When selecting packaging materials for your business, understanding board rigidity can make or break your product protection strategy. Many manufacturers struggle with flimsy packaging that fails during shipping, leading to damaged goods and unhappy customers.

The minimum thickness for rigid board packaging typically starts at 20 points (0.020″) for chipboard applications, while corrugated boards achieve rigidity at 125 points (0.125″) for single-wall construction. Professional rigid packaging commonly uses 40-120 PT boards, with 80 PT being optimal for most premium applications requiring maximum structural integrity.

This comprehensive guide will help you choose the perfect rigid board thickness for your packaging needs, ensuring your products arrive safely while optimizing costs.

Table of Contents

ToggleWhat Does “Rigid” Actually Mean in Packaging Terms?

Understanding rigidity goes beyond simple thickness measurements. The term describes packaging characterized by its sturdy and inflexible structure made from hard materials.

Rigid packaging maintains its shape even when empty, cannot be easily bent or deformed, and provides maximum protection during handling, transportation, and storage through materials like glass, metal, hard plastic, or thick paperboard.

Rigid packaging offers several key characteristics that distinguish it from flexible alternatives. Structural integrity ensures the container maintains its form throughout the supply chain, while inflexible design prevents damage from external forces. Material composition plays a crucial role, with hard materials providing the foundation for protective capabilities.

The regulatory definition for rigid plastic packaging containers (RPPCs) specifies they must have a “relatively inflexible shape or form” with capacity between 8 ounces and 5 gallons. This standardization helps manufacturers understand minimum performance expectations.

Durability represents another critical factor, offering resistance to external conditions like moisture, temperature fluctuations, and physical impact. These properties make rigid packaging ideal for premium products, fragile items, and long-distance shipping applications.

For businesses requiring maximum product protection, rigid packaging provides unmatched security compared to flexible alternatives, though this comes with increased material costs and storage requirements.

What Are the Standard Thickness Measurements for Rigid Boards?

The packaging industry uses multiple measurement systems, with the point system being the standard for paperboard thickness in the United States.

The point system measures thickness in thousandths of an inch (1 point = 0.001″), with common rigid board thicknesses including 10PT, 12PT, 14PT, 16PT, 20PT, and up to 120PT, with industry standard tolerance of ±5% caliper variation for consistent quality control.

| Measurement System | Range | Application |

|---|---|---|

| Point System (US) | 10-120 PT | Chipboard, luxury packaging |

| Metric (International) | 1-10mm | Global standards |

| GSM Weight | 350-1200+ GSM | European specifications |

| Corrugated Flutes | 1.5-15mm | Shipping containers |

The TAPPI T 411 standard uses 50 kPa (7.3 psi) pressure for official thickness measurements, ensuring consistent results across different testing facilities. This standardization allows accurate comparison between suppliers and materials.

Corrugated board classifications follow specific flute designations. E flute measures 1.5mm and provides the thinnest corrugated option for retail applications. B flute at 3mm offers versatile all-purpose performance, while C flute at 4mm represents the most common shipping grade. A flute at 5mm delivers excellent cushioning for fragile products.

International measurements use the metric system with millimeters or micrometers for precise specifications. GSM (Grams per Square Meter) provides weight-based measurements, with packaging materials typically requiring 350-400 GSM or higher for adequate rigidity.

Understanding these measurement systems helps specify requirements accurately when working with international suppliers or meeting regional compliance standards.

How Does Board Type Affect Minimum Rigidity Requirements?

