Ordering custom jewelry boxes for your business can feel overwhelming. You’re investing in packaging that represents your brand, protects valuable items, and creates memorable unboxing experiences. One wrong decision could impact your costs, brand image, and customer satisfaction.

Custom jewelry boxes require careful consideration of materials, sizes, minimum order quantities, production timelines, and design specifications. Understanding MOQs ranging from 100-2,500 units, production timelines of 4-6 weeks, and pricing from $0.25-$15 per unit helps you make informed decisions that align with your business needs and budget.

Let’s explore everything you need to know to make the best decision for your jewelry business.

Table of Contents

ToggleWhat Materials Work Best for Custom Jewelry Boxes?

Your choice of materials directly impacts both the protection of your jewelry and your brand’s perceived value. Different materials serve different purposes and price points, with each offering unique advantages.

Wood remains the most popular choice for premium jewelry boxes due to its durability and timeless aesthetic appeal. Cardboard and paper materials provide affordable versatility for small businesses, while leather offers sophistication and metal options deliver modern aesthetics with exceptional durability.

Wood Materials for Premium Appeal

Wood continues to be the top choice for luxury jewelry packaging due to its natural beauty and longevity. Hardwoods like oak, maple, and cherry offer superior strength and attractive grain patterns that enhance product presentation. Softwoods like pine provide an affordable option with good workability for custom designs.

Composite materials and engineered wood products balance cost and performance, offering consistent quality without the premium price of solid hardwoods. These materials accept stains and finishes well, allowing for brand color matching.

Cardboard and Paper Solutions

Cardboard remains the most cost-effective option for businesses ordering in bulk. Standard cardboard works exceptionally well for lightweight jewelry pieces and accepts custom printing beautifully. You can enhance cardboard boxes with various finishes:

- Foil stamping or embossing creates luxurious appearances at reasonable costs

- Matte, glossy, and textured surfaces complement different brand aesthetics

- Eco-friendly options using recycled content appeal to environmentally conscious consumers

Leather and Premium Materials

Leather jewelry boxes offer sophistication and durability for high-end brands. Genuine leather provides premium positioning with natural variations that add character, while faux leather offers cost-effective alternatives with consistent appearance. Suede finishes create soft textures ideal for protecting delicate jewelry pieces.

Metal options provide modern aesthetics and exceptional durability. Aluminum offers lightweight, corrosion-resistant properties, while brass and steel create clean, minimalist design appeal. Stainless steel serves as a premium option with excellent longevity.

| Material Type | Price Range | Best For | Durability |

|---|---|---|---|

| Standard Cardboard | $0.25-$0.75 | High-volume orders | Moderate |

| Rigid Paperboard | $1.80-$2.25 | Professional presentation | Good |

| Wood Boxes | $5.00-$15.00 | Premium jewelry lines | Excellent |

| Leather Options | $3.00-$8.00 | Luxury positioning | Very Good |

How Do You Determine the Right Box Sizes?

Proper sizing ensures optimal protection and presentation while controlling shipping costs. Understanding standard dimensions and measurement principles is essential for successful custom box design.

