Are you struggling to choose the right packaging solution for your products? With shipping costs soaring and warehouse space at a premium, understanding the key differences between collapsible and standard rigid boxes could save your business thousands of dollars annually. The wrong choice might leave you paying 60% more in shipping costs while your storage space remains frustratingly inefficient.

Collapsible rigid boxes can reduce shipping costs by 50-70% and save up to 75% storage space compared to standard rigid boxes, while maintaining identical premium quality and protection. Standard rigid boxes cost $2-$15+ per unit and arrive pre-assembled, while collapsible versions cost $1.10-$5.50+ per unit and require 1-2 minutes assembly time.

Let’s explore these packaging options in detail to help you make the most cost-effective choice for your business.

Table of Contents

ToggleWhat Exactly Is a Standard Rigid Box?

Understanding standard rigid boxes helps you appreciate why they’ve dominated luxury packaging for decades.

Standard rigid boxes, also known as set-up boxes, are premium packaging solutions constructed from thick chipboard or paperboard that is typically 2-6mm thick – approximately four times thicker than regular folding cartons. These boxes maintain their rigid structure permanently and arrive pre-assembled, requiring no additional setup.

Standard rigid boxes represent traditional luxury packaging at its finest. Once manufactured, they retain their box form from production to end-user, making them immediately ready for use but requiring substantial storage and shipping space.

The construction process involves wrapping the rigid chipboard structure with decorative specialty paper, fabric, or luxury materials like leather textures. This method provides maximum durability and creates an unmistakable impression of premium quality.

Key Construction Features:

Standard rigid boxes cannot collapse or fold, maintaining their dimensional integrity throughout their lifecycle. The thick chipboard foundation provides exceptional structural strength, making these boxes ideal for heavy products or items requiring maximum protection.

The wrapping process ensures smooth, professional finishes that enhance brand perception and customer unboxing experience. Most standard rigid boxes feature reinforced corners and edges that withstand repeated handling without showing wear.

Immediate Usability Benefits:

- Zero assembly time required upon delivery

- Consistent structural integrity from manufacture to end-use

- No training needed for staff handling

- Ready for immediate product placement and shipping

| Feature | Standard Rigid Box | Business Impact |

|---|---|---|

| Assembly Time | 0 minutes | Immediate productivity |

| Storage Requirement | 100% volume | Higher warehouse costs |

| Durability | Maximum strength | Superior product protection |

| Labor Needs | None | No additional staffing |

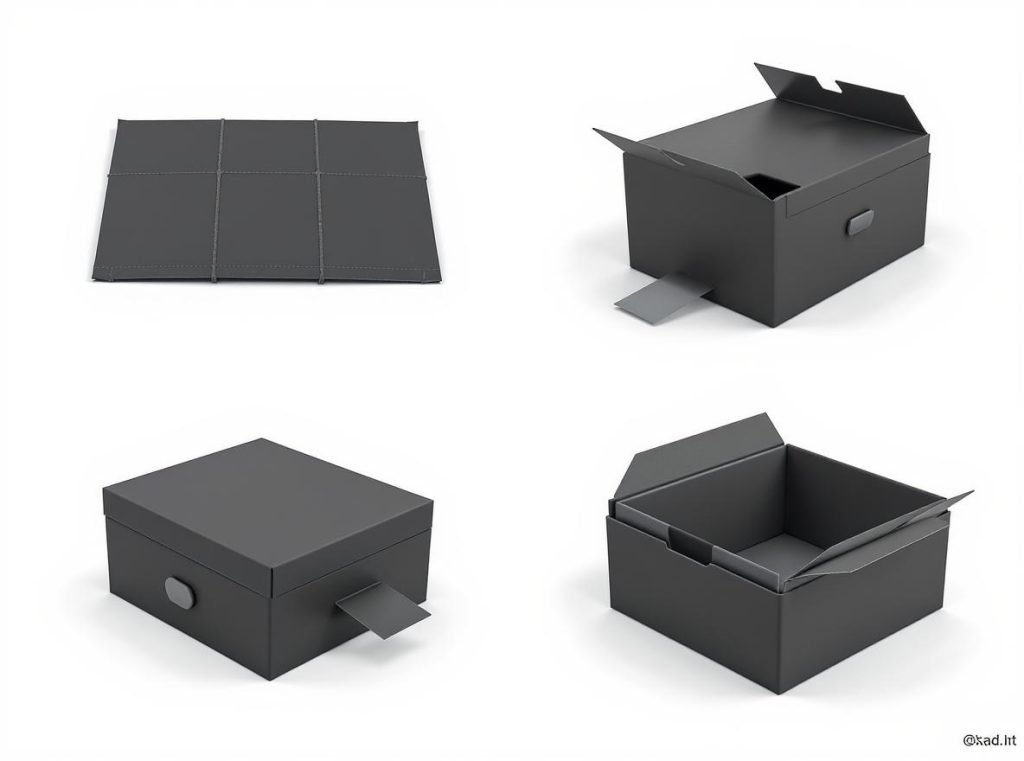

How Do Collapsible Rigid Boxes Work?

