Delicate jewelry requires specialized protection to prevent damage, tangling, and tarnishing during storage and shipping. Poor packaging decisions can result in scratched surfaces, broken chains, customer complaints, and damaged brand reputation that impacts future sales.

The best way to package small, delicate jewelry involves individual wrapping each piece in anti-tarnish materials, securing items in properly sized cushioned boxes with foam inserts, and implementing multi-layer protection during shipping. This systematic approach ensures pieces arrive in pristine condition while creating memorable unboxing experiences.

Let’s explore the complete packaging process to protect your delicate jewelry and enhance your brand’s professional image.

Table of Contents

ToggleWhat Essential Materials Do You Need for Professional Jewelry Packaging?

Understanding the right materials is crucial for creating packaging that protects products while reinforcing your brand’s luxury positioning.

Essential materials include jewelry boxes with proper wall thickness (minimum 1/16 inch), protective inserts like velvet-covered foam, anti-tarnish strips using copper-based polymers, acid-free tissue paper, and cushioning materials like small-bubble wrap. These components work together to prevent damage, tarnishing, and movement during transit.

Professional jewelry packaging requires carefully selected materials that address both protection and presentation needs.

Primary Packaging Foundations

Jewelry boxes form the foundation of professional packaging systems. Standard dimensions include small boxes (2″ x 2″ x 1.5″) for rings, medium boxes (3.5″ x 3.5″ x 1″) for bracelets and small necklaces, and large boxes (8″ x 6″ x 2″) for statement pieces. Materials range from kraft paperboard to premium leatherette, with most requiring minimum wall thickness of 1/16 inch for adequate protection.

Quality box construction prevents crushing during shipping while maintaining structural integrity under normal handling conditions.

Protective Insert Systems

Foam inserts provide excellent cushioning for delicate pieces, while velvet-covered foam adds luxury appeal that customers associate with premium brands. Cardboard inserts offer cost-effective protection for lightweight items, and molded EVA trays provide structured positioning with elegant presentation capabilities.

| Insert Type | Best For | Protection Level | Luxury Appeal |

|---|---|---|---|

| Velvet-covered foam | Rings, earrings | High | Premium |

| Molded EVA trays | Multiple pieces | High | Professional |

| Cardboard dividers | Lightweight items | Medium | Basic |

| Foam cushioning | All delicate pieces | High | Standard |

Anti-Tarnish Protection Materials

Anti-tarnish strips use copper-based polymers that react with hydrogen sulfide and other corrosive gases, neutralizing them before they contact jewelry. Individual wrapping materials prevent scratches and tangling, with anti-tarnish tissue paper protecting silver and other metals from oxidation during storage and shipping.

Cotton wrapping offers breathable protection for organic materials like pearls, while soft cloth pouches made from velvet, satin, or microfiber provide reusable protection that extends brand visibility.

How Should You Properly Wrap Individual Jewelry Pieces?

Proper individual wrapping prevents scratches, tangling, and chemical reactions while maintaining professional presentation standards throughout the unboxing process.

Begin by cleaning each piece with appropriate methods for the material, then wrap individually in anti-tarnish tissue paper or soft cloth. For necklaces and bracelets, always fasten clasps before wrapping to prevent tangling. Place wrapped items in individual pouches or compartments within the jewelry box.

The individual wrapping process requires attention to material-specific needs and proper handling techniques for optimal protection.

Step-by-Step Protection Process

Start by cleaning each piece before packaging to remove oils, lotions, and residues that can cause tarnishing over time. Use appropriate cleaning methods for each material—gentle jewelry cleaner for diamonds and hard gemstones, soft damp cloth for pearls and opals.

Different jewelry types require specific wrapping approaches:

- Silver jewelry: Requires anti-tarnish strips or pouches to neutralize hydrogen sulfide gases

- Pearls and organic materials: Need breathable storage to prevent moisture buildup

- Mixed metal pieces: Should be separated to prevent chemical reactions

- Gemstone jewelry: Needs cushioning to prevent scratches from harder stones

Material-Specific Protection Requirements

Wrap pieces individually in tissue paper or soft cloth to prevent contact between different metals and gemstones. For necklaces and bracelets, always fasten clasps before wrapping to prevent tangling and reduce stress on chains during storage and shipping.