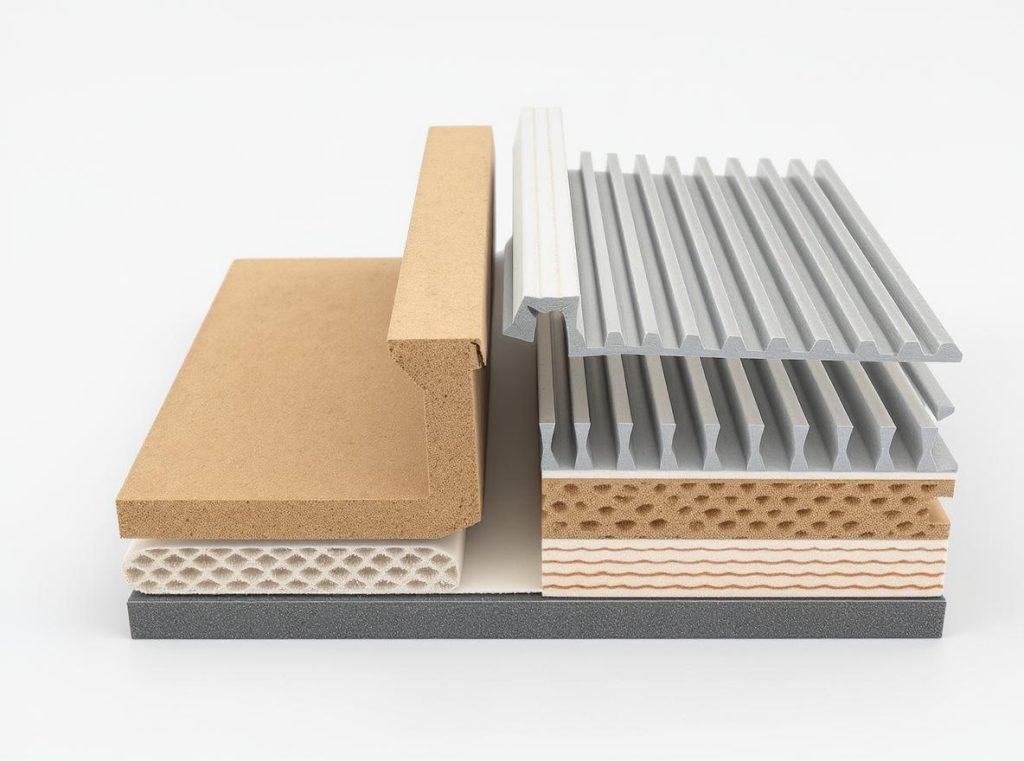

Different board materials achieve rigidity through distinct structural approaches, significantly impacting minimum thickness requirements for equivalent performance levels.

Chipboard requires 15-125 points thickness through dense single-layer construction, while corrugated boards achieve similar rigidity at 125+ points using multi-layer fluted structures, with each construction type offering unique advantages for specific applications.

Chipboard characteristics include thickness ranges from 0.015″ to 0.125″ using dense, compressed recycled fibers in single-layer construction. This material provides excellent stiffness despite thinner profiles, making it ideal for retail packaging, dividers, and luxury boxes where space efficiency matters.

Corrugated board characteristics feature thickness ranges from 0.125″ to 0.5″+ depending on wall construction. The multi-layer fluted structure between linerboards delivers superior compression and impact resistance, perfect for shipping boxes and heavy-duty packaging applications.

Load-bearing specifications demonstrate clear thickness-to-strength relationships based on testing data:

- 1mm board holds 0.5kg (1.1 lbs) and withstands 192.63 N/m² pressure

- 2mm board holds 2kg (4.4 lbs) and withstands 770.55 N/m² pressure

- 3mm board holds 5kg (11.0 lbs) and withstands 875.63 N/m² pressure

Wall construction variations provide different performance levels. Single-wall corrugated supports up to 120 lbs maximum weight according to Box Maker’s Certificate (BMC) standards. Double-wall corrugated handles up to 180 lbs maximum weight, while triple-wall corrugated manages up to 300 lbs maximum weight.

The choice between chipboard and corrugated depends on specific application requirements, with chipboard offering space efficiency and corrugated providing superior impact protection.