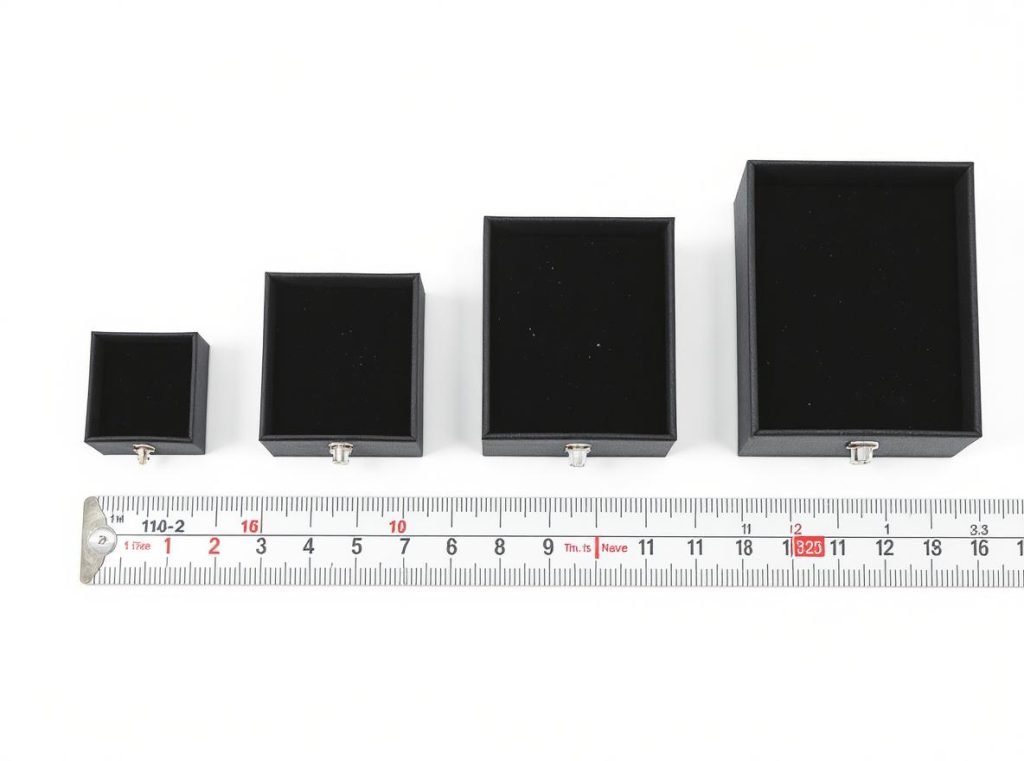

Small jewelry boxes typically measure 2-3 inches for rings and earrings, medium boxes range 3-5 inches for bracelets and pendants, while large boxes measure 5-8 inches for necklaces and statement pieces. Interior dimensions are critical for proper fit, with standard ring boxes measuring 2″ × 2″ × 1.5″ internally.

Standard Size Categories

Understanding industry-standard dimensions helps optimize both protection and cost efficiency:

Small jewelry boxes work perfectly for:

- Ring boxes: 2″ × 2″ × 1.5″ interior dimensions with slotted inserts

- Earring storage: 2-3 inches for studs and simple designs

- Individual charms: Compact protection for single pieces

Medium jewelry boxes accommodate:

- Bracelet boxes: 3.5″ × 3.5″ × 1″ interior space for most styles

- Pendant storage: With adequate chain accommodation

- Earring sets: Multiple pairs or larger designs

Large jewelry boxes handle:

- Necklace boxes: 7″ × 5″ × 1.25″ for standard chains

- Statement pieces: Chunky or oversized jewelry items

- Complete sets: Multiple coordinated pieces

Measurement Best Practices

Interior dimensions determine jewelry fit and protection. Measure the longest dimension, widest point including protrusions, and thickness requirements. Add 2-3mm padding space around each dimension for secure fit without excess bulk.

External dimensions affect shipping costs and storage efficiency. Minimize wasted space while ensuring adequate protection. Consider standard shipping box size limits and retail display requirements when finalizing dimensions.

What Are Typical Minimum Order Quantities?

Understanding MOQs helps you budget effectively and plan inventory purchases. Requirements vary significantly based on supplier size, customization level, and production methods.

Most manufacturers set MOQs between 500-1,000 units for custom jewelry boxes, though ranges vary considerably. Large manufacturers typically require 1,000-2,500 units minimum, while mid-size suppliers often accept 500-1,000 units. Small-scale producers may accommodate 100-500 units, and print-on-demand services can handle orders as low as 1-24 units.

MOQ Ranges by Supplier Type

Understanding different supplier categories helps identify appropriate partners:

Large manufacturers focus on high-volume production with MOQs of 1,000-2,500 units. These suppliers offer the most competitive per-unit pricing but require significant upfront investment and longer production planning.

Mid-size suppliers provide flexibility with 500-1,000 unit minimums. This category often offers the best balance of pricing, quality, and service for growing businesses.