Collapsible rigid boxes represent an innovative engineering solution that maintains luxury appeal while dramatically improving logistics efficiency.

Collapsible rigid boxes combine the premium look and feel of traditional rigid boxes with flat-pack shipping advantages. These boxes fold completely flat using precision die-cutting and scoring techniques, then assemble in 1-2 minutes using magnetic closures, adhesive strips, or interlocking panels.

The engineering behind collapsible designs focuses on maintaining structural integrity while enabling complete collapse. Advanced scoring techniques create fold lines that remain invisible when the box is assembled, preserving the premium aesthetic customers expect.

Assembly Mechanisms:

Modern collapsible rigid boxes utilize several closure systems designed for ease of use. Magnetic closures feature concealed magnets embedded beneath surface materials, creating seamless assembly without visible hardware.

Adhesive strip systems use double-sided tape applied to corner flaps, providing secure closure while maintaining clean lines. Interlocking panel designs feature tabs that snap into place, creating mechanical connections that rival permanently assembled boxes.

Quality Maintenance During Collapse:

The folding capability doesn’t compromise material quality or thickness. Collapsible boxes use the same 2-6mm chipboard as standard versions, maintaining identical protective properties and luxury feel.

Engineering Precision:

Precision die-cutting ensures perfect fold alignment every time. Reinforcement points at critical stress areas prevent wear during repeated folding cycles, while strategic scoring placement maintains box aesthetics.

The assembly process transforms flat sheets into fully functional luxury packaging that provides high durability comparable to standard rigid boxes, maintaining premium presentation and protective qualities.

What Are the Main Storage and Shipping Differences?

Storage and shipping efficiency often determine which box type delivers better return on investment for your packaging budget.

Collapsible rigid boxes achieve 50-70% reduction in shipping costs and enable 2.5 times more units per shipping container compared to standard rigid boxes. They can be stored flat when not in use, dramatically reducing warehouse space requirements by up to 75%.

The space efficiency advantage becomes immediately apparent when comparing shipping volumes. Standard rigid boxes maintain full dimensions throughout transport, requiring substantial container space regardless of whether they’re filled with products.

Shipping Volume Comparison:

A typical shipping container holds approximately 1,000 standard rigid boxes due to their permanent dimensions. The same container accommodates 2,500 collapsible boxes in flat-pack form, representing a revolutionary improvement in shipping efficiency.

This volume difference translates directly to cost savings. For a typical order of 1,000 units, standard rigid boxes might cost $2,500-$4,000 in shipping charges, while collapsible versions cost only $800-$1,500 for the same quantity.

Storage Efficiency Benefits:

Warehouse space costs continue rising in most markets, making storage efficiency increasingly important. Collapsible boxes store flat when not needed, allowing businesses to maintain larger inventory levels in existing spaces or reduce storage rental costs.

Practical Storage Applications:

- Seasonal businesses can store off-season inventory efficiently

- E-commerce operations maximize warehouse capacity

- Retail locations maintain backup packaging without dedicating excessive storage space

- Distribution centers process larger order volumes in existing facilities

The storage advantage compounds over time, with monthly savings ranging from $200-$300 for businesses maintaining moderate packaging inventories.

| Storage Aspect | Standard Rigid | Collapsible Rigid | Efficiency Gain |

|---|---|---|---|

| Warehouse Space | 100% volume | 25% volume | 75% space savings |

| Shipping Container Capacity | 1,000 units | 2,500 units | 150% more units |

| Monthly Storage Costs | Full expense | Reduced by 60-75% | $200-$300 savings |

Which Box Type Is More Cost-Effective for Your Business?

Total cost analysis reveals surprising differences between initial pricing and long-term value propositions.

Standard rigid boxes cost $2-$15+ per unit while collapsible rigid boxes cost $1.10-$5.50+ per unit. When factoring shipping and storage expenses, collapsible boxes deliver 60-75% of total standard rigid box costs, with break-even points occurring at order quantities as low as 500 units.

Initial unit pricing might suggest standard boxes offer better value, but comprehensive cost analysis tells a different story. The precision engineering required for collapsible designs adds minimal manufacturing cost while delivering substantial operational savings.