Avoid plastic containers that can trap humidity, instead using fabric pouches or lined compartments with adequate ventilation for organic materials like pearls.

What Are the Best Packaging Solutions for Different Jewelry Types?

Different jewelry categories require specific packaging approaches to address their unique vulnerabilities and presentation needs.

Rings need individual compartments measuring 2″ x 2″ x 1.5″ internally, necklaces require flat storage with anti-tangle measures in boxes ranging from 3.34″ x 3.34″ x 1″ to 7″ x 5″ x 1.5″, and earrings benefit from secure pairing systems with foam inserts featuring holes for posts. Matching packaging to jewelry type prevents category-specific damage risks.

Understanding each jewelry type’s specific requirements helps you select appropriate protection and presentation solutions.

Ring and Small Item Solutions

Ring boxes typically measure 2″ x 2″ x 1.5″ internally, with slotted inserts designed to hold ring bands securely without pressure on settings. For engagement rings, ultra-slim proposal boxes with external dimensions 1.875″ x 0.5″ x 1.5″ provide discreet portability while maintaining complete protection.

Ring-specific considerations include stone protection through secure fitting, band protection against scratches, size accommodation for various ring dimensions, and easy removal without applying force to delicate settings.

Earring Protection Systems

Earring packaging varies significantly by style and requires careful consideration of movement prevention. Stud earrings fit in compact boxes (2.125″ x 1.625″ x 0.75″) with foam inserts featuring precisely sized holes for posts, while dangle and hoop earrings require larger dimensions (3″ x 3″ x 1.25″) to prevent bending and tangling.

Specialized insert design ensures earring backs remain secured and pairs stay together throughout shipping and handling processes.

Necklace and Chain Management

| Necklace Type | Box Dimensions | Special Features |

|---|---|---|

| Pendant necklaces | 3.34″ x 3.34″ x 1″ | Slits for chain securing |

| Statement pieces | 7″ x 5″ x 1.5″ | Custom-molded trays |

| Delicate chains | 4″ x 4″ x 1.25″ | Anti-tangle hooks |

| Bracelet sets | 3″ x 3″ x 1.5″ | Curved display pillows |

Necklace boxes range from standard pendant sizes to large statement piece dimensions, with inserts that include slits or hooks to secure chains and prevent tangling during transport.

How Do You Choose the Correct Box Size for Maximum Protection?

Selecting appropriate box dimensions balances protection effectiveness, shipping costs, and customer experience while preventing both damage and waste.

Measure jewelry length, width, and height, then add 1/4 to 1/2 inch extra space per dimension for cushioning materials. Avoid oversized packaging that increases shipping costs and allows excessive movement, while ensuring adequate space for protective materials without compression.

Proper sizing directly impacts protection effectiveness, shipping expenses, and customer perception of your brand’s attention to quality details.

Accurate Measurement Techniques

Measure jewelry in its natural resting position when determining box requirements. Chains need length accommodation for flat storage, while rings require minimal space but secure vertical positioning to protect settings.

Consider the thickness of protective materials when calculating internal dimensions. Foam inserts, tissue paper, and cushioning materials require space that affects overall box size requirements.

Standard Sizing Categories and Applications

Small jewelry boxes suitable for rings and studs feature interior dimensions of 2-3 inches in primary dimensions with depths of 1-1.5 inches for optimal protection without waste.

Medium boxes accommodate bracelets and small necklaces with interior dimensions of 3.5-5 inches length/width and 1-2 inches depth for comfortable fit with cushioning materials.

- Micro boxes: Ideal for stud earrings, small rings

- Compact boxes: Perfect for engagement rings, simple necklaces

- Standard boxes: Suitable for most bracelets, pendant necklaces

- Large presentation boxes: Required for statement pieces, jewelry sets

Cost-Effectiveness Balance

Shipping costs increase significantly with package dimensions due to dimensional weight pricing, but inadequate protection risks returns and negative reviews. Calculate total cost including potential damage claims when selecting packaging dimensions.

Establish standard box sizes that accommodate multiple jewelry types to reduce inventory complexity while ensuring consistent protection standards across your product range.