Small-scale producers accommodate 100-500 units, making them ideal for testing new designs or serving niche markets. Per-unit costs are higher, but total investment remains manageable.

Factors Affecting MOQ Requirements

Design complexity significantly impacts minimum orders. Simple designs with basic customization often have lower MOQs, while intricate designs with multiple colors and special finishes require higher minimums to justify setup costs.

Material selection also influences requirements:

- Standard materials like cardboard typically have lower MOQs

- Premium materials like wood or leather require higher minimums

- Specialty finishes increase minimum order requirements

Production methods determine feasibility. Digital printing allows smaller runs with higher per-unit costs, while offset printing requires larger quantities for cost efficiency.

Alternative Solutions for Small Orders

Several options exist for businesses needing smaller quantities:

Print-on-demand services offer no minimum orders with higher per-unit costs, perfect for testing designs or small-scale operations. Group ordering allows multiple businesses to combine orders and share bulk pricing benefits. Semi-custom packaging uses pre-designed templates with limited customization, offering lower MOQs while maintaining professional appearance.

How Long Does Custom Production Take?

Production timelines vary based on complexity, quantity, and supplier capabilities. Understanding these timeframes helps with planning and inventory management.

Most custom jewelry box orders require 4-6 weeks for completion, including design approval (1-2 weeks), production setup (3-5 days), manufacturing (2-4 weeks), quality control (2-3 days), and packaging/shipping (3-5 days). Complex designs may extend timelines to 6-8 weeks.

Standard Production Timeline Breakdown

Understanding each phase helps you plan effectively:

Design approval phase typically takes 1-2 weeks depending on revision cycles. Your packaging supplier should provide digital proofs showing exact colors, dimensions, and printing placement. Review these carefully since changes after approval can significantly delay production.

Production setup requires 3-5 days for tooling preparation, printing plate creation, and machinery configuration. This phase remains constant regardless of order size.

Manufacturing time spans 2-4 weeks based on order complexity and quantity. Simple designs with basic customization may complete faster, while intricate designs with multiple finishes extend production time.

Factors Affecting Production Time

Order complexity significantly impacts timelines. Simple designs with basic customization may complete in 3-4 weeks, while intricate designs with multiple finishes can extend to 6-8 weeks.

Order quantity also affects production schedules. Smaller orders may process faster due to reduced setup requirements, while larger orders might require additional time for quality control and packaging.

Supplier capacity determines availability. Busy periods, equipment maintenance, or seasonal demand can extend timelines, while off-peak ordering may reduce production time.

Rush Order Considerations

Many suppliers offer expedited production for additional fees. Rush orders typically reduce timelines by 25-50% but incur premium pricing of 15-30% above standard rates. These orders require design approval within 24-48 hours and may limit customization options to ensure faster completion.

Consider rush orders only when absolutely necessary, as standard timelines typically produce better quality results and more cost-effective pricing.

What Design Options Should You Consider?

Custom jewelry boxes offer extensive design possibilities that enhance brand identity and customer experience. Understanding available options helps create packaging that truly represents your brand.

Popular design options include offset printing for high-quality large runs, digital printing for flexible small quantities, foil stamping for metallic accents, and embossing for tactile appeal. Interior options feature velvet lining in various colors, satin finishes, foam protection, and custom compartment designs.

Printing and Finishing Techniques

Modern printing technology enables stunning visual effects that elevate your brand presentation:

Offset printing provides high-quality, cost-effective results for large production runs. This method offers excellent color consistency and fine detail reproduction across thousands of units.

Digital printing provides flexibility for small quantities and complex designs. While per-unit costs are higher, the ability to customize individual boxes or print small batches makes this ideal for testing or boutique brands.

Screen printing offers durability for simple designs and logos, with excellent color saturation and longevity.

Premium Finishing Options

Special finishes create tactile experiences that enhance perceived value:

- Foil stamping: Metallic accents in gold, silver, or copper add luxury appeal

- Embossing: Raised designs create tactile interest and premium feel

- UV coating: Protective gloss finish enhances durability and appearance

- Soft-touch coating: Velvety texture provides premium positioning

Interior Design Elements

Interior layouts should complement your jewelry while providing protection:

Lining materials protect jewelry and enhance presentation. Velvet remains the classic luxury option available in various colors, while satin provides smooth finishes with subtle sheen. Foam inserts offer protective cushioning for delicate pieces.