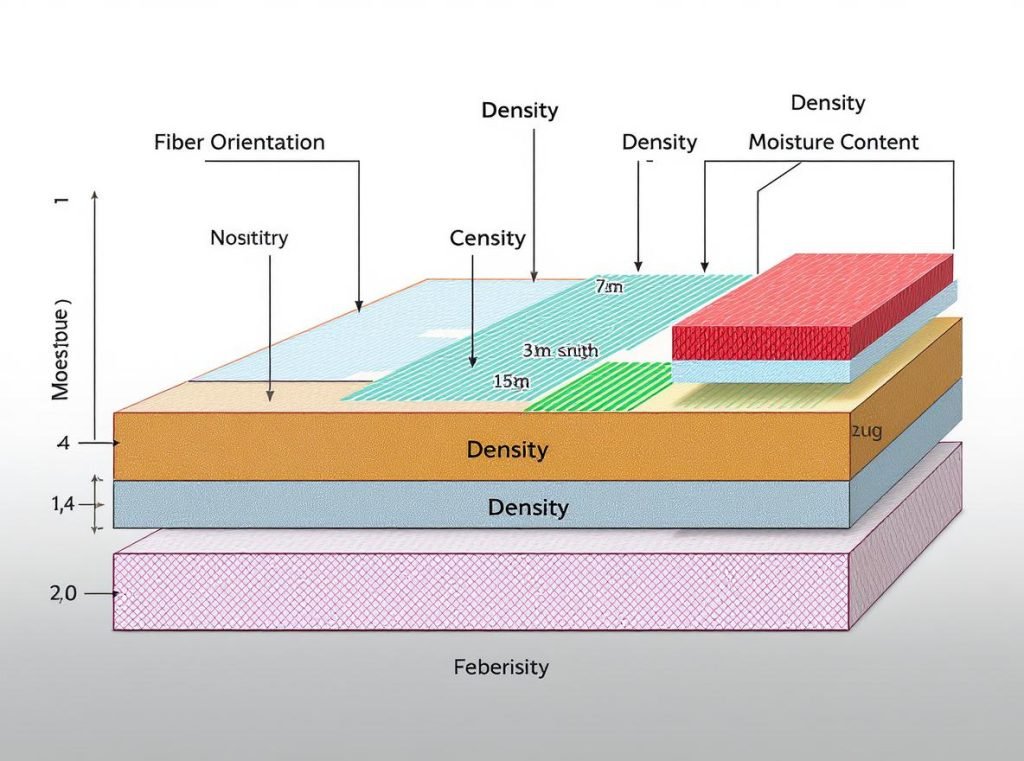

What Factors Besides Thickness Determine Board Rigidity?

Board rigidity results from complex interactions between multiple material and design characteristics beyond simple thickness measurements.

Key rigidity factors include fiber composition quality, manufacturing processes like calendering pressure, moisture content (optimal 7±1%), basis weight, density, and environmental conditions, with material properties often providing more performance impact than thickness increases alone.

Material properties significantly influence rigidity performance. Virgin fibers provide higher strength compared to recycled content, while fiber orientation affects stiffness differently in machine direction versus cross-direction. Basis weight and density increases typically improve structural integrity across all board types.

Manufacturing processes control final rigidity characteristics through several mechanisms:

- Calendering pressure increases density and stiffness during production

- Adhesive systems quality affects multi-layer board performance

- Surface treatments can enhance structural properties

- Quality control maintains consistent thickness throughout production runs

Environmental factors affect perceived rigidity significantly. Temperature and humidity impact fiber swelling and board dimensions, while moisture exposure can reduce compression strength by 20-40%. Storage conditions and age degradation from UV exposure can weaken fiber bonds over time.

Testing demonstrates that higher density boards often outperform thicker alternatives with lower density construction. This relationship explains why GSM measurements frequently provide better rigidity predictions than thickness measurements alone.

Understanding these interdependent factors helps optimize material selection for specific applications, balancing cost, performance, and environmental requirements effectively.

When Do You Need Different Rigidity Levels for Packaging?

Packaging applications require carefully matched rigidity levels based on product weight, shipping conditions, and protection requirements.

Lightweight products need 10-20 PT boards for cosmetics and food items, medium-duty applications require 20-40 PT boards for electronics and retail packaging, while heavy-duty applications demand 40-120 PT boards for luxury goods and maximum protection requirements.

| Application Category | Board Thickness | Typical Products | Weight Capacity |

|---|---|---|---|

| Lightweight | 10-20 PT | Cosmetics, cereals, stationery | Under 2 lbs |

| Medium-duty | 20-40 PT | Electronics, subscription boxes | 2-10 lbs |

| Heavy-duty | 40-120 PT | Jewelry, automotive parts | 10+ lbs |

| Shipping containers | 125-500 PT | Corrugated boxes | Up to 300 lbs |

Lightweight applications include cosmetics and personal care items, food products like cereals, greeting cards and stationery, and general retail packaging where presentation matters more than heavy-duty protection.

Medium-duty applications encompass subscription boxes, electronics packaging, premium retail presentation, and situations requiring moderate protection during distribution and handling.

Heavy-duty applications involve luxury goods and jewelry packaging, industrial components, automotive parts packaging, and any situation demanding maximum protection against impact and compression forces.

