When premium brands launch products worth hundreds or thousands of dollars, cheap packaging undermines perceived value instantly. Customers expect luxury goods to arrive in packaging that matches their investment, yet many companies struggle to find solutions that justify premium pricing.

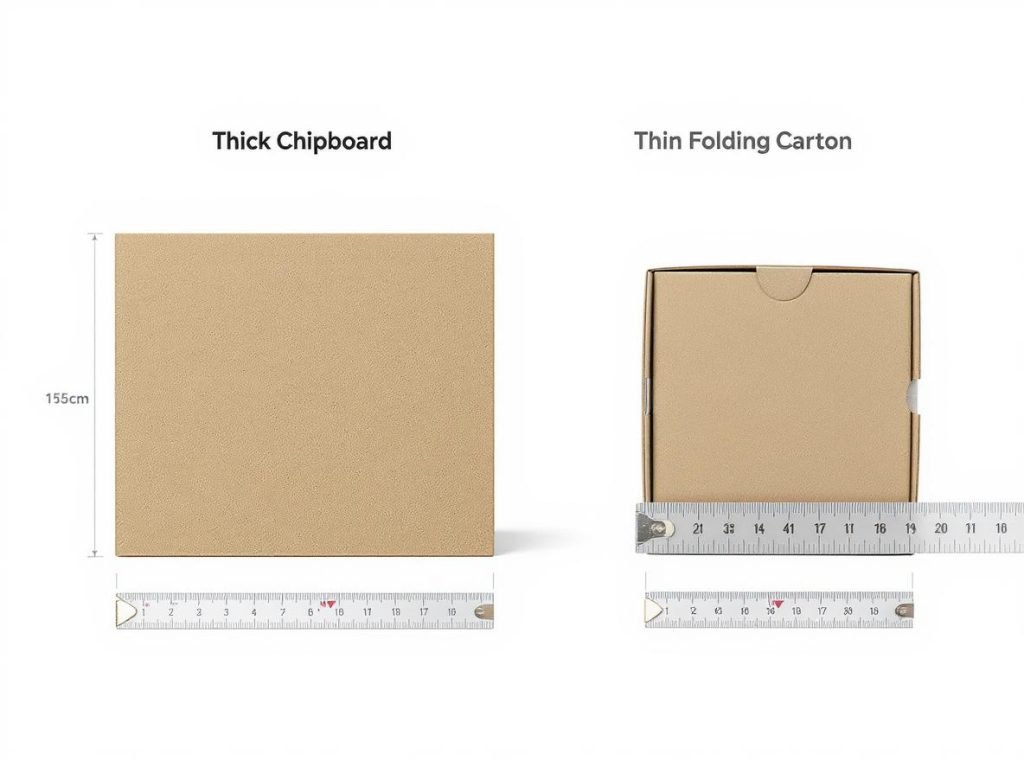

Rigid boxes are constructed from chipboard that is four to five times thicker than traditional folding cartons, providing exceptional structural integrity and luxury presentation that immediately communicates quality and value to customers.

Discover why leading luxury brands like Chanel, Tiffany, and Hermès have maintained virtually unchanged rigid box designs for over a century, and how this packaging choice drives customer loyalty and business growth.

Table of Contents

ToggleWhat Are Rigid Boxes and How Do They Differ from Regular Packaging?

Understanding the fundamental construction differences between rigid boxes and conventional packaging reveals why luxury markets consistently choose this premium solution.

Rigid boxes, also known as set-up boxes, use chipboard ranging from 800GSM to 2100GSM—creating material thickness of 1.5-3mm compared to folding cartons’ 0.3-1mm thickness.

This substantial material difference translates into measurable performance advantages. Rigid boxes achieve compressive strength of up to 35kg/cm²—2.3 times stronger than folding cartons’ 18kg/cm² capacity. The construction process involves wrapping decorative materials like specialty papers, fabrics, or leather around the thick chipboard core, creating seamless premium finishes.

Unlike folding cartons that collapse for shipping, rigid boxes maintain their three-dimensional form from manufacturing through end-use. This non-collapsible nature immediately signals quality and permanence to customers.

Key structural advantages include:

- Permanent shape retention during shipping and storage

- Enhanced crush resistance protecting delicate contents

- Professional appearance surviving multiple handlings

- Ability to support heavier luxury products without compromise

| Feature | Rigid Boxes | Folding Cartons |

|---|---|---|

| Material Thickness | 1.5-3mm chipboard | 0.3-1mm paperboard |

| Compressive Strength | 35kg/cm² | 18kg/cm² |

| Structure | Non-collapsible | Collapsible |

| Shipping Method | Pre-assembled | Flat-packed |

At Acreet, our manufacturing expertise ensures every rigid box meets luxury market standards. We work with chipboard thickness ranging from 36 to 120-point, wrapped in materials from textured papers to genuine leather, delivering packaging that exceeds premium positioning requirements.