Compartment design optimizes organization with ring rolls for secure individual storage, necklace hooks to prevent tangling, earring slots for organized pair storage, and adjustable dividers for flexible space configuration.

Hardware and Functional Elements

Closure mechanisms affect both usability and brand perception:

- Magnetic closures: Convenient and secure operation

- Ribbon ties: Elegant and traditional appeal

- Snap closures: Durable and reliable function

- Hinged lids: Classic jewelry box design

| Design Element | Cost Impact | Visual Impact | Functionality |

|---|---|---|---|

| Foil Stamping | +$0.50-$2.00 per unit | High | Decorative |

| Embossing | +$0.30-$1.50 per unit | High | Tactile |

| Velvet Lining | +$0.25-$1.00 per unit | Medium | Protective |

| Magnetic Closure | +$0.15-$0.75 per unit | Low | Functional |

How Do You Evaluate Potential Suppliers?

Selecting the right supplier is crucial for successful custom jewelry box production. A systematic evaluation process ensures you partner with manufacturers who meet your quality, timeline, and budget requirements.

Key evaluation criteria include production capabilities, quality standards, communication responsiveness, and pricing transparency. Request samples to assess material quality and craftsmanship, verify certifications, and check customer references before making final decisions.

Research and Initial Evaluation

Industry exhibitions provide direct supplier interaction opportunities. These events allow you to examine product samples firsthand, discuss customization capabilities with manufacturers, and compare multiple suppliers in one location.

Online platforms offer extensive supplier databases through B2B platforms like Alibaba and Global Sources. These provide detailed supplier profiles, customer reviews and ratings, product catalogs, and direct communication tools.

Critical Assessment Factors

Quality standards should be your primary consideration. Look for suppliers who use durable materials appropriate for jewelry packaging, offer customization options that meet your design needs, maintain consistent quality across production runs, and provide samples for evaluation.

Production capabilities determine project feasibility. Assess manufacturing capacity for your order size, equipment sophistication for desired finishes, quality control processes throughout production, and scalability for future growth.

Communication quality ensures smooth project management. Evaluate response time to inquiries, English proficiency for clear communication, technical understanding of requirements, and willingness to provide detailed quotations.

Verification and Quality Assurance

Sample evaluation provides quality assurance before committing to large orders. Request samples to assess material quality and finish consistency, construction durability and structural integrity, design accuracy compared to specifications, and overall craftsmanship.

Reference checking validates supplier reliability. Contact previous clients to discuss order fulfillment timeliness, quality consistency across multiple orders, problem resolution capabilities, and overall satisfaction with the partnership.

Facility inspection ensures production capability when possible. Evaluate production equipment and technology level, quality control systems and testing procedures, workforce skills and training programs, and facility cleanliness and organization.

What Budget Considerations Are Important?

Understanding all cost components helps create realistic budgets and avoid unexpected expenses. Custom jewelry box pricing involves multiple factors that significantly impact total investment.

Material costs typically represent 40-60% of total pricing, with standard options ranging from $0.25-$0.75 per unit for basic packaging to $5.00-$15.00 for premium materials. Setup fees, shipping costs, and special finishes add to the total investment.

Detailed Cost Structure

Understanding pricing components helps optimize your budget:

Material costs form the largest expense category:

- Corrugated packaging: $2.70-$3.50 per unit

- Folding cartons: $1.80-$2.25 per unit

- Rigid boxes: $8.50-$10.00 per unit

- Flexible packaging: $0.25-$0.75 per unit

- Jewelry pouches: $0.30-$1.50 per unit

Production costs include labor and manufacturing expenses. Setup fees cover one-time charges for tooling and plates, while labor intensity varies with design complexity. Specialized equipment time and quality control measures add to overall pricing.