Detailed Cost Breakdown:

Manufacturing costs for collapsible boxes include specialized die-cutting and scoring processes. However, these upfront investments quickly generate returns through reduced logistics expenses.

For businesses ordering 1,000+ units annually, the financial impact becomes significant:

Standard Rigid Box Total Costs:

- Unit cost: $2-$15+ per box

- Shipping expenses: $2,500-$4,000 per 1,000 units

- Storage costs: $300-$500 monthly for warehouse space

- Assembly labor: $0 (pre-assembled)

Collapsible Rigid Box Total Costs:

- Unit cost: $1.10-$5.50+ per box

- Shipping expenses: $800-$1,500 per 1,000 units

- Storage costs: $75-$125 monthly for warehouse space

- Assembly labor: $50-$100 for batch assembly

Return on Investment Timeline:

The break-even analysis favors collapsible designs for most business scenarios. Companies ordering 500+ units typically recover any additional manufacturing costs within 2-3 months through shipping and storage savings.

Volume-Based Advantages:

Larger order quantities amplify the cost advantages of collapsible designs. Businesses ordering 5,000+ units annually often save $10,000-$15,000 in total packaging costs by choosing collapsible options over standard rigid boxes.

How Do Assembly Requirements Compare?

Assembly considerations impact operational workflow and labor allocation in measurable ways.

Standard rigid boxes require zero assembly time and arrive ready for immediate use, while collapsible boxes need 1-2 minutes per unit for setup. Assembly labor costs typically range from $50-$100 for batch processing of 1,000 units, representing minimal impact compared to shipping and storage savings.

The assembly factor influences workflow planning, but modern collapsible designs minimize this concern through user-friendly engineering. Most assembly processes require no tools and can be mastered by any staff member with minimal training.

Standard Box Workflow:

Pre-assembled boxes eliminate setup time, allowing immediate transition to product packaging and shipping. This approach suits high-volume operations where every minute counts and assembly space is limited.

Quality control focuses solely on inspecting the assembled box and verifying proper closure after product placement. No assembly variables exist to create potential quality issues.

Collapsible Box Assembly Process:

Modern collapsible designs prioritize intuitive assembly sequences. Most boxes feature clear folding patterns that workers learn quickly, typically mastering the process within 10-15 practice attempts.

Assembly Training Requirements:

- Initial training: 15-30 minutes per worker

- Proficiency development: 50-100 practice assemblies

- Quality control: Visual inspection of fold alignment and closure security

- Batch processing: Most efficient assembly method for volume operations

Operational Efficiency Analysis:

The 1-2 minute assembly time per box translates to labor costs of $50-$100 per 1,000 units, assuming standard warehouse labor rates. This minimal expense pales compared to the $1,500-$3,000 savings in shipping costs alone.

Time Management Benefits:

Assembly can occur during lower-activity periods, optimizing labor utilization without disrupting primary fulfillment operations. Many businesses integrate assembly into inventory receiving processes, eliminating dedicated assembly time.

What About Durability and Protection Differences?

Product protection capabilities determine whether your packaging adequately safeguards valuable merchandise during handling and transport.

Both collapsible and standard rigid boxes provide excellent protection using identical 2-6mm thick chipboard construction. When properly assembled, collapsible boxes deliver high durability comparable to standard versions, with zero damage rates reported for properly designed applications.

Material specifications remain consistent between both box types, ensuring equivalent protective performance. The folding mechanism in collapsible designs doesn’t compromise structural integrity when assembly guidelines are followed correctly.

Construction Quality Standards:

Both box types utilize the same chipboard thickness ranges and wrapping materials. Premium options feature 3-6mm chipboard for maximum protection, while standard applications use 2-3mm thickness for cost-effective durability.

Surface materials, whether specialty papers, fabric, or leather textures, maintain identical specifications across both designs. The wrapping process follows the same quality standards regardless of collapsible functionality.

Impact Resistance Comparison:

Properly assembled collapsible rigid boxes demonstrate impact resistance equivalent to standard versions. The assembly process creates mechanical connections that distribute stress loads effectively throughout the structure.

Edge protection, corner reinforcement, and compression strength remain consistent when assembly procedures are followed correctly. The folding mechanism is engineered to maintain structural integrity under normal shipping and handling conditions.

Long-term Durability Factors:

- Moisture resistance: Identical performance with proper material selection and assembly

- Compression strength: Equal capacity for stacking and storage pressure

- Structural integrity: Same reinforcement capabilities when correctly assembled

- Wear resistance: Comparable surface durability and protection

Quality Control Considerations:

Assembly quality directly impacts protection performance for collapsible designs. Proper training ensures consistent assembly techniques that maximize durability potential.

| Protection Factor | Standard Rigid | Collapsible Rigid | Performance Difference |

|---|---|---|---|

| Impact Resistance | Excellent | Excellent (when assembled) | None |

| Edge Protection | Maximum | Maximum (with proper assembly) | None |

| Compression Strength | High | High (correctly assembled) | None |

| Long-term Durability | Excellent | Excellent (quality assembly) | None |

Which Industries Benefit Most from Each Box Type?

