems for tracking implementations, comprehensive impact assessment procedures evaluating effects on production, timeline, and costs, version control systems ensuring all stakeholders work with current specifications, customer approval workflows requiring formal sign-off, and rapid prototyping services for testing design changes before full production implementation.

Professional change management separates mature manufacturers from amateur operations:

Systematic Engineering Change Orders:

Professional factories implement formal ECO systems that document all proposed modifications, track approval processes, and maintain historical records of design evolution. These systems prevent the chaos that destroys project timelines and inflate costs.

Comprehensive Impact Assessment:

When design changes are requested, experienced factories immediately evaluate impacts on production processes, tooling requirements, material specifications, quality procedures, and delivery schedules. They provide detailed analysis including cost implications and timeline adjustments.

Advanced Design Capabilities:

Leading factories maintain sophisticated CAD capabilities using professional software like SolidWorks, AutoCAD, and UG. Their engineering teams can rapidly implement design modifications, update technical drawings, and coordinate tooling changes.

Change Management Process Flow:

| Stage | Activities | Timeframe | Deliverables |

|---|---|---|---|

| Request Review | Initial feasibility assessment | 24 hours | Preliminary impact analysis |

| Impact Analysis | Detailed cost and timeline evaluation | 48 hours | Comprehensive change proposal |

| Customer Approval | Formal approval process | Variable | Signed change authorization |

| Implementation | Design updates and tooling modifications | Project-specific | Updated specifications and samples |

Tooling and Fixture Management:

Professional manufacturers maintain detailed records of all tooling and fixtures, enabling rapid assessment of modification requirements. They coordinate tooling changes with production schedules to minimize disruption.

What Post-Delivery Support Should You Expect?

The relationship with your factory shouldn’t end when products ship. Modern Chinese manufacturers increasingly recognize the importance of comprehensive after-sales support for building long-term partnerships.

Premier Chinese factories offer extensive post-delivery support including product warranty coverage for manufacturing defects, technical troubleshooting assistance using video calling and AR technologies, spare parts supply and replacement component availability, remote technical assistance for problem diagnosis, installation manuals and technical documentation, and training materials for end-user teams.

Post-delivery support reveals whether you’re working with a strategic partner or just a supplier:

Comprehensive Warranty Programs:

Professional manufacturers stand behind their products with formal warranty coverage addressing manufacturing defects and quality issues. They maintain clear procedures for warranty claims and provide rapid resolution of covered problems.

Advanced Remote Support Technologies:

Modern factories leverage video calling and augmented reality (AR) technologies for remote problem diagnosis and technical assistance. These systems enable real-time collaboration between factory engineers and customer technical teams.

Documentation and Training Excellence:

Quality manufacturers provide comprehensive post-delivery documentation including installation manuals, operation instructions, maintenance schedules, and technical support hotlines staffed by qualified engineers.

Ongoing Partnership Services:

- Performance monitoring and feedback collection for continuous improvement

- Market trend analysis and product enhancement recommendations

- Capacity planning assistance for seasonal demand fluctuations

- New product development collaboration opportunities

- Cost optimization reviews for repeat orders and product evolution

Spare Parts and Component Support:

Professional factories maintain inventory systems for spare parts and replacement components, ensuring long-term product support and customer satisfaction throughout product lifecycles.

What Technology Infrastructure Separates Leaders from Followers?

The technology systems your factory uses reveal their commitment to modern manufacturing practices and their capability to support complex international partnerships.

Top-tier Chinese factories invest in comprehensive technology infrastructure including Enterprise Resource Planning (ERP) systems for integrated business management, Manufacturing Execution Systems (MES) for production floor control, Quality Management Systems compliant with ISO 9001 standards, secure network systems for protecting intellectual property, cloud-based collaboration platforms, and mobile communication systems enabling real-time updates.

Technology infrastructure assessment reveals operational sophistication:

Enterprise Integration Systems:

Professional factories implement comprehensive ERP systems that integrate all business functions including production planning, inventory management, quality control, and customer communication. These systems provide the data visibility needed for reliable project management.

Smart Manufacturing Technologies:

Leading Chinese manufacturers embrace Industry 4.0 technologies including IoT sensors, artificial intelligence, automated production systems, and digital twin technology. These systems enhance monitoring, control, and optimization capabilities.

Information Security Infrastructure:

Quality factories invest in secure network systems, intellectual property protection protocols, and data backup systems. They understand that protecting customer information is essential for international partnerships.

Technology Assessment Criteria:

| System Category | Professional Standard | Capability Indicators | Business Benefits |

|---|---|---|---|

| ERP Integration | Comprehensive business management | Real-time data visibility | Accurate planning and commitments |

| MES Implementation | Production floor control | Live production monitoring | Quality consistency and efficiency |

| Quality Management | ISO 9001 compliance | Statistical process control | Predictable quality outcomes |

| Communication Systems | Multi-platform integration | 24/7 accessibility | Seamless international collaboration |

How Can You Evaluate a Factory’s Technical Support Before Committing?

Smart buyers conduct comprehensive evaluations of technical support capabilities before placing orders. Here are the systematic approaches that reveal whether a factory can provide the support your business demands.

Evaluate Chinese factory technical support through structured factory audits covering technical team qualifications, comprehensive infrastructure evaluations including manufacturing equipment and IT systems, process maturity assessments examining Standard Operating Procedures and change management capabilities, communication responsiveness testing, reference verification from similar projects, and certification validation for industry compliance standards.

Due diligence prevents costly mistakes and builds confidence in manufacturing partnerships:

Technical Team Assessment Protocol:

Evaluate engineering qualifications, English proficiency levels, experience with similar products, and continuous education programs. Request to speak directly with engineers who would support your project to assess their technical competence and communication skills.

Infrastructure Evaluation Methodology:

Conduct virtual or physical factory tours examining manufacturing equipment sophistication, quality control testing capabilities, IT systems integration, and documentation systems effectiveness. Look for modern equipment, calibrated measurement tools, and organized production environments.

Process Maturity Indicators:

- Standard Operating Procedures documentation and implementation consistency

- Change management processes for handling engineering modifications systematically

- Problem-solving methodologies and root cause analysis capabilities

- Continuous improvement programs with performance tracking systems

- Management systems compliance with international standards

Warning Signs to Avoid:

Be cautious of factories exhibiting overworked staff with insufficient support systems, poor communication skills creating collaboration barriers, lack of formal procedures for technical issues, inadequate management systems, and resistance to factory audits or operational transparency.

Verification Methods:

Test communication responsiveness through technical inquiries, review client testimonials and case studies from similar projects, request technical documentation samples, verify certifications and industry compliance, and conduct reference checks with existing customers working on comparable projects.

Summary

Exceptional technical support from top-tier Chinese factories includes dedicated multilingual engineering teams with 21+ years of experience, 24/7 communication infrastructure, AI-powered quality control achieving 99% defect detection, comprehensive pre-production DFM consultation, systematic ECO change management, smart factory technologies delivering 28.4% faster development cycles, and extensive post-delivery warranty services with AR-enabled remote support.

Ready to experience world-class technical support for your packaging needs? Contact Acreet today to discuss how our comprehensive support system, qualified engineering team, and advanced manufacturing technologies can streamline your custom packaging projects and ensure your complete satisfaction from design to delivery.