Box Maker’s Certificate (BMC) standards provide clear weight guidelines for corrugated applications. These specifications ensure safe transportation while preventing over-packaging that increases costs unnecessarily.

Shipping distance and handling frequency also influence rigidity requirements, with international shipments typically needing higher specifications than local deliveries due to increased handling cycles and potential rough treatment.

How Do You Test if Your Board Meets Rigidity Standards?

Professional rigidity testing ensures your packaging performs consistently under real-world conditions using standardized measurement protocols.

Primary testing methods include TAPPI T 411 thickness measurement at 50 kPa pressure, ASTM D642 compression testing for packaging systems, bending stiffness testing using four-point bending methods, and Edge Crush Test (ECT) for vertical crush resistance evaluation.

TAPPI T 411 represents the standard thickness measurement protocol, using 50 kPa (7.3 psi) pressure to measure single-sheet thickness variations. This test applies to paper, paperboard, and combined board materials, providing essential verification of manufacturer specifications.

ASTM testing standards offer comprehensive evaluation methods:

- ASTM D642 provides compression testing for complete packaging systems

- ASTM D4169 covers distribution testing for packages under various conditions

- ASTM D3043 evaluates structural panel flexural properties

- ASTM D645 offers equivalent testing to TAPPI T 411 for thickness verification

Specialized rigidity tests provide detailed performance data. Four-point bending method offers the most accurate results for corrugated boards, while two-point bending serves as the standard for solid boards. Professional L&W 4-Point Bending Testers deliver precise measurements expressed in mN (bending resistance) or mNm (bending moment).

Compression and crush tests evaluate structural performance under load. Edge Crush Test (ECT) measures vertical crush resistance, Box Compression Test (BCT) provides direct measurement of finished box performance, and Ring Crush Test evaluates compression strength of individual components.

International standards alignment ensures global compatibility through FEFCO, EN, ISO, and TAPPI harmonized testing methods, with ISO 2234:2015 and EN ISO 12048 covering European packaging standards.

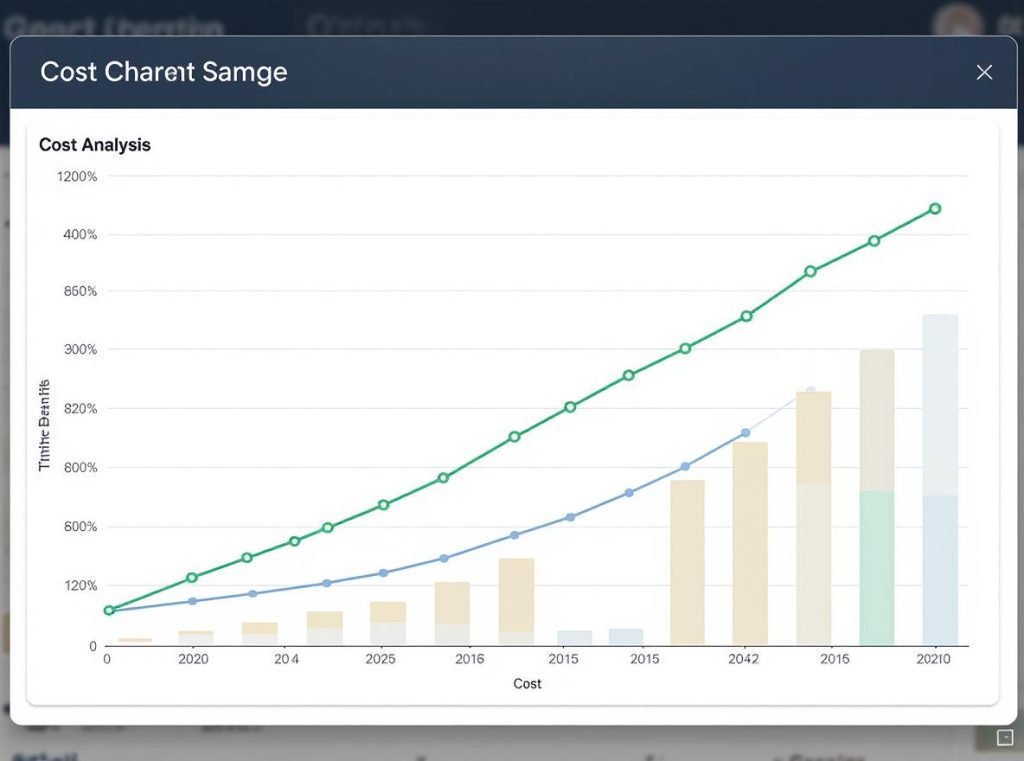

What Are the Cost Implications of Different Rigidity Levels?

