E-commerce businesses face mounting pressure to deliver products safely while managing shipping costs. Poor packaging choices result in damaged goods, unhappy customers, and financial losses that can devastate your bottom line.

Corrugated boxes have become the gold standard for e-commerce shipping because they offer superior protection through their three-layer construction, reduce shipping costs by up to 50%, and provide 100% recyclability. Their ability to withstand 32-125 psi pressure while remaining lightweight makes them the preferred choice for retailers shipping everything from electronics to clothing worldwide.

This comprehensive guide will explore why corrugated boxes dominate the e-commerce shipping industry and how they can transform your packaging strategy.

Table of Contents

ToggleWhat Makes Corrugated Boxes Different from Regular Cardboard?

Understanding the distinction between corrugated and regular cardboard is crucial for making informed packaging decisions. Many business owners mistakenly assume these materials are identical, leading to poor packaging choices that result in damaged products.

Corrugated cardboard consists of three layers of kraft paper: two flat outer layers (linerboards) and a middle layer featuring a wave-like fluted structure. Regular cardboard is made from only one layer of paper, making it significantly weaker and less protective for shipping applications.

Structural Engineering Advantages

The fundamental difference lies in the engineering design. Corrugated boxes feature a paper sandwich construction where the corrugated medium (fluted layer) sits between two flat linerboards. This creates rigid columns that can support substantial weight while providing air pockets that act as natural shock absorbers.

Regular cardboard undergoes a simpler manufacturing process where pulp is fed through rollers and pressed into a flat sheet. This single-layer construction results in material that is weak and easy to bend or tear, making it suitable only for lightweight applications like cereal boxes and greeting cards.

Performance Comparison

The structural differences translate into significant performance advantages:

| Feature | Corrugated Boxes | Regular Cardboard |

|---|---|---|

| Layer Construction | Three-layer sandwich | Single layer |

| Strength Level | High crush resistance | Weak, easily damaged |

| Weight Capacity | Up to 125 pounds | Limited to light items |

| Shipping Suitability | Excellent protection | Poor protection |

| Cost Effectiveness | Superior value | Lower initial cost |

The fluted design makes corrugated boxes significantly stronger than regular cardboard, with enhanced resistance to crushing, puncturing, and tearing – essential qualities for surviving the rigors of e-commerce shipping and handling.

How Do Corrugated Boxes Protect Products During Shipping?

Product protection remains the primary concern for e-commerce businesses. Damaged goods lead to returns, refunds, and negative reviews that can permanently harm your brand reputation and customer trust.

Corrugated boxes provide comprehensive protection through their shock-absorbing fluted layer, pressure resistance capabilities of 32-125 psi, and multi-directional strength. Studies show they can reduce product damage by up to 50% compared to other packaging materials.

Advanced Impact Absorption System

The fluted layer acts as a sophisticated shock absorption system with thousands of air pockets that absorb impacts and vibrations during transit. When packages experience drops or impacts, these air columns compress and distribute force across the entire surface area, preventing concentrated pressure points that could damage contents.

This cushioning effect is particularly valuable for fragile items like electronics, glassware, and precision instruments that require gentle handling throughout the shipping process.

Comprehensive Protection Features

Corrugated boxes offer multi-layered protection against various shipping hazards:

- Compression resistance from the fluted structure supporting stacking weight

- Puncture resistance from the outer linerboards protecting against sharp objects

- Moisture protection when properly sealed and treated

- Temperature insulation from air pockets within the flutes

- Vibration dampening during transportation

Pressure Resistance Capabilities

The engineering design enables corrugated boxes to handle substantial pressure ranging from 32 to 125 psi depending on the construction. This strength allows them to withstand the stacking pressures encountered in warehouses and during transportation without compromising the integrity of contents.

Different flute types provide varying levels of protection based on specific shipping requirements and product characteristics.

Why Are Corrugated Boxes Cost-Effective for E-commerce?

Cost management directly impacts profitability in e-commerce operations. Packaging expenses can quickly erode profit margins if not carefully controlled, making cost-effectiveness a critical factor in material selection for growing businesses.

