Choosing the wrong box style can cost your business thousands in damaged products, excessive packaging materials, or shipping inefficiencies. As a packaging decision-maker, understanding the fundamental differences between Regular Slotted Cartons (RSC) and Full Overlap (FOL) boxes is crucial for optimizing your shipping operations and protecting your products during transit.

The main difference lies in flap design: RSC boxes have flaps that meet in the middle of the box opening, while FOL boxes feature extended flaps that completely overlap to the opposite side. This structural difference impacts strength, material usage, assembly time, and cost-effectiveness for different shipping applications.

Understanding these distinctions will help you make informed packaging decisions that balance protection, efficiency, and budget considerations for your specific products and shipping requirements.

Table of Contents

ToggleWhat Exactly Is a Regular Slotted Carton (RSC)?

RSC boxes dominate the packaging industry as the go-to solution for countless businesses worldwide. Understanding RSC characteristics helps you evaluate whether this standard option meets your specific shipping needs.

A Regular Slotted Container is the most common and widely used box style in the packaging industry. All four flaps on both the top and bottom are the same length, with the two outer flaps meeting perfectly in the middle when closed, creating a consistent, rectangular shape that’s easy to tape and stack.

The RSC design features a straightforward construction where all flaps have equal length. The two outer flaps are normally the lengthwise flaps and are one-half the container’s width, ensuring they meet at the center of the box when closed. This creates the characteristic seam down the middle where major panels are typically taped together.

RSC boxes are made from one piece of corrugated fiberboard and delivered flat, saving valuable storage space for businesses with limited warehouse capacity. Most RSC boxes can be constructed from recycled kraft paper or FSC-certified materials for sustainability-focused operations.

Key structural characteristics include:

- Equal-length flaps creating perfect center alignment

- Single-piece corrugated construction with manufacturer’s joint

- Compatible with both manual and automated packaging systems

- Available in single-wall, double-wall, or triple-wall configurations

- Minimum sizing constraints: height ≥2 inches, width ≥3 inches

What Makes a Full Overlap (FOL) Box Different?

FOL boxes represent a premium approach to corrugated packaging, designed specifically for demanding shipping environments where standard protection isn’t sufficient.

Full Overlap boxes are characterized by their unique design where all flaps are approximately the width of the box, and when closed, the outer flaps extend all the way to the opposite side and completely overlap, creating essentially a double-thick construction that significantly enhances structural integrity.

The defining feature distinguishes FOL from all other box styles: complete flap overlap rather than meeting at the center. When properly closed, the outer flaps come within one inch of complete overlap, with approximately a 1/8-inch gap allowing flaps to lie flat without tension.

FOL boxes offer configuration flexibility with overlapping flaps available on top only, bottom only, or both surfaces depending on protection requirements. This adaptability allows customization based on product vulnerability and specific handling conditions.

Enhanced protection features include:

- Complete flap overlap creating multiple corrugated layers

- Superior stacking capability under heavy loads

- Enhanced resistance to compression and crushing forces

- Improved corner and edge protection during transit

- Better security against accidental opening during handling

How Do Assembly and Sealing Methods Compare?

Assembly efficiency directly impacts packaging operation productivity and labor costs. The practical differences between RSC and FOL assembly create significant operational considerations.