Shipping and handling can significantly impact total costs. Package weight affects shipping rates, box dimensions incur size premiums, international shipping adds customs duties, and rush delivery commands premium pricing.

Cost Optimization Strategies

Bulk ordering provides significant savings with volume discounts of 20-40% on large orders. Balance inventory management costs against unit savings, consider seasonal planning during supplier low periods, and negotiate better rates for committed volumes.

Design simplification reduces production complexity:

- Minimize colors: Fewer colors reduce printing costs significantly

- Standard sizes: Avoid custom tooling charges where possible

- Simple finishes: Basic printing costs less than specialty treatments

- Efficient layouts: Optimize material usage in production planning

Investment Planning

Budget for all cost components including materials, setup fees, printing charges, and shipping expenses. Consider long-term needs when evaluating pricing, as larger orders typically offer better per-unit economics.

Factor in reorder convenience and customer satisfaction when making material choices. Premium materials may cost more initially but can improve brand perception and customer loyalty.

How Do You Ensure Quality Control?

Implementing comprehensive quality control measures protects your investment and brand reputation. A systematic approach ensures consistent results and customer satisfaction.

Quality control should include pre-production material inspection, in-process monitoring, and final inspection protocols. Key standards include dimensional accuracy within tolerance, color difference within ΔE≤1.5, and structural reliability through load-bearing tests of 5kg for 24 hours.

Pre-Production Quality Planning

Material inspection forms the foundation of quality control. Verify specified materials are used, ensure uniform color matching across batches, test material strength and durability, and confirm environmental compliance with safety standards.

Design verification prevents costly production errors. Confirm all dimensions and details match specifications, verify colors and logo placement in artwork, review physical samples before mass production, and ensure closures and mechanisms function properly.

Production Monitoring Standards

In-process inspections catch problems early during manufacturing. Monitor dimensional accuracy within specified tolerances, check color registration and print clarity, ensure proper construction and alignment, and verify coating and surface treatment consistency.

Load-bearing tests ensure structural reliability through static testing with 5kg weight for 24 hours, dynamic testing with pressure up to 15kg at controlled speeds, fatigue testing through repeated opening/closing cycles, and drop testing to simulate shipping stresses.

Final Quality Verification

Visual inspection identifies cosmetic defects including surface quality checks for scratches or imperfections, color accuracy verification within ΔE≤1.5 tolerance, print quality assessment for sharp graphics, and finish consistency confirmation.

Functional testing validates performance standards through closure operation testing, structural stability verification, interior fit assessment, and packaging integrity checks.

Documentation requirements provide quality traceability through inspection records, corrective action documentation, batch tracking systems, and quality certificates when required.

Best Practices Implementation

Supplier audits ensure consistent quality standards through regular evaluations of quality systems, equipment maintenance verification, staff training confirmation, and continuous improvement assessment.

Statistical process control helps maintain consistency through appropriate sampling protocols, control charts for key metrics, trend analysis for pattern identification, and data-driven corrective actions.

Summary

Ordering custom jewelry boxes requires comprehensive planning across multiple critical factors. Choose materials that align with your brand positioning and budget, from cost-effective cardboard options at $0.25-$0.75 per unit to premium wood boxes at $5.00-$15.00 per unit. Understand MOQ requirements ranging from 100-2,500 units depending on supplier size and customization complexity. Plan for production timelines of 4-6 weeks, including design approval, manufacturing, and quality control phases. Evaluate suppliers based on production capabilities, quality standards, and communication responsiveness while implementing comprehensive quality control measures including material inspection, in-process monitoring, and final verification protocols.

Ready to create stunning custom jewelry boxes that elevate your brand and protect your valuable products? Contact Acreet today for a comprehensive consultation and competitive quote. Our experienced team specializes in custom packaging solutions for jewelry businesses worldwide, offering flexible MOQs, premium materials, and exceptional quality control standards. Whether you need 100 units for a boutique launch or 10,000 units for wholesale distribution, we’ll guide you through every step of the process.

Visit acreet.com or send us your inquiry today to discover how our custom jewelry box solutions can transform your product presentation and drive business growth.