Corrugated boxes deliver exceptional value through low raw material costs, bulk shipping advantages, and damage prevention savings. Their lightweight design reduces shipping expenses while their strength allows businesses to ship more items per container without box failure.

Manufacturing Cost Efficiency

The cost of raw materials and labor used to manufacture corrugated boxes remains relatively low compared to alternative packaging materials. The efficient production process and widespread availability of recycled paper materials help keep costs manageable for businesses of all sizes.

Corrugated boxes can be produced in large quantities with consistent quality, enabling manufacturers to offer competitive pricing for bulk orders.

Shipping Cost Optimization

The lightweight nature of corrugated boxes provides significant shipping cost advantages:

- Minimal weight addition to shipments reduces dimensional weight charges

- Strong construction allows more items per container shipment

- Efficient stacking reduces storage and transportation space requirements

- Customizable sizing eliminates need for excessive filler materials

Right-Sizing Benefits

Corrugated boxes can be customized to fit products precisely, eliminating the need for excessive filler materials like bubble wrap or foam peanuts. This right-sizing capability reduces both material costs and shipping expenses while maintaining optimal product protection.

Businesses can achieve significant cost savings by selecting appropriate box dimensions that minimize wasted space and reduce volumetric weight charges from carriers.

Long-Term Financial Benefits

Although corrugated boxes may cost more initially than basic cardboard alternatives, their superior strength and durability prevent product damage during transportation. This damage prevention avoids costly returns, replacements, and customer service expenses that can significantly impact profitability over time.

What Environmental Benefits Do Corrugated Boxes Offer?

Sustainability has become a crucial consideration for modern businesses as consumers increasingly prefer eco-friendly packaging options. Environmental regulations and corporate responsibility initiatives are pushing companies toward greener packaging alternatives.

Corrugated boxes are 100% recyclable and compostable, with over 90% of corrugated cardboard being recycled in the United States. They’re made from renewable resources and use less energy to produce than plastic alternatives, supporting circular economy principles.

Outstanding Recyclability Performance

Corrugated boxes represent one of the most environmentally friendly packaging options available. The recycling rate for corrugated cardboard exceeds 90% in the United States, demonstrating the material’s success in circular economy applications where materials are continuously reused rather than discarded.

The paper fibers used in corrugated boxes can be recycled multiple times without losing structural integrity, maximizing the useful life of the raw materials.

Renewable Resource Foundation

Corrugated boxes are manufactured from renewable resources, with most raw materials sourced from responsibly managed forests. The corrugated industry actively supports sustainable forestry practices, ensuring that new trees are planted to replace those harvested.

This approach maintains healthy ecosystems while providing continuous access to renewable packaging materials for future production needs.

Reduced Carbon Footprint

The production process for corrugated boxes uses less energy than manufacturing plastic alternatives, particularly when made from recycled materials. The energy-efficient manufacturing process produces fewer greenhouse gas emissions, helping businesses reduce their environmental impact.

When corrugated boxes reach the end of their useful life, they biodegrade naturally within a few months, unlike plastic packaging that can persist in the environment for decades.

Circular Economy Support

Corrugated packaging supports circular economy principles through:

- High recycling rates that keep materials in productive use

- Biodegradable composition that returns safely to the environment

- Renewable resource base that doesn’t deplete finite materials

- Energy-efficient production processes that minimize environmental impact

How Customizable Are Corrugated Boxes for Branding?

Brand presentation significantly impacts customer perception and repeat business success. Professional packaging creates positive first impressions and reinforces brand identity with every delivery, turning shipping containers into powerful marketing tools.

Corrugated boxes offer extensive customization possibilities through high-quality printing, structural modifications, and premium design features. Modern printing technologies enable full-color graphics, logos, and brand messaging that transform shipping containers into memorable unboxing experiences.

Advanced Printing Capabilities

Corrugated material accepts various printing techniques that deliver professional results:

- Full-color offset printing for photographic quality graphics

- Flexographic printing for cost-effective designs with good quality

- Digital printing for short runs and variable data applications

- Embossing and debossing for textured effects and premium appearance

The smooth surface of corrugated boxes provides an excellent canvas for high-quality graphics that enhance brand recognition and customer engagement.