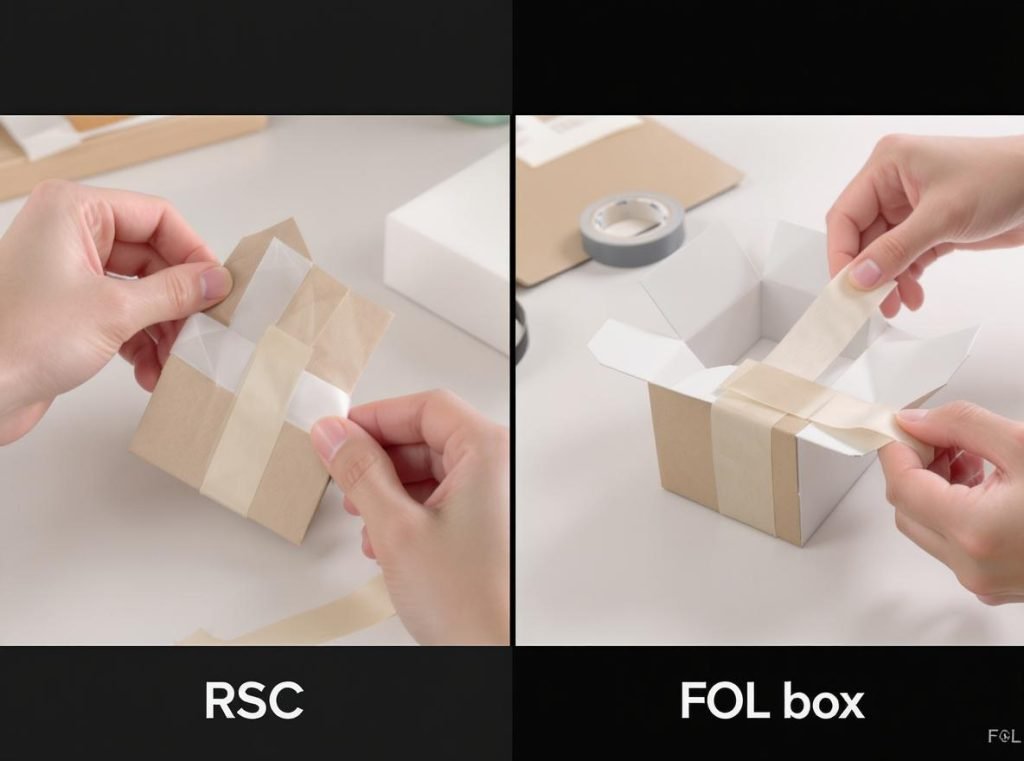

RSC boxes require more tape to seal effectively due to shorter flaps that can spring back open, while FOL boxes often need only minimal tape because their overlapping design creates natural closure strength and easier sealing.

RSC assembly involves folding four equal-length flaps toward the center, requiring careful positioning for proper alignment. Two smaller inner flaps fold first, followed by two larger outer flaps folding on top for closure. However, the shorter flaps can be difficult and challenging to fold and secure because they want to spring back into an open position.

FOL assembly offers operational advantages despite using more material. The extended flaps provide larger surfaces for secure tape application, and often only a small tab of tape is necessary to hold the closure. FOL boxes are much easier and quicker to seal, usually with much less tape than RSC alternatives.

| Assembly Factor | RSC Boxes | FOL Boxes |

|---|---|---|

| Tape Requirements | Higher (flaps spring back, need more strips) | Lower (single strip often sufficient) |

| Assembly Speed | Fast once mastered | Slightly slower initial positioning |

| Sealing Difficulty | Challenging due to short flaps | Easy due to overlap strength |

| Worker Training Time | Minimal | Minimal to moderate |

| Closure Security | Good with proper taping technique | Excellent due to self-reinforcing design |

Which Box Style Offers Better Strength and Protection?

Product protection remains the critical factor determining packaging success or failure. Comparing structural performance helps identify which box style suits specific protection requirements and shipping conditions.

FOL boxes provide superior strength and protection due to their overlapping flap design that creates essentially double-, triple-, or quadruple-wall construction, while RSC boxes offer adequate protection for standard applications but have vulnerabilities at the center seam and are susceptible to crushing.

RSC boxes have inherent structural limitations that affect their protective capability. The design creates a weak joint where major flaps come together in the middle, especially if not taped properly. Large spans of unsupported corrugated make RSC designs very susceptible to crushing and corner damage during handling.

FOL boxes excel in demanding shipping environments through multiple protection mechanisms. The overlapping flaps enhance structural integrity, preventing collapse or deformation even when stacked with other boxes. The multiple overlapping layers of corrugated prevent edge and corner damage while providing superior resistance to external impacts.

Protection performance comparison:

- Compression resistance: FOL superior due to double-layer strength

- Edge crush protection: FOL significantly higher from multiple layers

- Stacking capability: FOL handles much heavier loads safely

- Impact resistance: FOL provides better cushioning against drops

- Rough handling tolerance: FOL especially resistant to shipping abuse

What Are the Cost Implications of Each Box Style?

Budget considerations significantly influence packaging decisions, particularly for high-volume operations where small per-unit differences create substantial financial impact over time.

RSC boxes cost less initially because they use less material and require no custom tooling, while FOL boxes have higher material costs but can provide better long-term value through reduced product damage, lower labor costs, and decreased tape usage.

RSC cost advantages stem from material efficiency and production simplicity. RSC boxes use less material, translating to direct cost savings. They don’t require any tooling to create custom sizes, unlike die-cut alternatives that typically cost $800-1200 in tooling expenses. Print plates are generally lower in cost as well compared to more complex packaging designs.