Understanding the relationship between rigidity requirements and costs helps optimize packaging budgets while maintaining adequate product protection.

Material costs typically represent 70% of total packaging cost, with conversion processes adding 20% and overhead plus profits accounting for 10%, making material thickness optimization crucial for cost control while maintaining required performance levels.

Base material economics follow predictable patterns across thickness increases. Raw material costs dominate total expenses, with each point thickness increase adding measurable material cost. Conversion processes remain relatively stable across different thicknesses, while overhead and profit margins scale with material value.

Volume and efficiency considerations significantly impact per-unit costs:

- Bulk pricing reduces costs dramatically for large orders

- Die-cutting setup involves upfront tooling costs for custom shapes

- Inventory space requirements increase with thicker boards

- Shipping weight impacts transportation costs throughout the supply chain

Long-term value analysis reveals cost-benefit trade-offs beyond initial material expenses. Thicker boards reduce damage-related costs through improved product protection, while premium thickness enhances perceived brand value. Rigid boards often provide better reusability compared to thinner alternatives, and proper sizing prevents over-packaging costs.

Comparative economics data shows significant potential savings through smart material selection. Chipboard versus corrugated can deliver 30-50% cost reduction for appropriate applications, while material optimization typically achieves 15-20% reduction through strategic selection.

Case studies demonstrate that right-sizing technology, with 27% market growth projected for 2025, helps balance protection requirements with material efficiency for optimal cost performance.

For businesses seeking expert guidance on material selection that balances rigidity requirements with cost optimization, consulting experienced packaging manufacturers provides valuable insights into achieving the best performance-to-price ratio.

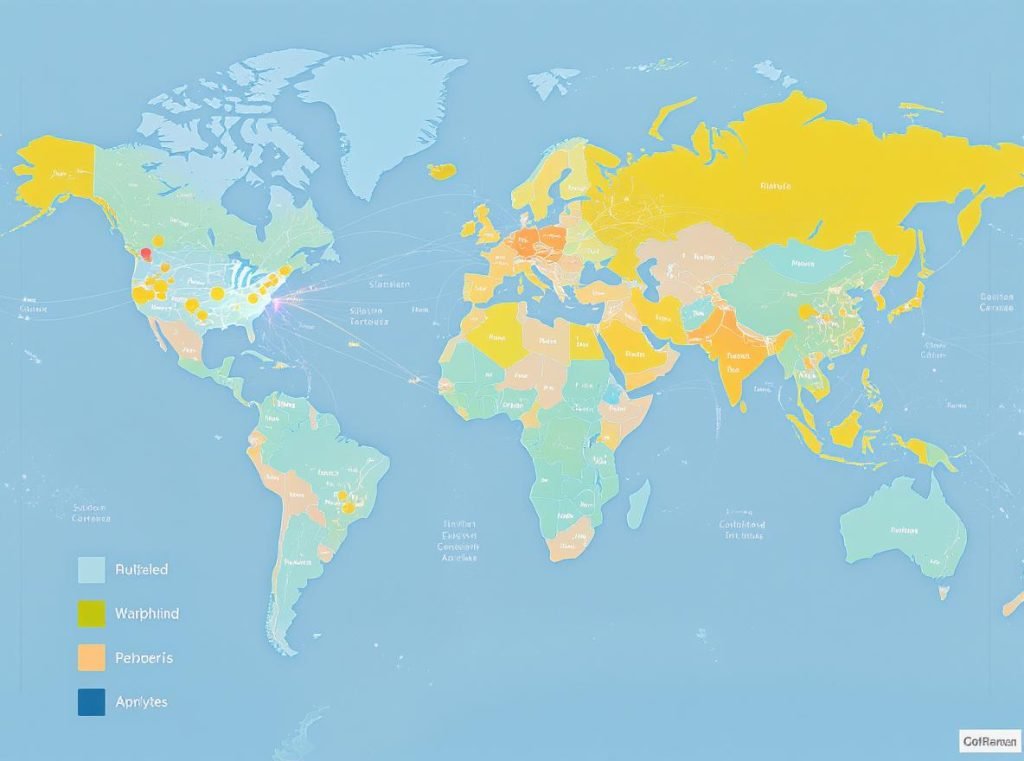

How Do Regional Standards Affect Rigidity Specifications?