Structural Customization Options

Beyond visual customization, corrugated boxes can be tailored to various shapes and sizes to accommodate unique product dimensions and special requirements. Die-cut designs allow for custom shapes, ventilation holes, and specialized closures that enhance functionality while supporting brand differentiation.

Custom structural features include:

- Auto-lock bottom containers for quick assembly

- Telescoping designs for variable-depth packaging

- Specialized closures that eliminate tape requirements

- Integrated handles for improved customer convenience

Premium Unboxing Experience

Custom-printed corrugated boxes create elevated unboxing experiences that reinforce brand identity and increase customer satisfaction. The ability to design both interior and exterior surfaces provides opportunities for creative packaging solutions that delight customers and encourage social media sharing.

Interior printing allows for creative brand messaging visible when customers open packages, creating memorable moments that enhance brand loyalty and word-of-mouth marketing.

What Are the Different Types of Corrugated Boxes for E-commerce?

Different products require different packaging approaches based on their size, weight, fragility, and shipping requirements. Understanding available options helps businesses select the most appropriate corrugated box styles for their specific needs and customer expectations.

E-commerce businesses can choose from Regular Slotted Containers (RSC), Half-Slotted Containers (HSC), Full Overlap designs, and specialty options. Each type offers unique advantages for different product categories, shipping volumes, and protection requirements.

Regular Slotted Container (RSC)

The RSC represents the most common box style in e-commerce shipping, featuring four flaps on both ends that meet in the center when folded. This design provides excellent efficiency and minimal material waste, making it ideal for a wide range of shipping applications.

RSC boxes offer optimal strength-to-weight ratios and work well for most standard shipping needs, from clothing and books to electronics and household items.

Half-Slotted Container (HSC)

HSCs feature flaps on only one end, with the other end remaining open. This design enables quick access to contents and is often used with separate lids for storage applications or when products need to be inserted from the open end.

Full Overlap Slotted Container (FOL)

FOL boxes have extended flaps that completely overlap when folded, providing additional protection for heavy or fragile items. This design is particularly useful for products requiring extra cushioning and protection during shipping.

The overlapping flaps create double-wall protection at the most vulnerable points, enhancing overall package integrity.

Specialty E-commerce Designs

Modern e-commerce has driven innovation in corrugated box design, including:

- Die-cut mailers for specific product shapes and easy opening

- Theft-protection designs with integrated security features

- Presentation boxes with magnetic closures for premium products

- Multi-compartment designs for product sets and kits

These specialized options help businesses create unique packaging solutions that differentiate their products and enhance customer experience.

How Do You Choose the Right Corrugated Box Specifications?

Selecting appropriate corrugated box specifications prevents both under-protection and over-packaging issues. Wrong choices lead to damaged goods or unnecessary expenses that negatively impact profitability and customer satisfaction.