What Advanced Anti-Tarnish Protection Methods Should You Use?

Preventing tarnishing during storage and shipping maintains jewelry quality and reduces customer complaints about discolored or damaged pieces.

Use anti-tarnish strips with copper-based polymers in direct contact with jewelry, implement Intercept Technology for professional-grade protection, and control moisture with silica gel packets. Combined approaches provide comprehensive protection against oxidation, corrosion, and environmental damage.

Advanced tarnish prevention requires understanding chemical causes and implementing multiple protective layers throughout your packaging system.

Professional-Grade Protection Technology

Anti-tarnish strips use copper-based polymers that react with hydrogen sulfide and other corrosive gases, neutralizing them before they contact jewelry pieces. Place strips in direct contact with jewelry within sealed containers for maximum effectiveness.

Intercept Technology provides professional-grade protection through semiconductor technology that transforms plastic into protective barriers. This NASA-trusted technology permanently neutralizes corrosive gases, fungus, and bacteria, making it ideal for valuable collections and long-term storage.

Environmental Control Implementation

Moisture management using silica gel packets absorbs excess humidity that accelerates tarnishing processes. Replace or recharge silica gel regularly according to manufacturer instructions to maintain consistent effectiveness.

Proper storage environments should be cool, dry, and away from direct sunlight. Avoid humid areas like bathrooms, and use opaque containers to protect colored gemstones from UV damage that can cause fading over time.

Chemical Reaction Prevention

| Metal Type | Primary Risk | Protection Method | Effectiveness Period |

|---|---|---|---|

| Silver | Hydrogen sulfide | Anti-tarnish strips | 6-12 months |

| Copper alloys | Oxidation | Moisture control | Ongoing |

| Gold | Surface contamination | Acid-free materials | Permanent |

| Platinum | Chemical reactions | Separation storage | Long-term |

Separate different metals to prevent galvanic corrosion and chemical reactions between dissimilar materials during extended storage periods.

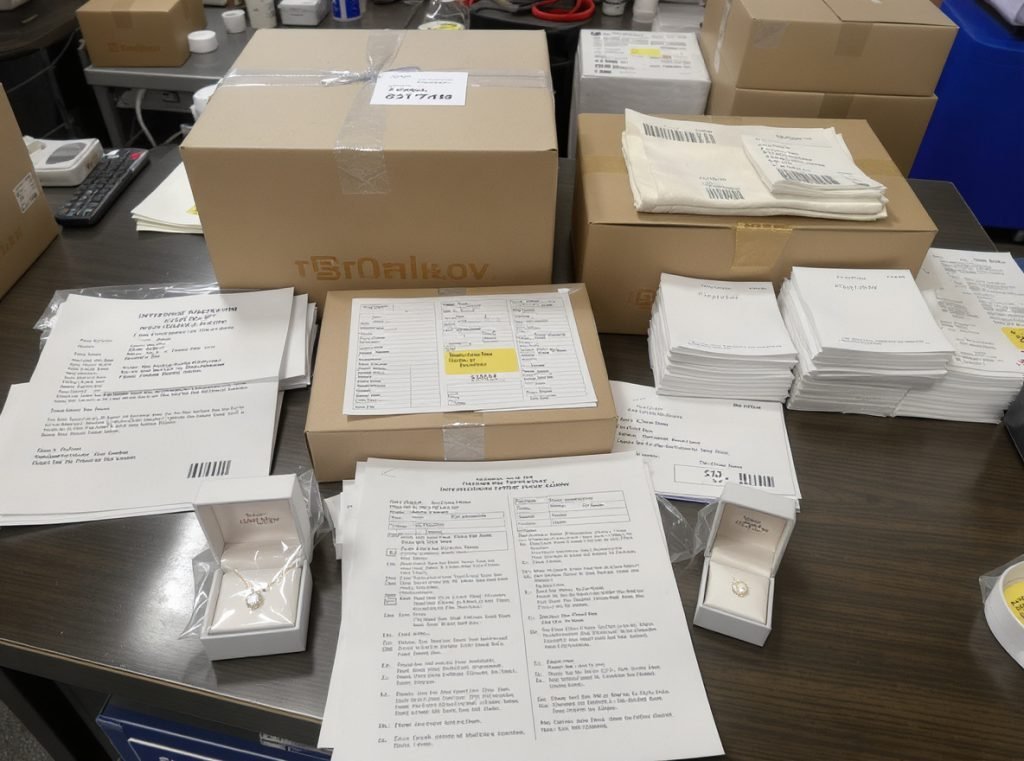

How Should You Package Jewelry for International Shipping Success?