Global packaging markets operate under different regulatory frameworks and performance standards, affecting how rigidity requirements are specified and evaluated across international markets.

United Nations packaging certification provides global standards for hazardous materials transport, while regional variations include FEFCO standards in Europe, TAPPI methodologies in North America, JIS standards in Japan, and ASTM specifications in the United States.

United Nations standards establish the global regulatory framework through UN packaging certification requirements for hazardous materials transport. Performance testing includes rigorous drop, compression, and leak tests with specific marking requirements using codes that indicate material types and test levels. This international recognition system works across multiple transportation modes.

Regional variations create specific compliance requirements for different markets. FEFCO (Europe) focuses on corrugated packaging standards and recyclability guidelines, while TAPPI (North America) emphasizes pulp and paper testing methodologies. JIS (Japan) provides Japanese Industrial Standards for packaging materials, and ASTM (US) offers American Society for Testing and Materials specifications.

Medical device packaging represents a specialized compliance area with ISO 11607 international standard for sterile medical device packaging. FDA recognition accepts both ISTA 3A and ASTM D4169 for medical applications, with material specifications including PETG, APET, and HIPS for rigid medical packaging that must withstand various sterilization methods.

International shipping requires packaging that meets the most stringent standards among origin, transit, and destination regions. This often means designing to the highest applicable rigidity requirements to ensure compliance throughout the entire supply chain.

Understanding these regional differences helps avoid costly compliance issues while optimizing material specifications for target markets and transportation requirements.

What Are the Latest Innovations in Rigid Board Technology?

The packaging industry continuously develops new materials and manufacturing techniques that deliver improved rigidity performance while addressing environmental and cost concerns.

2024-2025 innovations include bio-based materials like bamboo paper and bagasse alternatives, automated packaging systems with 27% projected market growth, smart sensors for IoT integration, and AI-driven design optimization achieving 15-20% material reduction while maintaining protection levels.

Sustainable material innovation focuses on bio-based alternatives including bamboo paper, bagasse, and palm leaf materials that meet rigidity requirements while supporting circular economy goals. The industry targets 100% recyclable or compostable materials, with hybrid solutions combining traditional and innovative materials for optimal performance.

Advanced manufacturing technologies drive efficiency improvements through automated packaging systems, right-sizing technology for dynamic package optimization, 3D printing applications for custom prototypes and short runs, and AI-driven design systems that optimize material usage and performance simultaneously.

Smart packaging integration incorporates Internet of Things (IoT) applications including smart sensors for time-temperature indicators and freshness monitoring. RFID integration provides track-and-trace capabilities throughout the supply chain, while QR codes and NFC enable enhanced consumer interaction and authentication. Digital printing advances support variable data and personalization capabilities.

Market growth projections indicate significant expansion opportunities. The global rigid packaging market reaches $609.27 billion in 2025, growing to $775.44 billion by 2029 with a 6.2% compound annual growth rate. Key drivers include e-commerce growth, sustainability demands, and customization needs.

Innovation focus areas include cost efficiency improvements, supply chain optimization, and brand differentiation through advanced materials and smart technology integration.

For companies looking to leverage these cutting-edge innovations in their packaging solutions, partnering with forward-thinking manufacturers ensures access to the latest rigidity enhancement technologies and sustainable alternatives.

Summary

Selecting appropriate board rigidity requires balancing material type, thickness specifications, regional standards, and cost considerations. Professional rigid packaging typically starts at 20 PT for chipboard or 125 PT for corrugated applications, with specific requirements varying based on product protection needs and compliance requirements. Modern innovations offer sustainable alternatives while maintaining performance standards.

Ready to optimize your packaging rigidity with cutting-edge materials and expert guidance? Contact Acreet today for comprehensive consultation on custom rigid board solutions that perfectly match your product protection needs, regulatory requirements, and budget parameters. Our experienced team combines traditional expertise with innovative technologies to create packaging that protects your products while maximizing cost efficiency and sustainability goals.