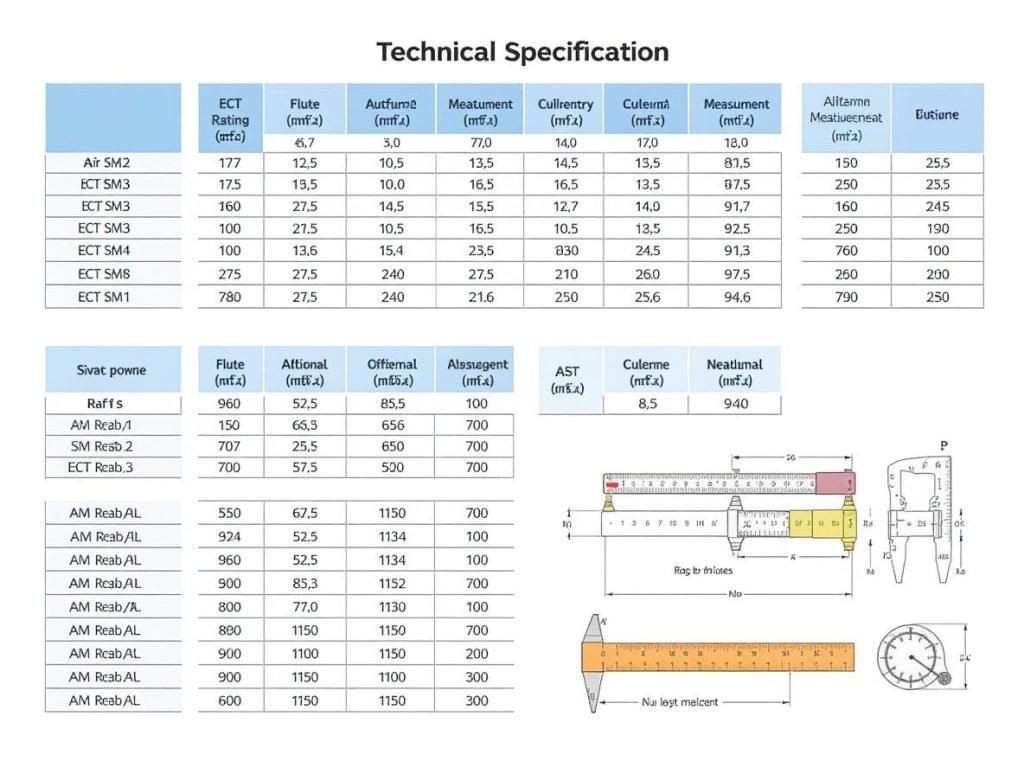

Choose corrugated box specifications based on flute type, Edge Crush Test (ECT) ratings, and product requirements. Consider A-Flute for maximum cushioning, C-Flute for balanced performance, and appropriate ECT ratings ranging from 32 ECT for packages up to 65 pounds to 48 ECT for heavier items.

Understanding Flute Types and Applications

Different flute sizes offer varying levels of protection and functionality:

| Flute Type | Thickness | Best Applications | Key Benefits |

|---|---|---|---|

| A-Flute | 5mm | Fragile items, maximum cushioning | Superior shock absorption |

| C-Flute | 4mm | General shipping, most widely used | Good balance of strength and printability |

| B-Flute | 3mm | Better printing surface applications | Enhanced graphics quality with decent strength |

| E-Flute | 1.5mm | Retail packaging and displays | Thinnest option, excellent print quality |

Edge Crush Test (ECT) Ratings

ECT measures the compressive strength of corrugated board and indicates a box’s ability to withstand stacking pressure during storage and transportation. Common ECT ratings and their applications include:

- 32 ECT: Suitable for packages up to 65 pounds

- 44 ECT: Appropriate for packages up to 95 pounds

- 48 ECT: Recommended for double-wall applications up to 100 pounds

Higher ECT ratings provide greater strength but may increase material costs, so matching ratings to actual requirements optimizes both protection and expenses.

Popular E-commerce Box Sizes

Standard corrugated box sizes commonly used in e-commerce include:

- Small items (6″ x 4″ x 4″): Jewelry, cosmetics, and small electronics

- Medium products (12″ x 9″ x 6″): Clothing, kitchenware, and books

- Large items (20″ x 14″ x 10″): Oversized products and multiple-item orders

Selection Criteria for Optimal Performance

When choosing corrugated box specifications, consider these critical factors:

Product characteristics: Weight, fragility, and dimensional requirements

Shipping conditions: Distance, handling intensity, and storage duration

Stacking requirements: Warehouse storage and transportation needs

Environmental factors: Temperature, humidity, and moisture exposure

Cost considerations: Material expenses versus protection requirements

Proper specification selection ensures optimal product protection while maintaining cost-effectiveness and operational efficiency.

Summary

Corrugated boxes have earned their position as the e-commerce shipping standard through their superior three-layer construction, cost-effectiveness, and environmental sustainability. Their ability to reduce damage by up to 50% while supporting circular economy principles makes them the smart choice for businesses seeking reliable packaging solutions.

Ready to optimize your e-commerce packaging strategy with professional corrugated solutions? Contact Acreet today for custom corrugated boxes tailored to your specific shipping needs. Our experienced team can help you select the right specifications, design eye-catching branding, and create packaging that protects your products while enhancing your customer experience. Send us your inquiry and discover how expert packaging solutions can transform your shipping operations!