FOL boxes have higher upfront material costs due to extended flaps requiring more corrugated material. However, total cost analysis reveals potential savings through operational efficiency. FOL boxes require less tape for sealing, reducing material and labor costs. The easier sealing process can lower labor expenses, and superior protection reduces damage-related costs including returns and replacements.

Long-term cost considerations include:

- Initial material costs (RSC lower, FOL higher)

- Tooling requirements (RSC none, FOL minimal)

- Labor efficiency (FOL faster sealing, less rework)

- Damage prevention (FOL significantly better protection)

- Customer satisfaction impact (FOL enhanced experience)

- Total cost of ownership analysis favoring appropriate application selection

When Should You Choose RSC Over FOL Boxes?

Selecting RSC boxes optimizes operations when standard protection meets requirements and cost efficiency takes priority over maximum strength.

Choose RSC boxes when shipping lightweight to medium items like clothing and small electronics, when cost-efficiency is the primary concern, or when you need the most efficient corrugated box option for high-volume, fast-paced packaging operations.

RSC boxes work exceptionally well for products that are sturdy and don’t have vulnerable damage issues. They’re ideal for general shipping applications where standard protection suffices, and automated packaging systems benefit from their standardized dimensions and quick assembly requirements.

Optimal RSC applications include:

- Lightweight to medium-weight products under normal shipping conditions

- High-volume operations prioritizing speed and efficiency over maximum protection

- Budget-conscious shipping programs where material costs are critical

- Products with additional protective packaging inside the box

- Standard e-commerce fulfillment operations handling durable goods

- Automated packaging lines requiring consistent, predictable box behavior

RSC boxes excel when storage optimization matters, as their flat-pack delivery saves warehouse space. They’re perfect for businesses needing custom sizes without tooling costs, making them incredibly flexible for varying product dimensions.

When Should You Choose FOL Over FOL Boxes?

FOL boxes serve specific applications where enhanced protection justifies additional material investment and operational considerations.

Choose FOL boxes when shipping fragile electronics, glassware, machinery, heavy items, or products requiring extra protection during transit, especially when packages will endure rough handling or be stacked on their side.

FOL boxes are specifically recommended for challenging shipping scenarios including heavy machinery, fragile electronics, antiques, family heirlooms, mirrors, and paintings. They excel when products require superior crush resistance and edge protection during multiple handling points.

Critical FOL applications include:

- Heavy items requiring enhanced stacking strength and structural integrity

- Fragile or valuable products where damage costs exceed material savings

- Long-distance shipping with multiple handling points and rough conditions

- Products shipped in harsh environmental conditions or rough handling zones

- Items that will be stacked on their side during storage or transport

- Premium products where packaging quality reflects brand standards

FOL boxes deliver superior performance for long items that might be vulnerable to crushing in standard packaging, and applications requiring maximum corner and edge protection during extended shipping cycles.

How Do RSC and FOL Boxes Impact Branding and Customer Experience?

Packaging serves as a crucial brand touchpoint that influences customer perception, unboxing experience, and overall satisfaction with product delivery.

Both RSC and FOL boxes offer excellent customization opportunities for branding, but FOL boxes really shine when you want your packaging to make a bold, premium statement with their substantial construction delivering a more premium, sturdy feel.

RSC boxes provide extensive branding capabilities at lower costs. They can be customized with printed graphics and branding, enhancing visual appeal while remaining highly and easily customizable. Recent advancements make interior printing possible on RSCs at minimal added cost, while creative options like printed tape have leveled the playing field between RSC and premium packaging alternatives.

FOL boxes can also be customized with branding and graphics and are often used for premium or high-end products. Their substantial construction creates positive first impressions when customers receive shipments. Enhanced protection minimizes damage risk, leading to improved customer satisfaction and reduced returns.

| Branding Factor | RSC Advantage | FOL Advantage |

|---|---|---|

| Cost per branded impression | Lower material costs | Premium positioning |

| Perceived quality | Standard, functional | Premium, substantial |

| Customization flexibility | Extensive options available | Extensive with premium appeal |

| Unboxing experience | Functional and familiar | Enhanced and memorable |

| Brand message alignment | Efficiency and value-focused | Quality and premium-focused |

What Are the Environmental Considerations?

Sustainability increasingly influences packaging decisions as businesses and consumers prioritize environmental responsibility while maintaining operational efficiency.