International shipping presents unique challenges including longer transit times, multiple handling points, varying climate conditions, and complex customs requirements.

International jewelry shipping requires discrete outer packaging, enhanced cushioning layers, waterproof protection, accurate customs documentation, and insurance coverage. Extended transit times demand superior protection against environmental factors and rough handling during multiple transfer points.

International considerations extend beyond domestic shipping requirements, demanding additional protective measures and regulatory compliance knowledge.

Customs Documentation and Compliance

Accurate customs declarations must include correct HS codes and detailed item descriptions for jewelry categories. Research country-specific restrictions on precious metals, as some nations limit gold imports without special permits or licensing requirements.

Declare correct values and material purities to avoid complications, unexpected duties, and potential confiscation at customs checkpoints.

Enhanced Protection for Extended Transit

Double-boxing techniques provide additional protection for valuable items during international shipping. Place jewelry in primary packaging, wrap in protective foam, then place in a slightly larger outer box with additional cushioning materials for impact absorption.

Discreet outer packaging prevents theft by avoiding identifying words or graphics that reveal valuable contents. Use plain, sturdy boxes without “Fragile” labels that might indicate precious cargo to potential thieves.

Insurance and Tracking Requirements

FedEx offers specialized high-value jewelry programs with coverage up to $100,000 domestically and $25,000 internationally for comprehensive protection. Always require signature on delivery to prevent unattended packages and ensure secure receipt confirmation.

Research destination country import regulations, required documentation, and restricted materials to ensure smooth customs clearance and legal compliance.

What Sustainable Packaging Options Protect the Environment?

Eco-friendly packaging options address environmental concerns while maintaining protection standards and appealing to environmentally conscious customers who value sustainability.

Sustainable jewelry packaging includes recycled cardboard boxes, FSC-certified papers, organic cotton pouches, biodegradable cushioning materials, and plant-based plastic alternatives. These options reduce environmental impact while maintaining professional presentation and comprehensive protection standards.

Environmental responsibility increasingly influences customer purchasing decisions, making sustainable packaging a competitive advantage and brand differentiator.

Renewable and Recycled Material Options

Recycled and recyclable materials include kraft paper made from 90-100% post-consumer waste, recycled cardboard with maintained structural integrity, and FSC-certified papers from responsibly managed forests supporting circular economy principles.

Organic fabric options such as GOTS-certified organic cotton, hemp, and burlap provide reusable packaging that extends brand visibility while offering luxury appeal without environmental concerns.

Innovative Sustainable Technologies

Plant-based alternatives include biodegradable plastics made from cornstarch, sugarcane bagasse molded into elegant protective shapes, and bamboo pulp inserts that replace synthetic foam materials effectively.

| Sustainable Material | Traditional Alternative | Environmental Benefit | Cost Impact |

|---|---|---|---|

| Cornstarch plastic | Petroleum plastic | Biodegradable | 10-20% higher |

| Hemp pouches | Synthetic fabric | Renewable resource | Similar |

| Bamboo inserts | Foam padding | Fast-growing material | 15-25% higher |

| Recycled cardboard | Virgin paperboard | Waste reduction | 5-10% lower |

Performance Balance Considerations

Environmental considerations shouldn’t compromise protection effectiveness or customer experience. Research sustainable materials that meet your protection requirements while supporting environmental goals and brand values.

Test eco-friendly alternatives thoroughly to ensure they provide adequate protection during typical shipping conditions and handling scenarios before full implementation.

How Do You Create Unforgettable Unboxing Experiences?

The unboxing experience significantly impacts customer satisfaction, social media sharing potential, and repeat purchase likelihood for jewelry brands.

Create memorable unboxing through layered reveals, premium tactile materials, personalized touches, and careful attention to visual presentation. The packaging journey should build anticipation and reinforce your brand’s quality commitment while encouraging social media engagement.