Different industries have operational characteristics that favor one box type over another based on volume, storage, and customer experience requirements.

E-commerce and direct-to-consumer brands benefit most from collapsible rigid boxes due to shipping cost advantages and storage constraints, while luxury retail stores and high-end electronics prefer standard rigid boxes for immediate display readiness and maximum perceived value.

Industry requirements vary in ways that influence optimal packaging selection. Understanding these patterns helps businesses align choices with operational realities and customer expectations.

E-commerce and Online Retail Applications:

Online businesses typically operate from limited warehouse space while managing high shipping volumes. Collapsible rigid boxes address both constraints effectively through space efficiency and shipping cost reduction.

These businesses benefit from:

- 50-70% reduction in inbound packaging shipping costs

- Maximized warehouse inventory capacity for product storage

- Flexible inventory management during seasonal fluctuations

- Lower storage rental expenses or expanded product inventory space

Luxury Electronics and Premium Products:

High-end electronics manufacturers often prefer standard rigid boxes for their maximum durability and immediate presentation readiness. These products require zero assembly variables and consistent structural integrity for retail display applications.

Premium electronics benefit from the perceived value that immediate, professional presentation provides to customers, making the additional storage and shipping costs worthwhile investments.

Subscription Box and Fulfillment Services:

Companies shipping recurring orders favor collapsible designs for their storage efficiency and cost management benefits. The assembly time integrates smoothly into fulfillment workflows, while the space savings enable larger inventory management.

Cosmetics and Personal Care Brands:

Emerging cosmetics brands particularly benefit from collapsible options, achieving premium presentation while controlling operational costs. Established luxury brands may prefer standard boxes for traditional retail channel compatibility.

Corporate Gifting and Promotional Products:

Businesses with seasonal or project-based packaging needs appreciate collapsible boxes’ storage advantages between usage periods. The flat storage capability enables maintaining larger inventories for unexpected opportunities.

Bulk B2B and Industrial Applications:

Companies packaging heavy products or serving industrial markets often prefer standard rigid boxes for their immediate strength and reliability without assembly quality variables.

The optimal choice depends on balancing storage constraints, volume requirements, assembly capabilities, and customer experience priorities specific to each industry’s operational model and distribution channels.

Making the Right Choice for Your Packaging Strategy

Strategic packaging decisions require evaluating multiple factors beyond initial unit costs to optimize long-term business performance.

Choose standard rigid boxes if you prioritize immediate usability, have minimal storage constraints, operate primarily through traditional retail channels, or package extremely heavy products requiring maximum structural integrity without assembly variables.

Standard rigid boxes excel in situations where operational efficiency depends on eliminating any assembly requirements and where storage space costs remain secondary to immediate functionality.

Choose collapsible rigid boxes if shipping and storage costs significantly impact your profitability, you operate primarily in e-commerce or direct-to-consumer sales, you need storage flexibility for seasonal operations, or you want premium presentation while controlling operational expenses.

Collapsible designs prove optimal for businesses where logistics efficiency directly affects bottom-line performance and where minimal assembly requirements can be accommodated within existing workflows.

Implementation Considerations:

Both options offer complete customization capabilities, premium aesthetic appeal, and excellent product protection when properly specified. Success depends on aligning your choice with operational requirements, cost structure priorities, and customer experience objectives.

For businesses uncertain about the optimal choice, consider starting with smaller test quantities to evaluate assembly workflows, storage benefits, and customer response before committing to larger inventory investments.

Partnership Opportunities:

Working with an experienced packaging manufacturer like Acreet ensures proper specification of either box type to meet your specific requirements. Professional guidance helps optimize material selection, closure mechanisms, and customization options for maximum effectiveness and cost efficiency.

Summary

Understanding the differences between collapsible and standard rigid boxes empowers informed packaging decisions that significantly impact operational costs and efficiency. Collapsible boxes deliver 50-70% shipping cost reductions and 75% storage space savings while maintaining identical premium quality and protection. Standard rigid boxes provide immediate usability and maximum durability without assembly requirements, making them ideal for specific operational scenarios.

Your optimal choice depends on shipping volume, storage capacity, assembly capabilities, and cost priorities. Consider consulting with Acreet’s packaging experts to develop custom solutions that optimize both functionality and cost-effectiveness for your specific business requirements and market positioning.