Why Do Luxury Brands Choose Rigid Boxes Over Folding Cartons?

Premium brands face unique market pressures where packaging directly influences purchasing decisions and brand perception at critical customer touchpoints.

Research indicates that luxury packaging increases visual attention rates by 3.2 times compared to standard packaging, while customers instinctively associate high-quality packaging with high-quality products.

The psychology operates through perceived value enhancement. When customers encounter substantial, well-constructed packaging, they immediately justify premium pricing in their minds. This cognitive connection between packaging quality and product value supports higher profit margins and reduces price sensitivity.

Brand storytelling capabilities represent another decisive factor. Rigid boxes accommodate sophisticated design elements including embossing, foil stamping, magnetic closures, and custom inserts that are impossible to achieve with thinner materials. These premium features create memorable brand experiences that differentiate products in competitive markets.

Historical precedent supports this strategy. Luxury brands like Chanel, Tiffany, Hermès, and Lanvin have maintained virtually unchanged rigid box packaging designs for over a century, demonstrating the enduring appeal and brand recognition power of consistent premium presentation.

The superior protection qualities make rigid boxes essential for luxury goods requiring careful handling. Robust construction safeguards delicate items during shipping and storage, reducing product damage costs while maintaining brand reputation for quality.

What Premium Features Make Rigid Boxes Perfect for High-End Products?

Advanced design elements transform functional packaging into luxury experiences that create emotional connections between brands and customers.

Magnetic closures represent the pinnacle of rigid box sophistication, providing satisfying tactile experiences with subtle resistance followed by gratifying clicks when opening, while ensuring secure closure without additional clasps.

The magnetic closure system eliminates functional compromises while enhancing aesthetic appeal. Customers experience anticipation building through the opening process, followed by satisfaction from the premium feel and pride in owning products with luxury presentation.

Premium material options extend far beyond basic papers. High-end covering materials include textured and patterned specialty papers, silk, vinyl, and genuine leather. Each contributes unique luxury appearances and tactile experiences that reinforce brand positioning.

Advanced finishing techniques available for rigid boxes include:

- Foil stamping in gold, silver, and specialty metallic colors

- Embossing and debossing for tactile brand elements

- Spot UV coating creating selective gloss effects

- Soft-touch coatings producing velvet-like textures

- Window cutouts showcasing products elegantly

Custom insert systems protect products while creating organized presentations. Precision-cut foam, molded pulp, or fabric-lined compartments secure items perfectly, preventing movement and damage while enhancing the unboxing ritual.

These premium features work synergistically to create comprehensive luxury experiences. The substantial box weight, smooth opening mechanisms, thoughtful internal layouts, and attention to detail contribute to memorable moments customers associate with quality and exclusivity.

How Do Rigid Boxes Enhance Product Protection and Presentation?

Superior construction provides unmatched product security while creating premium presentation experiences that justify luxury pricing and build customer satisfaction.

The non-bending construction of rigid boxes prevents crushing and maintains shape integrity even under external pressure, making them ideal for fragile luxury items requiring careful handling throughout distribution.

Protection extends beyond basic durability. Thick chipboard walls absorb impact energy that would otherwise damage contents. The rigid structure enables precise custom inserts that hold products securely, eliminating movement that causes scratches or breakage during transit.

Temperature and moisture resistance protect sensitive items like cosmetics and electronics during international shipping. These protective qualities reduce return rates, maintain customer satisfaction, and protect brand reputation for quality.

Professional presentation remains consistent throughout the product lifecycle. Unlike folding cartons that may show wear, rigid boxes maintain premium appearance from manufacturing through multiple customer interactions.

The reusability factor adds long-term value as customers often repurpose high-quality rigid boxes for storage, extending brand visibility and reinforcing perceived value. This durability contributes to sustainability goals while maintaining brand presence in customers’ homes.

The “unboxing ritual” has become particularly important in social media marketing. Premium packaging creates shareable moments that provide organic marketing value when customers post their experiences online, amplifying brand reach through customer-generated content.

What Industries Benefit Most from Rigid Box Packaging?

Specific sectors have adopted rigid boxes as industry standards due to unique requirements that align perfectly with premium packaging capabilities and market expectations.

The jewelry industry represents a primary market, with the global jewelry box market projected to grow from $164.3 million in 2025 to $234 million by 2035 at a 3.6% CAGR, driven by luxury positioning requirements.