RSC boxes use less material making them more resource-efficient, while FOL boxes may actually be more sustainable in many applications due to superior protection reducing product damage and the reduced need for additional packaging materials.

RSC environmental advantages include lower material consumption, reduced resource usage during manufacturing, and typically made from 100% recyclable materials. They can be manufactured from recycled kraft paper or FSC-certified materials, supporting circular economy principles.

However, comprehensive environmental analysis reveals that FOL boxes may offer superior sustainability benefits despite higher material usage. Superior protection reduces product damage, minimizing waste from damaged goods requiring replacement. The reduced need for additional packaging materials due to inherent strength, combined with less tape required for sealing, can reduce overall environmental impact.

Environmental decision factors include:

- Raw material consumption (RSC lower per unit)

- Product damage prevention (FOL superior protection)

- Transportation efficiency and carbon footprint optimization

- End-of-life recyclability (both excellent when properly disposed)

- Total packaging system environmental impact

- Product-to-packaging ratio optimization for specific applications

How Do These Box Styles Perform in Automated Packaging Systems?

Modern fulfillment operations increasingly depend on automated packaging systems for efficiency, consistency, and cost control in high-volume operations.

RSC boxes are well-suited for automated packaging systems due to standardized dimensions and quick assembly, while FOL boxes can work effectively in automation but may require specialized handling equipment due to their unique flap configuration.

RSC boxes work well with both manual and automated packing processes. Their standardized dimensions facilitate consistent machine handling, quick assembly supports high-speed automated lines, and consistent flap dimensions ensure reliable machine folding and sealing. For optimal automation performance, RSC boxes must meet precise quality standards including squareness, tight dimensional tolerances, quality score lines for clean folding at high speeds, and consistent glue seam integrity.

FOL boxes offer specific automation advantages despite requiring some equipment modifications. Their reduced tape usage can simplify sealing mechanisms, self-reinforcing design reduces dependency on perfect tape application, and better performance under automated stacking due to superior crush resistance.

Automation compatibility considerations:

- Equipment setup and changeover requirements

- Machine programming complexity for different flap configurations

- Quality control standards and reject rate management

- Production speed capabilities and throughput optimization

- Maintenance requirements and system downtime minimization

- Investment in specialized handling equipment for FOL applications

What Custom Options Are Available for Each Box Style?

Customization capabilities enable businesses to optimize packaging for specific products, brand requirements, and operational efficiency while maintaining cost-effectiveness.

Both RSC and FOL boxes offer extensive customization options including unlimited size variations within manufacturing constraints, multiple material specifications, comprehensive printing capabilities, and structural modifications to meet specific application requirements.

RSC customization offers significant flexibility without tooling costs. Custom sizes can be created without expensive tooling requirements, with the ability to right-size packaging to exact dimensions needed. Material options include single-wall or double-wall construction, various flute types for different strength requirements, and multiple corrugated board grades for specific applications.

FOL customization provides additional structural options including flaps on top only, bottom only, or both surfaces, full overlap on all four panels or selective overlap configurations, and various corrugated board grades for different protection levels. Custom board thickness can be specified based on product requirements.

Both styles support extensive printing and branding options:

- Custom printed graphics and comprehensive branding capabilities

- Single/double-sided color printing with flood printing in PMS colors

- Interior printing capabilities for enhanced unboxing experiences

- Upload your own artwork with professional design support

- Premium presentation options for high-end product positioning

At Acreet, we specialize in creating custom RSC and FOL boxes perfectly tailored to your specific requirements. Our experienced design team works with you to optimize box specifications, material selection, and printing options, ensuring the perfect balance between protection, cost-effectiveness, and brand representation for your unique applications.

Summary

The choice between RSC and FOL boxes fundamentally depends on balancing protection requirements, cost considerations, and operational efficiency. RSC boxes excel as the industry standard for cost-effective applications with adequate protection needs, while FOL boxes provide superior strength and premium positioning for demanding shipping environments. Understanding your specific product vulnerability, shipping conditions, and budget constraints enables informed packaging decisions that optimize both product protection and business profitability.

Ready to optimize your packaging solution with the perfect box style? Contact Acreet today for expert consultation on RSC or FOL boxes precisely matched to your product requirements and shipping conditions. Our packaging specialists will analyze your specific needs, recommend the optimal box style, customize specifications, and ensure your products arrive safely while maintaining cost-effectiveness. Send us your packaging inquiry and discover how the right box choice can transform your shipping operations and enhance customer satisfaction.