Exceptional unboxing experiences generate positive reviews, social media content, and word-of-mouth marketing that drives organic business growth.

Sensory Design Integration

Material selection drives emotional connection and brand perception. Soft-touch finishes on boxes, velvet-lined interiors, and quality ribbons create tactile luxury that customers associate with premium products and exceptional value.

Choose materials that align with your brand personality—smooth matte finishes for modern elegance, textured linen for rustic charm, or glossy surfaces for contemporary appeal.

Multi-Layer Presentation Strategy

Design your packaging with multiple reveal layers that build anticipation throughout the unboxing process. Start with attractive outer packaging, progress through protective layers, and culminate with premium jewelry presentation that creates lasting memories.

Each layer should contribute to both protection and presentation, creating a journey from receipt to final reveal that delights customers and encourages sharing.

Brand Integration and Personalization

| Personalization Element | Customer Impact | Implementation Cost | Brand Benefit |

|---|---|---|---|

| Custom tissue paper | High recognition | Low | Strong branding |

| Handwritten notes | Emotional connection | Medium | Personal touch |

| QR code interactions | Modern engagement | Low | Digital integration |

| Branded care cards | Professional trust | Low | Value addition |

Custom elements include laser-engraved initials or dates, handwritten thank-you notes, and branded care instructions that provide ongoing value to customers.

QR codes linking to virtual try-ons, styling tips, or warranty information add modern interactive elements without cluttering physical packaging space.

What Critical Packaging Mistakes Should You Avoid?

Understanding frequent packaging errors helps prevent product damage, customer complaints, and negative reviews that can significantly harm your business reputation and sales.

Common mistakes include insufficient cushioning leading to scratched jewelry, inappropriate box sizes causing movement damage, neglecting anti-tarnish protection for silver pieces, using acidic materials that accelerate tarnishing, and inconsistent packaging procedures. These errors result in damaged products, unhappy customers, and increased return costs.

Learning from common mistakes helps establish robust packaging procedures that consistently deliver positive customer experiences and protect your brand reputation.

Protection and Material Errors

Mixed storage of different metals in single containers can cause chemical reactions and accelerated tarnishing. Always separate silver from other metals and provide individual compartments or pouches for each piece to prevent galvanic corrosion.

Acidic materials including regular paper and some cardboards can tarnish metals over time through chemical reactions. Use only acid-free tissue paper and archival-quality storage materials for long-term protection and customer satisfaction.

Sizing and Design Problems

Oversized packaging increases shipping costs significantly while providing poor protection due to excessive item movement during transit. Undersized boxes risk damage from compression and create negative unboxing experiences that disappoint customers.

Poor insert design that doesn’t properly secure items leads to shifting during transport, tangled chains, and scratched surfaces that require costly replacements and damage brand reputation.

Process Consistency Issues

- Inadequate cushioning: Leads to scratched surfaces and damaged settings

- Moisture-trapping materials: Accelerates tarnishing in humid conditions

- Inconsistent procedures: Creates variable quality and customer experiences

- Cost-cutting consequences: Often increases total costs through returns and replacements

Quality Control Implementation

Establish standardized procedures that all team members follow regardless of order volume or time pressure constraints. Document your packaging procedures and provide comprehensive training to ensure consistent execution across all orders and staff members.

Calculate true costs including potential damage claims when evaluating packaging investments, as quality packaging represents insurance against much higher costs associated with customer dissatisfaction and product replacement requirements.

Summary

Professional jewelry packaging requires careful material selection, appropriate protection methods, and attention to customer experience details. Success depends on understanding each jewelry type’s specific needs, implementing effective anti-tarnish protection, choosing correct box dimensions, and creating memorable unboxing experiences that encourage repeat business. Avoid common mistakes through consistent procedures and adequate protection investment.

Ready to elevate your jewelry brand with custom packaging solutions that protect your products while enhancing customer experience? Acreet specializes in creating premium jewelry packaging systems that combine optimal protection with stunning presentation. Contact us today for personalized packaging design consultations and discover how our expertise in custom box manufacturing can transform your brand’s unboxing experience and customer satisfaction.