Jewelry brands require packaging that preserves product luster, prevents micro-scratches, and elevates the gifting experience. Advanced features like magnetic closures, NFC-tagged authentication, and modular inserts that convert boxes into vanity organizers are becoming standard expectations.

Electronics companies utilize rigid boxes to protect expensive, delicate items while enhancing premium unboxing experiences. Major brands like Apple and Samsung have made rigid packaging integral to their marketing strategies, recognizing that unboxing experiences contribute significantly to customer satisfaction and brand perception.

The cosmetics industry relies heavily on rigid boxes to reflect brand essence and attract discerning customers. High-end skincare, perfumes, and makeup benefit from sturdy construction and attractive presentation, with brands like Estée Lauder, Chanel, and Dior using rigid boxes to ensure commanding shelf presence.

Industries achieving maximum benefit include:

- Luxury fashion accessories and leather goods requiring premium presentation

- Fine wines and premium spirits needing protection and gift-worthy packaging

- High-end corporate gifts and awards demanding professional presentation

- Artisanal food products and gourmet items justifying premium pricing

- Collectibles and limited editions requiring protective storage solutions

Each industry shares common needs: packaging that communicates quality, provides superior protection, and enhances overall customer experience while supporting premium pricing strategies.

How Do Rigid Boxes Impact Customer Experience and Brand Loyalty?

Premium packaging creates multisensory experiences that engage customers on emotional and psychological levels, driving measurable business outcomes and long-term relationships.

Memorable unboxing experiences lead to increased brand affinity and repeat purchases, with studies showing customers who experience premium packaging are significantly more likely to make repeat purchases and recommend brands to others.

The psychological impact operates through several mechanisms. First impressions set expectations and create emotional connections that influence all subsequent brand interactions. Perceived value enhancement justifies premium pricing while reducing price sensitivity.

Brand differentiation through premium packaging creates memorable experiences that distinguish products from competitors in crowded markets. The tactile elements—texture, weight, and opening sounds—contribute to comprehensive sensory journeys that reinforce luxury positioning.

Social sharing potential amplifies brand reach exponentially. Premium unboxing experiences generate organic social media content as customers share their experiences across platforms, providing valuable word-of-mouth marketing that reaches new audiences authentically.

Customer loyalty benefits extend beyond initial purchases. Enhanced retention rates, positive referrals, and increased customer lifetime value result from positive packaging experiences. The psychological satisfaction from premium packaging creates emotional bonds that drive long-term brand relationships.

Research indicates that luxury packaging creates emotional responses including anticipation during opening, satisfaction from premium materials, and pride in product ownership. These emotions drive brand advocacy and organic marketing through customer enthusiasm and recommendations.

What Should You Consider When Choosing Rigid Box Manufacturing?

Selecting manufacturing partners requires evaluating multiple factors that directly impact product quality, production timelines, and overall business success.

Quality standards should be the primary consideration, with manufacturers adhering to international certifications like ISO standards while maintaining structured quality control systems throughout production processes.

Material capabilities determine final product quality and appearance. Evaluate suppliers’ access to various chipboard thicknesses, specialty papers, fabrics, and finishing techniques including foil stamping, embossing, magnetic closures, and custom insert fabrication.

Production capacity and lead times typically range from 2-6 weeks depending on design complexity, quantity requirements, and customization levels. Key factors affecting timelines include design complexity, order quantities, specialty processes like embossing or magnetic closures, and shipping logistics.

Cost considerations extend beyond unit pricing to include total ownership costs. While rigid boxes command higher upfront investments than folding cartons, consider long-term value through enhanced brand perception, customer loyalty, and reduced damage rates during shipping.

Sustainability practices increasingly influence customer preferences and purchasing decisions. Look for manufacturers using:

- Recycled and recyclable materials for environmental responsibility

- FSC-certified papers from sustainably managed forests

- Water-based inks and bio-based adhesives reducing environmental impact

- Efficient production processes minimizing waste and energy consumption

At Acreet, we’ve invested in state-of-the-art equipment and trained craftspeople who understand luxury packaging requirements. Our comprehensive capabilities include in-house design services, structural engineering, prototyping, and quality management systems ensuring every box meets exact specifications while supporting your sustainability goals.

Summary

Rigid boxes represent the ultimate choice for luxury products by combining superior protection, premium presentation, and unforgettable customer experiences that justify investment and drive business growth. Their proven track record across luxury industries, from jewelry to electronics, demonstrates measurable impact on brand perception and customer loyalty.

Ready to elevate your brand with custom rigid boxes that command premium pricing? Contact Acreet today for expert consultation on luxury packaging solutions that transform your products into memorable experiences and build lasting customer relationships.